Injector Inspector Gadget – Best Diesel Injector Repair Kits

Understanding Diesel Injector Repair Kits

Diesel injector repair kits are specialized component packages designed to restore fuel injector performance without replacing the entire unit. If you're looking for a solution to common injector problems, here's what you need to know:

What Are Diesel Injector Repair Kits? What They Typically Include When You Need Them Maintenance packages containing replacement parts for worn injector components O-rings, seals, filters, nozzles, feed tubes When experiencing rough idle, power loss, black smoke, or fuel leaks

Diesel injectors are precision components that deliver an exact amount of fuel into your engine's combustion chamber. Over time, these critical parts can develop issues due to contamination, heat cycling, and normal wear and tear.

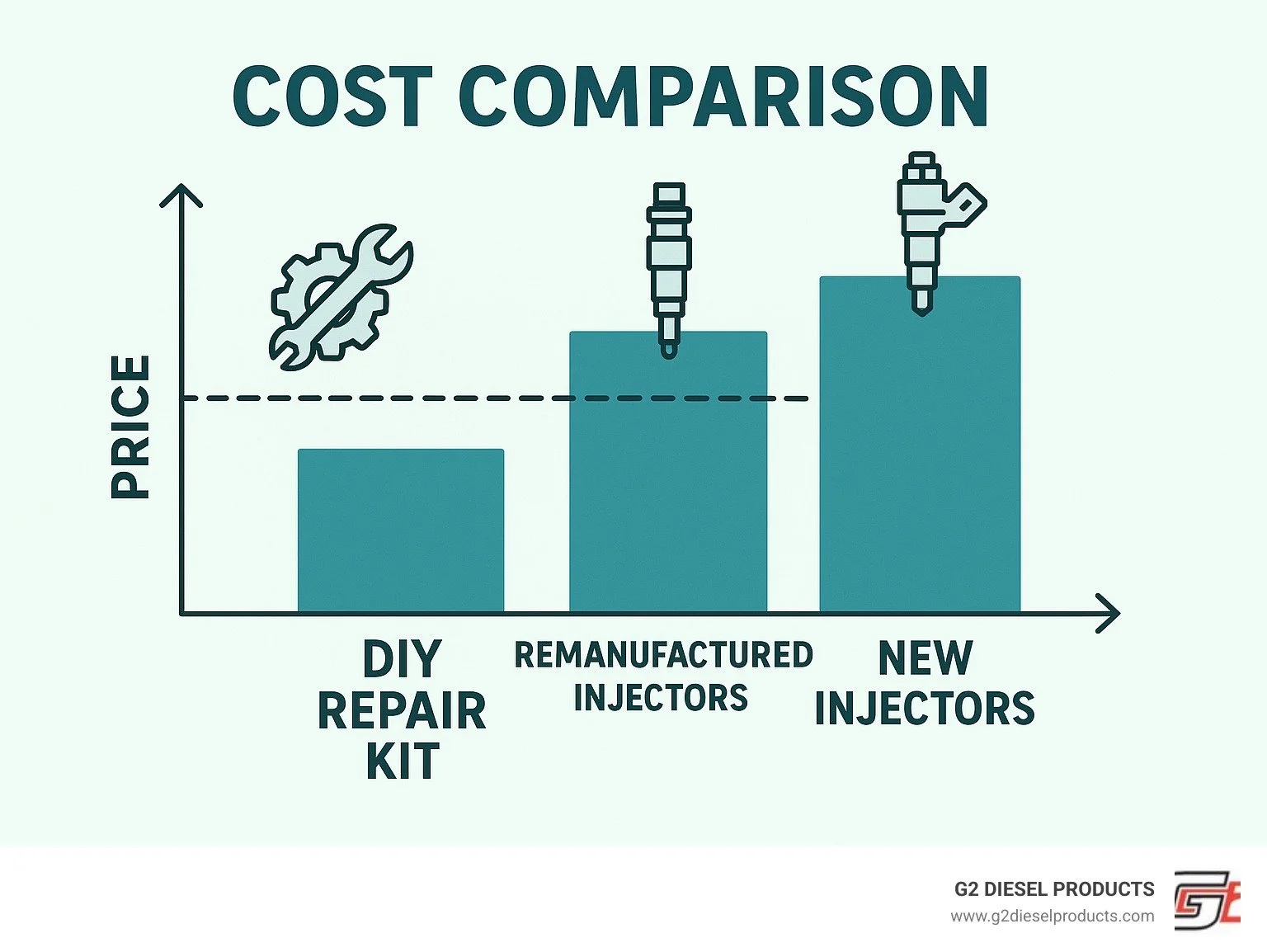

When injectors fail, your options are typically:

Replace the entire injector - Often costs $250-$1000+ per injector

Use a repair kit - Usually $15-$300 depending on components

Professional rebuilding service - Midrange cost option

Fleet managers and diesel technicians know that contamination in the fuel supply is one of the most common reasons for both premature failure of components as well as the original reason for initial failure. A repair kit addresses these issues by replacing the vulnerable components.

"Replacing worn injector components with a rebuild kit can restore fuel delivery, reduce leaks, and improve fuel efficiency and performance," notes a technical bulletin from a major parts manufacturer.

The benefits of using repair kits include:

Cost savings - Fraction of full replacement cost

Reduced downtime - Faster than waiting for new injectors

Sustainability - Less waste than full replacement

Customization - Address specific failure points

Not all kits are created equal, however. They vary based on injector type (common rail, port, mechanical), engine make, and the specific components included. The most comprehensive kits include everything from basic O-rings to feed tubes and specialized tools.

Why Diesel Injectors Fail

Let's talk about why these precision components give up the ghost. Diesel injectors live a tough life – they're like the marathon runners of your engine, constantly working under extreme conditions.

Your diesel injectors face a daily assault from heat, pressure, and contaminants that would make most engine parts cry uncle. Understanding why they fail helps you catch problems early and save your wallet some serious pain.

The biggest troublemakers? Fuel contamination tops the list. Those tiny dirt particles and water droplets in your diesel act like sandpaper on precision components. Industry research shows this nasty stuff causes over 70% of injector failures. It's like trying to drink a smoothie through a fine straw – eventually, things get clogged up.

Heat cycling is another silent killer. Every time your engine runs and cools down, metal parts expand and contract. Do this thousands of times, and even the toughest components start to fatigue. It's the mechanical equivalent of bending a paperclip back and forth until it snaps.

Those little O-rings might seem insignificant, but when they harden and crack, trouble follows. Modern fuels with ethanol or biodiesel additives can be particularly harsh on rubber components, causing them to deteriorate faster than you might expect.

Many technicians overlook leaking feed tubes when diagnosing problems. As one technical bulletin puts it: "Failure to replace each fuel feed tube when replacing fuel injectors is a common mistake that leads to product failure." These tubes often leak back to the return line, creating symptoms that mimic injector failure.

Carbon buildup rounds out the top culprits. When fuel doesn't burn completely, it leaves deposits that clog nozzles and disrupt spray patterns. This is like trying to use a shower head with mineral buildup – the spray pattern gets weird and uneven.

When injectors start failing, your engine will typically send out distress signals: misfiring cylinders, hard starting (especially on cold mornings), excessive smoke billowing from your exhaust, disappointing fuel economy, and often a distinctive injector "knock" or ticking noise. Your dashboard might light up with check engine codes related to fuel delivery issues.

A diesel tech from Harrisburg recently told us: "I see trucks coming in all the time with injector issues that could have been prevented with basic maintenance. By the time they arrive at our shop, they're often facing a complete injector replacement when a simple repair kit could have solved the problem months earlier."

Early Warning Signs You Shouldn't Ignore

Your engine usually gives you several hints before catastrophic failure occurs. Think of these as your diesel's way of asking for help:

A rough idle is often the first red flag. If your engine feels unsteady or unstable at idle, one or more injectors might not be delivering fuel properly.

Notice a gradual loss of power? If your truck feels like it's running out of steam, especially when hauling or climbing hills, your injectors could be the culprit.

Black soot accumulating around your tailpipe or excessive smoke from the exhaust suggests fuel isn't burning efficiently – a classic sign of injector problems.

A strong fuel odor inside the cabin or around the engine often indicates leaking injectors. Your nose knows when something's not right!

Watching your fuel consumption climb for no apparent reason? When injectors can't atomize fuel properly, your mileage suffers noticeably.

As one Volvo fleet manager shared with us: "We've implemented a proactive maintenance program where we use diesel injector repair kits at the first sign of these symptoms. It's saved us thousands in downtime and major repairs."

Catching these warning signs early can mean the difference between a simple repair and a major overhaul. Your diesel is talking to you – it pays to listen!

Diesel Injector Repair Kits 101: Components & Compatibility

Let's talk about what's really inside those diesel injector repair kits and why finding the right match matters so much for your truck. Think of these kits as medicine cabinets for your ailing injectors – they contain exactly what you need to breathe new life into these precision parts.

When you pop open a quality repair kit, you'll typically find a collection of small but mighty components:

Those rubber seals and O-rings might not look impressive, but they're actually the workhorses of the kit. They create the tight seals that keep fuel where it belongs and prevent those frustrating leaks that lead to poor performance. They're usually the first parts to wear out, especially with today's modern fuels.

The tiny filters and screens might remind you of miniature tea strainers – and they serve a similar purpose! They catch all the nasty contaminants before they can damage the delicate injector nozzle. Without these, your injector's days would be numbered.

Pintle caps protect the business end of your injector – that precision-machined tip that controls exactly how much fuel flows into your engine. Think of them as little helmets for the most important part of your injector.

Many people overlook feed tubes, but they're crucial connections between your fuel rail and injector. As one technician told us recently, "I've seen perfectly good injectors blamed for problems that were actually caused by worn feed tubes."

Those little copper washers and shims might seem insignificant, but they're engineering marvels that create proper sealing and set the exact height needed for the perfect spray pattern. A difference of just a few thousandths of an inch can affect your engine's performance!

For those more serious repairs, helicoil inserts can save the day when threads get stripped in injector bores – often saving you from much more expensive repairs.

Finding the right kit for your engine is a bit like matchmaking – compatibility is everything. Modern common rail systems, which operate under extreme pressure (sometimes up to a whopping 30,000 psi), need completely different components than older mechanical injectors. HEUI systems found in many Ford and International engines have their own unique requirements, while marine diesel systems need special considerations for their saltwater environment. Even those smaller ATV and UTV injectors need specific kits custom to their compact design.

Here at G2 Diesel Products, we're a bit obsessive about matching the right kit to your specific Volvo, Mack, Kenworth, or Paccar truck. It's this attention to detail that prevents those frustrating situations where you install a new kit only to find the components don't quite fit or perform as they should.

Want to dive deeper into understanding your truck's fuel system? Check out our More info about Truck Fuel Systems resource page.

Benefits vs Full Injector Replacement

When your injectors start acting up, you're faced with a choice: repair or replace? For many fleet managers and diesel techs, repair kits offer compelling advantages.

The cost savings alone can be eye-opening. One fleet manager recently shared with us that he saved over 70% on maintenance costs by using diesel injector repair kits instead of buying brand new injectors for his Volvo fleet. That's money that goes straight back to the bottom line.

But it's not just about saving a buck. A properly rebuilt injector can perform just like new because you're replacing all the critical wear items – the nozzles, filters, and seals that directly affect how fuel is delivered and atomized. It's like giving your injectors a complete makeover rather than just covering up the problems.

There's an environmental angle too. When your injectors aren't performing properly, your emissions take a hit. "I've seen trucks come in blowing black smoke that cleared up completely after we rebuilt the injectors with a quality kit," one shop owner told us. Your truck runs cleaner, which is good for both compliance and the planet.

Time is money in the trucking business, and repair kits offer a major advantage here. While ordering new injectors might leave your truck sidelined for days, a skilled tech can rebuild your existing injectors in a matter of hours using the right kit. For a working truck, that's the difference between a minor pit stop and a major setback.

Let's not forget the sustainability aspect. In an industry increasingly focused on reducing waste, rebuilding injectors makes good environmental sense. You're reusing the durable injector body and electronics while replacing only what's worn out – a small but meaningful contribution to more sustainable practices.

As one Kenworth fleet supervisor put it, "We only replace the entire injector if there's actual damage to the body or electronics. Otherwise, a good repair kit handles 90% of our injector issues at a fraction of the cost." That's practical wisdom born from years of experience.

Best Diesel Injector Repair Kits in 2024

Looking for the perfect way to bring your diesel injectors back to life without breaking the bank? You're in the right place! After years in the diesel parts industry and countless conversations with mechanics who've tried it all, we've put together this roundup of truly exceptional diesel injector repair kits that deliver results in 2024.

What makes a repair kit truly worth your time and money? As Mike, one of our veteran technicians in Harrisburg, always says: "The difference between a good kit and a great kit is whether you need to make a second parts run." That wisdom has guided our selection process.

We've focused on kits that offer exceptional value for DIY enthusiasts while meeting professional-grade standards. Each option we recommend provides comprehensive coverage—not just the basic O-rings that leave you hunting for additional parts halfway through a job.

These kits shine when it comes to addressing both internal and external seals, which is crucial for a complete repair. Many include performance upgrade components that actually improve on factory specifications, especially for high-mileage trucks that need a little extra attention.

While our expertise centers on Volvo, Mack, Kenworth, and Paccar applications, the principles behind these selections apply across most diesel engines. We've carefully evaluated each kit based on component quality, completeness, and real-world performance feedback from technicians who use them daily.

What you won't find here are cheap knockoffs that fail prematurely or incomplete kits that waste your time. Each recommendation represents the sweet spot where quality meets value—giving you everything needed to restore proper fuel atomization, eliminate leaks, and bring back that smooth, powerful performance your diesel engine should deliver.

In the sections that follow, we'll break down each specialized kit type, explaining exactly what makes it stand out and which problems it solves best. Whether you're dealing with leaky seals, contaminated filters, or worn feed tubes, we've got you covered with options that professional diesel techs trust.

More info about Common Rail Injectors

1. Seal & O-Ring Refresh Kit

Let's talk about the foundation of injector repair – the humble Seal & O-Ring Refresh Kit. These kits might seem simple, but they're the workhorses of diesel injector repair kits, addressing the components that fail most frequently.

Think of these kits as the first line of defense against diesel injector problems. They focus on replacing those rubber bits that take a constant beating from heat cycles, pressure changes, and the increasingly complex chemical makeup of modern diesel fuels.

What's in the box? You'll typically find a complete set of ethanol-resistant O-rings that won't harden or crack when exposed to biodiesel components. The premium kits include both internal and external seals, copper crush washers for proper sealing, and return line seals to prevent those frustrating fuel leaks that leave spots on your shop floor.

"We use these basic seal kits as part of our 100,000-mile service," a Paccar fleet maintenance supervisor told us recently. "It's cheap insurance against the downtime caused by injector leaks." That's the beauty of these kits – they're preventive maintenance in a package, allowing you to address small issues before they become expensive problems.

One thing I particularly appreciate about these kits is their versatility. While the specific sizes vary depending on your engine, the fundamental concept applies across virtually all diesel injection systems. Whether you're working on a Volvo, Mack, Kenworth, or Paccar truck, a quality seal kit will have you covered.

Here's a pro tip from our technicians: when installing new seals, take a moment to inspect each one carefully, and apply a light coating of clean diesel fuel as lubricant during assembly. This simple step can significantly extend the service life of your newly installed components.

These kits typically include clear installation guides with torque specifications, making them accessible even for those with moderate mechanical experience. The right torque is crucial – too tight and you'll damage the new seals, too loose and you'll have leaks.

For the best selection of quality components for your diesel engine, check out our Diesel Engine Parts section, where you'll find everything you need to keep your truck running smoothly.

2. High-Pressure Common Rail Rebuild Kit

Modern common rail diesel systems operate at extraordinary pressures—up to 30,000 psi in some applications. This extreme environment demands specialized components that can withstand these conditions while maintaining precision fuel delivery.

Key Components:

High-pressure resistant internal O-rings

Precision filter baskets (often as fine as 2-5 microns)

Nozzle gaskets and shims

Specialized CR injector spacers

Anti-vibration dampers

These comprehensive kits are designed specifically for the latest generation of diesel engines found in Volvo, Mack, Kenworth, and Paccar trucks. The precision-matched components ensure proper fuel atomization, which directly impacts power, fuel economy, and emissions.

"Contamination is the number one killer of common rail injectors," explains our lead technician. "The filter baskets included in these kits are the last line of defense, and they need to be replaced whenever an injector is serviced."

What separates premium common rail kits from basic options is the inclusion of precisely calibrated shims and spacers. These components ensure the injector sits at the exact height needed for optimal spray pattern in the combustion chamber.

For technicians working with common rail systems, we recommend always performing an ultrasonic cleaning of the injector body before installing new components from the kit. This extra step removes microscopic contaminants that could compromise the new components.

Scientific research on fuel cleanliness

3. Mechanical Injector Nozzle Service Kit

While sleek common rail systems may dominate today's diesel landscape, countless older mechanical injection systems continue to power trucks, tractors, and generators across America. These trusty workhorses deserve specialized attention, which is exactly what mechanical diesel injector repair kits provide.

These kits are a godsend for owners of pre-common rail diesel engines, offering everything needed to breathe new life into aging injectors:

"I've rebuilt the injectors on my '96 Mack three times now using quality nozzle kits," shares Tom, a loyal customer from Nebraska. "Each time, it's like getting a brand new truck for the price of a nice dinner."

What makes these kits special is their focus on the heart of mechanical injection: the nozzle assembly. Each kit typically includes fresh nozzle tips, a variety of precisely-measured shims, replacement needle valves, new pressure springs, and copper sealing washers. This comprehensive approach ensures you're addressing all wear points, not just the obvious ones.

The real magic happens when you use the included shim pack to dial in the perfect "pop pressure" – that sweet spot where your injector releases fuel with just the right force. Too low, and you'll waste fuel with poor atomization. Too high, and your engine might struggle to start in cold weather. The variety of shim thicknesses lets you fine-tune this crucial setting.

These kits are particularly valuable for vintage vehicles, agricultural equipment, and marine applications where replacement injectors might be expensive or difficult to source. The relatively straightforward design of mechanical injectors makes them ideal candidates for DIY repair, even for those with modest mechanical skills.

For best results, we recommend using a dedicated nozzle testing apparatus when working with these kits. This equipment lets you verify spray pattern and pop pressure before reinstallation, ensuring your weekend project delivers professional-grade results.

Whether you're maintaining a classic diesel tractor or keeping a trusted work truck on the road, these mechanical injector service kits deliver remarkable value – often extending engine life while improving performance, all without breaking the bank.

4. Thread & Bore Repair Kit

Let's face it—sometimes the problem isn't the injector itself but the home where it lives. The cylinder head threads can become stripped or damaged, especially when removing those stubborn, seized injectors that seem determined to stay put forever. This is where Thread & Bore Repair Kits become absolute lifesavers.

Key Features:

Helicoil M6x1 stainless steel thread inserts

Precision sleeve inserts for ovaled bores

Specialized drill bits and taps

Installation tools

Detailed installation guide

These specialized diesel injector repair kits have rescued countless cylinder heads from premature retirement. As one of our technicians from Harrisburg recently told me with a grin, "We had a Kenworth roll in with three stripped injector bores. The owner was already mentally preparing for a massive repair bill. Using the thread repair kit, we had it back on the road the same day, saving the customer thousands in parts and labor."

What's remarkable about these kits is the precision engineering of the sleeve inserts. They fit the injector perfectly, creating a flawless seal even after significant thread damage. Here's an interesting fact—the stainless steel construction of the Helicoil inserts actually provides greater strength than the original aluminum threads found in many cylinder heads. Talk about making something better than new!

While these repairs require a steady hand and some attention to detail, the process is surprisingly straightforward with the right kit. The most critical step (which many first-timers overlook) is thoroughly cleaning out all metal shavings from the cylinder after drilling and tapping. Quality kits include specialized air tools designed specifically for this cleanup process.

These kits have proven particularly valuable for specific models known to have thread issues, including BMW N54/N55 engines and Mercedes Sprinter OM647 diesels. The investment in a good thread repair kit pays for itself the very first time you save a cylinder head from replacement.

More info about Common Rail Injectors

5. Integrated Feed Tube Replacement Kit

That little metal tube connecting your fuel rail to the injector might not look like much, but ask any diesel tech about feed tubes and watch their expression change. These unassuming components are often the hidden culprits behind many diesel headaches.

Diesel injector repair kits that include feed tubes are worth their weight in gold. As one crusty veteran mechanic told me, "I've seen too many perfectly good injectors yanked out because nobody checked the feed tubes first."

These comprehensive kits typically include:

Brand new fuel feed tubes (precisely machined for proper flow)

Banjo seals and washers that prevent high-pressure leaks

Return line O-rings that stop those mysterious fuel odors

Clear installation instructions with proper torque specifications

Specialized tools that make installation a breeze instead of a nightmare

What makes these kits special is their focus on the entire fuel pathway. When a truck comes limping into the shop with a misfire, the injector often gets blamed immediately. But here's the truth – feed tubes wear out and can leak fuel back to the return line, creating symptoms identical to a bad injector.

I've chatted with countless technicians who've learned this lesson the hard way. One Volvo specialist put it perfectly: "I don't even consider servicing injectors without replacing the feed tubes anymore. It's cheap insurance against comebacks." That sentiment echoes throughout repair shops nationwide.

These kits have become particularly popular with mobile technicians and field service crews. When you're fixing a truck on the side of the highway or at a remote job site, the last thing you want is to make two trips because you missed the real problem. The comprehensive approach eliminates guesswork.

A technical service bulletin we've seen proven true time and again states bluntly: "Failure to replace each fuel feed tube when replacing fuel injectors is a common mistake that leads to product failure." These integrated kits address this issue directly, saving both time and reputation.

The systematic approach these kits provide means you're addressing the entire fuel delivery path, not just the injector itself. This prevents the frustration of fixing one component only to have another fail shortly after – a situation that leads to unhappy customers and warranty headaches.

For best results, always follow the torque specifications included with quality feed tube kits. Over-tightening can damage threads, while under-tightening leads to leaks. That perfect middle ground is critical for reliable performance.

More info about Common Rail Injectors

Step-by-Step: How to Use a Diesel Injector Repair Kit

Rolling up your sleeves to rebuild your diesel injectors? You're making a smart choice that can save you hundreds of dollars. Let me walk you through the process of using your diesel injector repair kit like a pro would.

Think of your workspace as a mini operating room. Cleanliness isn't just nice—it's essential. I've seen perfectly good repairs fail because of a single speck of dirt in the wrong place.

"I tell all my apprentices the same thing," says our lead technician. "A human hair can wreck an injector faster than anything else. That's how precise these components are."

Before diving in, gather everything you'll need. There's nothing worse than having an injector half-disassembled and realizing you're missing a crucial tool. Always start by relieving the fuel system pressure—this isn't just about convenience, it's about safety.

Take photos as you go! I can't stress this enough. Even experienced mechanics do this because it provides a roadmap for reassembly. Label each injector with its cylinder number using masking tape—mixing them up can cause performance issues later.

If you have access to an ultrasonic cleaner, use it. This removes invisible contaminants that even careful hand cleaning might miss. Many shops offer this service for a reasonable fee if you don't have the equipment.

One often overlooked step is bench testing your rebuilt injector before reinstallation. Even a simple visual spray test can catch problems before you've put everything back together. It's the difference between doing the job once or twice.

Diesel injector repair kits: Tools You Need

Success starts with having the right tools at hand. You don't need a professional garage setup, but a few quality items make all the difference.

A quality socket set with deep sockets is your foundation. Pair this with a torque wrench that can handle precise, low-torque settings—this isn't the place for "feels tight enough" guesswork.

You'll need an injector puller designed for your specific engine model. Using the wrong tool or trying to improvise can damage both the injector and your cylinder head. Trust me, I've seen the costly results of this shortcut.

For cleaning, use a brass wire brush—never steel, which can create scratches that become failure points. Lint-free cloths and brake cleaner are essential for keeping everything spotless during the rebuild process.

When working with the tiny precision components, a small pick set makes removing O-rings much easier without damaging the channels they sit in. A digital micrometer helps verify components are within spec—especially important for older engines.

Don't forget to use a fuel-safe lubricant on O-rings during installation. Dry O-rings can twist or tear, while petroleum-based lubricants can cause them to swell or deteriorate.

The good news? Most diesel injector repair kits are designed for someone with basic mechanical skills. As one customer told me last month, "I was worried I'd mess something up, but the instructions in my G2 kit were so clear that I knocked it out in a Saturday afternoon."

Diesel injector repair kits: 10-Step Procedure

Here's your roadmap to a successful rebuild:

First, carefully remove the injector using your puller tool. Patience here prevents damage—never force an injector that's resisting removal. Sometimes a penetrating oil and some wait time can save you headaches.

Next, inspect the injector body thoroughly. Look for hairline cracks, excessive wear, or unusual discoloration. These can indicate that a repair kit won't be sufficient, and you might need a complete replacement.

Clean all external components using brake cleaner and your brass brush. Pay special attention to carbon buildup around the nozzle and body—this can affect how the new components seat.

Now comes the precision work—disassemble according to your kit instructions. Different injector types (common rail, HEUI, mechanical) have specific procedures. Follow them exactly, even if you think you know a shortcut.

Replace every seal and O-ring included in your kit, even if some look fine. These rubber components age in ways not always visible to the eye, and the cost of doing this job twice far outweighs the value of saving a few components.

When installing new filters and nozzles, handle them only by the edges and never touch the precision surfaces. Even the oil from your fingertips can affect performance.

During reassembly, double-check component orientation at each step. Taking an extra moment here can save hours of troubleshooting later.

If possible, bench test before reinstallation. Even a basic visual check of spray pattern can confirm your rebuild was successful.

Always reinstall with new feed tubes if they're included in your kit. These are common failure points that can mimic injector problems, and replacing them is cheap insurance against future issues.

Finally, after installation, run the engine and verify there are no leaks before considering the job complete. A small seep now becomes a major problem later.

"The number one mistake I see in our shop? Improper torque during reinstallation," our senior technician often reminds us. "Too tight distorts components, too loose means leaks. Always use a calibrated torque wrench and follow the specs exactly."

With attention to detail and the right diesel injector repair kit, you'll restore performance while saving significantly compared to full replacement. Your engine (and wallet) will thank you.

More info about Common Rail Injectors

Cost Comparison: DIY Kits vs Professional Replacement

When your diesel injectors start giving you trouble, your wallet is probably the next thing that feels the pain. Understanding the real costs of different repair options can save you hundreds—even thousands—of dollars. Let's break down what you're really looking at when deciding between DIY kits and professional replacement.

The most budget-friendly option is typically using diesel injector repair kits yourself. These kits generally run between $50 and $300 depending on how comprehensive they are. The basic seal kits sit at the lower end of that range, while complete rebuild packages with specialized components cost more. You'll need to invest 2-4 hours of your time, and possibly in some specialized tools if you don't already have them.

"I was looking at over $2,400 for new injectors on my Kenworth," shares Mike, a long-haul owner-operator from Ohio. "I took a chance on a $180 repair kit and spent a Saturday in my garage. That truck ran another 150,000 miles without injector issues."

Moving up the cost ladder, remanufactured injectors offer a middle-ground solution. These typically cost around $400 or more per injector, though you'll get some money back when you return your old injector as a core. The installation is quicker than rebuilding, and most come with some form of warranty coverage.

At the top end, new OEM injectors represent the premium option. Dealership service for injector replacement can easily exceed $1,000 per injector when factoring in parts and labor. While this is the most expensive route, it comes with full warranty protection and the highest confidence level.

Beyond the obvious parts and labor costs, consider these hidden factors that could sway your decision:

Downtime costs can be significant, especially for commercial vehicles. Every day your truck sits idle could mean hundreds or thousands in lost revenue. A quick DIY repair might get you back on the road faster than waiting for a shop appointment.

Warranty considerations matter too. If your engine is still under warranty, DIY repairs might affect your coverage. Always check your warranty terms before deciding to tackle the job yourself.

Labor rates vary widely across the country. In some areas, professional labor costs might make full replacement more economical than spending hours on a DIY project, especially if you're not confident in your mechanical skills.

Reliability is perhaps the most important long-term factor. Will your repair last as long as a new injector would? Quality diesel injector repair kits from reputable suppliers like G2 Diesel Products are designed to restore near-original performance when installed correctly.

A Mack fleet manager with decades of experience put it best: "We tracked our maintenance costs over three years and finded that using quality repair kits proactively saved us roughly 65% compared to the replace-when-failed approach we used before. The math just makes sense."

For Volvo, Mack, Kenworth, and Paccar trucks specifically, proactive maintenance using high-quality repair kits typically provides the optimal balance between controlling costs and maintaining reliability. This approach has become standard practice among many fleet operations that need to watch their bottom line without sacrificing performance.

More info about shopping injectors

Frequently Asked Questions about Diesel Injector Repair Kits

You've got questions, and we've got answers! After years of helping truck owners and fleet managers maintain their diesel engines, we've gathered the most common questions about diesel injector repair kits to help you make smart decisions about your maintenance approach.

What engines are compatible with these kits?

Not all diesel engines are created equal, and neither are the repair kits designed for them. Compatibility depends on your specific engine and injector type:

Common rail systems dominate modern trucks from 2003 onward, including our specialty Volvo, Mack, Kenworth, and Paccar engines. These high-pressure systems require kits designed to handle up to 30,000 psi of fuel pressure.

HEUI (Hydraulic Electronic Unit Injector) systems, popular in Ford Power Stroke and International engines, use engine oil pressure to amplify fuel pressure and need specialized rebuild components.

For those maintaining older workhorses with mechanical injectors, traditional rebuild kits focus on nozzles, pintle caps, and basic sealing components.

"I was surprised to find kits available for my vintage marine diesel," shared one customer who maintains a commercial fishing boat. "The rebuild process is nearly identical to truck applications, just with marine-specific seals."

Even smaller diesel applications like motorcycles and ATVs have dedicated kits available, though these are more specialized and may require ordering from powersports suppliers.

At G2 Diesel Products, we focus on providing precisely matched kits for heavy-duty truck applications, particularly for Volvo, Mack, Kenworth, and Paccar engines. Always double-check your exact engine model and injector type before ordering.

Do I need special skills or software?

The good news is that basic injector rebuilds are accessible to mechanically-inclined truck owners and maintenance technicians without requiring dealer-level diagnostic equipment or specialized training.

Basic mechanical aptitude is essential - you should be comfortable disassembling small components and keeping track of parts. As one customer told us, "If you can change your own brakes, you can handle a basic injector rebuild."

Attention to detail matters tremendously. A single speck of dirt or a misaligned O-ring can turn a simple repair into a major headache.

Understanding torque specifications is critical. Our kits include detailed torque specs, and following them precisely prevents leaks and component damage. "The torque wrench is your best friend during injector work," notes our lead technician.

Maintaining a clean workspace might be the most underrated skill. Professional shops have dedicated clean rooms for injector work, but you can create a suitable environment by working in a dust-free area and keeping components covered when not being handled.

For common rail systems, while the mechanical rebuild itself doesn't require special software, performing injector coding after installation might require dealer tools for some newer applications. Our customer service team can advise if your specific application needs post-installation coding.

What are the risks of DIY repair?

Working with diesel injector repair kits brings tremendous cost savings, but it's important to understand the potential risks:

High-pressure fuel systems can cause serious injury if not properly depressurized before service. Modern common rail systems store pressure even when the engine is off. Always follow manufacturer procedures for pressure relief before beginning work.

Improper torque is a leading cause of post-repair problems. "Too tight is just as bad as too loose," warns our senior technician. "I've seen cylinder heads cracked by overtightened injectors, and I've seen fuel leaks from undertightened ones."

Contamination remains the invisible enemy of injector performance. Even particles smaller than a human hair can damage precision components. One shop owner shared: "We use magnifying glasses to inspect components before assembly and lint-free gloves during the entire process."

Warranty considerations matter for newer trucks. DIY repairs may affect your engine warranty coverage, so check your warranty terms before proceeding if your truck is still covered.

Diagnostic limitations can make it difficult to verify your repair success without specialized equipment. Many professional shops offer injector testing services that can validate your DIY work for a fraction of the cost of a full repair.

"I always tell first-timers to start with just one injector," suggests a fleet maintenance supervisor from Pennsylvania. "Complete the entire process from removal to reinstallation before moving on to the next one. This builds confidence and prevents having multiple disassembled injectors if you get stuck."

With proper preparation and realistic expectations, diesel injector repair kits offer an accessible and cost-effective maintenance option for most truck owners and fleet operations.

Conclusion

Let's face it—your diesel engine is only as good as its fuel delivery system. Throughout this guide, we've taken a deep dive into diesel injector repair kits and finded how these humble packages of components can make a world of difference in your truck's performance, your wallet, and even your stress levels.

Think about what we've learned: injectors fail for predictable reasons, give clear warning signs, and in many cases, can be brought back to life without breaking the bank. That's pretty empowering knowledge, isn't it?

The math makes a compelling case for quality repair kits:

You'll save a substantial chunk of change compared to buying new injectors. A repair kit might cost you a tenth of what you'd spend replacing all your injectors—money that stays in your business or personal account.

Your truck will thank you with restored performance. There's nothing quite like feeling that smooth power delivery again after a rough-running engine has been properly serviced.

Mother Nature appreciates it too. Fewer emissions, less waste from discarded parts, and improved fuel efficiency all add up to a smaller environmental footprint.

Your engine gets a new lease on life. Addressing injector issues before they cascade into bigger problems can add years to your engine's service life.

And perhaps most importantly for working trucks—less downtime. Every day your rig sits in the shop is a day it's not making you money.

Here at G2 Diesel Products, we're proud to be part of your maintenance solution. From our home base in Harrisburg, PA, we've built our business on understanding what matters to diesel truck owners. We know your Volvo, Mack, Kenworth, or Paccar truck isn't just a vehicle—it's a livelihood, a commitment, and sometimes even a home away from home.

Diesel technology keeps evolving, and so do our products. We're constantly testing, improving, and refining our diesel injector repair kits to make sure they deliver the performance you expect and the reliability you deserve.

I've spoken with countless fleet managers and owner-operators over the years, and they all say something similar: "The cheapest repair is the one you prevent." By incorporating regular injector maintenance into your schedule and using quality repair kits at the first sign of trouble, you're making a smart investment in your equipment's future.

Whether you're managing a dozen trucks or just keeping your personal rig running strong, choosing the right repair kit is one of those decisions that pays dividends every time you turn the key.

Need help finding exactly the right kit for your specific application? Our team lives and breathes diesel, and we're always happy to share what we know. Reach out anytime—we speak your language.