How to Test Diesel Electronic Unit Injectors Like a Pro

Why Testing Diesel Electronic Unit Injectors Matters for Fleet Reliability

Getting accurate diesel electronic unit injector testing specs is crucial for maintaining peak engine performance and avoiding costly downtime. Here are the key specifications you need to know:

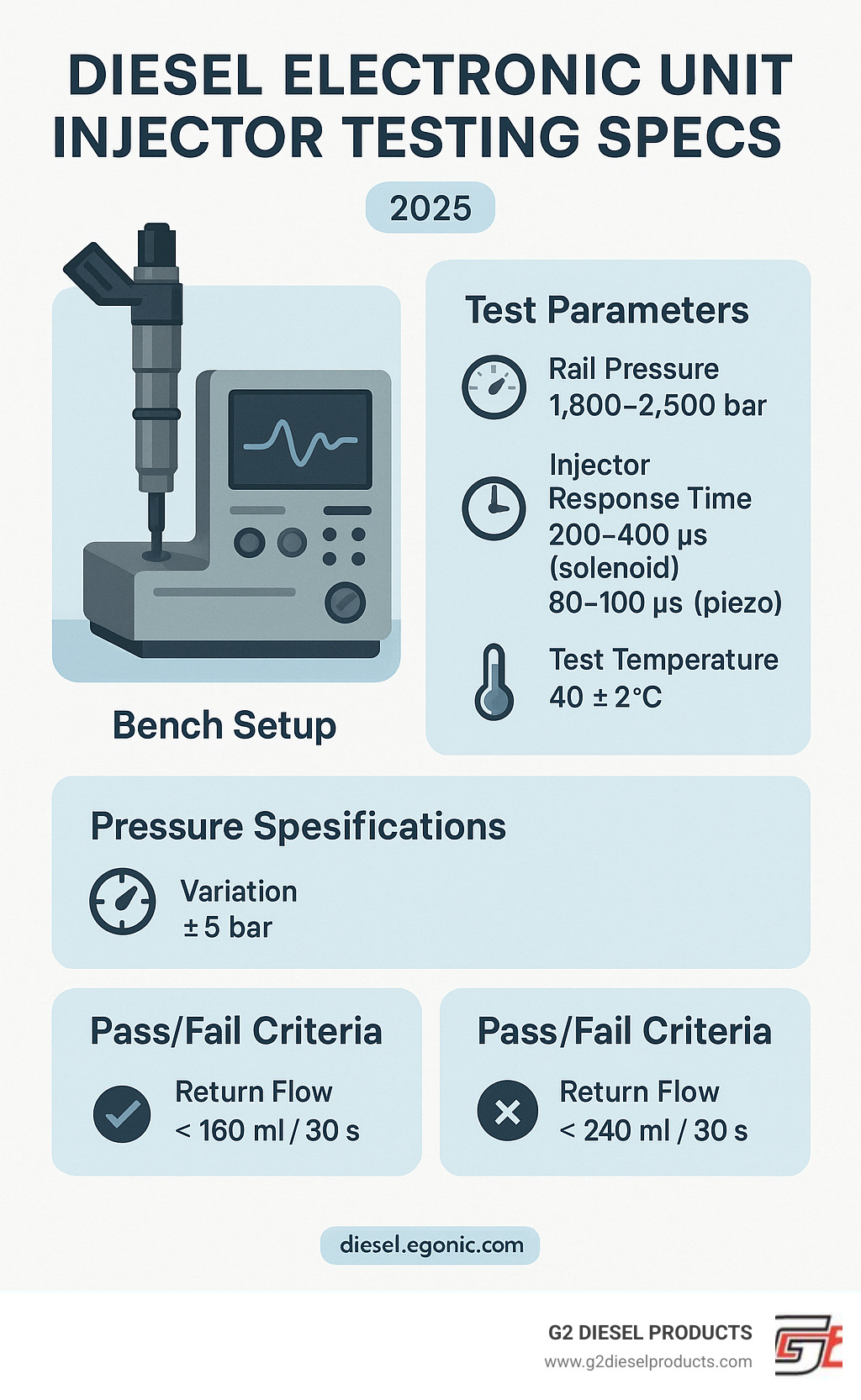

Standard Testing Parameters:

- Rail Pressure: 1,800-2,500 bar (26,000-36,000 psi)

- Injector Response Time: 200-400 microseconds (solenoid), 80-100 microseconds (piezo)

- Test Temperature: 40±2°C fuel temperature

- Return Flow: <160 ml/30 seconds (acceptable), >240 ml/30 seconds (replace)

- Coil Resistance: 2.8-3.6 Ω (varies by manufacturer)

- Delivery Volume: Varies by injector type and application

Modern diesel engines depend on precise fuel delivery to meet emissions standards and deliver reliable power. Electronic unit injectors (EUIs) operate at incredibly high pressures - up to 2,500 bar in advanced systems. When these precision components fail, your entire fleet suffers.

Professional testing ensures each injector delivers the right amount of fuel at exactly the right time. Without proper testing specs, you're essentially flying blind when diagnosing performance issues or planning maintenance schedules.

The stakes are high. A single failed injector can cause engine damage, reduce fuel economy by 10-15%, and trigger expensive emission system repairs. Fleet managers who understand testing specifications make better decisions about when to repair, remanufacture, or replace injectors.

Understanding Electronic Unit Injectors (EUI) Fundamentals

Electronic unit injectors combine mechanical pressure generation with electronic control precision. A mechanical cam creates intense fuel pressure while an electronically controlled solenoid valve determines exactly when that pressurized fuel gets injected.

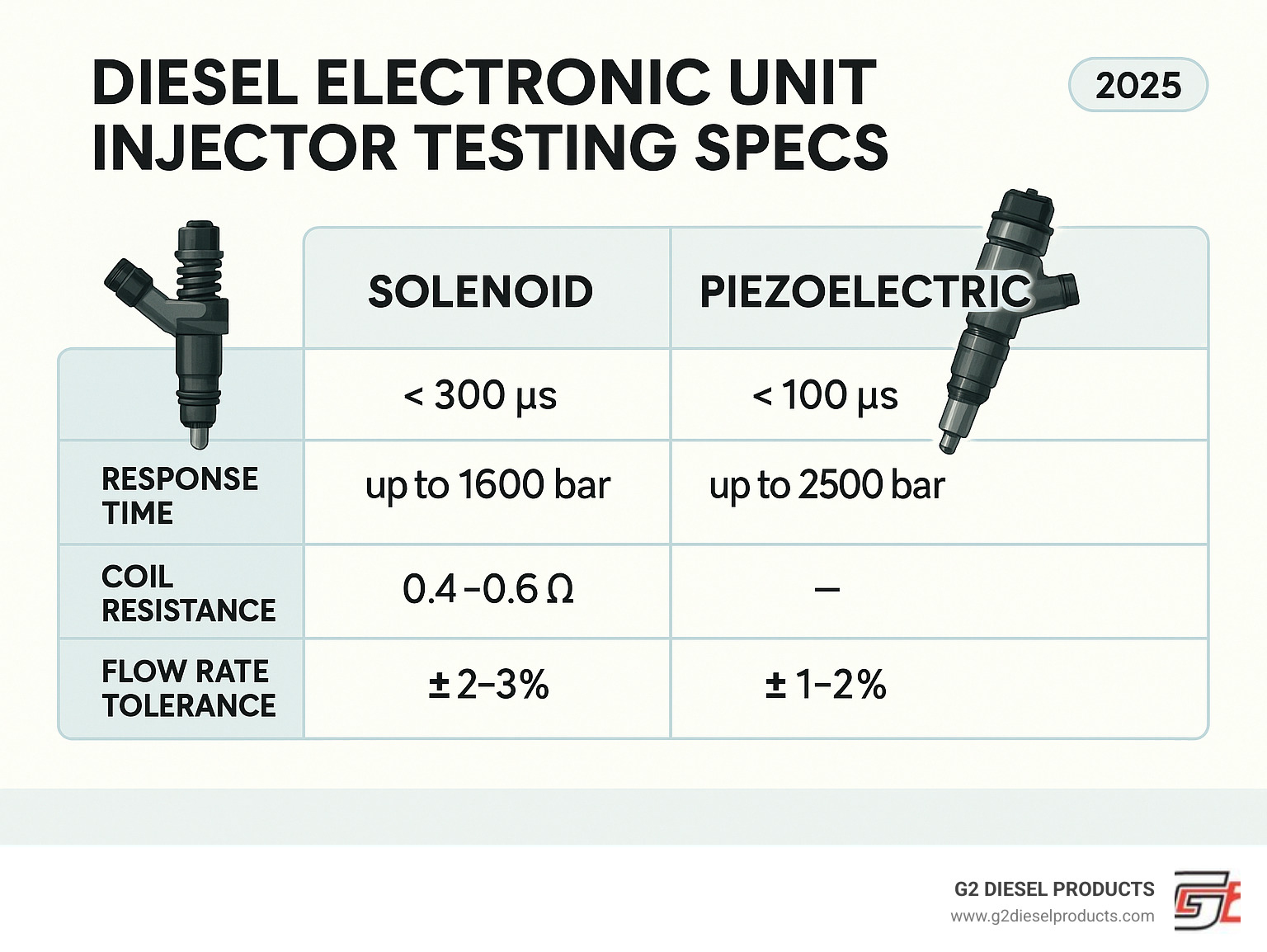

Standard EUIs generate injection pressures up to 1,800 bar (26,000 psi), with advanced systems reaching 2,500 bar (36,000 psi). This extreme pressure creates fuel droplets smaller than 20 microns for optimal combustion efficiency.

The response time varies dramatically depending on the injector technology. Solenoid EUIs typically respond in 200-400 microseconds, while piezoelectric systems achieve 80-100 microseconds. This speed is crucial for meeting today's strict emissions standards and diesel electronic unit injector testing specs.

How Electronic Unit Injector Works

Key Components & Functions

The plunger and barrel assembly serves as the heart of pressure generation with tolerances measured in microns. The spill valve acts as the electronic gatekeeper, controlled by the solenoid. The solenoid coil provides electromagnetic force with resistance typically ranging from 2.8-3.6 Ω.

The nozzle assembly contains the needle valve and spray holes that determine fuel atomization quality. Seals and O-rings prevent leaks under extreme pressure cycling. Cooling and lubrication circuits use fuel circulation to prevent component seizure.

Operating Pressures & Response Times

Baseline pressure for most standard EUIs sits at 1,800 bar (26,000 psi), while advanced systems push up to 2,500 bar (36,000 psi). HEUI systems use engine oil pressure multiplied through a 7:1 intensifier ratio to achieve injection pressures of 21,000-26,000 psi.

Common Injector Architectures

Solenoid-actuated EUIs represent the most common type, using electromagnetic coils to control the spill valve. HEUI systems use high-pressure engine oil to actuate the injector plunger. Piezoelectric EUIs use piezoelectric crystals for ultra-fast response. Smart EUIs feature built-in sensors providing real-time feedback to the ECM.

Diesel Electronic Unit Injector Testing Specs (Primary Keyword)

When it comes to diesel electronic unit injector testing specs, precision is everything. Modern test benches maintain rail pressures up to 2,200 bar with precision tolerances of just ±5 bar.

The foundation of reliable testing starts with understanding your bench operating parameters. Rail pressure capability should range from 0-2,200 bar (up to 32,000 psi). Fuel temperature control is critical—maintaining 40±2°C ensures consistent, repeatable results. Fuel filtration must be less than 5 μm to prevent contamination.

Your critical test measurements include delivery volume per injection cycle, return flow rate testing, injector response time measured in milliseconds, and coil resistance and inductance measurements. Professional test benches come loaded with more than 7,000 test plans covering different brands and models.

Unit Injector and Unit Pump Systems

Standard Parameters & Acceptable Ranges

Delivery volume typically falls between 50-200 ml per 1000 strokes, depending on the injector size. Return flow testing breakdown: less than 160 ml per 30 seconds means good condition, 160-240 ml is borderline, more than 240 ml means replacement time.

Balance rate measurements within ±2.5 MM3 are in specification, ±4 MM3 is borderline, and greater than ±4 MM3 is out of spec. Coil resistance for most solenoid injectors should fall between 2.8-3.6 Ω.

OEM-Specific Variations

Injector coding (trim codes) directly impacts testing procedures. Each injector receives a unique code representing its individual flow characteristics. Different manufacturers use entirely different coding systems including IMA coding, C2i and C3i coding protocols, and QR coding systems.

Diesel Injector Testing Services

Impact of Contamination on Test Results

Water contamination creates internal corrosion and affects electrical resistance measurements. Particulate contamination larger than 5 μm causes accelerated wear. Fuel quality impacts test repeatability and accuracy. Preventive filtration and regular maintenance prevent contamination problems.

Step-by-Step Bench Testing Procedure

Getting your diesel electronic unit injector testing specs right starts with proper bench setup. Modern test benches need 15 kW minimum power, 0-4,500 RPM rotation speed range, and 0-2,200 bar rail pressure capability with ±5 bar precision.

Temperature control at 40±2°C fuel temperature ensures repeatable results. Safety comes first when working with high-pressure fuel systems - always wear safety glasses and protective clothing.

Preparing Injectors for the Bench

Clean handling prevents contamination that can skew results. Ultrasonic cleaning removes deposits and contaminants. Visual inspection catches cracks, corrosion, and damage. Seal replacement happens during every testing cycle.

Diesel Fuel Injector Cleaning Service

Running the Core Tests

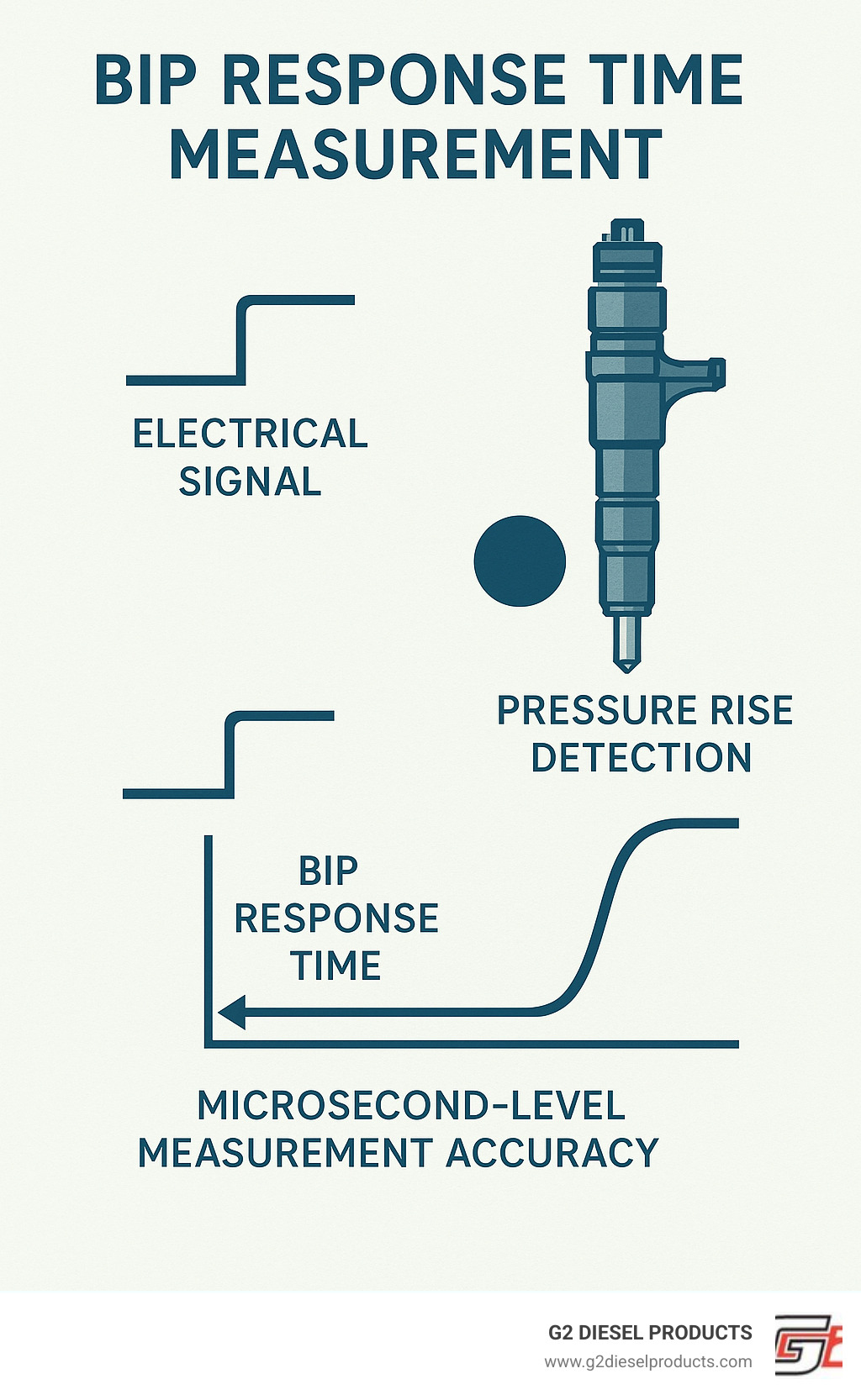

Pre-test leak checking prevents wasted time. Static flow testing measures basic delivery performance. Dynamic flow testing shows real-world performance. Injector response time measurement uses BIP (Beginning of Injection Pulse) function. Spray pattern analysis reveals atomization quality problems.

Post-Test Data Analysis & Pass/Fail Criteria

Compare everything to manufacturer specifications. Pass/fail criteria should be clearly defined: Flow rate within ±5% of specification is acceptable. Return flow less than 160 ml/30 seconds indicates good internal sealing. Trim code generation calculates individual injector characteristics for ECM programming.

Interpreting Results & Troubleshooting Common Failures

When you pull diesel electronic unit injector testing specs from your test bench, each pattern tells a story about component condition.

Seized plunger failures show delivery volume dropping to nearly zero with electrical current spikes. Broken spring issues create erratic delivery volumes and unpredictable spray patterns. Cracked body problems announce themselves with external leaks during pressure testing.

Electrical failures show up in resistance measurements - open circuits read infinite resistance while short circuits drop to zero. High return flow over 160 ml in 30 seconds indicates internal wear, with readings above 240 ml requiring replacement.

Balance rate testing identifies performance variations between injectors. Readings within ±2.5 MM3 are in specification, while ±2.5-4 MM3 falls into borderline territory, and anything beyond ±4 MM3 is out of spec.

When Results Are Out of Spec

Making the remanufacturing versus replacement decision requires weighing injector age, service history, and cost factors. Component salvage evaluation determines which parts can be reused. Re-testing after repair is critical - never assume the fix worked without verification.

Preventive maintenance scheduling based on test data helps prevent failures. Regular testing every 100,000 miles or annually prevents middle-of-nowhere breakdowns.

Latest Advancements in EUI Testing Technology

AI-powered diagnostics can spot patterns human technicians might miss. Remote capabilities enable cloud-based data storage and automatic software updates. Advanced measurement systems capture data at microsecond speeds with real-time curve display.

latest research on diesel injection pressures

Frequently Asked Questions about Diesel Electronic Unit Injector Testing Specs

What bench pressure should I set for modern solenoid EUIs?

For most modern solenoid EUIs, 1,800 bar (26,000 psi) is your standard test pressure. Advanced systems require up to 2,200 bar for accurate testing. Always check the specific OEM test plan for your injector model. Maintain ±5 bar precision during testing with temperature control at 40±2°C.

HEUI systems work differently, using oil pressure multiplied through a 7:1 ratio, so 500-3,000 psi oil pressure becomes 21,000-26,000 psi injection pressure.

How do I know if injector return-flow is excessive?

The magic numbers for diesel electronic unit injector testing specs are: Good injectors return less than 160 ml in 30 seconds. Borderline injectors return 160-240 ml. Replace immediately if you see more than 240 ml in 30 seconds.

Run your test at 1,400 bar (20,000 psi) rail pressure with the engine at 1,200 RPM and coolant temperature above 82°C. Individual injector return shouldn't exceed 40 ml per 10 seconds.

How often should fleet EUIs be bench-tested?

Highway trucks can go 100,000 miles or annually between tests. Severe duty applications need attention every 50,000 miles or twice yearly. Critical applications should get checked every 25,000 miles or quarterly.

Smart fleet managers using condition-based maintenance report 15-20% reduction in injector-related downtime. A $200 injector test can save you from a $5,000 engine repair.

Conclusion

Mastering diesel electronic unit injector testing specs transforms fleet maintenance. Understanding that proper testing requires precise pressures between 1,800-2,500 bar and controlled temperatures at 40±2°C equips you to make informed decisions that keep trucks running smoothly.

Modern test benches with ±5 bar precision tolerances and over 7,000 test plans ensure accurate diagnostics. Whether dealing with solenoid EUIs responding in 200-400 microseconds or advanced piezoelectric systems hitting 80-100 microseconds, having the right specifications makes all the difference.

Fleet managers implementing comprehensive testing programs consistently report 15-20% reduction in injector-related downtime. When you maintain return flow below 160 ml per 30 seconds and ensure delivery volumes stay within ±5% of specification, you're protecting entire engines from costly damage.

Regular testing helps meet emissions compliance requirements while maintaining fuel efficiency. Preventive maintenance scheduling based on actual test data beats guesswork every time, optimizing maintenance budgets while preventing unexpected failures.

At G2 Diesel Products, we've seen how proper testing transforms fleet operations. Our experience with Volvo, Mack, Kenworth, and Paccar applications has taught us that quality testing is the foundation of reliable performance.

Every properly tested injector contributes to cleaner emissions, better fuel economy, and extended engine life. When you invest in understanding and implementing proper diesel electronic unit injector testing specs, you're investing in the long-term success of your fleet.

More info about Diesel Injector Testing Services