The MX13 Fuel System: From Issues to Solutions

Why the Paccar MX13 Fuel System Deserves Your Attention

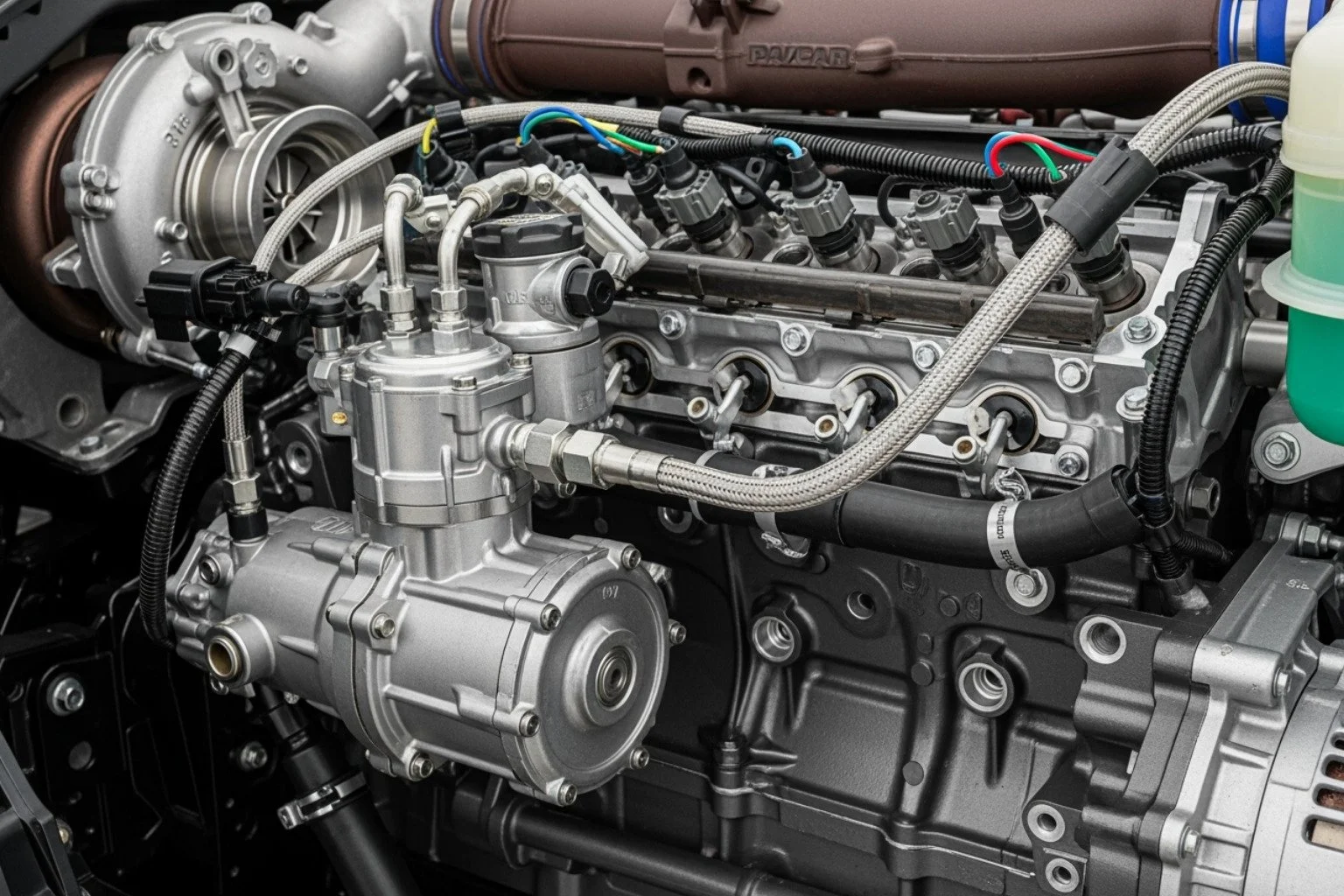

The Paccar MX13 fuel system is the heart of your engine, a marvel of modern engineering designed for power, efficiency, and emissions compliance. It operates on a sophisticated high-pressure common rail (HPCR) architecture, a system that has become the industry standard for its ability to deliver precisely metered fuel at immense pressures. This precision is key to unlocking optimal performance and meeting stringent EPA regulations. However, this complexity also introduces a unique set of challenges for fleet managers and owner-operators. When a component in this intricate system falters, it can trigger a cascade of problems, leading to costly downtime, frustrated drivers, and missed deadlines.

Common complaints range from the frustratingly simple, like a truck that loses its prime and won't start after sitting overnight, to more severe issues like injector knocking, sudden engine stalling, and persistent power loss. Diagnostic trouble codes such as P1086 (Fuel Rail Pressure Control Error) and P00BA (Low Fuel Pressure - Forced Limited Power) are often the first digital cries for help. The system's reliance on extreme pressures—often exceeding 29,000 PSI—means that even a minor issue like a pinhole leak or a contaminated filter can have major consequences. This comprehensive guide is designed to demystify the Paccar MX13 fuel system, providing you with the knowledge to perform effective troubleshooting, implement robust maintenance schedules, and make informed repair decisions to keep your fleet on the road and running profitably.

Understanding the Paccar MX13 Fuel System Components

The Paccar MX13 fuel system is an ecosystem of interdependent components. A failure in one part inevitably affects the others. Gaining a deeper understanding of each component's role is fundamental to accurate diagnosis and effective repair.

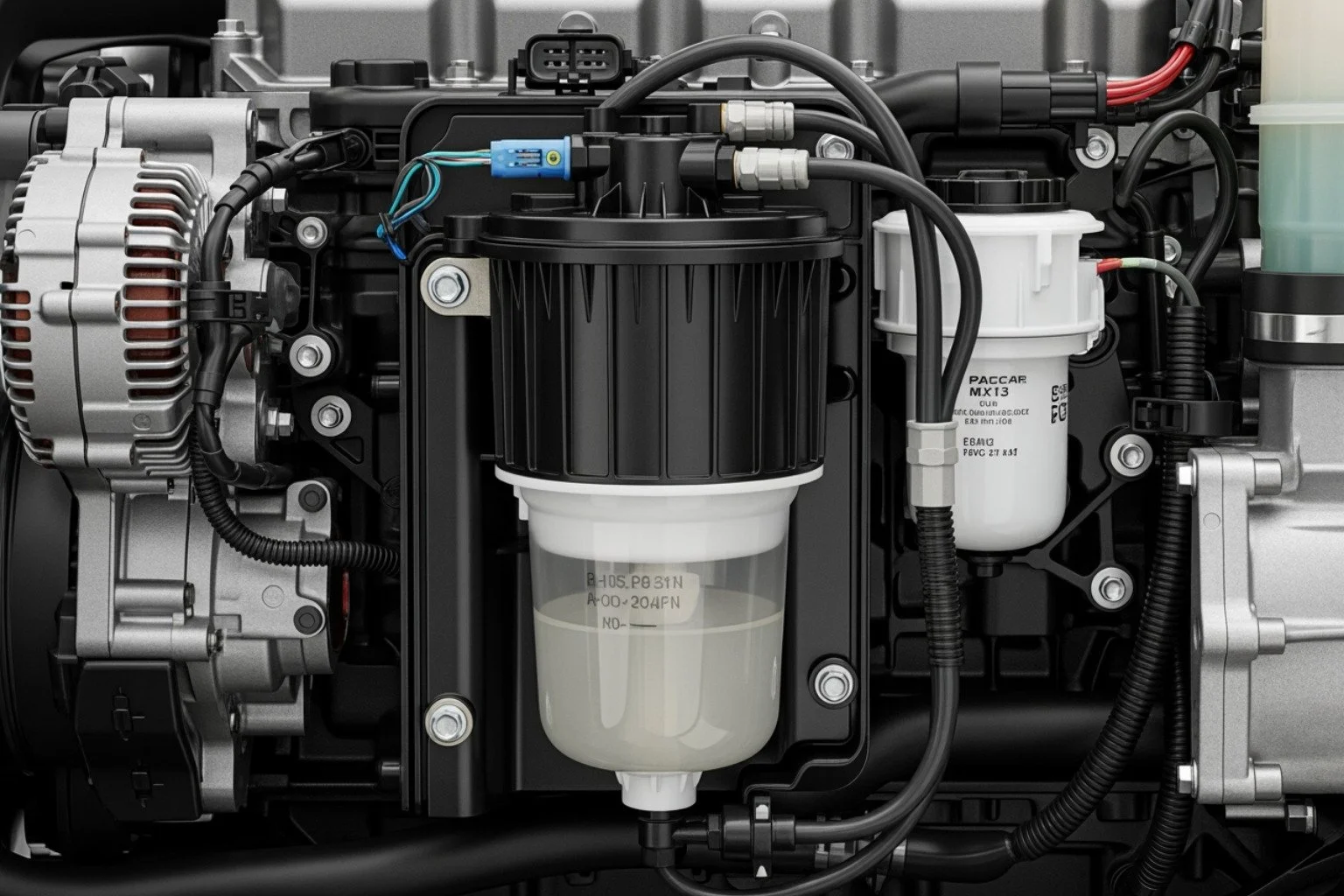

Fuel Filtration Module: This is far more than just a filter; it's the system's primary gatekeeper. PACCAR's integrated module houses the primary filter, a highly efficient water separator, a fuel pre-heater, and a hand primer pump. The chassis-mounted filter (primary) is the first stage, designed to catch larger contaminants and separate bulk water. The engine-mounted filter (secondary) provides much finer filtration, often rated in single-digit microns, to protect the high-pressure pump and injectors from microscopic abrasive particles that can cause rapid wear.

Water Separator: Water is the arch-nemesis of any HPCR system. It causes corrosion, reduces the lubricity of diesel fuel, and can flash to steam inside an injector tip, causing explosive damage. The separator uses baffles or a coalescing medium to force water droplets out of suspension, where they collect in a bowl to be drained. The Water-in-Fuel (WIF) sensor in the bowl is a critical warning device.

Fuel Pre-Heater: This 12-volt, thermostatically controlled heater is essential for preventing fuel gelling in cold climates. When fuel temperature drops, paraffin wax crystals can form, clogging filters and starving the engine of fuel. A less obvious failure mode of the pre-heater is a cracked housing or failed seal, which can become a stealthy source of air leaks, causing hard starting and loss of prime without any visible external fuel leak.

Hand Primer Pump: This simple manual pump is your best friend after a filter change or if the truck runs out of fuel. It allows you to manually draw fuel from the tanks and push it through the filters, purging air from the low-pressure side of the system. The seals within the primer pump itself can wear out over time, becoming a common and often overlooked source of air intrusion.

Low-Pressure Fuel Pump: Typically an electric or gear-driven pump, this component's job is to pull fuel from the tanks and provide a steady, positive pressure (usually 60-90 PSI) to the high-pressure pump. A weak low-pressure pump will strain to supply adequate volume, leading to power loss under load and starving the high-pressure pump, which relies on this flow for lubrication and cooling.

High-Pressure Pump: This is the heart of the system, a mechanical marvel driven by the engine's camshaft or gear train. It takes the low-pressure fuel and intensifies it to over 29,000 PSI. This extreme pressure is what allows for the incredibly fine atomization of fuel needed for efficient and clean combustion. A catastrophic failure of this pump can send metal debris throughout the entire fuel system, necessitating a complete and extremely expensive replacement of the pump, common rail, all fuel lines, and all six injectors.

Common Rail: This fortified steel tube acts as a hydraulic accumulator. It stores the high-pressure fuel from the pump and distributes it to each injector. Its primary role is to dampen the intense pressure pulses from the pump, ensuring that every injector has a consistent, stable pressure to draw from. It also houses the fuel rail pressure sensor and a pressure relief valve for safety.

Fuel Injectors: These are no longer simple mechanical valves. Modern MX13 injectors are sophisticated electro-hydraulic devices controlled directly by the ECM. They use rapid-fire electrical signals to open and close a valve, delivering multiple, precisely timed injections of atomized fuel into the cylinder during a single combustion cycle. This precision is what allows for quiet operation, fuel efficiency, and low emissions. For reliable OEM-spec replacements, consider our Reman Paccar MX13 fuel injectors.

Electronic Control Module (ECM): The ECM is the brain, processing data from dozens of sensors—including fuel rail pressure, engine speed, throttle position, and boost pressure—to make thousands of calculations per second. It then commands the fuel injectors and the metering unit on the high-pressure pump to deliver the exact amount of fuel needed for any given operating condition.

For a deeper dive into the system's architecture, see our guide on Paccar fuel systems.

Common Problems and Telltale Symptoms

The Paccar MX13 fuel system, despite its robust design, is susceptible to a number of common failure points. Recognizing the early warning signs is crucial for preventing a minor annoyance from escalating into a major repair bill and significant downtime. The most frequent issues—loss of prime, air intrusion, injector failures, and clogged filters—are often interconnected, creating a diagnostic puzzle for technicians.

The Vicious Cycle of Air in the Fuel System

Air is the invisible enemy of the HPCR system. Unlike fuel, air is compressible, and its presence introduces a host of performance issues. When air enters the low-pressure (suction) side of the system, it can cause the fuel to drain back to the tank when the engine is off, a condition known as loss of prime. This is why a truck may run perfectly but refuse to start after sitting for several hours. The symptoms of air intrusion are unmistakable:

Hard Starting or No-Start: The engine cranks excessively as the fuel pumps struggle to purge the air and build pressure. This is most common after the truck has been parked overnight or for an extended period.

Engine Stalling at Idle: The engine may start and run for a few moments before sputtering and dying as a large air pocket reaches the high-pressure pump.

Rough Idle and Sputtering: The engine shakes, vibrates, or sounds erratic at idle as inconsistent fuel delivery causes cylinders to misfire.

Hesitation and Reduced Power: During acceleration, the engine may cough or sputter. The truck will feel sluggish and unresponsive as the compressible air disrupts the precise fuel metering required for power.

Common sources of air leaks include hardened or cracked O-rings on the fuel filter housing, hairline cracks in plastic quick-connect fittings, worn seals in the hand primer pump, or chafed fuel lines.

Understanding Dashboard Warning Lights and Fault Codes

Your dashboard is the engine's primary communication tool. Ignoring its warnings is a recipe for disaster.

Check Engine Lamp (CEL): This is your first alert. It often signals fuel pressure-related faults. Key codes to watch for include P1086 (Fuel Rail Pressure Control Error - Pressure Too Low), P00BA (Low Fuel Pressure - Forced Limited Power), P0087 (Fuel Rail/System Pressure - Too Low), and P0088 (Fuel Rail/System Pressure - Too High). These codes indicate the ECM is detecting a dangerous deviation from its target fuel pressure.

Stop Engine Lamp: This is a critical emergency warning. It signifies a severe fault that could lead to catastrophic engine damage. If this light illuminates, pull over safely and shut down the engine immediately. Continuing to drive could turn a repairable issue into a complete engine failure.

Water in Fuel (WIF) Light: This indicates the water separator bowl is full. Do not delay in draining it. Allowing water to pass into the fuel system can destroy the high-pressure pump and injectors in a very short time.

High Exhaust System Temperature (HEST) & Diesel Particulate Filter (DPF) Lamps: These aftertreatment warnings can be directly linked to fuel system health. A faulty injector that leaks or has a poor spray pattern can cause incomplete combustion. This sends excessive unburnt fuel and soot into the aftertreatment system, overwhelming the DPF and causing it to clog prematurely. This leads to more frequent, fuel-consuming regenerations and can eventually damage the DPF itself.

How-To Guide: Fuel Filter Replacement and Priming

Performing regular fuel filter changes is the single most effective preventative maintenance task you can do for the longevity of your Paccar MX13 fuel system. This procedure is straightforward, but precision is key. Cutting corners can introduce contaminants or air, negating the benefit of the new filters and potentially causing damage.

Recommended Tools and Parts for Fuel System Service

Success begins with preparation. Having the right tools and high-quality parts on hand makes the job smoother and prevents mid-job delays.

Tools: A reliable torque wrench, a filter wrench or strap wrench, a socket set (including the correct size for the engine filter cap, often 36mm), clean lint-free rags, a suitable drain pan, nitrile gloves, and safety glasses.

Parts: Always use new, high-quality fuel filters that meet or exceed OEM specifications. Cheap, off-brand filters may not have the correct micron rating or may use inferior media that can collapse under pressure, leading to catastrophic failure. You will need both the chassis-mounted (primary) and engine-mounted (secondary) filters. The new filters should come with new O-rings and seals; never reuse old ones.

Supplies: A container of fresh, clean diesel fuel for pre-filling and lubricating seals, and a small amount of clean engine oil for the filter cap O-ring.

Step-by-Step Fuel Filter Replacement (EPA 2017+ Example)

While this procedure is based on EPA 2017 and newer MX-13 engines, the core principles apply to most model years. Always refer to the specific service manual for your engine's year and model.

1. Safety First: Park the truck on level ground, shut off the engine, and allow it to cool completely. Disconnect the negative battery cable to prevent any accidental starts. Ensure you are working in a well-ventilated area away from any open flames or sparks.

2. Chassis-Mounted Primary Filter:

Place a drain pan under the filter housing. If your truck has a fuel blending valve, turn it to the PRIME (closed) position.

Thoroughly clean the outside of the filter housing to prevent dirt from entering the system.

Disconnect the Water-in-Fuel (WIF) sensor connector.

Loosen the drain valve on the bottom of the filter bowl and allow all fuel to drain out.

Unscrew the filter bowl, remove the old filter element, and discard it. Inspect the old filter for any signs of metal flakes, which would indicate a failing fuel pump.

Clean the inside of the filter bowl meticulously. Pro Tip: Pre-fill the clean bowl about halfway with fresh diesel fuel. This significantly reduces the amount of air you'll need to purge later.

Lubricate the new seals with clean diesel fuel, install the new filter element, and carefully thread the bowl back onto the housing. Torque to the manufacturer's specification.

Reconnect the WIF sensor.

3. Engine-Mounted Secondary Filter:

Clean the fuel tank cap before removing it to release any vacuum in the tank. Thoroughly clean the area around the engine filter cap.

Place a drain pan and slightly loosen the filter cap (usually a 36mm hex). This will allow fuel to drain back. Wait at least 5 minutes for a complete drain.

Remove the cap completely and pull the old filter element straight up and out. Remove and discard the old cap O-ring.

Meticulously clean the housing, paying close attention to the threads and the O-ring groove.

Lubricate the new filter's internal seal with clean diesel fuel. Insert the new element, pushing down with a slight circular motion until it seats, then rotate it 90 degrees to lock it into place.

Lubricate the new cap O-ring with clean engine oil (not diesel fuel) to prevent it from binding or tearing.

Install the cap and tighten by hand until you feel the O-ring make contact. Then, use a torque wrench to tighten the cap to the precise specification, typically 30 lb-ft ± 6 (40 N·m ± 8). Over-tightening can crack the plastic housing, while under-tightening will cause leaks.

How to Prime the Paccar MX13 Fuel System

Proper priming is not optional; it is essential to prevent the high-pressure pump and injectors from running dry, which causes immediate and severe damage.

Prepare for Priming: Double-check that all filter caps are torqued correctly and all sensor connections are secure. If equipped, ensure the blending valve is in the PRIME position.

The 150-Second Pump: Locate the hand primer pump on the side of the engine. Unscrew the knob. Begin pumping with steady, full strokes. You must pump continuously for approximately 150 seconds (2.5 minutes). This may feel excessive, but it is the factory-recommended duration required to fully purge air from the entire low-pressure circuit.

Rest and Reprime: After the initial 150-second pump, wait one full minute. This allows any remaining small air bubbles to coalesce. Then, pump for another 25 firm strokes to ensure the system is fully packed with fuel.

Start and Idle: Securely tighten the primer pump knob. Reconnect the battery. Start the engine. It may crank longer than normal as the last bit of air is purged from the high-pressure side. Once it starts, let it idle for a minimum of 5 minutes without revving the engine. Listen for any sputtering, which indicates remaining air.

Final Leak Check: With the engine running, carefully inspect the filter housings, lines, and connections for any signs of fuel leaks. If your truck has a blending valve, remember to return it to the RUN (open) position before driving.

Advanced Troubleshooting and Fuel Quality

When routine maintenance like a filter change doesn't resolve persistent issues, it's time to move into advanced diagnostics. Problems like loss of prime, injector knocking, and low-pressure faults often require a more methodical approach to pinpoint the root cause.

Diagnosing Loss of Prime and Elusive Air Leaks

A truck that consistently loses prime is suffering from an air leak on the suction side of the fuel system. Finding these leaks can be challenging because they often don't leak fuel externally. The key is to systematically check all potential entry points:

Check Valves: The fuel filter module contains check valves designed to prevent fuel from draining back to the tank. If a valve is stuck open due to debris or wear, the system will lose prime. Isolating and testing these valves often requires specialized tools.

Fuel Lines and Fittings: The plastic quick-connect lines and T-fittings used in modern fuel systems can develop hairline cracks over time, especially at connection points or where they might rub against the chassis. A common diagnostic technique is to replace sections of the fuel line with clear tubing to visually check for air bubbles being pulled into the system while the engine is running.

Fuel Heater and Primer Pump: As mentioned, the seals on the fuel pre-heater sensor and within the hand primer pump assembly are common failure points. A vacuum test on the low-pressure circuit can help reveal leaks in these components.

Tank Vents and Equalizing Lines: Clogged fuel tank vents can create a vacuum in the tanks that the low-pressure pump struggles to overcome, hindering fuel flow. On trucks with dual tanks, a faulty equalizing valve or a leak in the crossover line can cause uneven fuel draw and introduce air into the system.

The Persistent Issue of Injector Knocking

A sharp, metallic knocking sound, especially under light load or acceleration, often points directly to a fuel injector problem. The most common cause on the MX13 is the formation of carboxylate deposits (a type of soap) inside the injector's delicate control valve. This buildup disrupts the injector's ability to open and close precisely, causing erratic fuel delivery that results in a knock. Paccar has released software updates and improved injector designs to combat this, but many engines remain susceptible.

Diagnostic trouble codes P1086 and P00BA are frequently associated with internal injector leakage, which is a primary cause of knocking and low rail pressure. If a chemical fuel system flush fails to resolve the knock, the affected injector(s) will need to be replaced. Using diagnostic software to perform an individual cylinder cutout test can help identify which injector is at fault.

Diagnosing High-Pressure Pump and Rail Issues

Problems on the high-pressure side are less common but far more severe. A failing high-pressure pump can manifest as a no-start condition accompanied by a P0087 or P1086 code. The first diagnostic step is to check the fuel filter for metal debris. If you find a glittery metallic sheen in the fuel or filter media, the high-pressure pump has started to disintegrate. At this point, a catastrophic failure is imminent. The only correct repair is to replace the entire fuel system: the high-pressure pump, common rail, all high-pressure lines, and all six injectors to prevent the metal contamination from destroying the new components.

The Critical Role of Fuel Quality

The MX13's HPCR system is highly intolerant of poor-quality fuel. Adhering to Paccar's recommendations is not just a suggestion—it's essential for system longevity.

Diesel Type: Use only Ultra-Low-Sulfur Diesel (ULSD). Higher sulfur content will permanently damage the DPF and SCR aftertreatment components.

Cetane Number: Cetane is a measure of diesel's ignition quality. Use fuel with a minimum cetane number of 45 in cold weather (below 32°F/0°C) and 42 in warmer weather. Higher cetane reduces ignition delay, leading to smoother starts, quieter operation, and more complete combustion.

Fuel Lubricity: The ULSD refining process reduces diesel's natural lubricity. Fuel must meet the ASTM D6079 standard to ensure it provides enough lubrication to protect the high-pressure pump and injectors from premature wear. Most retail diesel is treated with additives to meet this standard.

Biodiesel Blends: Paccar approves biodiesel blends up to B20 (20% biodiesel, 80% petroleum diesel) as long as the fuel meets ASTM D6751 standards and is sourced from a BQ-9000 accredited producer. Be aware that biodiesel is a solvent and can dislodge sediment in older tanks, requiring more frequent filter changes (recommended every 25,000 miles). It can also be less stable and more prone to gelling in cold weather.

Cold Weather Operation: Do not use kerosene or gasoline to thin fuel. Rely on the factory-installed fuel pre-heater and use high-quality, EPA-approved winterizing additives (anti-gels) from reputable brands to prevent fuel gelling.

Frequently Asked Questions about the Paccar MX13 Fuel System

Navigating the complexities of the Paccar MX13 fuel system often leads to questions. Here are detailed answers to some of the most common queries from drivers and technicians.

What are the most common fuel system issues on a Paccar MX13?

The most frequently reported problems are a direct result of the system's complexity and tight tolerances. They include:

Losing Prime: The engine fails to start after sitting, typically overnight. This is almost always caused by air entering the low-pressure fuel lines, allowing fuel to drain back to the tank.

Air Intrusion: This is the root cause of losing prime, but it also causes symptoms while running, such as engine stalling, rough idle, and sputtering during acceleration. Common culprits are old O-rings, cracked plastic fittings, or worn primer pump seals.

Injector Knocking: A distinct metallic knock caused by internal injector deposits (carboxylate buildup) or wear. This is often accompanied by fault codes related to low fuel pressure.

Clogged Fuel Filters: Leading to a gradual or sudden loss of power, especially under heavy load. This is a maintenance issue that can strain the entire system if neglected.

Fuel Leaks: Visible leaks from the filter housing or lines are a clear sign of a failed seal or O-ring and are a significant fire hazard.

How often should I change the fuel filters on my MX13?

The factory recommendation is to replace both the primary (chassis) and secondary (engine) fuel filters at every oil drain interval. For the MX13, this interval can range from 30,000 to 75,000 miles, depending on the truck's application and duty cycle. However, this interval should be shortened significantly under certain conditions. If you regularly use biodiesel blends (B6-B20), Paccar recommends changing fuel filters every 25,000 miles. Biodiesel's solvent properties can clean sludge from fuel tanks, which then clogs the filters more rapidly. Never attempt to save money by extending filter life; the cost of a set of filters is negligible compared to the cost of a new high-pressure pump or a set of injectors.

Can I use biodiesel in my Paccar MX13 engine?

Yes, Paccar approves the use of biodiesel blends up to B20 (20%). However, this approval is conditional. The fuel must meet the strict quality standard ASTM D6751 (in North America) or EN 14214 (in Europe), and it must be purchased from a BQ-9000 Accredited Producer. Using higher blends (like B50 or B100) or fuel from non-accredited sources can lead to filter plugging, seal degradation, and injector deposits, and will void your engine warranty. Also, be aware that biodiesel contains slightly less energy than petroleum diesel, which may result in a minor reduction in fuel economy and power.

What do fault codes P1086 and P00BA mean?

These are two of the most common and critical fuel system codes on an MX13. P1086 translates to "Fuel Rail Pressure Control Error - Pressure Too Low," while P00BA means "Low Fuel Pressure - Forced Limited Power." Both codes indicate that the ECM is commanding a certain fuel pressure, but the fuel rail pressure sensor is reporting a value that is significantly lower than the target. This triggers a check engine light and, in the case of P00BA, a severe engine derate to protect the system. Common causes include a major air leak, severely clogged fuel filters, a weak low-pressure pump, a failing high-pressure pump, or one or more leaking fuel injectors.

What is an engine derate and how is it related to the fuel system?

An engine derate is a self-protection measure programmed into the ECM. When a serious fault is detected that could cause engine damage, the ECM will automatically limit the engine's torque and horsepower. For a driver, this feels like a major loss of power. Many fuel system faults, especially those related to low fuel pressure (like P00BA), will trigger a derate. It's the engine's way of forcing you to address a critical problem before catastrophic failure occurs.

Conclusion: Keeping Your MX13 Running Smoothly

Your Paccar MX13 fuel system is the lifeblood of your truck, a complex network responsible for the power and efficiency you depend on. Maintaining its health is not just about preventing breakdowns; it's about protecting your investment, ensuring driver safety, and maximizing your operation's profitability. The difference between a reliable engine that reaches a million miles and one plagued by constant issues often comes down to the care and attention given to its fuel system.

The key takeaway is that a proactive approach is always superior to a reactive one. Most of the common, costly problems are preventable through diligent maintenance and an understanding of the system's needs.

Unyielding Preventative Maintenance: Adhering to a strict schedule for fuel filter changes using high-quality filters is your best and cheapest insurance policy against contamination and fuel starvation.

Insist on Quality Parts: The extreme pressures and tight tolerances of the HPCR system demand components that meet or exceed OEM specifications. From injectors to pumps, choosing cheaper, unproven parts is a gamble that can lead to catastrophic and expensive system-wide failures.

Listen to Your Engine: A dashboard warning light or a new engine noise is not a suggestion; it's a direct communication. Addressing issues like diagnostic codes P1086 and P00BA, injector knocking, or a persistent loss of prime early on can save thousands in repairs and lost revenue.

Correctly diagnosing the root cause of a problem the first time is crucial to avoiding repeat repairs. At G2 Diesel Products, our Harrisburg, PA-based team of experts has encountered every fuel system issue imaginable. We are committed to providing not just parts, but solutions. For reliable, remanufactured injectors and components that restore performance and keep your engine running smoothly, explore our range of Paccar diesel fuel injectors.

By investing in proper maintenance and quality parts, you empower your Paccar MX13 to go the distance, delivering the reliable performance your business is built on.