Paccar PX-9 Fuel System: Keeping the Diesel Flowing

Understanding Your PACCAR PX-9's Fuel Delivery System

The paccar px-9 fuel system is the heart of your 8.9-liter engine, a powerhouse known for its robust performance in Kenworth and Peterbilt trucks. This intricate network of components is responsible for delivering precisely metered fuel to create the power and torque your fleet depends on every single day. However, its sophistication also makes it sensitive to contamination and wear. When your PX-9 starts hard, loses power, or shows dashboard warning lights, the fuel system is often the primary culprit. A single day of downtime can cost thousands, making a thorough understanding of how this system works essential for proactive diagnosis, effective maintenance, and keeping your trucks earning on the road.

Quick Reference: PACCAR PX-9 Fuel System Essentials

Engine Type: 8.9-liter inline 6-cylinder diesel

Power Range: 260-450 HP with 860-1,250 lb-ft torque

Key Components: Electric lift pump, fuel filters, high-pressure pump, common rail, injectors

Maintenance Interval: Fuel filter every 50,000 miles (80,000 km)

Required Fuel: Ultra-low-sulfur diesel (ULSD) with minimum 42-45 cetane number

Priming Method: Key cycling 3-5 times activates electric lift pump

The PX-9's fuel delivery system uses high-pressure common rail technology controlled by an Electronic Control Module (ECM). This precision engineering delivers excellent fuel economy and meets EPA 2021 emissions standards, but it requires every component to work in perfect harmony. This article provides a comprehensive guide for owners, operators, and technicians. Whether you're dealing with air in the lines, troubleshooting a rough idle, or planning preventative maintenance, knowing your fuel system basics saves critical time and money.

Anatomy of the PACCAR PX-9 Fuel System

Each component in the paccar px-9 fuel system has a specific job in delivering fuel from the tank to the combustion chamber. A failure in any one part can compromise the entire system. Understanding this flow is key to troubleshooting and maintenance.

Fuel Tank & Electric Lift Pump: The journey begins in the fuel tank. The in-tank electric lift pump is the first mover, drawing fuel from the tank and sending it forward under low pressure (typically 10-15 PSI). This initial pressure is crucial for priming the system and feeding a steady supply of fuel to the high-pressure pump, preventing cavitation and damage.

Fuel Filter and Water Separator: This crucial module acts as a security checkpoint. It removes dirt, debris, and damaging water from the fuel before it can reach sensitive parts. The filter media is rated in microns to trap incredibly small particles that could otherwise score the internals of the pump and injectors.

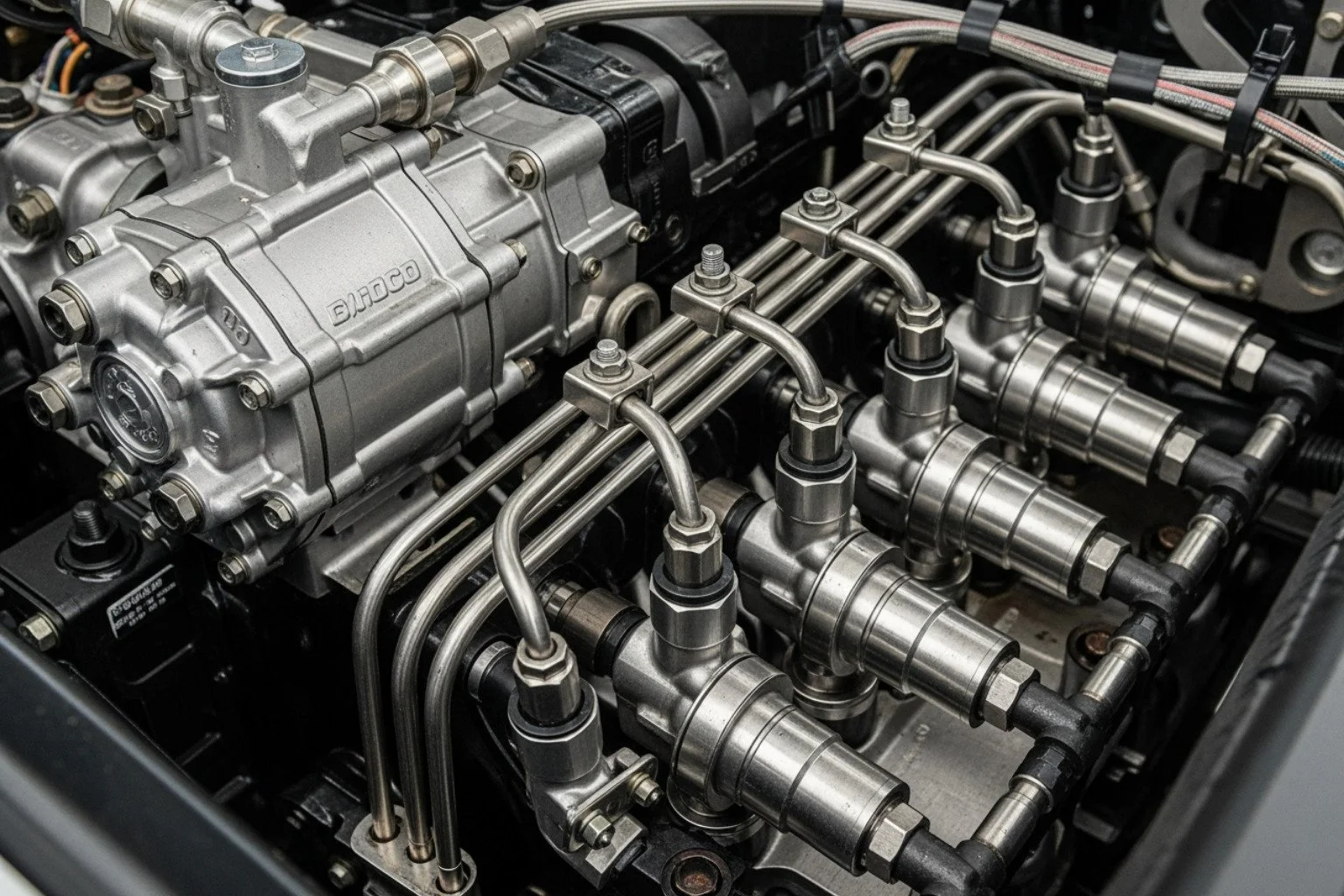

High-Pressure Fuel Pump: This is the muscle of the system, often a gear-driven pump like a Bosch CP4. It takes the low-pressure fuel from the lift pump and intensifies it to extreme pressures, often exceeding 25,000 PSI. This immense pressure is necessary to atomize the fuel properly when it's injected into the high-compression environment of the combustion chamber.

High-Pressure Common Rail: The common rail is a fortified steel tube that acts as a pressure accumulator. It holds the high-pressure fuel from the pump and distributes it to all six injectors. This design ensures that a constant, stable pressure is available to every injector, allowing for precise and independent injector firing, which is a massive improvement over older fuel system designs.

Diesel Fuel Injectors: These are the precision instruments of the system. Controlled by the ECM, they use sophisticated solenoids or piezoelectric actuators to open and close a nozzle multiple times per combustion cycle. These multiple injection events (pilot, main, and post-injections) help reduce engine noise, lower emissions, and facilitate DPF regeneration. At G2 Diesel Products, we specialize in manufacturing high-quality diesel fuel injectors that meet these demanding requirements to ensure peak performance in engines like the PX-9.

Return Lines: Unused fuel from the injectors and pressure relief valve is carried back to the tank through return lines. This process also helps cool the fuel and components, completing the circuit.

For a detailed visual breakdown, you can reference a Paccar PX-9 Fuel System Diagram.

The Role of the Electronic Control Module (ECM)

The Electronic Control Module (ECM) is the brain of the paccar px-9 fuel system. It processes data from dozens of sensors across the engine and chassis to manage fuel delivery with incredible precision. The ECM's primary functions include:

Injection Timing and Fuel Pressure Regulation: Using inputs from the crankshaft position sensor, camshaft position sensor, accelerator pedal, and rail pressure sensor, the ECM calculates the exact moment to fire each injector and for how long. It simultaneously commands the high-pressure pump's inlet metering valve to maintain the target pressure in the common rail, optimizing power, and fuel efficiency under all operating conditions.

Engine Performance Monitoring: The ECM constantly analyzes sensor data for anomalies that could indicate a potential issue. By monitoring parameters like fuel temperature, boost pressure, and exhaust gas temperature, it can often detect problems before they become catastrophic failures, protecting your engine from severe damage.

Fault Code Generation: When a problem is detected outside of normal operating parameters, the ECM stores a Diagnostic Trouble Code (DTC) and illuminates a warning lamp on the dashboard. These codes are essential for technicians to perform quick and accurate troubleshooting with diagnostic software. For more technical details, you can explore more info about PACCAR resources.

Fuel, Filters, and Fluids: The Lifeblood of Your Engine

The reliability and longevity of your paccar px-9 fuel system depend heavily on the quality of the fuel you use and the effectiveness of your filtration. Using the right fluids is the simplest and most cost-effective way to protect your investment and keep your truck on the road.

Recommended Fuel Types and Specifications

Your PX-9 requires fuel that meets specific ASTM standards to protect its sophisticated high-pressure components and aftertreatment system.

Fuel Type: Ultra-Low-Sulfur Diesel (ULSD) is mandatory. Sulfur, when burned, creates compounds that permanently damage the catalysts in the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system. Using high-sulfur fuel is a violation of EPA regulations and will lead to costly aftertreatment repairs.

Cetane Number: Cetane measures a fuel's ignition quality—how quickly it ignites under compression. PACCAR recommends a minimum of 45 cetane in temperatures below 32°F (0°C) for easier starting and smoother operation, and 42 cetane in warmer conditions. Low cetane fuel leads to a longer ignition delay, causing rough running, incomplete combustion, and increased emissions.

Fuel Lubricity: ULSD has less natural lubricity than older diesel formulas. The fuel must be slick enough to protect the tightly-toleranced moving parts in the high-pressure pump and injectors. Look for fuel that meets the ASTM D6079 standard, which uses a High-Frequency Reciprocating Rig (HFRR) test to ensure a wear scar diameter of 0.02 inches (0.52 mm) or less.

Winter Operation: To prevent fuel gelling in cold weather—where paraffin waxes in diesel crystallize and clog filters—use a winter-blend diesel or an approved, alcohol-free anti-gelling additive. A clogged fuel filter in freezing temperatures can shut an engine down completely.

Diesel Exhaust Fluid (DEF): While not part of the fuel system, clean, unadulterated DEF meeting ISO 22241-1 specifications is essential. Contaminated DEF can destroy the SCR system and will cause the ECM to derate engine power, eventually leading to a no-start condition.

For more details on fuel quality, see our guide on Paccar Fuel Systems.

Biodiesel and Alternative Fuel Considerations

PACCAR approves the use of biodiesel blends up to B20 (20% biodiesel), but only if the fuel meets strict ASTM D7467 standards and comes from a BQ-9000 accredited producer. While potentially offering environmental benefits, using B6 to B20 blends requires more frequent maintenance: the fuel filter change interval is halved from 50,000 miles to 25,000 miles, and engine oil service intervals are also shortened. This is because biodiesel has a solvent effect that can loosen existing deposits in fuel tanks, leading to rapid filter clogging. It can also be less stable and more prone to water absorption, increasing the risk of microbial growth.

How the Fuel Filter and Water Separator Function

Your fuel filter and water separator module is the primary defense for your high-pressure pump and injectors. It uses multi-stage filtration, with a primary filter (often around 10-30 microns) catching larger debris and a secondary filter (as fine as 2-5 microns) trapping microscopic particles that could cause catastrophic damage.

Simultaneously, it performs water separation. Since water is denser than diesel, the separator's design encourages small water droplets to merge (coalesce) and settle in a collection bowl. Draining the water separator daily or weekly is a critical task. If allowed to accumulate, this water can cause rust and corrosion inside the fuel system and promote microbial growth (often called "algae"), which creates a sludge that clogs filters and starves the engine of fuel. Regular draining and on-schedule filter changes are cheap insurance against six-figure repair bills.

Essential Maintenance for a Healthy PX-9 Fuel System

Consistent, proactive maintenance is the key to keeping your paccar px-9 fuel system operating reliably and efficiently for hundreds of thousands of miles. Following PACCAR's recommended schedule protects your investment, prevents costly downtime, and ensures your engine performs as designed.

Component Interval Fuel Filter 50,000 miles (80,000 km) DEF Filter 200,000 miles (320,000 km) Coolant System Check Daily/Scheduled (as per manual) Air Filter Varies by condition

PACCAR's Recommended Maintenance Schedule

PACCAR provides detailed schedules based on whether your truck operates under standard or severe duty cycles. Given the nature of commercial trucking—stop-and-go driving, heavy loads, high idle time, and operating in extreme temperatures—most vehicles fall into the severe category.

The fuel filter must be changed every 50,000 miles. This isn't just a suggestion; a clogged filter forces the lift pump to work harder and can starve the high-pressure pump, leading to pressure fluctuations and power loss. This interval is reduced to 25,000 miles if you use biodiesel blends (B6-B20) due to their tendency to clean tanks and clog filters faster.

The DEF filter has a much longer service life, typically requiring replacement every 200,000 miles, to prevent debris from clogging the DEF injector.

Daily checks are your first line of defense. A quick walk-around to visually inspect for fuel leaks around lines and fittings and to drain the water separator can prevent a small issue from becoming a major roadside breakdown.

PACCAR organizes maintenance into intervals from A through H. Always refer to your specific operator's manual for the schedule that applies to your vehicle's chassis and application. You can Access PACCAR Operator's Manuals for the most current guidelines.

PACCAR Recommendations for Fuel System Cleaning

PACCAR's philosophy on fuel system cleaning is simple: prevention is the best strategy. The modern common rail system is designed to run cleanly on high-quality fuel, making most aftermarket cleaners unnecessary.

Use Quality Fuel: Your first and best line of defense is consistently using clean Ultra-Low-Sulfur Diesel (ULSD) from reputable suppliers. This fuel meets ASTM standards for cleanliness and lubricity, keeping your system clean naturally.

Avoid Unapproved Additives: PACCAR strongly advises against using aftermarket fuel additives. Many contain aggressive solvents or alcohols that can damage the sensitive non-metallic seals and O-rings in the fuel system, leading to leaks. Others can alter fuel properties in a way that interferes with the ECM's precise calibration or leaves behind deposits on injector nozzles, disrupting the spray pattern.

Change Filters Regularly: A fresh fuel filter is your system's best friend. It is the only guaranteed way to prevent contaminants from reaching and causing abrasive wear on the high-pressure pump and injectors.

In cases of severe contamination (e.g., from a bad load of fuel), professional tank and line cleaning may be required, but this should be a last resort. For reliable replacement components that meet or exceed OEM specifications, G2 Diesel Products offers a wide selection of Diesel Engine Parts to keep your PX-9 running strong.

Step-by-Step Guide: How to Prime and Bleed the PX-9 Fuel System

After changing a fuel filter or if the truck has run out of fuel, air can enter the paccar px-9 fuel system. This air gets trapped in the lines and prevents the high-pressure pump from building the pressure needed to start the engine, leading to hard starting, extended cranking, or a rough idle. Fortunately, the PX-9's electric lift pump makes priming the system a straightforward process without the need for manual hand pumps.

The electric lift pump automatically draws fuel from the tank and pushes it through the new filters, purging air from the low-pressure side of the system.

Procedure for Bleeding Air After a Filter Change

If you have air in the fuel lines, follow this simple priming procedure to get your engine started quickly:

Turn the key to the "ON" position without cranking the engine. You should hear the electric lift pump hum for about 30-60 seconds as it runs to build pressure and push air through the system.

Wait for the lift pump to stop. This indicates it has completed its priming cycle.

Repeat the process 3-5 times. Turn the key "OFF," wait about 10 seconds, and then turn it back to "ON." Each cycle pushes more fuel through the system, forcing trapped air through the return lines and back to the tank.

Attempt to start the engine. It may crank for a few seconds longer than usual or run slightly rough for a moment as the last of the air is purged from the high-pressure side.

Check for leaks. Once the engine is running smoothly, visually inspect the filter housing and any connections you touched for any signs of fuel leakage. A small leak can allow air to be sucked back into the system.

Pro Tip: To make priming faster and reduce dry cranking, you can pre-fill your new fuel filters with clean, filtered diesel before installation. Crucially, pour the clean fuel into the small outer holes of the filter, not the large center hole. This ensures the fuel is filtered before it enters the clean side of the system. If the engine still won't start after several priming cycles, re-check for leaks or a loose fitting, as even a tiny air leak on the suction side can prevent priming.

Troubleshooting Common PX-9 Fuel System Issues

Downtime is costly, but many paccar px-9 fuel system problems present clear symptoms that can lead you to a quick diagnosis. Warning lights on your dashboard, such as the "Check Engine" or "Stop Engine" lamp, are your first clue, often accompanied by Diagnostic Trouble Codes (DTCs) stored in the ECM that a technician can read.

Common symptoms pointing to a fuel system issue include loss of power, rough idling, poor fuel economy, engine stalling, and hard starting. Understanding these patterns can save significant diagnostic time. You can Find official service information for PX Engines through our technical resources.

Issue 1: Hard Start or No-Start Condition

If your PX-9 cranks but won't start, or takes an unusually long time to fire, the ECM is likely not seeing enough rail pressure to initiate injection. Consider these causes:

Clogged Fuel Filters: Severely restricted filters can starve the engine of fuel, preventing the lift pump from supplying the high-pressure pump.

Air in the System: Often occurs after a filter change or from a small leak on the suction side. The system cannot compress air to 25,000 PSI.

Weak or Failed Electric Lift Pump: If you don't hear the pump cycle when the key is turned on, it may have failed or its fuse/relay is bad. No fuel is being delivered to the high-pressure pump.

Leaking Fuel Injectors: An injector stuck open or leaking internally will bleed off rail pressure, preventing the system from reaching the minimum pressure required for starting.

Failed High-Pressure Pump: The pump may be worn and unable to generate sufficient pressure.

Faulty Rail Pressure Sensor or Regulator: If the sensor is reading incorrectly or the regulator is stuck open, the ECM may not command the pump correctly or pressure will be lost back to the tank.

Issue 2: Loss of Engine Power and Poor Performance

When your truck feels sluggish, struggles on grades, or can't reach full RPM, the fuel system is a likely culprit. The engine is not getting the fuel volume it needs under load.

Fuel Filter Restriction: This is the most common cause. A partially clogged filter may allow enough fuel for idling but restricts flow under high-power demands.

Contaminated Fuel: Water or debris in the fuel can cause misfires and damage components, leading to poor performance.

Failing High-Pressure Pump: An inability to maintain target rail pressure under load leads directly to poor injector performance and significant power loss.

Injector Malfunctions: A single clogged, sticking, or leaking injector can reduce overall engine power and efficiency.

Boost Leaks or Air System Issues: A leak in the charge air cooler or tubing can cause a loss of boost pressure, leading the ECM to reduce fueling to prevent smoke, which feels like a loss of power.

DEF System Issues / Engine Derate: Problems with DEF quality, level, or system components can trigger a severe engine derate to force the operator to seek service. The SPN 3521 FMI 18 code, for example, points to a DEF quality issue that the ECM interprets as a risk to the SCR system.

Issue 3: Rough Idle or Engine Misfire

A shaky idle or a noticeable stumble often points to an inconsistent fuel delivery to one or more cylinders.

Dirty or Failing Injectors: This is the most common cause. Contamination can cause an injector to stick, leak, or develop a poor spray pattern, leading to uneven combustion. A technician can perform a cylinder cutout test with diagnostic software to isolate the problematic cylinder.

Incorrect Fuel Pressure: Low or wildly fluctuating pressure in the common rail affects all injectors and can cause a rough run condition.

Air Leaks: Small, intermittent air bubbles being sucked into the fuel on the suction side can cause random misfires.

Water in Fuel: If water gets past the separator, it will cause a severe misfire as it passes through an injector instead of diesel fuel.

Frequently Asked Questions about the Paccar PX-9 Fuel System

Here are straightforward answers to the most common questions we receive about the paccar px-9 fuel system.

What are the symptoms of a bad fuel injector on a PX-9?

A failing fuel injector will typically cause several noticeable symptoms as it disrupts the precise fuel delivery required for smooth operation. Look out for:

Rough Idle: The engine may shake or vibrate more than usual at a standstill because one cylinder is not contributing its full share of power.

Engine Misfires: You might feel a stumble or hesitation during acceleration or under load as the faulty injector fails to deliver fuel at the right time.

Loss of Power: The truck may feel sluggish and struggle with hills or heavy loads because the engine is not producing its rated horsepower.

Increased Fuel Consumption: A faulty injector that is leaking or has a poor spray pattern can waste fuel, leading to a noticeable drop in MPG.

Black Smoke from Exhaust: This indicates unburnt, atomized fuel, often from an injector that is stuck open or not atomizing fuel correctly, leading to a rich combustion event.

Check Engine Light: The ECM is very effective at detecting injector performance issues and will store a fault code, often identifying the specific cylinder with the problem.

If you experience these symptoms, professional diagnosis is recommended. G2 Diesel Products manufactures high-quality replacement injectors to restore your PX-9's performance.

How often should I drain the water separator on my PX-9?

This simple task is one of the most critical preventative maintenance steps for your fuel system.

Best Practice: Drain the separator bowl during your daily pre-trip inspection. It only takes a few seconds.

Minimum Frequency: If daily checks aren't possible, drain it at least weekly.

This is especially important in humid climates or areas with large daily temperature swings, as more condensation can form in the fuel tank. Draining the collected water is the only way to protect your high-pressure pump and injectors from catastrophic corrosion and damage.

Can I use a fuel additive in my Paccar PX-9?

PACCAR's official stance is to avoid unapproved fuel additives. Here's what you need to know:

Standard Operation: High-quality Ultra-Low-Sulfur Diesel (ULSD) that meets ASTM standards already contains the necessary detergents and lubricants for your engine. Most aftermarket additives are unnecessary and can potentially harm sensitive seals or leave deposits on injector nozzles, disrupting the spray pattern.

Cold Weather Exception: The only time an additive is recommended is for preventing fuel gelling in extreme cold. If you use one, ensure it is alcohol-free and specifically approved for modern high-pressure common rail diesel systems.

Always follow the additive manufacturer's directions precisely. In general, relying on quality fuel and consistent maintenance is a safer and more effective strategy than using additives.

What is the operating pressure of the PX-9 common rail, and why is it so high?

The Paccar PX-9 fuel system operates at extremely high pressures, often ranging from 5,000 PSI at idle to over 25,000 PSI under full load. This immense pressure is required to properly atomize the diesel fuel. When injected into the hot, compressed air in the cylinder, the fuel must be a fine mist to ignite quickly and burn completely. Higher pressure creates smaller fuel droplets, leading to more efficient combustion, better fuel economy, more power, and lower emissions.

Can I replace just one bad injector, or should I replace them as a set?

This is a common question. While you can technically replace just the one failed injector, it's often recommended to replace them as a complete set. The reasoning is that all injectors have been operating under the same conditions for the same number of hours. If one has failed due to wear, it's highly likely the others are nearing the end of their service life as well. Replacing them all at once can prevent a repeat repair in the near future, saving on labor costs and downtime. However, if an injector fails prematurely due to a specific defect and the others are relatively new, replacing a single unit may be a reasonable choice.

Conclusion

Understanding and maintaining your paccar px-9 fuel system is fundamental to your truck's reliability, profitability, and performance. The 8.9-liter PX-9 engine is a testament to modern engineering, but its longevity and efficiency are directly tied to the health of its fuel delivery components. By committing to the three pillars of fuel system health—using high-quality ULSD, adhering to PACCAR's maintenance schedule, and following correct diagnostic procedures—you invest in thousands of miles of trouble-free operation.

We've covered the system's anatomy, how to identify symptoms, troubleshoot common issues, and perform essential maintenance. Remember that most catastrophic failures start as small, preventable problems. Catching a clogged filter, a small air leak, or water in the fuel early is the key to avoiding costly repairs and unplanned downtime. The precision components in your fuel system, from the high-pressure pump to the injectors, demand clean, water-free fuel to deliver the power and efficiency you rely on day in and day out.

At G2 Diesel Products, we know that maximizing performance and engine life is your priority. Our high-quality injectors are engineered to meet or exceed the demanding specifications of your PX-9's fuel delivery system. When you need replacement parts you can trust to restore your engine's power and efficiency, we are here to help.

Ready to ensure your PACCAR PX-9 engine gets the best? Shop for Paccar Diesel Fuel Injectors and other essential diesel engine parts with us today. Because when your livelihood depends on your truck, you deserve components that won't let you down.