Keeping Your Volvo Roaring: Where to Find Quality Engine Parts

Why Volvo Truck Engine Parts Are Critical for Fleet Success

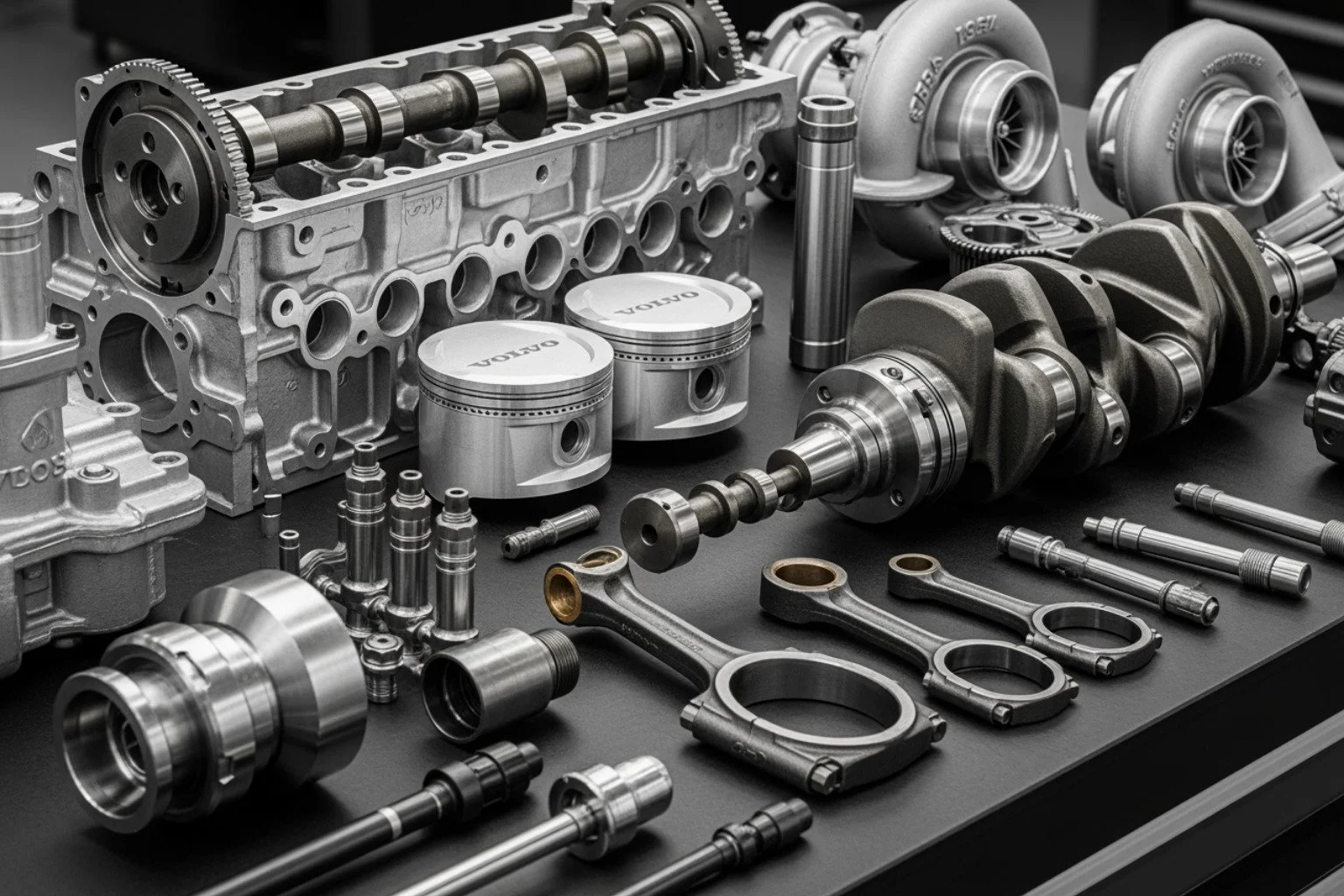

Volvo truck engine parts are the foundation of reliable and profitable fleet operations. For any fleet manager, the primary goals are maximizing uptime, ensuring driver safety, and controlling operational costs. The components chosen to maintain and repair your engines are not just spare parts; they are critical investments that directly influence these outcomes. The right components ensure your trucks deliver consistent, efficient performance day after day, while the wrong ones can trigger a cascade of failures, leading to costly, unscheduled downtime. In an industry where margins are tight and schedules are tighter, every part matters, from high-precision fuel injectors and complex turbochargers to the sophisticated engine control modules that orchestrate performance.

Understanding the true cost of a part goes far beyond its initial purchase price. This concept, known as Total Cost of Ownership (TCO), is paramount for savvy fleet managers. A cheaper, non-genuine part might save a few dollars upfront, but it can lead to staggering downstream costs. Consider the financial impact of a single unexpected breakdown: towing fees, emergency repair labor rates, lost revenue from a missed load, potential penalties for late delivery, and the intangible cost of a damaged customer relationship. High-quality parts, engineered to Volvo's exacting standards, are designed to prevent these scenarios, making maintenance costs predictable and protecting your bottom line.

Quick Reference for Volvo Truck Engine Parts:

Genuine Parts: Factory-engineered by Volvo for a precise fit and optimal performance. These parts undergo rigorous testing to ensure they integrate seamlessly with all other vehicle systems, upholding the truck's original design integrity.

Remanufactured Parts: A cost-effective and sustainable option where used parts are completely restored to original OEM specifications by factory-trained technicians. They offer the same performance and reliability as new parts and come with robust factory warranties.

Key Components: The heart of the engine includes fuel injectors, turbochargers, Engine Control Modules (ECMs), cylinder heads, and Exhaust Gas Recirculation (EGR) systems. The quality of these parts dictates power, efficiency, and emissions compliance.

Popular Engines: The workhorse D11, D12, and D13 series engines are renowned for their balance of power and efficiency, with horsepower ratings typically ranging from 325 to 500 HP.

Quality Standards: The benchmark for reliability is ensuring parts meet or exceed original equipment manufacturer (OEM) specifications. This guarantees the part is made from the correct materials and to the precise tolerances required for long-term durability.

Volvo trucks are engineered for the long haul, a testament to a legacy of safety, reliability, and innovation. Maintaining that legendary performance requires a commitment to using the right parts. Whether you're running a fleet of D11 engines for regional hauls or relying on the power of the D13 for heavy-duty, cross-country work, your choice of components directly impacts fuel efficiency, uptime, and profitability. The difference between premium-quality parts and cheap alternatives becomes painfully clear during an unexpected breakdown on a remote highway. Smart fleet managers know that investing in quality engine parts isn't just about fixing problems—it's a strategic decision to prevent them, keeping trucks on the road, drivers productive, and business moving forward.

The Anatomy of a Volvo Truck: Genuine vs. Remanufactured Parts

When it comes to sourcing Volvo truck engine parts, fleet managers and owner-operators are faced with a critical decision that extends beyond the immediate repair. The choice between genuine, remanufactured, and aftermarket parts will have a lasting impact on the vehicle's performance, reliability, and overall value. For those who prioritize quality and long-term dependability, the decision narrows to two primary options: genuine and remanufactured parts.

Genuine parts are the gold standard. They are designed concurrently with the vehicle by Volvo engineers, benefiting from millions of dollars in research and development. This precision engineering for Volvo engines ensures that every component works in perfect harmony with your truck's complex, integrated systems. They are manufactured to exact specifications from specific materials and meet or exceed OEM specifications, meaning they have been rigorously tested under extreme conditions to deliver the performance, fuel economy, and longevity your truck was designed for. While cheaper aftermarket parts are widely available, a comparison with aftermarket alternatives often reveals a stark reality. Aftermarket parts are frequently reverse-engineered without access to the original design blueprints, leading to subtle but critical deviations in material composition, tolerances, and fitment. These deviations can cause improper sealing, accelerated wear, and even catastrophic failure of related components, turning a small upfront saving into a major expense. Investing in genuine quality is the cornerstone of maximizing vehicle value and reliability.

Learn more about our quality Volvo engine parts

Why Quality Volvo Truck Engine Parts Matter for Longevity

Quality Volvo truck engine parts are not standalone items; they are integral cogs in a highly sophisticated machine. Their quality directly impacts engine performance and fuel efficiency. When every component works precisely as intended, your engine achieves optimal combustion, burning fuel more completely and producing maximum power with minimum waste. This synergy is evident in critical systems. For instance, the cooling system and exhaust components do more than just manage temperature and fumes. A genuine water pump maintains the correct coolant flow rate to prevent overheating, while precisely engineered exhaust manifolds and gaskets maintain the exact back pressure needed for the turbocharger to operate at peak efficiency. Likewise, high-quality filtration and lubrication systems are the engine's first line of defense. An OEM-spec oil filter contains the right media to trap harmful contaminants without restricting flow, while a quality fuel filter protects high-pressure injectors from microscopic debris that can cause irreparable damage. This seamless integration for optimal uptime means your truck spends more time on the road generating revenue and less time in the repair shop.

Remanufactured Parts: A Cost-Effective, High-Quality Alternative

Remanufactured parts offer a brilliant middle ground, providing OEM-level quality without the premium price tag of brand-new components. It is crucial to distinguish 'remanufactured' from 'rebuilt' or 'reconditioned.' The remanufacturing process is far more comprehensive. It involves factory-trained technicians and stringent quality processes where a used part (the 'core') is completely disassembled. Every single component is cleaned, meticulously inspected, and measured against original factory specifications. Any part that shows even the slightest wear—such as bearings, seals, gaskets, and electronic components—is discarded and replaced with new. Furthermore, remanufactured parts often incorporate the latest engineering updates, meaning the finished product can be superior to the original part it replaces. The result is restored performance and reliability that is functionally identical to a new part. To underscore this quality, reputable remanufactured parts come with industry-leading warranties for peace of mind, often matching the warranty of a new component and guaranteeing the quality of the materials and workmanship.

Find the benefits of remanufactured engine parts

The Core of Performance: A Deep Dive into Volvo Truck Engine Parts

The D11, D13, and D16 engines are the undisputed workhorses of the modern Volvo lineup, each engineered for a specific balance of efficiency, power, and durability. These engines are known for their impressive power-to-weight ratios, advanced fuel-saving technologies, and long service intervals.

The Volvo D11 engine is a lightweight powerhouse, delivering 325 to 425 horsepower and 1,250 to 1,550 lb-ft of torque. Its compact and lighter design makes it an ideal choice for regional hauls, less-than-truckload (LTL) applications, and weight-sensitive routes. This efficiency focus allows it to deliver up to 5% better fuel economy than older, comparable models, making a significant impact on a fleet's operating budget.

The Volvo D13 engine is the versatile, heavy-duty champion of the family, producing 375 to 500 horsepower and a formidable 1,450 to 1,850 lb-ft of torque. Found in the iconic VNL, FH, and FM series trucks, it excels at long-haul, cross-country routes and demanding vocational applications. The D13 is packed with advanced features like Turbo Compound (TC) technology, which captures and reuses waste exhaust energy to provide an extra 50 horsepower and improve fuel savings by up to 6.5%. Additionally, its patented Wave Piston design features a unique wave-shaped crown that improves flame propagation, ensuring a more complete and efficient combustion process.

The Volvo D16 engine is the pinnacle of power, designed for heavy-haul and extreme applications. Pumping out up to 600 horsepower and 2,050 lb-ft of torque, it provides the raw strength needed to move the heaviest loads over the steepest grades without breaking a sweat.

A Deep Dive into Volvo Engine Parts

Key Engine Components and Their Function

Understanding how key components function and the symptoms of their failure can empower fleet managers to schedule proactive maintenance and prevent catastrophic, on-road breakdowns.

Cylinder heads are complex components that seal the top of the combustion chamber. They house the valvetrain, injectors, and coolant passages. Due to extreme thermal and pressure cycles, they can be susceptible to cracking or warping. Failure symptoms include coolant in the oil (a 'milkshake' appearance), white smoke from the exhaust, overheating, or a noticeable loss of compression.

Turbochargers are critical for power and efficiency, using exhaust gas to spin a turbine that forces more compressed air into the engine. Modern Volvos use Variable Geometry Turbos (VGTs) that adjust to provide optimal boost across the RPM range. A failing turbo may cause a distinct whining or siren-like noise, excessive blue or black smoke, a significant loss of power, and fault codes related to boost pressure.

EGR (Exhaust Gas Recirculation) systems are essential for emissions control, reducing NOx by recirculating a portion of the exhaust gas back into the combustion chamber to lower temperatures. The EGR valve and cooler are common failure points. Malfunctions, often caused by soot buildup or internal coolant leaks, can lead to reduced engine performance, increased emissions, engine derating, and persistent check engine lights.

ECMs (Engine Control Modules) are the sophisticated brains of the engine, processing thousands of data points per second from sensors across the vehicle to manage everything from fuel injection timing to turbo actuation. A failing ECM can cause a wide array of baffling symptoms, including intermittent misfires, rough idling, stalling, sudden power loss, poor fuel economy, or the engine entering a protective "limp mode."

The Fuel System: Injectors as the Heartbeat of Efficiency

The fuel injection system is the heartbeat of a modern diesel engine, and the fuel injectors are its most critical component. They are tasked with atomizing and delivering a precise amount of fuel into the combustion chamber at exactly the right moment, under immense pressure. For Volvo D11, D12, D13, and D16 engines, which use high-pressure Electronic Unit Injectors (EUIs), high-quality injectors are absolutely essential for achieving rated power, meeting stringent emissions standards, and maximizing fuel economy. Poor-quality or worn injectors lead to incomplete combustion due to improper spray patterns or incorrect timing. This results in a host of problems: poor fuel economy, reduced power, excessive black smoke, engine knocking, and dilution of the engine oil with unburnt fuel, which can accelerate wear on other internal components.

At G2 Diesel Products, our fuel injectors are remanufactured and engineered to meet or exceed OEM standards, ensuring maximum fuel atomization for a clean, complete, and powerful combustion event. This precision translates directly to better fuel economy, lower operating costs, and a longer, healthier engine lifespan.

Precision Injection: A Guide to Volvo D13 Fuel Injectors

For specific Volvo D13 applications, we offer high-quality options like our Volvo D13 EUI Fuel Injector 22340652, designed to deliver the performance and reliability your fleet depends on.

Understanding Remanufactured Engine Packages for Volvo Trucks

When a Volvo engine reaches the end of its service life or suffers a catastrophic failure, fleet managers face a critical decision: undertake a lengthy and expensive in-frame overhaul, source a used engine of unknown history, or invest in a brand-new one? Remanufactured engine packages from Volvo offer a fourth, often superior, alternative. These are not simply "rebuilt" engines; they undergo a complete, factory-controlled overhaul that restores them to as-new condition. The process is meticulous: every component is disassembled, chemically cleaned, and rigorously inspected. Worn or outdated parts are replaced with new or re-machined components, and crucially, they often incorporate the latest engineering improvements and design updates that have been developed since the engine was first built. To guarantee quality, many of these engines are dyno tested and verified at the factory, ensuring they meet strict performance, power, and emissions standards right out of the crate. This process restores original performance and reliability while significantly reducing the downtime associated with a traditional overhaul.

The 7/8 and 3/4 Reman Packages

Volvo offers two main remanufactured engine packages, known as the 7/8 and 3/4 Reman, to suit different repair scenarios, timelines, and budgets. The choice depends on the condition of the existing engine's external components.

Feature 7/8 Reman Package 3/4 Reman Package What You Get A complete remanufactured engine with external parts, including the turbo kit, water pump, oil cooler, and a six-pack injector kit already installed. A remanufactured engine block and cylinder head (long block) with all internal components restored to OE specifications. Installation Approach Arrives as a fully assembled, drop-in unit—almost plug-and-play. This dramatically speeds up the repair process. Requires the technician to carefully transfer the external components (turbo, fuel system, manifolds, etc.) from the old engine to the new long block. Best For Situations demanding the absolute fastest turnaround, such as a catastrophic failure where external components may also be damaged. Ideal for minimizing downtime and getting a truck back to earning revenue quickly. Scenarios where the core engine structure (block, crank, pistons) needs an overhaul, but the external bolt-on components are still in good, serviceable condition. A more budget-conscious choice. What's Not Included Only requires the transfer of the alternator, starter, fan hub, and power steering pump from the old engine. All external accessories must be transferred, including the turbocharger, fuel system, EGR components, and other bolt-on parts. Timeline Typically available with a 60-day lead time through the VDSP (Volvo Dealer Stocking Program), providing a predictable schedule. Generally faster than a complete engine overhaul from scratch, but the installation time is longer than the 7/8 package. Warranty Coverage Comes with a powerful 3-year, 350,000-mile warranty when installed by an authorized Volvo dealer, offering exceptional peace of mind. Covered under the standard Volvo Reman Parts warranty, which can vary by component but still provides robust protection.

The 7/8 Reman Package is the ultimate solution for getting a truck back on the road with maximum speed and minimal hassle, backed by a comprehensive warranty. The 3/4 Reman Package is a highly cost-effective choice for fleets that have the technician time and serviceable external parts to complete the engine assembly.

Specific Remanufactured Engine Components

If a full engine replacement isn't necessary, individual remanufactured parts offer a targeted, high-quality repair solution that is far superior to a simple patch-up.

Reman cylinder heads are a prime example. They undergo electromagnetic crack detection, are pressure tested, and have their surfaces machined to perfect flatness. They receive new valve guides, valve stem seals, rotators, and factory-installed injector cups to ensure optimal sealing and long-term performance.

Reman turbochargers are completely disassembled and inspected. Worn components are replaced, and the rotating assembly is precision-balanced at high speeds to prevent vibration and ensure longevity. They typically come in complete kits with all necessary gaskets and seals and are backed by a 1-year, unlimited-mile warranty when installed by an authorized dealer.

Reman turbo actuators (SRA) for D11, D13, and D16 engines are a smart repair for a common failure point. They feature 100% new circuit boards, harnesses, and connectors and are calibrated and tested to original equipment specifications.

Six-pack injector kits for Volvo D11, D12, D13, and D16 engines are the recommended way to service the fuel system. They include a full set of six remanufactured injectors that incorporate the latest engineering upgrades, ensuring balanced engine performance, optimal fuel atomization, and consistent efficiency across all cylinders.

Reman Fuel Injector EX631029 Volvo D13 Mack MP8

These components provide the flexibility to address specific issues with factory-backed, remanufactured quality, ensuring a reliable and durable repair.

Sourcing and Verification: How to Get the Right Parts

Finding quality Volvo truck engine parts is more accessible than ever, but navigating the options requires diligence. The traditional route is through Volvo's impressive network of over 350 dealer locations across North America, which you can explore on the official Volvo Trucks website. Dealers offer direct access to genuine parts and expertise. However, the ability to source parts online from trusted independent suppliers provides unparalleled 24/7 convenience and often, more competitive pricing. Advanced digital catalogs allow you to search by part number or engine model, and many leading suppliers offer real-time inventory updates and expedited shipping options to minimize downtime.

At G2 Diesel Products, we've built our business around streamlining the online ordering process to get you back on the road as quickly as possible. Our user-friendly digital platform connects you directly to our extensive inventory of high-quality remanufactured components, reducing lead times, eliminating the guesswork of sourcing, and providing expert support just a click or a call away.

Find a Volvo Truck Parts Supplier

How to Choose the Right Volvo Truck Engine Parts

Ordering the wrong part is one of the most common and frustrating mistakes in truck maintenance. It leads to extended downtime, return shipping costs, and immense frustration for both the technician and the fleet manager. The golden rule to prevent this is simple: always start with your VIN or engine serial number. These numbers are the unique fingerprint of your vehicle.

Your 17-digit Vehicle Identification Number (VIN), typically found on a plate on the driver's side dashboard or door jamb, contains the complete build information for your truck as it left the factory. The engine serial number (ESN), located on a metal plate affixed to the engine block (usually on the left side), provides the specific identity of the engine itself. Providing one of these numbers to your parts supplier is the only way to guarantee a perfect fit. Even two trucks from the same model year can have different component configurations due to running production changes or optional equipment. Don't guess on compatibility. When in doubt, consulting with diesel parts experts, like the knowledgeable team at G2 Diesel Products, can help you cross-reference part numbers and confirm you're ordering the correct item. Taking a clear photo of the old part and any numbers stamped on it can also be invaluable for verification.

Order Volvo Truck Engine Parts Online

Beyond the Engine: Transmission, Cab, and Body Parts

A Volvo truck is a complex, integrated system where every component's quality matters. While the engine is the heart, other systems are just as critical for performance, safety, and value. The revolutionary I-Shift transmission, for example, is not just a gearbox; it's an intelligent system that uses an advanced electronic control unit to monitor speed, weight, and road grade to execute perfect, fuel-efficient shifts. Using genuine or high-quality remanufactured transmission parts, including sensors and control modules, is essential to ensure this sophisticated system operates flawlessly. An incorrect part can disrupt communication, leading to poor shift quality, reduced fuel economy, and potential damage to internal components.

Similarly, quality cab and body parts, including bumpers, grilles, mirrors, and painted exterior panels, are essential for maintaining your truck's professional appearance, aerodynamic efficiency, and resale value. Poorly fitting aftermarket body parts can create panel gaps that increase wind noise and aerodynamic drag, subtly hurting fuel economy over thousands of miles. More importantly, they can complicate repairs, increasing labor costs and downtime. Smart fleet managers understand that maintaining the entire vehicle—not just the engine—with quality components is the key to maximizing uptime, ensuring driver satisfaction, and preserving the asset's long-term value.

Frequently Asked Questions about Volvo Truck Engine Parts

Fleet managers, owner-operators, and technicians often have pressing questions about sourcing and using Volvo truck engine parts. Getting clear, accurate answers is key to making informed decisions that impact fleet reliability and profitability. Here are answers to some of the most common concerns.

What is the main benefit of using high-quality engine parts over generic aftermarket options?

The primary benefit is long-term value and risk mitigation. High-quality parts, whether genuine or remanufactured to OEM specs, are engineered specifically for your truck. This guarantees perfect fit, seamless integration with other systems, and optimal performance as the manufacturer intended. This precision prevents issues like improper sealing, premature wear, and unexpected downtime that are common with ill-fitting aftermarket parts. Furthermore, they are backed by strict quality control standards and comprehensive warranties, protecting your truck's longevity and resale value in ways that generic parts cannot. While the upfront cost of a quality part may be higher, the long-term reliability, improved fuel efficiency, and avoidance of catastrophic failure make them a far smarter and more profitable investment.

What is the difference between a rebuilt and a remanufactured part?

These terms are often used interchangeably, but they describe vastly different processes and levels of quality. A rebuilt part is simply repaired. A technician identifies the specific component that failed and replaces it, leaving the other used, aging components in place. It's a targeted fix for a single point of failure. A remanufactured part, in contrast, is completely restored to a like-new state. The entire unit (the 'core') is disassembled, and every single piece is cleaned, inspected, and measured against original specifications. Any component that shows wear, regardless of whether it has failed, is replaced with new or re-machined parts. Crucially, the part is often updated with the latest engineering improvements. The result is a component that performs like new and comes with a comprehensive factory warranty, offering superior reliability and a longer lifespan.

How do I ensure I'm ordering the correct part for my specific Volvo truck?

The most reliable and foolproof method is to use your truck's Vehicle Identification Number (VIN) or the engine serial number (ESN) when ordering. These numbers allow your parts supplier to access your truck's exact build sheet from the factory, guaranteeing a perfect match. Even trucks from the same model year can have different components due to mid-year production changes or different spec packages. Guessing based on the model is a recipe for costly downtime and return shipping fees. At G2 Diesel Products, we always recommend providing your Engine Serial Number when ordering parts for Volvo D11, D12, or D13 engines. When in doubt, consult with a diesel parts expert to verify the correct component before you place the order.

What are the common symptoms of a failing fuel injector in a Volvo D13?

Failing injectors on a D13 can manifest in several ways. Common symptoms include a noticeable loss of power or poor throttle response, a significant drop in fuel economy, rough idling or engine knocking, and excessive black smoke from the exhaust during acceleration. You might also experience hard starting, especially when the engine is cold. In some cases, a severely leaking injector can wash down the cylinder wall, leading to unburnt fuel diluting the engine oil, which can be detected during an oil analysis.

Can I use Mack parts on my Volvo engine since they seem similar?

This is a common question, as Volvo Group owns Mack Trucks, and there is significant platform sharing. For example, the Mack MP8 engine is fundamentally the same as the Volvo D13. In many cases, the core components are interchangeable. However, there can be critical differences in the programming of electronic components like the ECM, as well as variations in brackets, harnesses, and other ancillary parts. To avoid compatibility issues, it is always best to order the part specifically listed for your Volvo model using your VIN or ESN. A knowledgeable parts supplier can confirm cross-compatibility if it exists.

What are the most common maintenance mistakes that lead to premature engine part failure?

Three of the most common and costly mistakes are: 1) Extending oil change intervals beyond the manufacturer's recommendation, which leads to oil breakdown and accelerated wear on all internal components. 2) Neglecting the cooling system, allowing coolant to become acidic and causing corrosion, leaks, and overheating. 3) Using low-quality fuel and oil filters. Cheap filters can fail to trap harmful contaminants or can collapse, starving the engine of lubrication and allowing debris to damage high-precision components like turbochargers and fuel injectors.

Conclusion

Your Volvo truck is more than just a vehicle; it is the backbone of your business, a critical asset responsible for generating revenue and upholding your reputation for reliability. Its performance, longevity, and profitability are directly dependent on the quality of the parts used to maintain it. In a competitive industry, compromising on the components that keep your engine running is a significant risk to your operational stability and your livelihood. A strategic investment in high-quality Volvo truck engine parts is not an expense—it is a fundamental practice for protecting your investment, maximizing uptime, and ensuring your Volvo performs as its engineers intended for years to come.

Whether your fleet requires a precision-remanufactured fuel injector for a D13 engine, a complete 7/8 reman engine package to minimize downtime, or any other critical component, the right supplier makes all the difference. At G2 Diesel Products, we understand that for our customers, time is money and reliability is non-negotiable. We specialize in manufacturing and supplying reliable, high-quality diesel fuel injectors and engine components for Volvo, Mack, Kenworth, and Paccar trucks, built to meet or exceed OEM specifications.

We don't just sell parts; we provide solutions that support your success. When you choose G2 Diesel Products, you are partnering with a team of experts dedicated to quality. You get components designed to withstand the rigorous demands of your fleet, backed by industry expertise and a commitment to customer service. Our efficient processes, quick lead times, and customer-specific packaging ensure you get the right parts, right when you need them. Make the smart, strategic choice for your business—choose G2 Diesel Products to keep your fleet running strong.

Explore our full range of high-quality diesel fuel injectors and parts