Inside the Paccar MX Fuel System - A Clear and Simple Guide

Why the PACCAR MX Fuel System Powers Modern Heavy-Duty Trucks

The paccar mx fuel system is a sophisticated high-pressure common rail design that delivers precise fuel atomization at up to 2,500 bar (36,260 psi) in both MX-11 and MX-13 engines. This advanced system combines electronic control with mechanical precision to meet strict emissions standards while maximizing fuel economy and power output.

Key PACCAR MX Fuel System Components:

Low-pressure circuit: Fuel tanks → lift pump → primary filter → secondary filter

High-pressure circuit: Block-integrated pump → common rail → fuel injectors

Management systems: Water-in-fuel detection, pressure relief valve, aftertreatment injector

Filtration: Two-stage process (30 micron primary, 4-5 micron secondary)

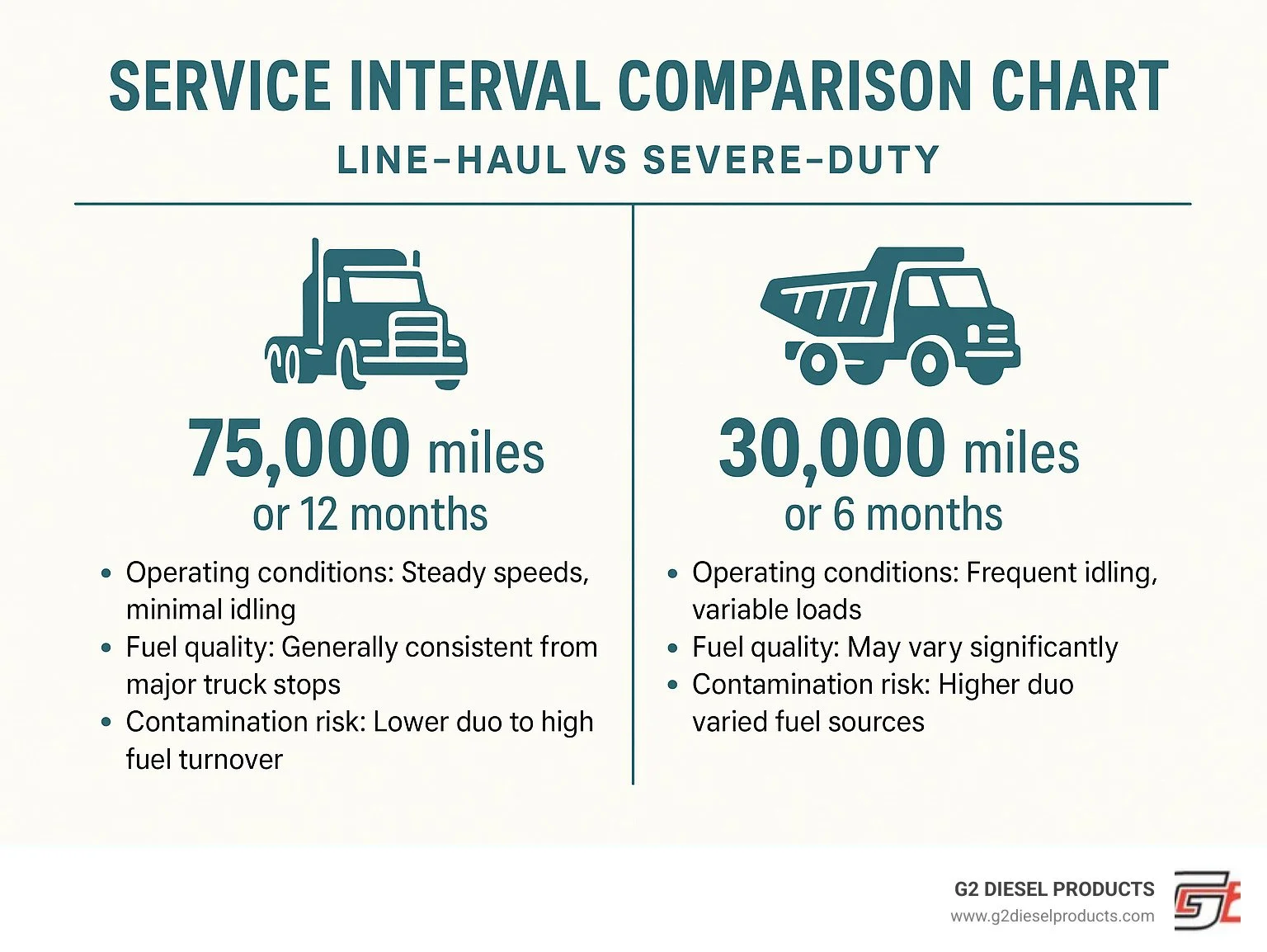

Service intervals: 75,000 miles standard duty, 30,000 miles severe duty

As one veteran diesel technician puts it: "I've never seen a $5,000 high-pressure pump failure that couldn't have been prevented by a 30-second water drain."

The system's block-integrated high-pressure pump eliminates external high-pressure lines, reducing weight and improving reliability. This design feeds a common fuel rail that supplies all injectors simultaneously, enabling multiple injection events per combustion cycle for cleaner burning and reduced noise.

Daily maintenance is critical - water must be drained from the primary fuel filter separator to prevent contamination. The system also requires proper fuel quality (Ultra-Low Sulfur Diesel meeting ASTM D975 standards) and can handle biodiesel blends up to B20 with modified service intervals.

Understanding this fuel system helps fleet managers like Frank minimize downtime, prevent costly repairs, and maintain warranty coverage across their PACCAR-powered trucks.

Understanding the paccar mx fuel system

The paccar mx fuel system represents a major leap forward from older diesel technologies. Instead of individual unit injectors doing all the work, this system uses a high-pressure common rail that feeds all injectors simultaneously. Think of it like a city water system - one central source supplying multiple outlets with consistent pressure.

Rail pressure reaches 2,500 bar (that's over 36,000 psi!) in both MX-11 and MX-13 engines. This incredible pressure creates a fine fuel mist that burns cleaner and more completely than older systems ever could.

What really sets PACCAR apart is their block-integrated pump design. Most manufacturers bolt their high-pressure pumps to the outside of the engine, creating potential failure points with all those external lines. PACCAR mounts theirs directly inside the engine block - no external high-pressure lines to leak or break. It's heavier to lift during service, but much more reliable in the long run.

The two-stage filtration system acts like a security checkpoint for your fuel. The primary filter catches particles down to 30 microns and separates water from diesel. The secondary filter is even pickier, stopping anything larger than 4-5 microns from reaching those expensive high-pressure components.

Here's something every driver should know: that water separator isn't optional equipment. Water in diesel fuel will destroy a high-pressure pump faster than you can say "roadside breakdown." The good news? The system makes water removal easy with both manual drains and automatic heating for cold weather.

For complete technical specifications on the MX-11 engine, check out the External specs on MX-11.

MX-11 vs MX-13 Design Highlights

Both engines share the same smart fuel system design, but they're sized for different jobs. The MX-11 displaces 10.8 liters and produces 355-430 horsepower, while the MX-13 bumps displacement up to 12.9 liters for higher power and torque output.

The beauty is in what stays the same. Both engines use identical rail pressure of 2,500 bar, the same two-stage filtration, and the same water management systems. Your maintenance crew doesn't need different procedures for different engines - a huge advantage for mixed fleets.

Pump location remains consistent between both engines - integrated into the block for maximum reliability. The MX-13 simply uses larger fuel delivery components to feed its bigger appetite, but the fundamental architecture is identical.

This rail pressure enables something pretty clever: multiple injection events per combustion cycle. The system can fire a small pilot injection to reduce noise, follow with the main injection for power, then add post-injection for emissions control. All perfectly timed by the engine's computer brain.

How the PACCAR MX Fuel System Moves Diesel Under 36,000 psi

Your fuel's journey starts simple and gets sophisticated fast. The lift pump in the tank creates modest pressure (30-75 psi) to push diesel through the pickup tube and toward the engine. Nothing fancy here - just reliable mechanical pumping.

Next stop: the primary filter and water separator. This is where heating elements kick in during cold weather to prevent gelling. The filter removes larger particles while the separator does exactly what its name suggests - separates water from diesel.

The secondary filter provides final cleaning before fuel reaches the high-pressure pump. Think of it as the last bouncer before the VIP section. Only the cleanest fuel gets past this point.

Now things get serious. The block-integrated high-pressure pump, driven directly by the engine's camshaft, pressurizes fuel to that incredible 2,500 bar. This pressurized fuel flows into the common rail - essentially a high-pressure storage tank that supplies all injectors.

Smart electronic injectors receive firing commands from the engine control module and deliver precise fuel amounts. Each injector can fire multiple times per combustion cycle, creating the perfect fuel-air mixture for power and emissions control.

Return lines carry excess fuel back to the tank, while a pressure sensor continuously monitors rail pressure. A pressure relief valve acts as a safety valve, preventing over-pressurization that could damage expensive components.

Don't forget the aftertreatment injector - it operates separately to spray diesel into the exhaust stream for diesel particulate filter regeneration. Same high-pressure fuel supply, different job entirely.

Water-in-Fuel Detection & Management

Water is diesel fuel's worst enemy, and the paccar mx fuel system treats it like the threat it is. The water-in-fuel (WIF) sensor sits in the primary filter housing, constantly watching for trouble.

When that WIF dashboard lamp lights up, don't ignore it. Grab a container, place it under the drain valve, and open the drain cock. Let water flow out until you see clear diesel, then close the valve. This daily drain procedure takes 30 seconds and can save you thousands.

The automatic heater system prevents water from freezing in the separator during cold weather. But here's the thing - it works best when water levels stay low through regular draining. Don't rely on the heater to fix a water problem.

If water contamination gets severe, the system has a fail-safe derate strategy. The engine computer will reduce power and eventually shut down the engine rather than let water destroy that expensive high-pressure pump. It's inconvenient, but much cheaper than a complete fuel system rebuild.

Key Components & Fuel Flow Path

Think of the paccar mx fuel system as a carefully choreographed dance where each component plays its part to deliver clean, pressurized fuel exactly when and where it's needed. From the moment diesel leaves your tank until it's atomized in the combustion chamber, every step matters.

The journey starts at your fuel tanks, where pickup tubes draw diesel through tank-mounted shut-off valves. If you're running a dual-tank setup, the selector valve automatically balances fuel draw between tanks - no more worrying about one tank running dry while the other stays full.

Your lift pump creates that crucial first pressure boost, generating 30-75 psi to push fuel through the cleaning process. This might not sound like much compared to the final 36,000 psi, but without this initial push, nothing else works.

The primary filter does the heavy lifting, removing particles down to 30 microns while its integrated water separator catches moisture that could destroy your expensive high-pressure components. Those heating elements aren't just nice-to-have features - they prevent water from freezing and blocking fuel flow on cold mornings.

Next comes the secondary filter, your last line of defense against contamination. At 4-5 microns, it catches particles so small you'd need a microscope to see them. This ultra-fine filtration protects the precision components downstream.

The high-pressure pump is where things get serious. This block-integrated unit pressurizes fuel to an incredible 2,500 bar (36,260 psi) - enough pressure to cut through steel if it found a pinhole leak. The common rail then distributes this high-pressure fuel to all injectors simultaneously, ensuring consistent performance across all cylinders.

Modern fuel injectors are marvels of engineering, opening and closing multiple times per combustion cycle based on commands from the engine control module. Return lines carry excess fuel back to the tank, while a pressure relief valve acts as a safety net against dangerous over-pressurization.

Don't forget the aftertreatment injector - it operates on a separate circuit to deliver diesel into the exhaust stream for DPF regeneration. When you see that regen light, this little injector is working overtime to keep your emissions system happy.

The priming pump on your filter housing is your best friend after maintenance. A few minutes of hand pumping can save you from the embarrassment of a truck that won't start after a filter change.

For detailed system diagrams and troubleshooting information, check out our Paccar MX-11 Fuel System Diagram resource.

Common Rail Hardware & Advantages

The common rail design revolutionized diesel fuel delivery by solving problems that plagued older systems for decades. Instead of each injector having its own pump, the common rail maintains constant high pressure for all injectors - think of it as a high-pressure fuel buffet where everyone gets served at the same time.

Superior atomization happens because 2,500 bar pressure creates fuel droplets so fine they burn completely, leaving virtually no unburned fuel behind. This isn't just good for emissions - it's money in your pocket through better fuel economy.

Multiple injection events per combustion cycle might sound complicated, but the benefits are real. A small pilot injection reduces that diesel knock and clatter, making your truck quieter and more pleasant to drive. The main injection delivers power, while post-injection helps your aftertreatment system do its job.

The noise reduction alone makes common rail worth it. Remember those old mechanical injection pumps that sounded like angry typewriters? Those days are gone. Modern common rail systems run so quietly that some drivers actually miss the familiar diesel sound.

Fuel economy improvements come from precise metering and timing that older systems simply couldn't match. When every drop of fuel is delivered at exactly the right moment, you get more work from every gallon.

The rail itself is precision-machined with individual connections to each injector. High-pressure sensors constantly monitor rail pressure, while electromagnetic injectors open and close with split-second timing. It's technology that would have seemed impossible just a few decades ago.

PACCAR MX Fuel System Dashboard Indicators

Your dashboard is constantly talking to you about fuel system health - the trick is learning its language. These warning lights aren't there to annoy you; they're early warning systems that can save you thousands in repair costs.

The Water-in-Fuel (WIF) lamp is your most important daily friend. When it lights up, everything else stops. Find a safe place to pull over, grab a container, and drain that water separator. Thirty seconds of your time can prevent a $5,000 high-pressure pump replacement.

Check Engine lights mean it's time for a diagnostic scan. Don't ignore these - what starts as a minor fault code can cascade into major problems if left unaddressed. Modern engines are smart enough to detect issues before they become failures.

Stop Engine warnings are exactly what they sound like - stop now, not in five miles when you find a better parking spot. These critical faults could damage your engine permanently if you keep running.

Low Fuel Pressure indicators (often triggering codes P0087 or P1087) usually point to filter restriction, air ingress, or pump problems. These need immediate attention to prevent engine damage or unexpected shutdowns.

DPF Regeneration Status lights tell you when your aftertreatment system is working. Don't interrupt an active regen unless absolutely necessary - your emissions system depends on completing these cycles.

The beauty of modern dashboard systems is they give you time to react. Unlike the old days when the first sign of trouble was a dead engine, today's trucks warn you before problems become catastrophes.

Maintenance & Service Intervals

Taking care of your paccar mx fuel system doesn't have to be complicated, but it does need to be consistent. Think of it like changing the oil in your car - skip it too long, and you'll pay the price later. The difference is that a neglected fuel system can cost you thousands instead of hundreds.

PACCAR has done the homework for you with specific service intervals based on how hard you work your truck. A highway hauler running steady miles needs different care than a concrete mixer stopping every few blocks.

Standard duty trucks running mostly highway miles can go 75,000 miles or 12 months between filter changes. That's both the primary and secondary filters getting swapped out together. Severe duty applications - think construction, delivery routes, or lots of city driving - need fresh filters every 30,000 miles or 6 months, whichever comes first.

Running biodiesel? The rules change. B20 blends require more frequent attention because biodiesel can hold more water and create different contamination challenges. Highway trucks using B20 need filter changes every 40,000 miles, while severe duty drops to 20,000 miles.

The daily routine is simple but critical: drain the water separator and give the system a quick visual check. Takes 30 seconds and prevents $5,000 repair bills.

When it comes to installation, that 30 lb-ft torque specification isn't a suggestion - it's insurance. Too tight and you'll crack the housing. Too loose and you'll suck air, lose prime, and wonder why your truck won't start on Monday morning.

Required Tools for Filter Service:

Filter wrench sized for PACCAR filters

Torque wrench that reads 30 lb-ft accurately

Clean 2-gallon drain pan minimum

Clean diesel fuel for O-ring lubrication

Safety glasses and nitrile gloves

Here's something most people learn the hard way: always use genuine PACCAR filters. That bargain filter might save you $20 today, but it could void your warranty and cost you thousands tomorrow. The paccar mx fuel system is engineered as a complete package, and every component matters.

Step-by-Step Filter & Water Separator Service

Filter changes aren't rocket science, but they do require attention to detail. Rush through the job, and you'll either contaminate the system or create air leaks that'll drive you crazy trying to diagnose later.

Start with safety and preparation. Let that engine cool down completely - hot diesel fuel burns just like any other hot liquid. Clean the area around the filters because the last thing you want is shop dirt falling into your fuel system. Have your tools ready and a good drain pan positioned.

The actual replacement follows a logical sequence. First, drain the water separator completely. Don't just crack it open - let everything flow out until you see clean diesel. This tells you exactly what kind of contamination you're dealing with.

Remove the filter cap with the proper wrench, turning counterclockwise. Lift the old filter straight up to avoid damaging the O-ring sealing surface. Take a good look at what comes out - excessive dirt or water tells you something about your fuel quality or tank condition.

Clean the filter housing with a lint-free cloth. Any debris left behind becomes contamination in your fresh system. Install the new filter, checking that the O-ring sits properly in its groove. A thin coat of clean diesel fuel on the O-ring helps it seal without binding.

Hand-tighten the cap first, then use your torque wrench to hit exactly 30 lb-ft. This is where patience pays off - rushing this step causes more comebacks than any other part of the job.

Prime the system properly with 150 seconds of hand pumping, wait a full minute, then add 25 more strokes. This isn't busy work - it's what prevents hard starting and air-related codes later.

Start the engine and check for leaks immediately. Look for fuel weeping around the cap and verify no air bubbles appear in the sight glass. A proper job shows no leaks and crystal-clear fuel flow.

Service Schedule Differences: Line-Haul vs Severe-Duty

Your truck's work schedule determines its maintenance needs, and the paccar mx fuel system reflects this reality. A truck running I-80 coast-to-coast faces different challenges than one delivering concrete in downtown Chicago.

Line-haul operations get the benefit of consistent conditions. Highway speeds mean steady fuel flow, minimal idling, and generally good fuel quality from major truck stops. These trucks can safely run 75,000 miles or 12 months between filter changes because contamination builds up slowly and predictably.

Severe-duty applications face a different world entirely. Stop-and-go driving, extended idling, and varied fuel sources create more contamination opportunities. Construction sites, urban delivery routes, and municipal operations fall into this category. These trucks need fresh filters every 30,000 miles or 6 months.

The difference isn't just academic - it's about preventing failures. Severe-duty trucks that try to stretch to highway intervals often face premature filter plugging, water contamination issues, and the expensive repairs that follow.

Biodiesel operations require their own approach regardless of duty cycle. B20 blends are fully approved for the paccar mx fuel system, but they demand respect. Biodiesel's hygroscopic nature means it attracts and holds water more readily than petroleum diesel. This changes the contamination game completely.

Highway trucks using B20 need filter changes every 40,000 miles, while severe-duty B20 operations drop to 20,000-mile intervals. It might seem excessive, but it's what keeps high-pressure pumps alive in biodiesel service.

Diagnostics, Troubleshooting & Common Problems

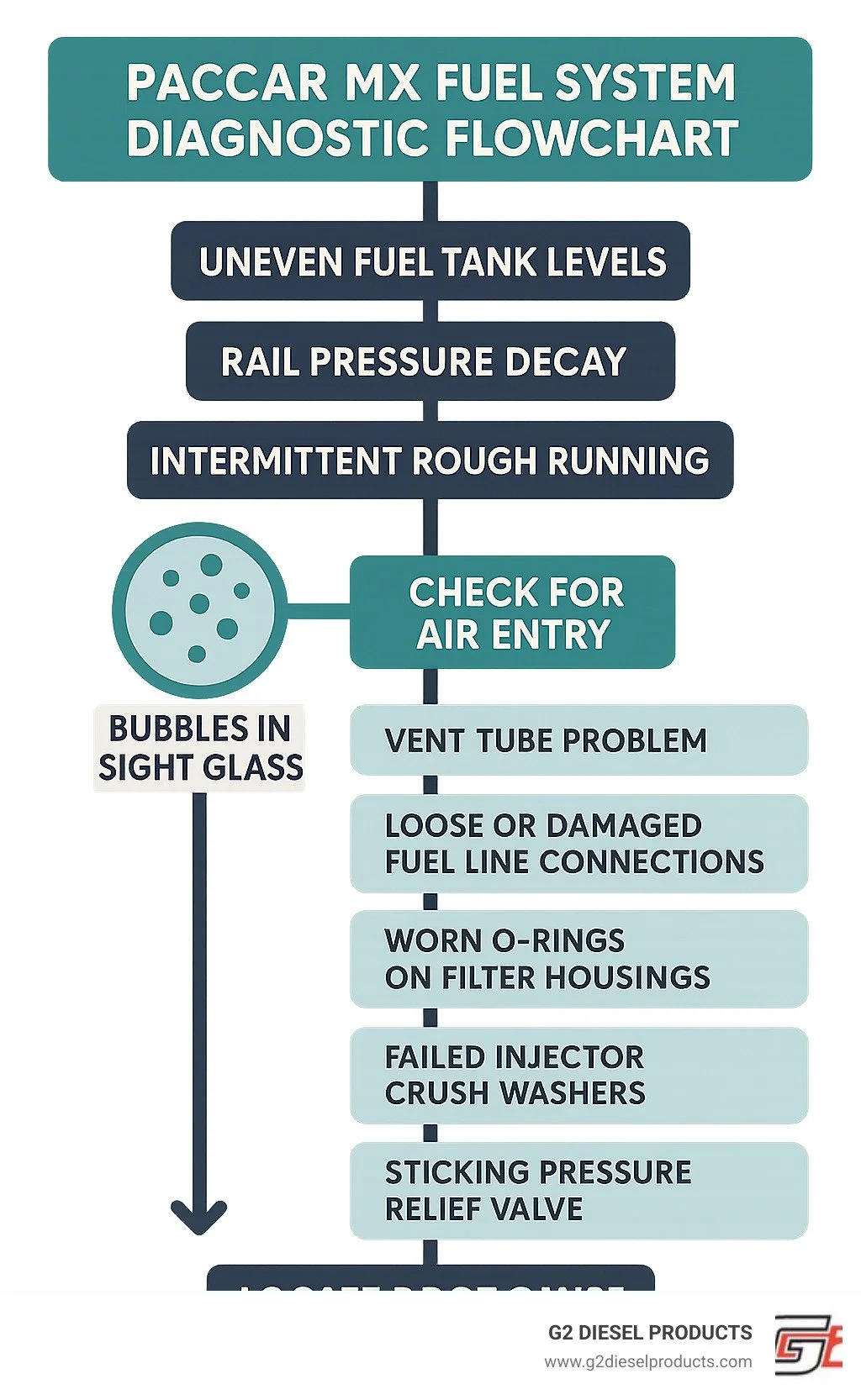

When your PACCAR-powered truck starts acting up, understanding common paccar mx fuel system problems can save you time, money, and frustration. Most issues trace back to three main culprits: air getting where it shouldn't be, water contamination, and filter-related troubles.

Hard starting or no-start conditions top the list of fuel system complaints. You'll typically find air in the system or a loss of prime as the root cause. It's frustrating when your truck fired right up yesterday but won't even cough today after sitting overnight.

Loss of prime after shutdown is a telltale sign of air intrusion. Somewhere in your system, air is sneaking in through worn seals or damaged components. The tricky part? These leaks often only show up when the engine is off and the system is under vacuum.

Low fuel pressure codes like P0087 and P1087 will light up your dashboard when filters get restricted or the pump starts struggling. These codes demand immediate attention - ignoring them can lead to expensive pump failures or engine damage.

Some specific problems we see regularly include deformed filter seals from certain production runs, cracked fuel heater sensors that allow invisible air leaks, and sticking pressure relief valves that bleed off system pressure when they should stay closed.

Air intrusion is particularly sneaky because small leaks might not cause problems while running, but they'll kill your prime overnight. Oscilloscope testing reveals these intermittent issues that hide during static pressure tests. Monitoring fuel pressure during cranking often exposes air-related problems that cause inconsistent starting.

For official maintenance procedures and technical bulletins, check out the Kenworth fuel filter bulletin for PACCAR's latest guidance.

Symptoms of Air Intrusion in the PACCAR MX Fuel System

Air in your paccar mx fuel system creates distinctive symptoms that help you zero in on the problem source. Learning to recognize these early warning signs prevents minor issues from turning into major headaches.

No-start or hard starting especially after sitting overnight is air intrusion's calling card. Your truck ran fine when you parked it, but now it cranks and cranks without firing. This happens because air slowly enters the system while parked, breaking the fuel column needed for startup.

The bubble sight glass becomes your best friend during diagnosis. If you see bubbles dancing around while the engine runs, air is definitely entering somewhere between the tank and that sight glass. This observation immediately narrows your search area and saves diagnostic time.

Uneven fuel tank levels in dual-tank systems often point to vent tube problems. A leaking vent tube creates a double whammy - it lets air into the system while preventing proper fuel equalization between tanks. You'll notice one tank draining faster than the other.

Rail pressure decay after shutdown is another smoking gun. If system pressure drops quickly when you turn off the engine, air is entering somewhere and breaking the fuel column. A healthy system should hold pressure for several minutes after shutdown.

Intermittent rough running from air pockets causing momentary fuel starvation can drive you crazy. The engine runs fine most of the time but occasionally stumbles or loses power when an air bubble reaches a critical component.

Common air entry points include loose fuel line connections, worn O-rings on filter housings, cracked vent tubes, failed injector crush washers on EPA-13 models, damaged fuel heater sensor housings, and sticking pressure relief valves. Each location requires different diagnostic approaches and repair techniques.

Using a PACCAR MX Fuel System Diagram for Rapid Fault-Finding

A good fuel system diagram transforms random troubleshooting into systematic detective work. Understanding flow arrows, pressure zones, and color coding helps you isolate problems quickly instead of throwing parts at symptoms.

Flow arrows show exactly how fuel moves through each component. Following these arrows during diagnosis keeps you on track and prevents backtracking. You'll know whether to work upstream or downstream from any given component.

Pressure zones distinguish the low-pressure circuit (30-75 psi) from the high-pressure circuit (2,500 bar). This matters because diagnostic techniques and safety procedures differ dramatically between these zones. You can't test high-pressure components with low-pressure equipment.

Color coding typically represents different pressure levels or fuel types. Many diagrams use blue for low pressure, red for high pressure, and green for return lines. Learning your diagram's color scheme speeds up troubleshooting considerably.

When problems arise, start at the tank and work systematically forward through each component. Test pressure at major checkpoints rather than guessing where problems might be. This methodical approach saves time and prevents unnecessary part replacement.

The diagram also reveals return flow paths, which are critical for understanding air intrusion. Many air entry problems occur in return lines where negative pressure can suck air through tiny leaks that would never show up under positive pressure testing.

Understanding component relationships helps too. For example, if the aftertreatment injector fails, it might affect main system pressure through shared supply lines. The diagram shows these connections that aren't obvious from external inspection.

Cold-Weather Operation, Fuel Quality & Approved Fuels

Winter weather can turn your reliable paccar mx fuel system into a source of frustration if you're not prepared. Fuel gelling, frozen water separators, and thick diesel that won't flow properly are all preventable problems with the right approach.

The foundation of cold-weather operation starts with using the right fuel. Ultra-Low Sulfur Diesel (ULSD) meeting ASTM D975 standards isn't just recommended - it's required for emissions compliance and warranty coverage. Your fuel supplier should provide winter-blend diesel with appropriate pour points for your operating region.

Biodiesel blends up to B20 are approved for PACCAR MX engines, but they require extra attention in cold weather. Biodiesel gels at higher temperatures than petroleum diesel, so you'll need to modify your cold-weather strategy accordingly. Always ensure biodiesel meets ASTM D6751 standards and comes from BQ-9000 certified producers.

Paraffinic fuels meeting EN15940 standards offer excellent cold-weather properties but may reduce fuel economy by up to 4%. These synthetic diesel fuels have superior cetane numbers and cleaner burning characteristics, making them ideal for extreme cold conditions.

Cetane number becomes critical when temperatures drop. You'll need a minimum cetane rating of 45 below 32°F (0°C) and 42 above freezing for reliable starting. Higher cetane numbers mean easier cold starts and less white smoke during warm-up.

The fuel system's built-in heaters work hard in winter, but they need help. Keeping fuel tanks as full as possible minimizes condensation that can freeze and block fuel flow. Anti-gel additives can provide extra protection, but only use products specifically approved for modern diesel engines with aftertreatment systems.

Battery health becomes even more important in cold weather. Extended cranking times put enormous strain on batteries, and a weak battery can't provide enough power for the fuel system's electric components to function properly.

Best Practices to Prevent Gelling & Injector Coking

Prevention is always cheaper than repair when it comes to cold-weather fuel problems. A few simple practices can save you from expensive towing bills and missed deliveries.

Winter-blend fuel is your first line of defense. Don't wait for the first freeze to switch - start using winter-grade diesel when nighttime temperatures consistently drop below 40°F. The small price difference is nothing compared to a service call on a frozen truck.

Tank blankets and fuel heaters provide active protection against gelling. Insulated tank covers help maintain fuel temperature overnight, while 12-volt fuel line heaters prevent gelling in critical flow areas. These systems work best when combined with proper fuel selection, not as a substitute for it.

The four-minute cooldown procedure becomes even more critical in cold weather. After hard running, let the engine idle at 1,000 rpm for four minutes before shutdown. This allows gradual cooling and prevents fuel from carbonizing on hot injector components - a problem that's worse in cold weather when fuel viscosity changes rapidly.

Daily water drains take on new urgency when temperatures drop. Water that's merely annoying in summer becomes system-blocking ice in winter. In humid conditions or with questionable fuel quality, drain the water separator multiple times per day. It's a 30-second job that can save hours of downtime.

Allow preheating systems to complete their full cycles before attempting to start. Modern engines have sophisticated preheating strategies, but they need time to work. Rushing the process leads to hard starting and excessive wear on fuel system components.

What to Avoid in the PACCAR MX Fuel System

Some mistakes can damage your paccar mx fuel system instantly, while others cause problems that show up weeks later. Understanding what to avoid protects your investment and maintains warranty coverage.

Gasoline is the ultimate fuel system destroyer. Even small amounts can damage seals, attack fuel lines, and create serious fire hazards. If gasoline contamination occurs, the entire fuel system requires flushing and seal replacement - an expensive lesson in careful fuel handling.

Alcohol-based fuels attack fuel system components and reduce the lubricity that injection components need for protection. This includes ethanol blends and methanol - both can cause seal swelling, fuel line deterioration, and pump damage over time.

Unapproved additives are tempting when problems arise, but they can void warranty coverage and damage aftertreatment systems. Fuel treatments that aren't specifically approved by PACCAR may contain chemicals that interfere with emissions control or damage sensitive components.

Contamination sources are everywhere if you're not careful. Dirty fuel containers, questionable fuel sources, and mixing different fuel types can introduce water, debris, or incompatible chemicals into your system. Always use clean containers and verify fuel quality before adding it to your tanks.

Starting fluids deserve special mention - never use them near fuel system components. These products can damage seals and create fire hazards. If your engine won't start, address the root cause rather than masking it with starting aids.

When you're unsure about fuel quality or additives, contact your PACCAR dealer for guidance. The few minutes spent getting proper advice can prevent thousands of dollars in repairs and keep your warranty intact.

Frequently Asked Questions about the paccar mx fuel system

Let's tackle the most common questions we hear from fleet managers and owner-operators about maintaining their paccar mx fuel system. These answers come straight from real-world experience and PACCAR's official guidance.

How often should I drain the water separator?

Here's the truth that every diesel mechanic wishes truck drivers knew: drain your water separator every single day during your pre-trip inspection. Yes, every day. This 30-second task prevents the kind of $5,000 high-pressure pump failures that make grown fleet managers cry.

Think of it this way - you wouldn't skip checking your oil, so don't skip draining water. Even high-quality truck stop fuel can contain moisture, especially during humid weather or temperature changes.

In really humid climates (we're looking at you, Gulf Coast drivers), you might need to drain multiple times per day. If you're running questionable fuel or operating in dusty conditions, increase the frequency even more.

The water-in-fuel warning light is your emergency backup, not your maintenance schedule. When that light comes on, you're already in the danger zone. Don't wait for warnings - make daily draining part of your routine.

Here's the simple procedure: Place a clean container under the drain valve, turn the drain cock counterclockwise, and let everything flow until you see clear diesel. Close it firmly and dispose of the water properly. That's it - 30 seconds that saves thousands.

What fuels are officially approved for MX engines?

PACCAR is pretty strict about fuel requirements, and for good reason. Your paccar mx fuel system and aftertreatment components depend on proper fuel quality to function correctly and maintain warranty coverage.

Ultra-Low Sulfur Diesel (ULSD) meeting ASTM D975 standards is your go-to fuel. This isn't just a recommendation - it's mandatory for emissions compliance. The low sulfur content protects your aftertreatment system from poisoning.

Biodiesel blends up to B20 are approved, but only from BQ-9000 accredited producers meeting ASTM D6751 standards. Here's the catch: biodiesel requires more frequent maintenance. Your filter changes drop to every 40,000 miles for highway use or 20,000 miles for severe duty. The extra maintenance cost is worth it if you're committed to renewable fuels.

Paraffinic fuels meeting EN15940 standards are also approved, though you might see up to 4% reduction in fuel economy. These synthetic fuels are becoming more common and offer excellent cold-weather performance.

Avoid the temptation to use "bargain" fuel from questionable sources. The money you save at the pump isn't worth the risk of injection system damage or voided warranties.

What warranty covers fuel-system components?

PACCAR backs their paccar mx fuel system with comprehensive warranty coverage that shows their confidence in the design. Understanding what's covered helps you make informed maintenance decisions.

Your base engine warranty covers the complete fuel system for 24 months, 250,000 miles, or 6,250 hours - whichever comes first. This includes injectors, filters, pumps, and all related components.

Major components get extended coverage - 60 months, 500,000 miles, or 12,500 hours for critical parts like the high-pressure pump, common rail, and electronic control components. That's serious long-term protection.

Emissions warranty varies by region but typically covers 60 months and 100,000 miles under EPA standards, or 350,000 miles under CARB standards. This protects your aftertreatment injector and related emissions components.

Here's the important part: warranty coverage requires proper maintenance using approved fuels and genuine parts. Keep your service records organized and follow the maintenance schedule religiously. PACCAR may require documentation for warranty claims, especially on expensive components.

When you need replacement injectors down the road, G2 Diesel Products manufactures high-quality alternatives that meet or exceed OEM specifications. Our injectors undergo rigorous testing to ensure reliable performance in your PACCAR-powered truck.

Conclusion

The paccar mx fuel system represents some of the most advanced diesel technology on the road today. This sophisticated high-pressure common rail design successfully balances raw performance with fuel efficiency while meeting strict emissions standards that keep getting tougher every year.

After working with these systems for years, we've learned that reliability comes down to the basics. Daily water separator drains might seem like a small thing, but they prevent those heart-stopping $5,000 pump failures that can sideline a truck for weeks. Proper filter maintenance based on your actual duty cycle - not just mileage - protects every component downstream from contamination.

Using approved fuels and genuine parts isn't just about following rules. It's about protecting your investment and maintaining warranty coverage when something does go wrong. We've seen too many warranty claims denied because someone tried to save a few dollars on off-brand filters or questionable fuel.

When problems do arise, systematic troubleshooting with proper diagrams saves both time and money. Following the fuel flow path methodically prevents the expensive guesswork that leads to unnecessary part replacement. Cold weather preparation with proper fuel blends and heating systems prevents those frustrating no-start situations when you need your truck most.

At G2 Diesel Products, we've built our reputation on understanding exactly how critical fuel injectors are to paccar mx fuel system performance. Our remanufactured injectors meet OEM specifications because we know there's no room for compromise in a system operating at 36,000 psi.

Whether you're running a single truck or managing a hundred-truck fleet, these guidelines help maximize the reliability and longevity of your PACCAR MX fuel system. Remember what that veteran technician told us: "I've never seen a $5,000 high-pressure pump failure that couldn't have been prevented by a 30-second water drain."

Prevention really is worth its weight in gold when dealing with high-pressure fuel systems. A few minutes of daily maintenance and following proper service intervals prevents the kind of catastrophic failures that can put a truck out of service for weeks.

For more information about replacement PACCAR injectors and our complete product line, visit More info about replacement PACCAR injectors. Our team in Harrisburg, PA stands ready to support your fuel system maintenance needs with quality parts and the kind of technical assistance that comes from years of hands-on experience.