Troubleshooting Mack Truck Injector Issues Like a Boss

Why Mack Truck Injector Problems Cost You More Than Just Money

Mack truck injector problems are among the most expensive and frustrating issues fleet managers face today. When injectors or injector cups fail, you're looking at thousands in repair costs, days of downtime, and the headache of finding replacement parts fast.

Most Common Mack Injector Problems:

Injector cup failures (copper cups crack, causing fuel in coolant)

Hard starting and rough idle from air in fuel system

Power loss below 1600 RPM due to low compression

Fuel economy drops from poor atomization

White/gray smoke from unburned fuel

Frequent DPF regenerations from incomplete combustion

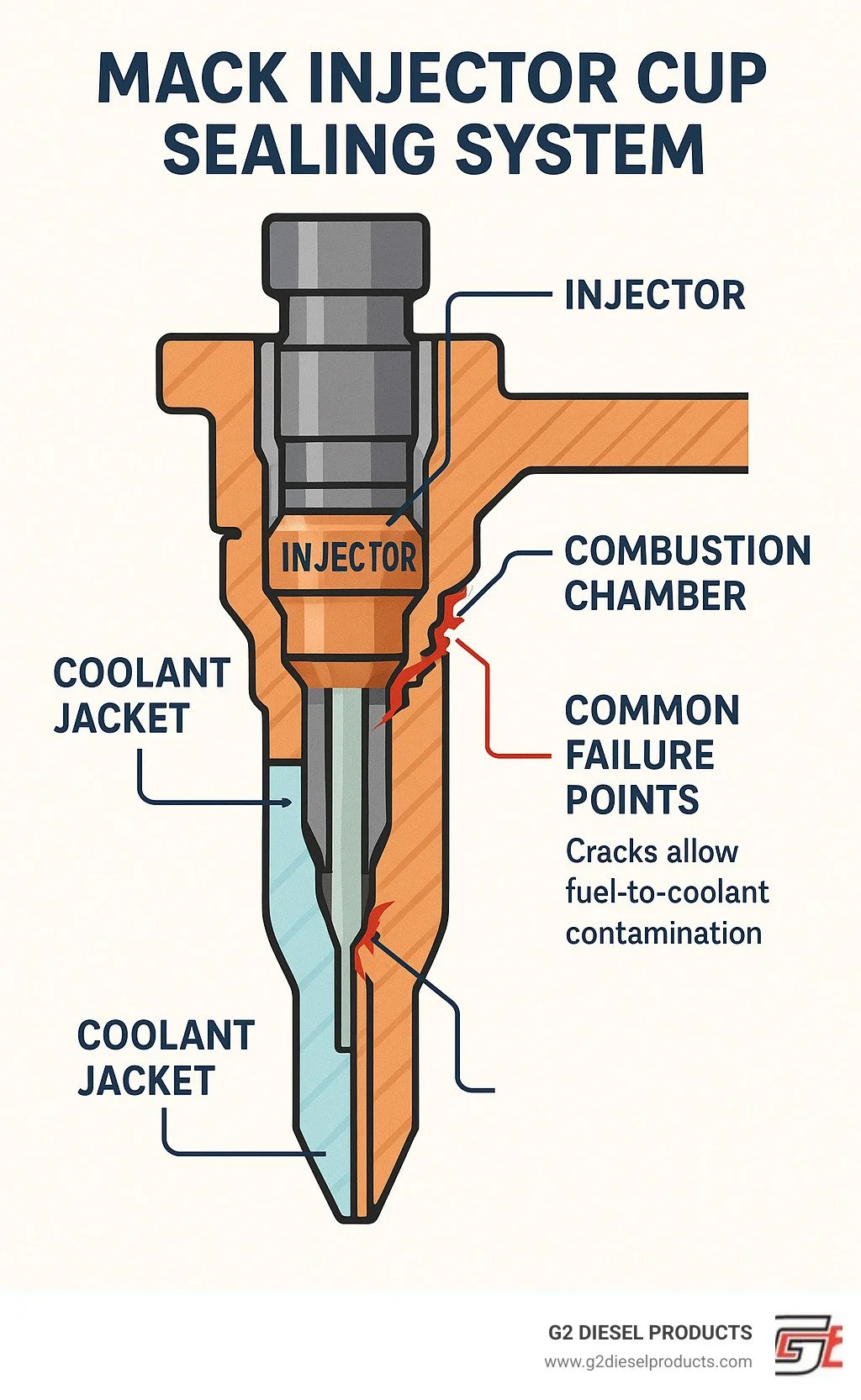

The root cause usually isn't the injector itself - it's the injector cup that seals the injector to the cylinder head. These cups handle extreme heat and pressure cycles. When they crack or leak, fuel mixes with coolant, air enters the fuel system, and your truck loses power.

MP7 and MP8 engines are especially prone to cup failures between 300,000-600,000 miles. The switch from copper to conical (steel) cups has helped, but mixing cup types in the same engine can cause serious damage.

Early detection saves money. Look for air bubbles in your fuel tank return line while the engine runs - it's one of the easiest ways to spot a failing cup before it leaves you stranded.

Understanding Mack Injector & Cup Designs

If you've been dealing with mack truck injector problems, understanding how injector cups evolved can save you from making expensive mistakes. The story of Mack's injector designs is really a tale of learning from failures - and it's knowledge that every fleet manager needs.

Back in the day, Mack engines like the E7, MP7, MP8, and ASET all relied on copper injector cups. On paper, copper seemed perfect - it conducts heat beautifully and forms tight seals when compressed. But real-world performance told a different story.

The problem was dissimilar metal corrosion. Picture this: you've got a copper cup sitting in a steel cylinder head, getting hammered by combustion pressures over 2,000 PSI and temperature swings from freezing cold starts to over 1,000°F under load. The copper and steel expand and contract at different rates, creating stress cracks that eventually turn into fuel leaks.

Modern Mack engines learned from these painful lessons. Today's conical steel injector cups eliminate the dissimilar metal headaches entirely. These one-piece stainless steel assemblies use the same thermal expansion characteristics as the cylinder head, and their conical shape distributes stress much more evenly than the old flat copper design.

Feature Copper Cups Conical Steel Cups Material Copper with washer Stainless steel one-piece Shape Flat with separate sealing washer Conical integrated design Durability Prone to cracking after 200k-400k miles Much longer service life Corrosion Dissimilar metal issues with steel head No dissimilar metal problems Sealing Relies on washer compression Superior conical seal design Cost Lower initial cost Higher upfront, better value long-term

Why Cup Material Matters for Sealing & Longevity

Think about what these little cups have to endure every single day. They're sealing against combustion pressures that would make your head spin, temperature cycles that go from ambient to furnace-hot hundreds of times per day, plus fuel pressure from the high-pressure rail and coolant pressure in the cylinder head jacket.

Copper cups simply couldn't handle this thermal abuse long-term. Every heat cycle stressed the copper differently than the surrounding steel, creating microscopic cracks that grew into major leaks. It's like flexing a paperclip back and forth - eventually, it breaks.

Steel conical cups solve this by matching the thermal behavior of the cylinder head itself. The conical shape spreads the stress load more evenly, and the one-piece design eliminates the weak spot where the old copper cups met their sealing washers. It's engineering that actually works in the real world.

Many fleets are upgrading to stainless steel cups even when doing routine maintenance, because the improved longevity more than makes up for the higher initial cost.

Risks of Mixing Copper and Conical Sleeves in One Engine

Here's where good intentions can lead to expensive disasters: never, ever mix copper and conical cups in the same engine. A 2013 Mack service bulletin specifically warns against this, and they're not kidding around.

When you mix cup types, you're creating uneven stress patterns throughout the cylinder head. The different expansion rates and sealing characteristics fight against each other, leading to problems like fuel gallery leaks between cylinders, combustion gas intrusion into the fuel system, and even cylinder head cracking from uneven thermal stress.

Some shops try to save money by replacing just the failed cups, but this penny-wise, pound-foolish approach often leads to repeat failures within months. When it's time for injector cup service, commit to replacing all six with the same type - preferably upgrading to the superior conical steel design.

The bottom line? Your engine was designed as a system, and mixing components with different thermal behaviors breaks that system. Do it right the first time, and you'll avoid the frustration of dealing with cascading mack truck injector problems down the road.

Spotting Symptoms of Mack Truck Injector Problems

Your truck is trying to tell you something, and learning to listen can save you from a very expensive conversation later. Mack truck injector problems rarely happen overnight - they start small and gradually get worse until your truck leaves you stranded.

The most obvious red flag is when your coolant starts smelling like diesel fuel. That contaminated coolant sample in the image above? That's what happens when an injector cup cracks and fuel starts mixing where it absolutely shouldn't be. If you catch a whiff of diesel when checking your coolant, don't ignore it.

Rough idle is usually one of the first things you'll notice, especially on cold mornings. Your truck might shake more than usual or sound uneven when idling. Hard starting follows close behind - what used to be a quick turn of the key now requires extra cranking time.

Here's a simple test that costs nothing: look at your fuel tank return line while the engine runs. See air bubbles streaming back? That's combustion gas escaping through cracked injector cups. It's like having a tiny leak in a straw - air gets where fuel should be, and nothing works right.

White or gray smoke on startup tells the same story. When injector cups fail, fuel doesn't atomize properly, so it burns incompletely and creates that telltale smoke. You might also notice power loss under load, especially below 1600 RPM where these engines should pull strongest.

Early-Warning Signs of mack truck injector problems

Smart operators watch for the subtle signs before the obvious ones appear. Declining fuel economy without any other changes is often the first clue. Your truck is working harder to make the same power because combustion isn't happening efficiently.

Engine surging at highway speeds feels like someone is gently tapping the accelerator. The engine can't maintain steady power because air in the fuel system disrupts the injection timing. Meanwhile, your passive regenerations start happening more frequently because incomplete combustion creates extra soot.

Don't dismiss that occasional diesel smell when you check fluids. Your nose often detects problems before diagnostic tools do. And if you see fault code SPN 3556 or similar injector-related codes, take them seriously even if the truck seems to run fine.

One fleet manager told us his 2012 MP7 started showing these early signs around 350,000 miles. He caught it early and avoided the cascade of problems that follow. Another operator wasn't so lucky - ignoring the symptoms on his 2008 Pinnacle led to repair bills that nearly equaled what he paid for the truck.

How Injector Cup Failures Wreck Performance & Emissions

When injector cups fail, they don't just affect fuel delivery - they trigger a domino effect throughout your entire engine system. Compression loss happens first as combustion pressure escapes through cracked cups instead of pushing the piston down with full force.

Poor fuel atomization follows because air in the fuel system prevents injectors from creating the fine spray pattern needed for complete combustion. Think of trying to spray paint with a clogged nozzle - you get blobs instead of smooth coverage.

This incomplete combustion overwhelms your EGR system with excess soot, clogging the cooler and valve. Your DPF gets plugged more frequently because it's trying to filter all that extra particulate matter. Meanwhile, oil dilution occurs as unburned fuel washes past the rings into your crankcase.

The good news? Fixing the root cause - those failing injector cups - often brings dramatic improvements in power and fuel economy. You're not just stopping a leak; you're restoring the precise combustion process that makes these engines so efficient when everything works correctly.

Diagnosing & Testing Injectors Like a Pro

Proper diagnosis separates the pros from the parts-changers. Mack truck injector problems often masquerade as other issues, so systematic testing is crucial.

Visual inspection comes first:

Check for fuel stains around injector hold-down bolts

Look for coolant contamination (milky or fuel-scented)

Inspect fuel return lines for air bubbles while running

Examine injector wiring for damage or corrosion

Fuel pressure testing reveals supply-side problems before you blame the injectors. Low supply pressure from a failing lift pump, clogged filters, or air leaks can mimic injector failures.

Injector balance testing using a diagnostic scanner shows which cylinders are contributing properly. This test measures each injector's fuel delivery under controlled conditions.

Leak-down testing checks compression and can reveal combustion chamber leaks that affect injector performance.

Coolant pressure testing while the engine is off can reveal cracks in injector cups or cylinder head passages.

For more detailed information about professional diagnostic approaches, check out this scientific research on injector cup issues.

Step-by-Step DIY Checklist for Mack Truck Injector Problems

Here's what you can check without expensive tools:

1. Primer Pump Check: With the engine off, pump the fuel primer. It should build resistance and lock down. If it stays spongy or won't lock, you have air in the system.

2. Return-Line Bubble Test: Start the engine and watch the fuel tank. Air bubbles in the return line indicate combustion gases entering the fuel system through cracked cups.

3. Head Bleed Valve Test: Crack open the bleed valve on the cylinder head while cranking. If air comes out instead of fuel, the fuel gallery isn't properly primed.

4. Bucket Feed Test: Disconnect the fuel supply and feed the pump from a clean bucket. If the engine runs normally, your problem is on the suction side, not the injectors.

5. ECM Scan: Pull codes and look for injector-related faults, especially cylinder-specific codes or fuel system pressure warnings.

When to Break Out the Pro Tools & Seek Expert Help

Some diagnostics require dealer-level tools:

PTT (Premium Tech Tool) bi-directional testing can command individual injectors and test their response. This reveals weak injectors that might pass basic tests.

Cylinder cut-out testing isolates each cylinder electronically to pinpoint the problem cylinder.

Ultrasonic cleaning and bench flow testing determine if injectors can be cleaned or need replacement.

Warranty considerations also matter. If your truck is under warranty, unauthorized repairs might void coverage.

Priming the Fuel System After MP7/MP8 Injector Work

Getting air out of MP7/MP8 fuel systems can be tricky. Here's the process that works:

Lock-down primer technique: Pump the primer until it locks down, then crank the engine. Never crank with the primer up - it will suck air.

Banjo fitting #8 orientation: On the cylinder head, ensure the thinner banjo fitting goes in position #8. This affects fuel flow and priming.

Compressed-air tank trick: Some techs pressurize the fuel tank with compressed air (carefully!) while cracking fuel lines to force fuel through the system.

For more information about maintaining your fuel injection system, visit our guide on Diesel Injector Repair Kits.

Repair & Replacement Procedures & Costs

When it comes to fixing Mack truck injector problems, precision isn't just important - it's everything. This isn't the kind of repair you tackle with basic hand tools on a Saturday afternoon. You'll need specialized equipment and a methodical approach.

The tool list reads like a wish list for expensive specialty equipment. You'll need a slide hammer with injector puller to get the old injectors out without damaging the cylinder head. The forming tap (specifically 8.3mm) extracts old cups, while the swedging bit (7.9 ± 0.05mm - yes, that tolerance matters) installs new conical cups properly. Don't forget protective sleeves to keep debris out of the fuel galleries during the process.

The replacement procedure follows a strict sequence that can't be rushed. After draining coolant and fuel, you'll remove valve covers and rocker assemblies - mark their positions first, because they need to go back exactly where they came from. Extracting injectors requires patience and the right technique with that slide hammer.

Once the old cups are tapped and removed, cleaning the injector bores becomes critical. Any debris left behind will compromise the new installation. Installing new cups involves sealing compound and precise use of the swedging tool to ensure proper seating.

Here's where many shops get tripped up: the torque sequence isn't negotiable. It's 20 Nm, then +180°, loosen to 10-15 Nm, retorque to 20 Nm, then final +90°. Those hold-down bolts can only be reused five times before they need replacement.

Programming ECM trim codes for new injectors is mandatory. Skip this step, and your new injectors won't perform properly. Finally, priming the fuel system and checking for leaks completes the job.

Labor time typically runs 6-8 hours for a complete set, assuming everything goes smoothly. Real-world experience from truck owners suggests budgeting for the unexpected - one forum member mentioned this was their seventh injector replacement, highlighting how repeat failures can drain your maintenance budget.

OEM vs Reman: Choosing the Right Replacement Parts

The parts you choose can make or break your repair investment. Cheap injectors might save money upfront, but they often lead to repeat failures and more downtime.

OEM parts offer guaranteed compatibility and full warranty coverage. The downside? Longer lead times when you need your truck back on the road, and higher costs that can strain your budget.

Quality remanufactured parts provide an excellent middle ground. The key word here is "quality" - not all reman injectors are created equal. Look for remanufacturers who use OEM cores and specifications, include design improvements over original parts, and back their work with comprehensive warranties.

Quick availability matters when your truck is down. At G2 Diesel Products, we understand that downtime costs money. Our Reman Fuel Injector EX631085 for Mack MP8 / Volvo D13 represents our commitment to both quality and fast delivery.

The best reman injectors often incorporate improvements learned from field failures. This means you might actually get better reliability than the original parts that came in your truck.

Preventing Repeat Failures After the Repair

Once you've invested in new injectors and cups, protecting that investment becomes your top priority. Nothing hurts more than watching expensive new parts fail prematurely because of preventable issues.

Coolant maintenance tops the prevention list. Use only Mack-approved coolant and maintain proper pH levels religiously. Poor coolant quality acts like acid on injector cups, accelerating corrosion and leading to premature failure.

Fuel filter intervals aren't suggestions - they're insurance policies. Contaminated fuel destroys injectors faster than almost anything else. Change filters religiously, even if they don't look dirty yet.

High-quality diesel makes a real difference in injector longevity. When possible, fuel at top-tier stations. Avoid cheap fuel additives that promise miracles - they often cause more problems than they solve.

Keep your ECM software current with the latest updates. Mack regularly releases improvements to injection timing and fuel delivery strategies. These updates often include lessons learned from field failures.

Don't neglect your valve adjustment schedule either. Proper valve clearances ensure optimal combustion, which reduces stress on injector cups. It's all connected in the combustion process.

For deeper insights into how maintenance affects injector life, this scientific research on passive regen impact provides valuable information about the relationship between regeneration cycles and injector longevity.

Keeping the Rest of the Engine Happy

Your engine is like a team - when one player struggles, everyone else has to work harder. Mack truck injector problems rarely happen in isolation, and fixing them without addressing related systems is like putting a bandage on a broken pipe.

Think about it this way: when injectors aren't atomizing fuel properly, your engine starts compensating. The turbo works harder to maintain power. The EGR system gets overwhelmed with extra soot. The DPF clogs faster from incomplete combustion. Before you know it, you're chasing problems all over the engine.

The EGR system takes a real beating when injectors aren't doing their job. Poor fuel atomization creates more soot, which clogs the EGR valve and cooler. That carbon buildup then affects airflow, making combustion even worse. It's a vicious cycle that can turn a simple injector repair into a major overhaul.

Your turbo's VGT actuator might start acting up too. When the engine loses power from failing injectors, the ECM commands more boost to compensate. This extra stress can cause the actuator to stick or fail, creating symptoms that look exactly like more injector problems.

Don't forget about crankcase ventilation either. A failing CCV system increases oil consumption and can mess with turbo operation. Many techs have spent hours diagnosing "injector problems" that turned out to be a simple breather filter.

The aftertreatment system probably suffers the most from injector issues. Incomplete combustion dumps extra soot into the DPF and DOC, forcing more frequent regenerations. These forced regens create extreme heat that stresses injector cups even more - another vicious cycle.

Maintenance Habits That Extend Injector & Cup Life

Smart maintenance prevents most injector problems before they start. It's not rocket science, but consistency matters more than perfection.

Oil changes every 25,000 miles using high-quality oil keep contamination from reaching critical components. Dirty oil doesn't just hurt bearings - it affects the entire engine's ability to handle heat and stress.

EGR cleaning every 100,000 miles prevents the carbon buildup that makes your engine work harder. A clean EGR system means better combustion, which means less stress on injector cups.

DPF service can't be ignored. Those warning lights aren't suggestions - they're your engine crying for help. Forced regenerations create extreme heat cycles that crack injector cups faster than normal operation.

Water separator O-rings are one of those small things that cause big problems. When these seals fail, they let air into the fuel system, creating symptoms that look exactly like failing injectors. Replace them during regular fuel filter changes.

Winter diesel preparation matters more than most people realize. Fuel waxing and filter plugging can create pressure drops that stress the entire injection system. Use appropriate additives when temperatures drop.

The key is understanding that everything connects to everything else. Take care of the whole engine, and your injectors will last much longer. Neglect the supporting systems, and you'll be replacing injectors more often than you'd like.

Frequently Asked Questions about Mack Injector Issues

What causes recurring Mack truck injector problems?

The most frustrating thing about Mack truck injector problems is when they keep coming back. If you're dealing with repeat failures, there's usually an underlying cause that wasn't addressed during the repair.

Poor coolant maintenance is the biggest culprit. When coolant pH levels drift outside the proper range or you use the wrong coolant type, it accelerates corrosion of injector cups. The copper cups are especially vulnerable to this - they'll fail much faster in contaminated coolant.

Incorrect installation causes many comebacks too. The torque sequence for injector hold-down bolts is critical and must be followed exactly. Skip a step or use the wrong torque values, and you'll see premature failures. Same goes for using old hold-down bolts beyond their reuse limit.

Mixing cup types in the same engine is a recipe for disaster. We can't stress this enough - never mix copper and conical cups in one engine. The different expansion rates create uneven stress that can crack the cylinder head itself.

Sometimes the real problem isn't the injectors at all. Underlying fuel system issues like contaminated fuel, failing lift pumps, or air leaks can stress injectors and cause premature failure. Fix the injectors without addressing these root causes, and you'll be back under the hood soon.

Excessive combustion heat from EGR problems or turbo issues also shortens injector life. When other engine systems aren't working properly, the injectors take the beating.

Can I DIY fix Mack truck injector problems or should I visit a dealer?

This is where many truck owners get stuck between saving money and avoiding bigger problems down the road.

Tool access is the first hurdle. Injector cup replacement requires specialized tools like swedging bits and forming taps that most shops don't have lying around. You can't just improvise with standard tools - the tolerances are too tight.

Trim coding is another dealbreaker for many DIY repairs. New injectors need their specific trim codes programmed into the ECM. Without access to dealer-level diagnostic tools, you can't complete this step properly.

Warranty concerns matter too. If your truck is still under warranty, unauthorized repairs might void your coverage. That's a expensive gamble if something goes wrong later.

The risk assessment comes down to your experience level and the cost of mistakes. Get the cup installation wrong, and you could damage the cylinder head. That turns a expensive repair into a catastrophic one.

Basic diagnosis and simple repairs are within reach for experienced mechanics. Checking for air bubbles in the return line or testing fuel pressure doesn't require special tools. But when it comes to cup replacement and ECM programming, professional service usually makes more sense.

How much downtime should I plan for a full set of injectors & cups?

Nobody likes surprises when it comes to downtime, so here's the realistic timeline for injector and cup replacement.

Shop scheduling typically takes 1-3 days depending on how busy your preferred shop is and whether they have parts in stock. Don't expect to roll in on Monday and roll out Tuesday unless you've planned ahead.

Labor time runs 6-8 hours for a complete set replacement. This includes removal, cup replacement, installation, and programming. Some shops might stretch this over two days to avoid rushing the job.

Programming time adds extra time for trim code updates and system verification. This step can't be rushed - get it wrong and the engine won't run properly.

Testing time is crucial but often overlooked. Proper checkout includes leak testing, fuel system priming, and road testing to verify the repair was successful.

Total downtime typically ranges from 2-5 days including parts procurement and scheduling. Plan for the longer end if you need the work done during busy seasons or if parts aren't readily available.

The key is planning ahead. If you're seeing early warning signs like air bubbles in the fuel return or declining fuel economy, start shopping for parts and scheduling the work before you're broken down on the side of the road.

Conclusion

There's nothing quite like the satisfaction of getting a truck back on the road after fixing stubborn Mack truck injector problems. When everything's working right - zero leaks, restored power, and full emissions compliance - you remember why you chose Mack in the first place.

The truth is, injector problems don't have to be the nightmare many fleet managers fear. Yes, they're expensive when they hit. Yes, the downtime hurts. But with the right approach, you can minimize both the frequency and the pain.

Early detection really is your best friend here. That simple check for air bubbles in your fuel return line takes thirty seconds and can save you thousands. When you catch problems early, you're fixing injectors instead of replacing entire engines.

Quality parts make all the difference between a repair that lasts and one that leaves you stranded again in six months. We've seen too many operators try to save money upfront only to spend double later on repeat failures.

The cup material upgrade from copper to conical steel represents real engineering progress. When you're doing injector work anyway, it makes sense to upgrade to the better design. Your future self will thank you.

At G2 Diesel Products, we understand that when your truck is down, every hour counts. That's why we focus on quick lead times and customer-specific packaging to get you back running fast. Our remanufactured injectors combine OEM specifications with improved designs - giving you the reliability you need without the wait times that kill your schedule.

Whether you're dealing with a single failing injector or planning a complete refresh of your fleet, having the right parts supplier changes everything. When problems hit - and they will - you want a partner who understands the urgency and delivers solutions that work.

For our complete selection of premium Volvo & Mack injectors and expert support, check out our diesel fuel injectors. Your truck - and your bottom line - will thank you.