Diesel Parts Done Right – Fulfillment Solutions Made Easy

The Essential Guide to Diesel Parts Fulfillment

Fulfillment solutions for diesel parts are specialized logistics services that ensure the efficient storage, processing, and delivery of diesel engine components from manufacturers to end users. If you're looking for quick answers about diesel parts fulfillment, here's what you need to know:

Fulfillment Solution Element Description Inventory Management Specialized warehousing with real-time tracking for 30,000+ diesel SKUs Order Processing Same-day shipping for orders placed before 1-3 PM (warehouse dependent) Packaging Solutions Custom packaging for heavy, fragile, and hazardous diesel components Technology Integration EDI/API connections with e-commerce platforms and dealer systems Returns Processing Core return management with automated RMA tracking and credit issuance

The diesel parts aftermarket is booming, with global projections showing growth from $548.5 billion in 2022 to nearly $985 billion by 2033 at a 5.5% CAGR. For fleet managers and diesel parts suppliers, this growth creates both opportunity and complexity.

Efficient fulfillment matters because diesel engines power the backbone of our economy. When a truck is down, costs accumulate rapidly - sometimes exceeding $1,000 per day in lost productivity. Getting the right part, packaged properly, and delivered quickly isn't just convenient - it's essential for business continuity.

What makes diesel parts fulfillment unique is the specialized handling requirements. From heavy turbochargers to precision-calibrated fuel injectors, these components demand expert care throughout the supply chain. Whether for Volvo, Mack, Kenworth, or Paccar engines, each part requires specific knowledge and handling protocols.

As one fleet manager put it: "The difference between a good parts supplier and a great one isn't just the quality of parts - it's their ability to get exactly what I need, when I need it, without damage or delays."

Modern fulfillment solutions have evolved to meet these challenges with specialized systems that combine technological efficiency with hands-on expertise.

Why Diesel Parts Fulfillment Matters

Let's talk about something that's changing the diesel industry right before our eyes. The diesel parts aftermarket isn't just growing—it's absolutely booming. With a projected 5.5% compound annual growth rate, we're looking at a market that will nearly double from $548.5 billion in 2022 to an impressive $984.7 billion by 2033. This isn't just a number on a spreadsheet—it represents a fundamental shift in how diesel parts move from manufacturers to the people who need them.

For folks managing fleets or running repair shops, vehicle uptime isn't just important—it's everything. When a diesel-powered truck sits idle, those dollars fly out the window fast—between $800 and $1,200 every single day, not even counting what you'll pay for the actual repairs. This reality is why fulfillment solutions for diesel parts have become so crucial to modern operations.

As our logistics manager at G2 DIESEL PRODUCTS often says, "The diesel repair world has changed. We don't count downtime in days anymore—we measure it in hours and minutes. Every minute a customer's truck sits idle, their profit margin shrinks. That's why our fulfillment system is built to get parts moving within hours, not days."

The expectations have completely changed too. Thanks to companies like Amazon, everyone now expects lightning-fast service—even for specialized industrial components that weigh 50 pounds and contain precision engineering. Today's customers want their diesel parts delivered with:

Same-day shipping when ordered before cutoff times, real-time inventory visibility so they know exactly what's available, near-perfect order accuracy (99.9% or better), damage-free delivery despite the challenges of shipping heavy components, and hassle-free returns processing when cores need to come back.

Managing diesel parts inventory presents unique challenges because of the sheer value involved. At G2 DIESEL PRODUCTS, we're responsible for inventory worth millions of dollars, with some individual components valued in the thousands. Good inventory management isn't just about keeping things organized—it's about protecting valuable assets that directly impact your bottom line.

According to research on automotive aftermarket growth, companies that excel at fulfillment are pulling ahead of their competition. It's becoming one of the key factors that separate thriving businesses from those just trying to keep up.

In today's diesel repair environment, having a partner who understands the unique challenges of diesel parts fulfillment isn't just nice to have—it's essential for maintaining your competitive edge and keeping your customers' vehicles where they belong: on the road making money.

Unique Challenges of Diesel Component Logistics

Let's be honest – shipping a diesel turbocharger isn't like sending a birthday card. When we talk about fulfillment solutions for diesel parts, we're dealing with a whole different world of logistics challenges that would make regular warehouse managers sweat.

Sizing & Weight Obstacles

Have you ever tried to casually pick up a Class 8 truck turbocharger? At over 100 pounds, it's more of a two-person job – and that's one of our lighter components! Engine blocks can tip the scales at a whopping 1,500 pounds, which is why our Harrisburg facility looks more like a heavy machinery operation than a typical fulfillment center.

"We joke that our warehouse staff skips the gym membership," says our warehouse manager with a smile. "But seriously, we've created specialized zones throughout our facility based on weight and handling needs. Our team uses forklifts, pallet jacks, and custom lifting equipment daily – it's not just about moving products efficiently, it's about keeping our people safe while handling these substantial parts."

The reality is that most diesel components won't fit in a standard shipping box. Many require full pallet shipping with specialized bracing and support. This isn't your standard pick-and-pack operation – it's industrial logistics with a need for precision.

Hazardous & Sensitive Materials

Diesel parts come with their own special brand of complexity – the kind that requires hazmat training and DOT compliance knowledge. When we handle fuel injectors at G2 DIESEL PRODUCTS, we're often dealing with components that contain diesel fuel residue. EGR coolers might arrive with coolant contamination, and many parts are still oil-wetted when they reach us.

These aren't just messy – they're regulated materials that demand specific handling protocols. Our team is trained to identify, package, and label these items according to Department of Transportation regulations. Getting this wrong doesn't just mean a delayed shipment – it could mean significant fines and unhappy customers.

On the flip side of this rugged industry are the surprisingly delicate electronic components. Modern diesel engines rely on sophisticated sensors and ECMs (Engine Control Modules) that can be damaged by something you can't even see – static electricity. Our anti-static packaging and handling procedures protect these sensitive parts from invisible threats that could cause major headaches down the road.

High-Value Core Returns

Perhaps the most unique aspect of diesel parts fulfillment is the circular economy we operate in. Many components in our industry aren't simply sold – they're exchanged.

"When I explain our core return process to people outside the industry, they're often surprised," our returns specialist tells me. "A customer buys a remanufactured injector from us, installs it, and then sends us back their old one – which we might eventually remanufacture and sell to someone else. It's recycling at an industrial scale."

This creates a reverse logistics challenge that most fulfillment operations never encounter. We need sophisticated systems to track which cores came from which customers, assess their condition, issue the appropriate credits, and route them to remanufacturing facilities.

To make this process painless for our customers, we've developed a straightforward Core Return Policy that balances customer convenience with our need for accurate tracking. Behind the scenes, there's a carefully choreographed dance of inspections, credits, and routing decisions that keeps valuable cores moving through the remanufacturing loop.

This isn't just good business – it's good for the planet too. Each remanufactured diesel component represents significant resource conservation compared to manufacturing new parts.

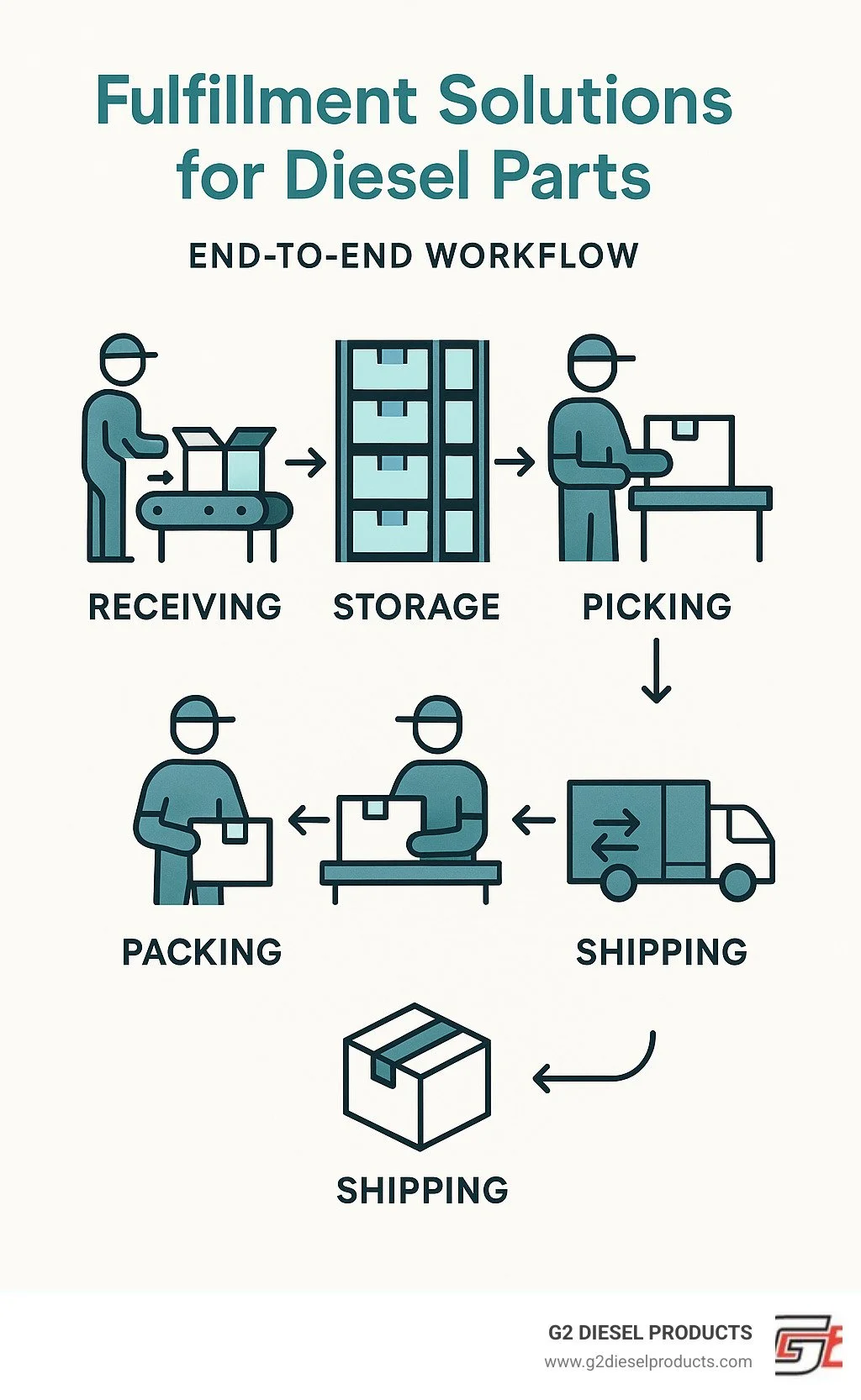

Fulfillment solutions for diesel parts – End-to-End Workflow

When I first walked into G2 DIESEL PRODUCTS' fulfillment center, I was struck by the choreographed dance of people, parts, and technology working in perfect harmony. There's something satisfying about watching a well-oiled logistics machine in action, especially one handling the specialized components that keep America's trucks running.

Inbound Receiving & Inventory Control in Fulfillment solutions for diesel parts

The journey of a diesel part begins the moment it arrives at our dock. Our team springs into action with our dock-to-stock process that gets new inventory inspected, logged, and shelved within 24 hours. It's like a relay race where speed matters, but accuracy wins the day.

"I remember when we used paper receiving logs," laughs our receiving manager. "Now with barcode scanning, we can process a shipment of 200 injectors in the time it used to take to handle 20."

Beyond the initial receiving, our inventory control relies on regular cycle counts rather than disruptive annual inventories. Each day, different sections of our warehouse get a thorough count, ensuring we maintain our impressive 99.9% inventory accuracy. This approach means we're constantly fine-tuning our stock levels without ever needing to shut down operations.

Every diesel component receives a unique barcode that tracks its entire journey through our facility. This simple technology has transformed how we manage the thousands of SKUs needed to service Volvo, Mack, Kenworth, and Paccar engines.

Order Processing & Same-Day Shipping in Fulfillment solutions for diesel parts

When your truck is down, every hour counts. That's why we've built our order processing around one simple goal: get the right parts moving as quickly as humanly possible.

For orders received before our 1 PM Eastern cutoff time, we offer same-day shipping. Our system automatically prioritizes incoming orders, generates pick tickets, and routes them to the right team members. It's a bit like air traffic control, but for diesel parts.

"The clock starts ticking the moment an order hits our system," explains our fulfillment director. "Our pickers know exactly which routes to take through the warehouse for maximum efficiency. It's not unusual for an emergency order to go from 'received' to 'shipped' in under 45 minutes."

We don't play favorites with shipping carriers either. By maintaining relationships with multiple services, we can choose the best option for each shipment based on destination, urgency, and package characteristics. You can learn more about these options in our Return and Shipping Policy.

Packaging & Damage Prevention

If you've ever received a precision diesel component that was damaged in transit, you know the frustration of waiting for a replacement. That's why we're a bit obsessive about our packaging.

Each fuel injector gets nestled into a custom-designed molded tray that holds it perfectly still during its journey. These trays then go into double-walled boxes with additional cushioning. It's like building a mobile fortress for each part.

For bulkier items like turbochargers, we take even more precautions. Our packaging team uses reinforced boxes, custom foam inserts molded to each component's shape, and internal bracing to prevent shifting. The result? Damage rates below 0.1% across all shipments.

"We had a customer in Alaska call us once to say his package had fallen off a delivery truck, been run over, and then sat in the snow overnight," our packaging lead recalls with a smile. "But when he opened it, the injectors inside were perfect. That's when you know you're doing something right."

Technology Integrations & Real-Time Tracking

The invisible backbone of our fulfillment solutions for diesel parts is a web of integrated technologies that keep information flowing as smoothly as the parts themselves.

Our systems connect directly with e-commerce platforms, dealer management systems, shipping carriers, and accounting software. These API and EDI connections mean that when you place an order through any channel, it enters our workflow without manual intervention or delays.

For repair shops waiting on critical components, our real-time tracking is a game-changer. Knowing exactly when a part will arrive allows mechanics to schedule their time efficiently and give accurate promises to their own customers.

"Before we implemented these integrations, we had three people whose full-time job was just entering orders from different systems," notes our IT director. "Now those folks are helping customers instead of typing all day."

Want to learn more about how our systems can integrate with your business? Visit our detailed page on Fulfillment Solutions for Volvo, Mack, Kenworth, Paccar Diesel Fuel Injectors.

From dock to doorstep, our end-to-end workflow is designed with one purpose: getting critical diesel components into your hands quickly, accurately, and in perfect condition. Because in this business, we know that parts in transit don't fix trucks – only parts in your hands do.

Outsourcing vs In-House: Cost, Compliance, Scalability

Let's talk about one of the biggest decisions diesel parts suppliers face today – should you handle fulfillment yourself or partner with a specialized third-party logistics (3PL) provider? It's a bit like deciding whether to cook dinner or order takeout – both will feed you, but each option comes with different trade-offs!

Here at G2 DIESEL PRODUCTS, we've chosen to keep our fulfillment operations in-house. Why? The specialized nature of our products and our commitment to quality control at every stage simply demand it. That said, we've definitely borrowed plenty of best practices from the 3PL world to make our operations sing.

"This isn't always a clear-cut choice," our operations director often says. "Some companies do best with a hybrid approach – handling their technical products in-house while sending the standard stuff to a 3PL partner."

Factor In-House Fulfillment 3PL Partnership Initial Cost High (warehouse, equipment, systems) Low (minimal setup fees) Ongoing Costs Fixed (regardless of volume) Variable (scales with volume) Control Complete oversight Partial oversight Scalability Limited by physical space Highly scalable Expertise Must be developed Immediately available Technology Significant investment required Included in service Geographic Reach Limited to your locations Multiple fulfillment centers possible

The 3PL route offers some compelling advantages. You'll avoid massive capital investments in warehouse space and equipment. When holiday rushes hit, you can scale up without hiring permanent staff. You'll tap into established logistics networks and technology systems that might take years to build yourself. And with distributed inventory, you can offer faster shipping to customers across wide geographic areas.

But there's something to be said for keeping those specialized diesel components under your own roof – especially when they require technical handling or must comply with hazardous materials regulations. That's often why many quality-focused diesel suppliers lean toward handling fulfillment themselves.

Regulatory & Safety Considerations

The regulatory landscape for diesel parts isn't just complex – it's a maze with constantly shifting walls. You're juggling OSHA requirements for safely handling heavy components (some weighing hundreds of pounds), DOT regulations for shipping anything with fuel residue, and EPA guidelines for components that might contain oil or other fluids.

Then there's export controls for certain components and ISO certification requirements that customers increasingly demand. Each regulatory framework requires specific training, documentation, and procedures that must be followed to the letter.

For in-house operations, this means developing expertise across multiple regulatory domains. If you're working with a 3PL, you'll need to verify they have appropriate certifications and training specifically for diesel components – not all 3PLs are created equal when it comes to specialized parts.

Material Safety Data Sheets (MSDS) aren't optional paperwork – they're essential documents that must be maintained for all hazardous materials. Your staff needs proper training in handling procedures, especially for components that might contain leftover fuel, oil, or cleaning chemicals. One mistake here can lead to fines, injuries, or worse.

Dynamic Demand & Forecasting

The diesel parts market rides a roller coaster of demand fluctuations. When harvest season hits, agricultural equipment orders surge. Construction booms drive replacement part demand. Economic shifts in transportation ripple through the entire supply chain. And when new regulations drop, suddenly everyone needs certain components upgraded simultaneously.

Effective fulfillment solutions for diesel parts must stretch during peak periods without snapping – maintaining accuracy and speed even when order volumes double. This requires sophisticated forecasting tools and flexible resource allocation strategies.

Analytics aren't just nice to have – they're essential for seeing around corners. By analyzing historical data patterns alongside current market trends, we can anticipate demand spikes weeks or months ahead, adjusting inventory levels and staffing before the rush hits.

For businesses with multiple distribution centers, network optimization becomes another critical puzzle piece. Deciding which products to stock at which locations can dramatically cut shipping times and costs, especially for those urgent "truck down" emergency orders that define our industry.

At G2 DIESEL PRODUCTS, we've built our fulfillment approach around these realities, creating systems that deliver consistency while remaining flexible enough to handle whatever the market throws our way.

Frequently Asked Questions about Diesel Parts Fulfillment

How fast can diesel parts be processed and shipped?

When your truck is down, every minute counts. That's why at G2 DIESEL PRODUCTS, we've built our entire operation around speed without sacrificing quality.

For in-stock items, we process orders received before 1 PM Eastern Time that very same day. This means your critical parts are picked, carefully packed, and handed to our shipping partners before we turn off the lights.

"The clock starts ticking the moment an order hits our system," explains our fulfillment manager. "Our team knows that somewhere, there's a mechanic and a truck owner waiting on that part to get back on the road."

Delivery timeframes vary based on your location and chosen shipping method:

Most ground shipments arrive within 1-5 business days, with closer locations seeing delivery in just 24-48 hours. Need it faster? Our expedited options can get parts to you overnight or second-day, and for truly urgent situations in certain regions, we can arrange same-day courier service.

Our dealer partners and fleet customers enjoy additional options like scheduled deliveries and dedicated transport for larger orders – just one way we customize our fulfillment solutions for diesel parts to match your business needs.

What packaging is safest for injectors, pumps, and turbochargers?

Diesel components require packaging as specialized as the parts themselves. One-size-fits-all solutions simply don't work when you're shipping precision-engineered parts worth hundreds or thousands of dollars.

For fuel injectors, we use anti-static trays custom-molded to cradle each injector perfectly. These trays, combined with protective nozzle caps and moisture-resistant sealing, keep these sensitive components safe inside double-walled boxes with strategic cushioning.

Fuel pumps receive special attention with port plugs that prevent contamination, comprehensive bubble wrap or foam protection, and heavy-duty boxes with internal bracing. Each box is clearly marked as fragile and heavy to ensure proper handling.

Turbochargers present unique challenges due to their weight and complex design. Our solution includes:

"We actually studied damaged shipments to design better packaging," shares our packaging specialist. "What we learned helped us create custom foam inserts that cradle turbochargers so perfectly they barely move even if the box is dropped."

Larger turbos get palletized for extra protection, and all turbo packages include special protection for fragile components like actuators and oil-resistant wrapping for units with residual lubricants.

The investment in proper packaging pays off in virtually zero damage claims – something both our customers and our accounting department appreciate!

How are core returns managed without disrupting inventory accuracy?

The core return process represents one of the trickiest parts of the diesel components business. When a remanufactured part goes out, we need the old part back – but these returns can create inventory nightmares if not managed properly.

Our solution starts with unique RMA barcodes that create a digital fingerprint for each returned core, linking it to the original order, customer information, and exact part number. This digital trail follows the core throughout our entire process.

"We treat cores like they're in quarantine," our returns manager explains with a smile. "They go to their own special area until we've thoroughly inspected them – keeping them completely separate from our sellable inventory."

Each core undergoes a detailed inspection to determine its remanufacturing potential and credit value. Once evaluated, our system automatically processes the appropriate credit to your account without you having to make a single phone call or send a follow-up email.

Accepted cores move directly to our remanufacturing department or partners with comprehensive condition reports, ensuring the rebuilding process starts with complete information about each component's status.

This systematic approach to core returns means you get timely credit for your returns while we maintain pristine inventory accuracy – a win-win that keeps fulfillment solutions for diesel parts running smoothly from beginning to end.

For more details about how we handle core returns, visit our Core Return Policy page.

Conclusion

When it comes to keeping America's trucks on the road, the details matter. Fulfillment solutions for diesel parts aren't just about warehousing and shipping—they're about understanding the unique challenges that come with handling precision engineered components that keep our economy moving.

Throughout this guide, we've walked through the specialized world of diesel parts logistics. From the weight challenges of handling 100-pound turbochargers to the delicate packaging needs of precision fuel injectors, it's clear that this isn't your standard fulfillment operation.

The diesel aftermarket is growing at breakneck speed, heading toward that impressive $985 billion mark by 2033. In this expanding marketplace, the companies that thrive will be those who master not just parts quality, but the entire fulfillment experience. When a truck is down, the clock is ticking—and every hour counts.

"We're not just shipping parts," as our logistics manager often reminds us, "we're shipping solutions to people with real problems that need solving right now."

At G2 DIESEL PRODUCTS, we've built our reputation on this understanding. Our Harrisburg facility isn't just a warehouse—it's a specialized operation designed from the ground up for the unique demands of diesel components. Our team doesn't just pick and pack; they understand what they're handling and why it matters.

The right packaging prevents damage. The right tracking provides peace of mind. The right core return process keeps costs down. All these elements work together to create a seamless experience that transforms one-time buyers into lifetime partners.

Whether you're a fleet manager trying to minimize downtime, a repair shop balancing multiple jobs, or a parts reseller building your business, having the right fulfillment partner makes all the difference. When your customers know they can count on receiving the right part, in perfect condition, exactly when promised, you've given them something invaluable: confidence.

For more information about how our specialized fulfillment capabilities can support your diesel parts needs, visit our page on fulfillment solutions for Volvo, Mack, Kenworth, Paccar Diesel Fuel Injectors.

In the end, great fulfillment solutions for diesel parts aren't just about moving boxes—they're about keeping promises. And in an industry where downtime means dollars, those promises matter more than most.