No More Shaky Engines: Kenworth W900 Rear Motor Mounts Reviewed

Why Kenworth W900 Rear Motor Mounts Are Critical for Fleet Performance

Kenworth W900 rear motor mounts are the unsung heroes keeping your big rig's engine properly positioned and your drivers comfortable. These heavy-duty components absorb engine torque, reduce vibration, and maintain critical driveline alignment in one of trucking's most demanding applications.

Quick Answer for Fleet Managers:

OEM Part Numbers: K066-377, K066-421, S22439

Replacement Interval: Every 3-5 years or 300,000-500,000 miles

Material Options: Rubber (OEM feel), Polyurethane (2-3x longer life)

Kit Contents: 2 upper mounts, 2 lower mounts, hardware, wear plates

Typical Cost Range: $180-$320 per complete kit

When rear motor mounts fail, the consequences go far beyond vibration. As one experienced trucker put it: "I felt like the trans was gonna come through the floor under load." Failed mounts can cause up to 1 inch of visible shifter movement under heavy torque, leading to driver complaints and potential drivetrain damage.

Warning Signs Include:

Excessive cab vibration at idle

Shifter movement during acceleration

Clunking sounds from the driveline

Visible gaps or cracked rubber

The W900's long-hood design and heavy-duty engines create unique challenges. Unlike shorter chassis, the W900's engine placement puts extra stress on rear mounts during jake brake application and hill climbing. This makes choosing the right mount material crucial for your specific operation.

Polyurethane mounts from manufacturers like ATRO typically last 2-3 times longer than standard rubber in W900 applications. However, they may transmit slightly more vibration - a trade-off many fleet managers accept for extended service intervals.

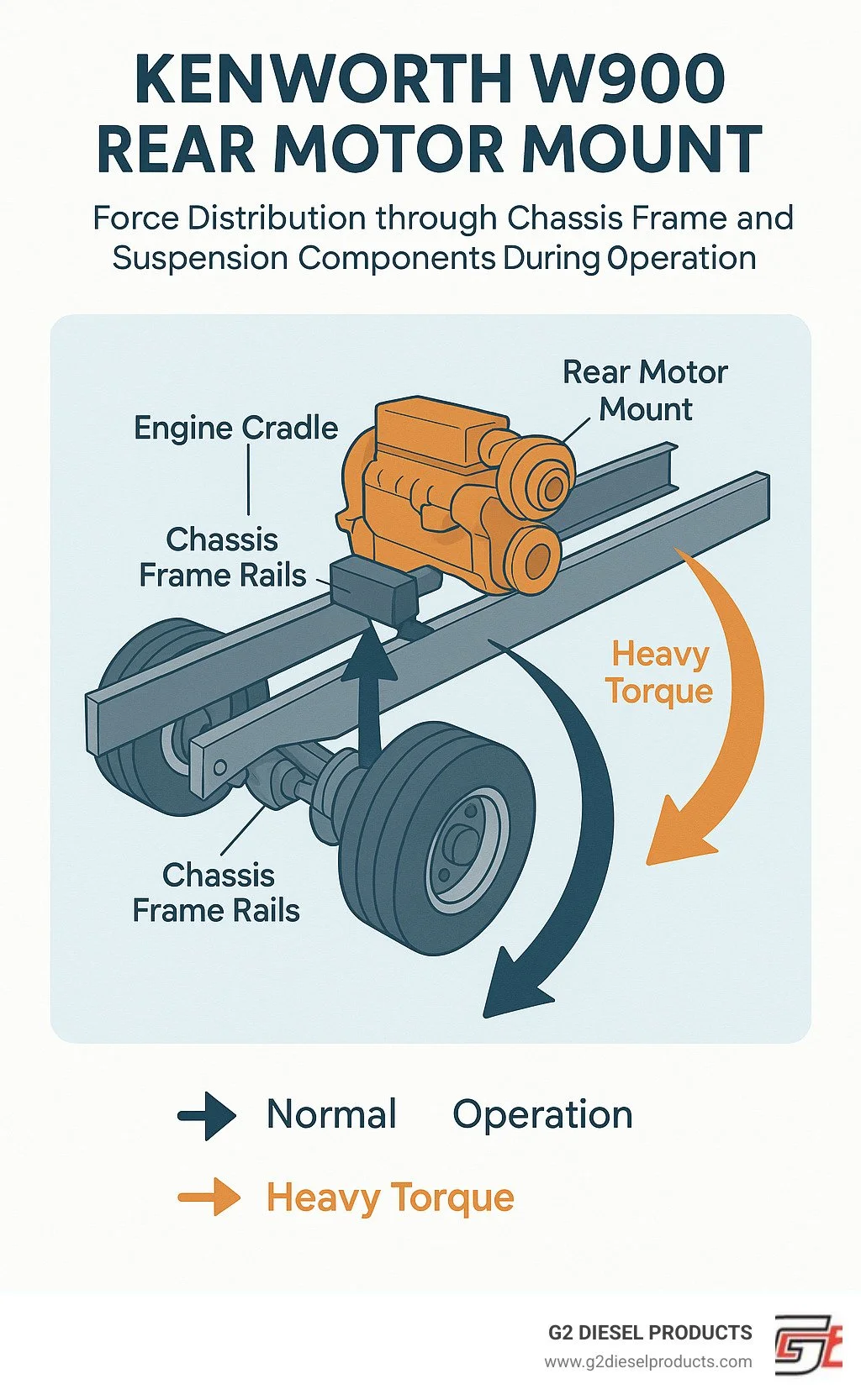

The engineering behind these mounts is more sophisticated than many realize. Each mount must handle multiple types of forces simultaneously: vertical loads from engine weight, horizontal forces from acceleration and braking, and torsional forces from engine torque. The W900's configuration amplifies these challenges due to its extended wheelbase and the leverage created by the long hood design.

Modern W900s equipped with high-output engines like the Cummins X15 or Paccar MX-13 generate substantially more torque than earlier generations. This increased power output places additional stress on mounting systems, making proper mount selection and maintenance even more critical for long-term reliability.

Fleet data consistently shows that proactive mount replacement reduces overall maintenance costs by preventing secondary damage to transmission components, u-joints, and exhaust systems. The investment in quality mounts pays dividends through reduced driver complaints, fewer roadside breakdowns, and extended component life throughout the drivetrain.

What You'll Learn

We'll cover everything you need to know about Kenworth W900 rear motor mounts in this comprehensive guide. You'll learn how to identify failing mounts, understand the differences between rubber and polyurethane options, and get step-by-step replacement procedures with proper torque specifications. We'll also review the best mount kits available and share maintenance tips that can extend service life and reduce downtime.

This guide addresses the most common questions fleet managers and owner-operators face when dealing with mount issues. From understanding the unique challenges of the W900 platform to selecting the right materials for your specific application, we'll provide the technical knowledge you need to make informed decisions about this critical component system.

How Rear Motor Mounts Keep Your Kenworth W900 Running Smooth

Kenworth W900 rear motor mounts are the link between raw engine power and a comfortable, reliable ride. Every time the engine fires, torque wants to twist the block, shake the frame and throw driveline angles out of spec. The rear mounts absorb that energy, keeping the engine in place and the cab calm.

Correctly functioning mounts do three critical jobs:

Maintain driveline alignment so u-joints, clutches and the transmission live longer.

Filter vibration before it reaches the cab, reducing driver fatigue.

Protect hard parts—exhaust, wiring, air and fuel lines—from stress fractures caused by engine movement.

Anatomy of a Rear Motor Mount

A W900 mount is a sandwich of two steel pads surrounding an elastomeric core (rubber or polyurethane). The upper pad bolts to the engine, the lower pad to the cradle bracket on the frame. Wear plates prevent metal-to-metal contact and high-strength hardware locks everything together. When the elastomer deflects, it soaks up torsional, vertical and side loads that would otherwise hammer the truck.

Why the W900 Layout Is Unique

The long-hood chassis puts more distance between front and rear supports, so the back mounts see higher leverage forces—especially with modern high-torque engines like the Cummins X15 or Paccar MX-13. Twin frame rails help distribute the load, but only if the mounts stay healthy and correctly torqued.

Symptoms of Worn Rear Motor Mounts

When Kenworth W900 rear motor mounts start failing, your truck will tell you - sometimes loudly. The key is knowing what to listen and feel for before small problems become expensive repairs.

The most dramatic symptom is shifter movement under load. One experienced driver perfectly captured this feeling in a trucking forum discussion about Bad Motor Mounts Signs...: "I feel like the trans is gonna come through the floor under load." That's your engine literally jumping around because the mounts can no longer hold it steady.

Excessive vibration at idle is usually the first sign most drivers notice. Big diesel engines always vibrate a bit - that's normal. But when you start feeling like you're sitting on a paint mixer, that smooth idle has turned into an uncomfortable shake that transfers right through the cab. Your coffee cup shouldn't be dancing on the dashboard.

Listen for driveline clunking during acceleration or when you let off the throttle. This metallic banging sound happens when the engine moves too much within loose mounts. It's not just annoying - all that movement puts stress on your exhaust flex pipes, air lines, and electrical connections. What started as a mount problem can quickly cascade into multiple system failures.

Visual inspection often reveals the most obvious problems. Fluid-soaked rubber is a dead giveaway - oil and coolant leaks break down the mount material faster than normal wear. You might also spot visible gaps where components should be touching, or see cracked rubber that's clearly past its prime.

The industry standard says if your engine shifts more than 1 inch during torque events, your mounts need immediate attention. That's a lot of movement for something that's supposed to stay put.

Other subtle symptoms can indicate developing problems before they become obvious. Unusual exhaust smoke patterns during startup might indicate that engine movement is affecting fuel injection timing or air intake geometry. Changes in engine noise can result from altered resonance characteristics when mounts lose their damping properties.

Steering wheel vibration at highway speeds sometimes traces back to worn engine mounts, especially if the vibration occurs at specific RPM ranges that correspond to engine firing frequencies. The vibration travels through the chassis and can be felt in the steering system even though the source is engine movement.

Premature wear of other components often provides clues about mount condition. If you're replacing u-joints, clutch components, or transmission mounts more frequently than normal, worn engine mounts might be the root cause. The misalignment created by failed mounts puts additional stress on these connected systems.

Driver fatigue complaints can also indicate mount problems. Excessive vibration, even at levels that aren't immediately obvious, contributes to driver fatigue over long distances. If drivers are reporting more tiredness or discomfort than usual, worn mounts might be a contributing factor.

Quick DIY Inspection Checklist

You don't need a shop to spot mount problems - a good flashlight check will reveal most issues. Crawl under the hood and look for obvious cracking, separation, or that telltale oil-soaked appearance that means the rubber is breaking down.

The pry bar deflection test gives you hard data. With the engine off, gently pry against the mount assembly while watching for movement. Any deflection greater than 1/4 inch suggests the internal components are worn beyond spec. Don't go crazy with the pry bar - you're testing, not trying to break anything.

Check idle shake by simply observing the engine at normal idle speed. If you can see significant movement from the driver's seat, your mounts are definitely past their prime. The engine should sit relatively still, not rock back and forth like a boat.

The torque brake test is your final confirmation. Hold the service brakes and gently increase engine RPM while watching the engine. Healthy mounts will keep everything steady. Worn mounts will let the engine visibly twist and move - exactly what you don't want happening under real driving conditions.

For a more thorough inspection, check the mount hardware for looseness or corrosion. Loose bolts can create symptoms similar to worn mounts, but they're much easier and cheaper to fix. Look for witness marks on metal surfaces that indicate excessive movement or contact where there shouldn't be any.

Document your findings with photos and measurements when possible. This creates a baseline for future inspections and helps track the rate of deterioration. Many fleet maintenance programs use this documentation to predict replacement timing and schedule maintenance more effectively.

Temperature checks can also provide valuable information. Mounts that run significantly hotter than others may be working harder due to misalignment or internal damage. An infrared thermometer can quickly identify temperature differences that warrant closer inspection.

Types, Materials & Performance Comparison

When choosing Kenworth W900 rear motor mounts you really have just three compounds, each with its own trade-offs:

Material Service Life Vibration Damping Oil Resistance Cost Best Use Rubber 3-5 yrs Best Poor $ Highway comfort Polyurethane 6-10 yrs Good Excellent $$ Mixed or fleet High-Temp Poly 8-12 yrs Good Excellent $$$ Severe heat / heavy haul

• Rubber = OEM feel, softest ride, shortest life.

• Polyurethane = longer life, minor increase in vibration most drivers never notice.

• High-temp poly = premium uptime for desert, mountains or dirty vocational work.

Match compound to route: long-haul fleets usually pick polyurethane for extended intervals; heavy vocational or hot-climate fleets step up to high-temp formulations; owner-operators chasing maximum comfort may stick with rubber, accepting more frequent swaps.

Best Kenworth W900 Rear Motor Mount Kits in 2024

Shopping for Kenworth W900 rear motor mounts has never been easier, with several excellent aftermarket options that often outperform original equipment. The key is finding kits that include everything you need for a complete, professional installation.

Most quality kits cross-reference the common OEM numbers you'll see - K066-377, K066-421, and S22439. These comprehensive packages typically weigh between 14-15.5 pounds and include both upper and lower mounts, wear plates, wear sleeves, and all the specialized hardware you'll need.

Here's what separates the good kits from the great ones: complete hardware packages. Nothing's more frustrating than getting halfway through a job and realizing you're missing a critical bolt or washer. The best manufacturers understand this and include every nut, bolt, and washer you'll need.

When browsing Kenworth Suspension Parts, double-check compatibility with your specific engine. Some mounts are designed specifically for ISX15 applications, while others work across multiple engine families. Getting this right the first time saves headaches later.

Top Pick: Polyurethane Kenworth W900 Rear Motor Mounts

For most W900 operators, high-temperature polyurethane kits like the KT59-62004-HT hit the sweet spot between durability and performance. These aren't your basic polyurethane mounts - they're engineered specifically for the demanding conditions that W900s face every day.

What makes these special? The high-temp rating means they won't soften and fail when you're pulling heavy loads up mountain grades. Fleet managers love them because they typically come with a 3-year warranty that covers both the U.S. and Canada.

The real-world feedback speaks volumes. These mounts consistently last 2-3 times longer than rubber equivalents while maintaining their damping characteristics throughout their service life. No gradual deterioration - they perform like new until replacement time.

Budget Pick: Rubber Kenworth W900 Rear Motor Mounts

Sometimes you just want that original equipment feel, and there's nothing wrong with that approach. Rubber mounts equivalent to the K066-377 deliver the smoothest, quietest ride you can get from a W900.

These work particularly well for highway operations where you're not dealing with constant contamination or extreme heat cycles. The vibration damping is excellent - your coffee cup won't dance around the dash like it might with stiffer materials.

The trade-off is service life. You'll be replacing them more frequently than polyurethane options, but some operators prefer this approach for the superior comfort they provide.

Premium Upgrade: High-Temp Poly Performance Set

For operations that demand the absolute best durability, premium polyurethane formulations deliver what fleets call "set it and forget it" performance. These mounts often provide double the service life of standard rubber while shrugging off oil contamination that would destroy lesser materials.

The trucking community consistently praises these upgrades. Forum discussions regularly feature operators reporting successful service well beyond 500,000 miles. One experienced driver put it perfectly: "Slight increase in vibration, but I'll take that trade-off for not crawling under the truck every few years."

Fleet managers particularly appreciate the predictable service intervals these mounts provide. When you're managing dozens or hundreds of trucks, knowing exactly when maintenance is due makes scheduling much easier.

Step-by-Step Replacement Guide & Torque Specs

Swapping Kenworth W900 rear motor mounts is straightforward if you follow safe procedures.

Park on level ground, chock wheels, set brakes and disconnect batteries.

Support the engine at the bellhousing with a floor jack and wooden block.

Depressurize air-ride if equipped and protect nearby hoses/wiring.

Remove cradle crossmember bolts (usually 20 mm x 120 mm). Penetrating oil or gentle heat helps on rusty trucks.

Unbolt and remove both old mounts.

Inspect and clean engine and cradle surfaces; replace any cracked cradle brackets.

Install new mounts as a matched pair. Start bolts finger-tight to avoid cross-threading.

Torque sequence: upper bolts first, then lower, in two steps to final spec. Main mounting bolts on most kits require 350 ft-lb; confirm with your kit instructions.

Apply thread-locker and re-torque after 500 miles.

Shortcutting support, mixing mount materials, or skipping the re-torque are the top causes of repeat failures.

Maintenance Schedule, Costs & Pro Tips

• Inspect visually every 25k–50k miles (cracks, fluid-soaked rubber, gaps). • Replace every 3–5 years or 300k–500k miles; severe service may cut that in half. • Kits run $180–$320. A full set swap takes a competent shop 4–6 hours. • Always replace hardware, avoid impact guns for final torque, and never mix rubber with poly.

Fresh mounts cut cab vibration, extend clutch and u-joint life, and prevent costly exhaust or wiring damage—benefits that dwarf the parts bill.

Frequently Asked Questions about Kenworth W900 Rear Motor Mounts

How often should I inspect mounts?

Look them over at every major PM—roughly 25k–50k miles. Add a quick check any time a driver reports new vibration or shifter movement.

Do polyurethane mounts increase vibration?

Slightly, yes, but most drivers adapt within a day or two. Fleets accept the trade-off for 2–3× the service life and better resistance to oil or heat.

Can I replace only one mount?

No. Always change rear mounts in matched pairs. Mixing new with old—or rubber with poly—creates uneven loading that quickly destroys both.

Conclusion

Taking care of your Kenworth W900 rear motor mounts isn't just about preventing vibration – it's about protecting your entire investment and keeping your drivers happy on the road. When these critical components are working properly, everything else falls into place: smoother rides, longer-lasting drivetrain components, and fewer surprise breakdowns.

The decision between rubber and polyurethane really comes down to what matters most for your operation. Rubber mounts give you that smooth, quiet ride that drivers love, especially if you're running highway miles where comfort is king. Polyurethane mounts are the workhorses – they'll outlast rubber by years and shrug off oil leaks and harsh conditions that would destroy standard mounts.

Here's the thing about preventive maintenance: it's always cheaper than emergency repairs. Replacing worn motor mounts on your schedule beats having a driver call from the side of the road because the shifter is jumping around like a jack-in-the-box. Plus, fresh mounts protect expensive components like your clutch, u-joints, and transmission from the kind of misalignment damage that really hurts the wallet.

Regular inspection makes all the difference. A quick look under the hood every few months can catch problems before they cascade into bigger issues. When you spot cracked rubber or excessive movement, don't wait – those symptoms only get worse, and the secondary damage gets more expensive.

At G2 Diesel Products, we know that every component in your truck works together as a team. While we focus on building the highest-quality diesel fuel injectors for Kenworth, Volvo, Mack, and Paccar trucks, we understand that reliable performance starts with a solid foundation – and that includes properly functioning motor mounts.

Whether you're maintaining a single truck or managing a fleet, the principles remain the same: quality parts, proper installation, and preventive maintenance keep you moving and making money. When you're ready to upgrade other critical systems, Shop premium diesel components at G2 Diesel Products for fuel system components that match your commitment to reliability and performance.