Inside Diesel Engines – How Common Rail Injectors Operate

The Evolution of Diesel Injection: How Common Rail Systems Changed Everything

How do common rail injectors work in a modern diesel engine? Here's a quick answer:

Common Rail Injector Operation How It Works

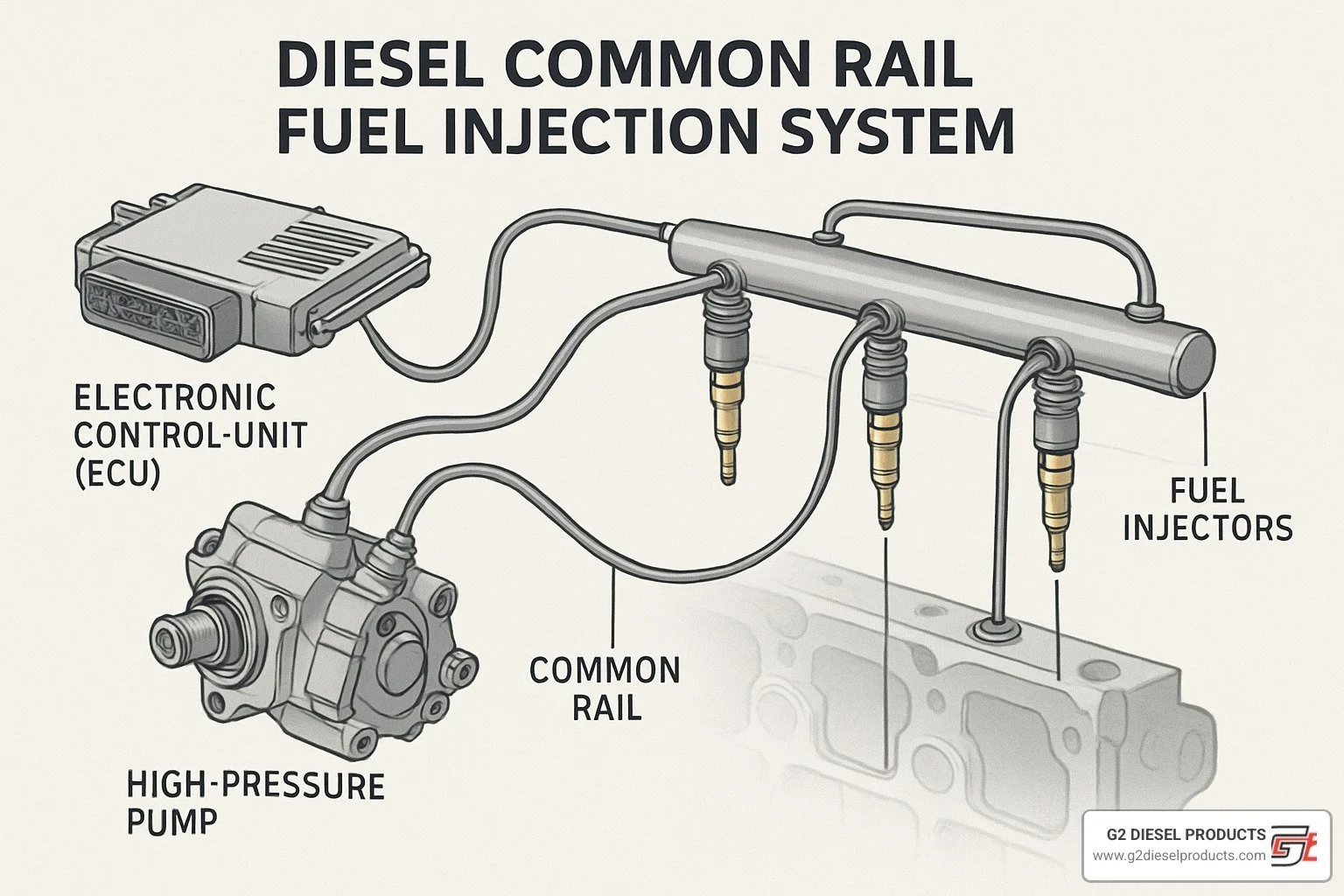

1. Fuel Supply: Low-pressure lift pump sends fuel to high-pressure pump

2. Pressurization: High-pressure pump (up to 36,000 psi/2,500 bar) feeds the common rail

3. Storage: Pressurized fuel is stored in the rail manifold, creating a reservoir

4. Electronic Control: ECU sends precise electrical signals to injector solenoid/piezo actuator

5. Injection: Actuator opens needle valve, releasing pressurized fuel through tiny nozzle holes

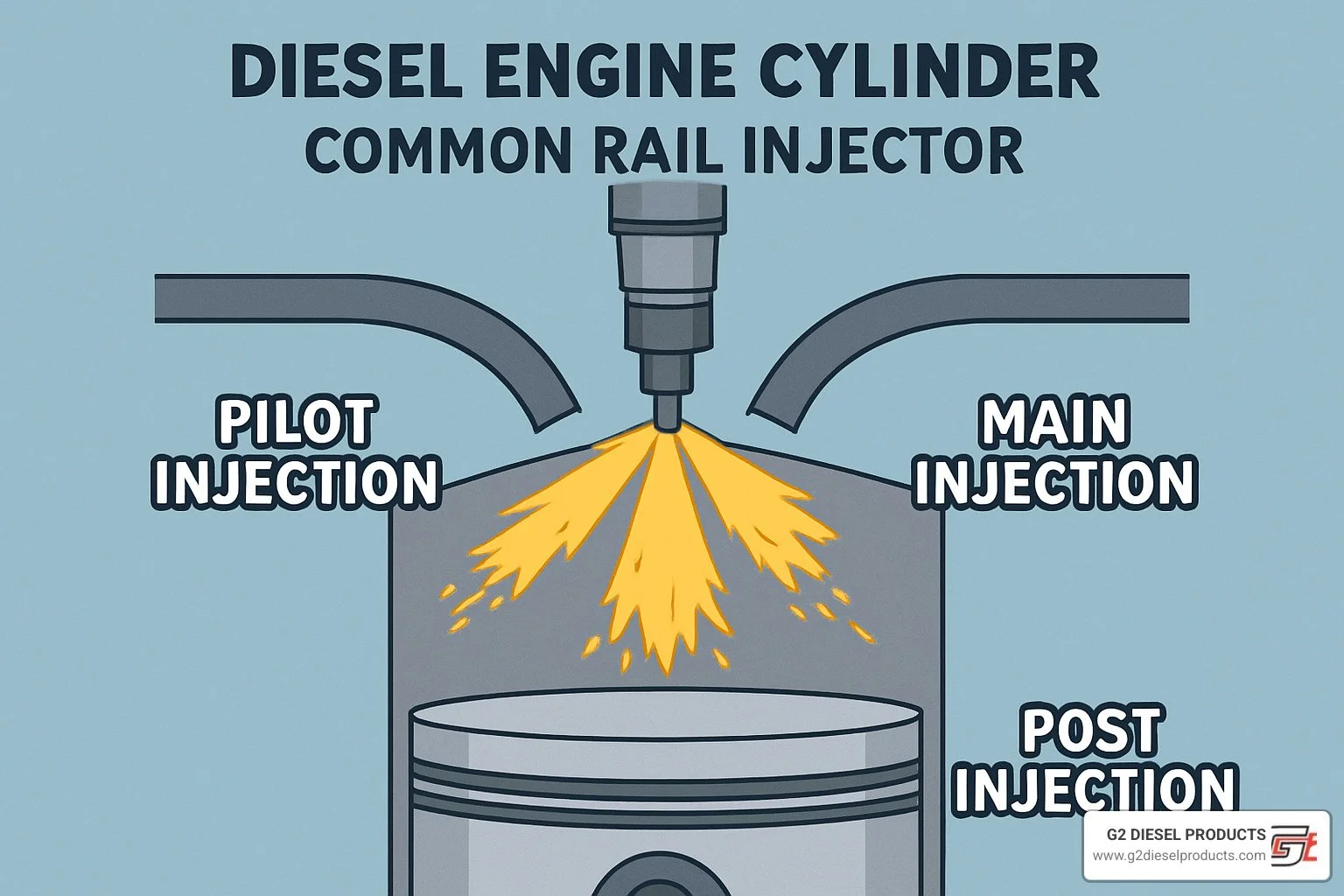

6. Multiple Events: Can perform 3-5 separate injections per combustion cycle (pilot, main, post)

The diesel engines powering your fleet today are light-years ahead of their predecessors, thanks largely to one innovation: common rail injection. This technology revolutionized diesel performance by separating the pressure generation from the actual injection event.

Before common rail systems, diesel engines relied on mechanical pumps that could only deliver high pressure at specific engine speeds. This meant inconsistent power delivery and higher emissions. Today's common rail systems maintain constant high pressure regardless of engine speed, enabling precise fuel delivery even at idle.

For fleet managers, this translates to tangible benefits: 25% more power and torque, improved fuel economy, significantly reduced emissions, and quieter operation. These advantages come from the system's ability to perform multiple injection events per combustion cycle at pressures exceeding 29,000 psi.

As one diesel technician put it: "Common rail injection allows us to precisely control when, how much, and at what pressure fuel enters the combustion chamber—it's like comparing a sledgehammer to a surgeon's scalpel."

Common Rail Basics & Components

Ever wondered how modern diesel engines manage to be so powerful yet fuel-efficient? The secret lies in the common rail system - a approach to fuel delivery that transformed diesel engine performance. Unlike older systems where each injector received fuel at different times and pressures, common rail creates a reservoir of high-pressure fuel that's available to all injectors equally - like a shared fuel buffet that's always fully stocked!

What Is a Common Rail Injector?

How do common rail injectors work differently from their predecessors? A common rail injector is essentially a precision fuel delivery device that sprays highly pressurized diesel fuel directly into the combustion chamber. The magic happens because these modern injectors don't have to create pressure themselves - they simply control when and how much pre-pressurized fuel enters the cylinder.

Think of it this way: older mechanical injectors were like having to pump water uphill every time you needed it. Common rail systems, by contrast, keep water in a tower (the rail) so it's always ready at high pressure when you turn on the tap (the injector).

This separation of pressure generation from injection timing is what makes all the difference. Traditional systems like the VP44 pump could only achieve full pressure at high engine speeds - around 1,800 RPM. When your engine slowed to 1,200 RPM, pressure would drop below 25,000 PSI, compromising fuel atomization and efficiency.

Common rail systems maintain full high pressure (over 30,000 PSI) even when you're idling at 1,000 RPM. This consistent pressure gives you better low-end torque, improved fuel economy, and significantly cleaner emissions - a win-win-win situation!

Main Hardware Inside the System

Let's break down the key players in this high-pressure team:

Lift Pump: The unsung hero of the system! This low-pressure pump draws fuel from your tank and delivers it to the high-pressure pump at about 5-10 PSI. It's like the assistant that makes sure the star performer never runs out of material.

High-Pressure Pump: Consider this the powerhouse of the whole operation. Modern pumps like the CP3 or HP4 use multiple pistons driven by a camshaft to generate pressures exceeding 2,000 bar (29,000 PSI). Remarkably, these pumps require less than 15 horsepower to drive—saving approximately 200 pounds in engine weight compared to older systems. Talk about doing more with less!

Common Rail: This thick-walled tube is essentially a pressure accumulator - a reservoir that stores fuel under extreme pressure. Think of it as a pressure battery that dampens pulsations from the pump and ensures all injectors have constant access to high-pressure fuel. It's built tough to handle the incredible pressures inside.

Rail Pressure Sensor: This precision sensor is the system's watchful eye, constantly monitoring actual pressure in the rail and feeding this data to the ECU. This feedback loop ensures pressure stays exactly where it should be for optimal performance.

Flow Limiters: Safety first! These clever devices can shut off individual injectors if they detect a leak by seating a ball valve, preventing catastrophic fuel loss that could damage your engine or worse.

Pressure Relief Valve: Another safety feature that opens at approximately 2,000 bar (29,000 PSI) to prevent over-pressurization. Think of it as the system's pressure release valve - there when you need it, invisible when you don't.

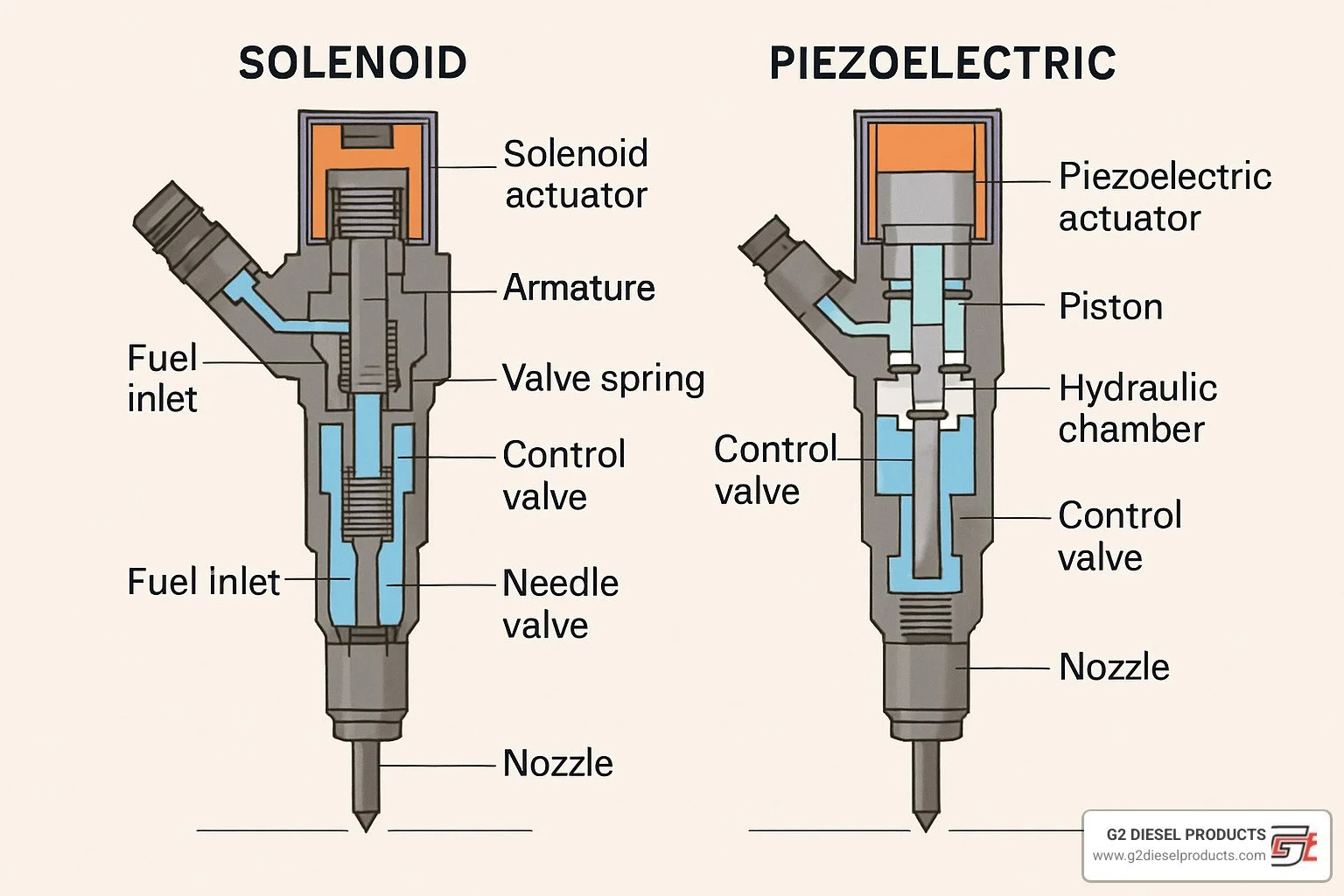

Injectors: The business end of the whole system. These precision devices contain either solenoid or piezoelectric actuators that control a needle valve with microscopic precision. When the ECU energizes the actuator, the needle lifts, allowing pressurized fuel to spray through tiny nozzle holes (typically five to seven orifices) directly into the combustion chamber.

At G2 Diesel Products, we understand these components inside and out. We specialize in manufacturing critical fuel system components for Volvo, Mack, Kenworth, and Paccar trucks, ensuring each Common Rail Injector meets or exceeds OEM specifications. Our deep knowledge of diesel engine parts comes from years of hands-on experience and the latest research on common rail history.

The precision engineering behind common rail technology is what allows modern diesel engines to deliver that perfect balance of power, efficiency, and cleaner emissions that fleet operators depend on every day.

How Do Common Rail Injectors Work — Step-by-Step

Ever wondered what happens when you turn the key in your diesel truck? Let's take a journey with your fuel from tank to combustion chamber to understand how do common rail injectors work in real-world conditions.

The process begins right at your fuel tank. When you start your engine, the lift pump springs to life, drawing diesel fuel and pushing it through a series of increasingly fine filters. Modern systems typically use a 2-micron final filter—that's about 40 times smaller than a human hair!—ensuring only the cleanest fuel reaches those precision components.

Once filtered, this fuel enters the high-pressure pump, where the real magic begins. This pump compresses the fuel to extraordinary pressures between 1,000 to 2,500 bar (that's up to 36,000 PSI—enough pressure to cut through steel!). Think of it as taking a garden hose and squeezing it down to the diameter of a needle.

This highly pressurized fuel then flows into the common rail—essentially a thick-walled tube acting as a fuel reservoir under extreme pressure. Unlike older systems where pressure varied with engine speed, the rail maintains consistent pressure regardless of whether you're idling at a stoplight or climbing a steep grade.

Your truck's brain—the Engine Control Unit (ECU)—constantly monitors dozens of inputs: how hard you're pressing the accelerator, engine temperature, load, speed, and more. Based on this data, it calculates exactly how much fuel each cylinder needs and precisely when it should be delivered.

When the moment is right, the ECU sends an electrical pulse to the injector. This happens incredibly fast—in some piezoelectric systems, the signal takes just 150 microseconds, which is about how long it takes light to travel 28 miles!

This electrical signal activates the injector's actuator, which relieves pressure in a control chamber above the needle valve. With this pressure differential, the intense rail pressure pushes the needle upward, opening a pathway for fuel.

The pressurized fuel rushes through the open valve and exits through tiny nozzle holes at tremendous velocity, creating a mist of fuel droplets finer than fog. This extreme atomization is crucial for complete combustion and clean emissions.

Fuel Pressurization Sequence

The journey to those extreme pressures follows a fascinating sequence. It starts with the humble lift pump delivering fuel at just 5-10 PSI—about the same pressure as your garden hose. This fuel enters the high-pressure pump where multiple pistons (typically three) take turns compressing the fuel with each rotation of the camshaft.

This design spreads the pumping work across the engine cycle, dramatically reducing the peak torque demands compared to older unit injector systems. It's like having three people push a heavy boulder instead of one person doing all the work.

Clever one-way check valves ensure fuel only flows toward the rail, building pressure with each pump stroke. Meanwhile, the pump control valve—acting on ECU commands—regulates exactly how much high-pressure fuel enters the rail, maintaining your target pressure regardless of driving conditions.

For safety, a pressure relief valve stands guard, ready to open if pressure exceeds safe limits (typically around 2,000-2,500 bar), preventing any potential damage to the system.

Injection Event Timeline — How do common rail injectors work inside the cylinder?

The actual injection process happens in the blink of an eye—the entire sequence takes just about 1 millisecond (0.001 seconds). If you could slow time down and watch, here's what you'd see:

First comes the pre-injection preparation, where your ECU calculates the perfect fuel delivery strategy based on your driving needs and engine conditions.

Next is the pilot injection—a tiny amount of fuel (just 1-2 mm³, about the size of a pinhead) enters the cylinder about 300-500 microseconds before the main event. This small injection creates a gentle start to combustion, significantly reducing that characteristic diesel knock that plagued older engines.

The main injection follows immediately, delivering the primary fuel charge that powers your engine. The duration of this injection directly determines how much power your engine produces—longer injection equals more fuel and more power.

But we're not done yet. Modern systems often include post injection events about 300-500 microseconds after the main injection. These small additional shots help complete combustion, reducing particulate emissions and assisting with regeneration of your aftertreatment systems.

Finally, when the ECU cuts power to the actuator, pressure equalizes in the control chamber, and the needle spring forces the needle back onto its seat, stopping fuel flow until the next cycle begins.

This entire sequence repeats for each cylinder, with the ECU orchestrating the timing across all cylinders based on the firing order. The ability to perform these multiple, precisely timed injections is what gives common rail systems their remarkable advantages in power, efficiency, and emissions control.

At G2 Diesel Products, we understand these complex systems inside and out, which is why our replacement injectors for Volvo, Mack, Kenworth and Paccar engines deliver the precision and reliability your fleet demands.

Electronic Precision & Multi-Pulse Strategy

Think of common rail systems as an orchestra, where the mechanical components create the powerful sound, but it's the conductor—the electronic brain—that brings harmony to the performance. This precision control is what truly sets modern diesel injection apart.

How do common rail injectors work with the ECU?

The Engine Control Unit (ECU) is like the mastermind behind every aspect of your engine's fuel delivery. Imagine having a fuel expert making split-second decisions for your engine thousands of times per minute. That's what the ECU does by processing information from dozens of sensors to determine:

The perfect moment to begin and end each injection

Whether to use three, four, or five injection events per cycle

Exactly how long each injection pulse should last (measured in microseconds!)

What rail pressure will work best for your current driving conditions

This isn't just approximate timing—it's microsecond precision. Your ECU can command injection pulses as brief as 150 microseconds (that's quicker than a blink of lightning) and adjust timing by mere degrees of crankshaft rotation. This level of control was simply impossible with older mechanical systems.

Did you know each injector has its own unique "trim code"? These codes help the ECU compensate for tiny manufacturing differences between injectors. When you replace injectors, these codes must be programmed into the ECU—it's like giving your engine's brain updated instructions for the new team members.

The ECU constantly monitors how everything's working through a closed-loop feedback system:

It checks the actual rail pressure against the sensor reading

Compares this to what it wants the pressure to be

Makes adjustments to the pump control valve as needed

Keeps an eye on engine performance and emissions

Continuously fine-tunes operation for optimal performance

This adaptive control means your engine maintains peak performance even as parts naturally wear over time or when you're driving in challenging conditions like extreme heat or cold.

Solenoid vs Piezo: Response & Accuracy

Solenoid injectors work a lot like a tiny electromagnet. When electricity flows through the coil, it creates a magnetic field that pulls an armature, which controls hydraulic pressure in the control chamber. This movement allows pressure to bleed off from above the needle, lifting it to release fuel. Think of it as using a magnet to flip a tiny switch that controls a much larger valve.

Piezoelectric injectors use something truly fascinating—crystals that physically change shape when electricity is applied. This stack of piezo crystals expands just enough to directly move a valve controlling hydraulic pressure. The beauty of this design is speed: piezo injectors respond about twice as fast as solenoids, allowing for more precise control and up to five separate injection events during each combustion cycle.

At G2 Diesel Products, we manufacture both types of injectors to match the specific needs of different engine platforms. Whether your fleet runs Volvo, Mack, Kenworth, or Paccar engines, we've got you covered with precision-engineered components that deliver optimal performance. Want to learn more about the technology behind these amazing components? Check out how common rail injection works in greater detail.

Advantages, Operating Pressures & Applications

Ever wonder why virtually every diesel engine today uses common rail technology? The benefits are so compelling that they've revolutionized the industry. Modern trucks now deliver 25% more power and torque than their predecessors, all while using less fuel and running cleaner.

How do common rail injectors work to achieve these remarkable improvements? It starts with maintaining consistent high pressure regardless of engine speed. Unlike older systems that struggled to deliver pressure at low RPMs, common rail systems keep full pressure even at idle. This gives you smooth, powerful acceleration from a standstill and better low-end torque for climbing hills.

The fuel economy improvements are equally impressive. Fleet managers typically see 5-15% better mileage compared to older injection systems. That translates to thousands of dollars saved annually per truck. These savings come from the system's ability to precisely control exactly when and how much fuel enters each cylinder.

Perhaps most remarkable is how common rail technology has transformed the diesel driving experience. Remember the characteristic diesel knock that announced every truck's arrival? Multiple injection events have virtually eliminated that noise, making modern diesels nearly as quiet as gasoline engines. Your neighbors will thank you!

These systems have also enabled "down-speeding" in modern trucks. Instead of cruising at the traditional 1,800 RPM, today's engines operate efficiently at just 1,060-1,150 RPM on the highway. Lower RPMs mean less wear, less noise, and better fuel economy. The weight savings are substantial too—about 200 pounds lighter than older systems.

Combustion Efficiency & Atomization Benefits

The magic happens when fuel exits the injector nozzle. At pressures up to 36,000 PSI (in third-generation systems), diesel fuel atomizes into microscopic droplets with dramatically increased surface area. Think of trying to burn a log versus sawdust—the sawdust burns instantly because of its greater surface area. The same principle applies here.

This finer atomization creates a cascade of benefits. More complete combustion means you extract more energy from every drop of fuel. The smaller Sauter mean diameter (fancy talk for droplet size) allows fuel to mix more thoroughly with air, creating a more homogeneous mixture that burns faster and more completely.

Cold mornings become less daunting too. Fine atomization enables reliable ignition even in frigid conditions, improving cold-start performance significantly. Your maintenance costs may drop as well, since more complete combustion means less carbon buildup on injector tips and combustion chambers.

All these improvements translate directly to lower Brake Specific Fuel Consumption (BSFC)—the amount of fuel needed to produce a unit of power. In practical terms, your trucks go farther on less fuel.

Emissions & Noise Reduction

Environmental regulations continue to tighten, and common rail technology has been crucial in meeting these challenges. The system's precision allows for sophisticated emission control strategies that were impossible with mechanical injectors.

Particulate matter (that black smoke from older diesels) is dramatically reduced thanks to better atomization and more complete combustion. The multiple injection events ensure thorough fuel oxidation, leaving little unburned fuel to form soot.

NOx emissions are controlled through precise timing of injection events. By carefully managing combustion temperatures, common rail systems limit nitrogen oxide formation. This works hand-in-hand with exhaust aftertreatment systems like Selective Catalytic Reduction (SCR) to meet the strictest emissions standards.

The noise reduction is something you'll notice immediately. The pilot injection creates a small initial combustion event that raises cylinder pressure gradually rather than suddenly. This "softening" of combustion dramatically reduces that distinctive diesel knock, making modern engines remarkably quiet.

These advantages have made common rail systems standard across virtually all diesel applications—from heavy-duty trucks (including Volvo, Mack, Kenworth, and Paccar) to light-duty pickups, marine engines, construction equipment, and agricultural machinery.

At G2 Diesel Products, we focus on heavy-duty truck applications, ensuring that fleets get the reliability and performance they need from their Diesel Engine Parts. Our Common Rail Injectors are engineered to deliver these benefits consistently throughout their service life.

Maintenance, Issues, and Future Evolution

Like any sophisticated system, common rail injectors need proper care to deliver their best performance and longest life. Think of them as the high-performance athletes of your engine—they need the right conditions to excel.

Common Failure Modes & Diagnostics

These precision components face extreme challenges every day—pressures up to 36,000 PSI, temperatures over 1,000°F, and millions of operating cycles. It's no wonder they sometimes develop issues:

Stiction is one of the most common problems. This "sticky friction" happens when tiny deposits build up on the precision-fit valve surfaces inside the injector. Imagine trying to slide across a wooden floor with honey on your socks—that's what happens to these components when deposits accumulate. The result? Sluggish operation or valves that get stuck completely.

Excessive return flow occurs when internal components wear down over time. When too much fuel bypasses through the return system, it's like having a leaky garden hose—you lose pressure where you need it most, reducing injection efficiency.

Nozzle coking happens when carbon deposits build up on injector tips. These deposits disrupt the carefully engineered spray patterns, much like putting your thumb partially over a garden hose nozzle. The result is poor atomization and incomplete combustion.

Electrical failures in solenoid windings or piezo stacks can prevent proper actuation. No matter how good the mechanical components are, if the electrical signal can't get through, the injector won't fire correctly.

Pressure sensor faults lead to inaccurate readings, causing the ECU to command improper fuel delivery—like trying to cook with a broken thermometer.

When diagnosing these issues, technicians typically use two approaches:

Balance rate testing measures how each injector's fuel flow deviates from the average. GM specifies that these rates should stay within ±4 at operating temperature. While useful, this test only tells part of the story—it doesn't catch back leakage, solenoid response time, or external leakage problems.

For a truly comprehensive diagnosis, bench testing is the gold standard. This involves removing injectors and testing them on specialized equipment that simulates full operating pressures while measuring delivery, return flow, response time, leakage, and spray pattern. It's like giving your injectors a complete physical exam rather than just checking their pulse.

To keep your common rail system healthy, follow these preventive maintenance steps:

Use high-quality diesel fuel from trusted sources

Replace fuel filters at recommended intervals (or more often in dusty conditions)

Keep water separators maintained to prevent moisture contamination

Consider quality fuel additives that improve lubricity and prevent deposits

Address check engine lights promptly, especially fuel system warnings

Maintain proper battery voltage, as low voltage affects injector operation

Install only OEM-quality replacement parts from trusted suppliers like G2 Diesel Products

Frequently Asked Questions about Common Rail Injectors

Q: What advantage does a common rail system have over older systems like the VP44?

A: How do common rail injectors work better than older systems? They maintain constant high pressure regardless of engine speed, enabling superior atomization at all RPMs. They also perform multiple injection events per cycle, which older systems simply couldn't do. This reduces emissions and noise while improving efficiency—it's like comparing precision archery to throwing rocks.

Q: What is the typical rail pressure in PSI and bar?

A: Modern systems operate between 1,600 bar (23,200 PSI) in first-generation systems to 2,500 bar (36,250 PSI) in third-generation systems. For reference, one bar equals 14.5 PSI—and that's about 1,000 times the pressure in your car tires!

Q: How does excess fuel return to the tank?

A: Not all fuel gets injected into the cylinders. The excess returns to the tank via low-pressure return lines. This return flow varies with engine load and serves a crucial secondary purpose: cooling the injectors. It's like a built-in cooling system for these hard-working components.

Q: Can common rail injectors be rebuilt?

A: Yes, quality rebuilders can restore many injectors to like-new performance by replacing worn components and recalibrating them. However, precision parts like nozzles are typically replaced rather than rebuilt due to their extremely tight tolerances—we're talking about clearances measured in microns (smaller than a human hair).

Q: How long should common rail injectors last?

A: With proper maintenance and clean fuel, these injectors typically last 150,000-200,000 miles in heavy-duty applications. However, this varies widely based on operating conditions, fuel quality, and maintenance practices. Some fleet operators report even longer lifespans with meticulous maintenance.

Future Evolution of Common Rail Technology

The technology continues to advance in exciting ways:

Higher pressures are coming. Fourth-generation systems are pushing toward 3,000 bar (43,500 PSI) for even finer atomization and better emissions control. That's like comparing a garden hose to a water jet cutter.

Alternative fuels compatibility is expanding as manufacturers adapt common rail systems to work with biodiesel blends, renewable diesel, and even hydrogen in some experimental direct-injection engines. This flexibility will be crucial as the industry diversifies its fuel sources.

Advanced materials including new ceramics and specialized coatings are being developed to withstand the extreme conditions while reducing wear. These materials allow components to last longer despite the punishing environment they operate in.

Integrated electronics with more sophisticated diagnostics and adaptive control strategies optimize performance across all conditions. Modern systems can make adjustments in real-time that would have been impossible with earlier technology.

Software updates now deliver many performance and efficiency improvements without hardware changes. Just like your smartphone gets better with updates, modern injection systems can be optimized through ECU programming.

At G2 Diesel Products, we stay at the cutting edge of these developments, ensuring our injectors for Volvo, Mack, Kenworth, and Paccar trucks incorporate the latest innovations while maintaining the reliability that keeps your fleet running day after day.

Conclusion

Let's recap: How do common rail injectors work? Throughout this article, we've seen that these remarkable components represent the perfect marriage of mechanical precision and electronic intelligence. They've transformed diesel engines from the rough, smoke-belching workhorses of yesterday into the refined, clean, and efficient powerplants driving today's transportation industry.

The benefits speak for themselves. Modern common rail systems deliver 25% more power and torque while simultaneously reducing emissions, improving fuel economy, and dramatically quieting operation. No wonder this technology has become the standard across virtually all diesel applications—from the heavy-duty trucks traveling our highways to marine vessels, off-road equipment, and even passenger vehicles.

Think about what happens inside these injectors: fuel pressurized to over 30,000 PSI being precisely metered through openings smaller than a human hair, with timing measured in microseconds. It's a testament to human engineering that these components perform this dance billions of times over their lifespan, often in the harshest operating environments imaginable.

Here at G2 Diesel Products, we take pride in being part of this technological revolution. Our manufacturing facilities in Harrisburg, PA produce top-quality common rail injectors specifically designed for Volvo, Mack, Kenworth, and Paccar trucks. Our goal is simple: help fleet operators maximize performance and reliability while meeting today's demanding emissions requirements.

Whether you're a fleet manager looking to reduce downtime, a technician diagnosing a tough problem, or an owner-operator wanting to understand what's happening under your hood, we hope this deep dive into common rail technology has been valuable. The more you understand these critical components, the better equipped you'll be to make smart decisions about maintenance and upgrades.

The precision engineering inside each common rail injector represents decades of innovation—and we're excited about what comes next. As manufacturers continue pushing boundaries with higher pressures, more sophisticated control strategies, and compatibility with alternative fuels, the future of diesel technology looks brighter than ever.