Local Diesel Injector Services That Won't Inject Pain into Your Wallet

Why Your Fleet's Performance Depends on Clean Diesel Injectors

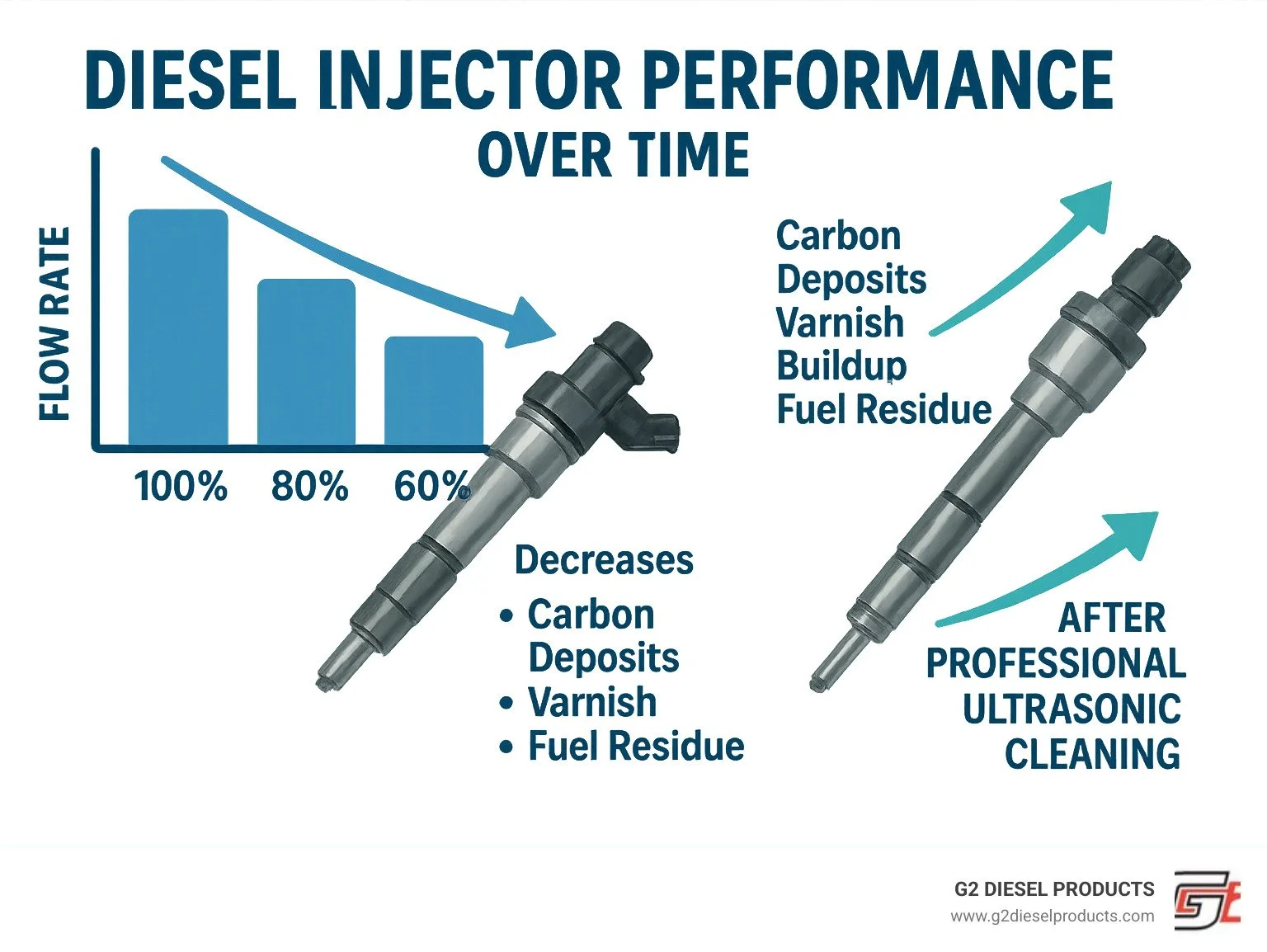

Diesel fuel injector cleaning service is essential for maintaining optimal engine performance and fuel economy. Professional cleaning can restore up to 95% of original injector performance, eliminating rough idle, poor acceleration, and excessive fuel consumption that plague dirty injectors.

Quick Service Options:

Professional ultrasonic cleaning: $20-30 per injector, 24-48 hour turnaround

On-car chemical cleaning: Lower cost but limited effectiveness

Off-car bench service: Complete flow testing and seal replacement

Recommended interval: Every 15,000-30,000 miles for fleet vehicles

Modern diesel engines rely on precise fuel atomization to meet emissions standards and deliver maximum power. When injectors become clogged with carbon deposits, varnish, and fuel residue, spray patterns distort and combustion suffers.

Fleet managers like Frank know that dirty injectors cost money. Poor fuel atomization leads to:

Reduced fuel economy

Increased emissions

Rough engine operation

Premature component wear

Professional cleaning services use heated ultrasonic baths and specialized equipment to remove deposits that simple fuel additives can't touch. The process involves flow testing before and after cleaning, ensuring injectors meet factory specifications.

One forum user learned this lesson the hard way when a dealer-recommended cleaning service went wrong, causing engine damage. This highlights why choosing the right service provider matters.

Why Clean Diesel Fuel Injectors Matters

Think of your diesel injectors as tiny precision instruments that need to spray fuel at exactly the right angle and pressure thousands of times per minute. When they're clean, everything runs smoothly. When they're dirty? Well, that's when your fuel bills start climbing and your engine starts acting cranky.

Carbon deposits are the main troublemakers here. These microscopic particles love to stick to injector nozzles, messing up the precise spray patterns that engineers spent years perfecting. When that happens, fuel and air don't mix properly, leading to incomplete combustion and wasted energy. It's like trying to paint with a clogged spray gun – you're not getting the coverage you need.

The ripple effects go far beyond just losing power. Poor combustion cranks up your emissions significantly, which means more frequent DPF regenerations and potentially failing emissions tests. Nobody wants that headache, especially when you're trying to keep a fleet running smoothly.

Your fuel economy takes a serious hit too. Spray-pattern distortion from dirty injectors can slash fuel efficiency by 10-15%. For high-mileage trucks, that's real money walking out the door every month. Plus, when combustion isn't complete, unburned fuel washes oil from cylinder walls and contaminates your crankcase oil, accelerating wear on expensive engine components.

The good news? Regular diesel fuel injector cleaning service can prevent most of these problems and restore your engine's original performance and MPG. Clean injectors mean better engine longevity, lower emissions, and more money staying in your pocket where it belongs.

More info about Diesel Fuel Injector Cleaner

How Injectors Become Clogged

Modern ultra-low-sulfur fuel is great for the environment, but it's created some new challenges for diesel engines. The old high-sulfur fuel actually had natural cleaning properties that helped keep injectors cleaner. Today's cleaner fuel relies heavily on additives to do what sulfur used to do naturally.

Those fuel additives serve important purposes – they prevent gelling, fight corrosion, and kill harmful microbes. But over time, additive residue builds up inside your injectors like soap scum in a shower. Even the highest quality fuel contains these necessary chemicals that gradually accumulate.

Varnish formation is another sneaky problem, especially if your equipment sits idle for extended periods. Heat cooks stagnant fuel into a sticky coating that can completely block injector passages. We've seen perfectly good injectors ruined after just one season of improper storage.

Rust particles find their way into fuel systems through contaminated tanks, corroded lines, or water infiltration. These metallic particles are particularly nasty because they're abrasive and can permanently damage precision-machined surfaces.

Bio-diesel gels present their own unique challenges. While environmentally friendly, biodiesel can gel at higher temperatures and supports microbial growth that creates biofilms. These organisms love to set up shop in your fuel system, creating clogs that require specialized cleaning.

Benefits of Regular Cleaning

Professional cleaning delivers results you can actually measure. Industry testing shows that properly serviced injectors can achieve 95% flow recovery, essentially bringing aged injectors back to near-new performance levels.

Smoother idle is usually the first improvement you'll notice. Clean injectors deliver consistent fuel metering across all cylinders, eliminating that rough, uneven idle that makes your truck sound like it needs coffee in the morning. This improvement is especially dramatic in high-mileage engines with significant deposit buildup.

Power restoration can be impressive too. We've seen cleaning restore 15-20% of lost horsepower in severely clogged engines. That means better acceleration, improved hill-climbing ability, and overall better drivability that makes your job easier and safer.

Fewer regens save both time and fuel. Clean injectors promote complete combustion, producing fewer particulates that clog your DPF. This can cut regeneration cycles by 30-50%, reducing downtime and keeping you productive.

Extended injector life represents serious cost savings. Professional cleaning with fresh seals can add 50,000-100,000 miles to injector service life, delaying expensive replacements. For fleet operators, those savings add up quickly across multiple vehicles.

Spotting Trouble: Symptoms Your Injectors Need Service

Your truck usually tells you when something's wrong – you just need to know how to listen. After years of working with diesel engines, we've learned that injectors rarely fail without warning. They give you plenty of hints along the way.

Rough idle is typically the first red flag. When you're sitting at a traffic light and your truck feels like it's doing a little dance, that's often dirty injectors talking. Clean injectors deliver fuel like clockwork to each cylinder. Dirty ones? They're more like that friend who's always late – some cylinders get fuel on time, others don't.

Hard starting becomes your morning nemesis, especially when it's cold outside. You turn the key, and instead of that satisfying diesel rumble, you get extended cranking that makes you wonder if today's the day your battery gives up. Clean injectors create a fine fuel mist that ignites easily. Clogged injectors struggle to atomize fuel properly, making your engine work harder just to wake up.

Engine misfires feel like someone's gently tapping the brakes while you're trying to accelerate. It's that subtle stumbling sensation that makes you think, "That didn't feel right." When injectors can't deliver enough fuel during high-demand situations, cylinders start skipping beats like a nervous drummer.

Black smoke rolling from your exhaust stack tells everyone behind you that something's not burning right. While a little puff during hard acceleration is normal for diesels, thick black clouds mean your injectors aren't creating the spray patterns needed for clean combustion. It's basically unburned fuel saying hello to the atmosphere.

High fuel consumption sneaks up on you gradually. You might not notice it week to week, but when you look at your fuel records over a few months, the numbers don't lie. If your truck's drinking more fuel without hauling heavier loads or changing routes, your injectors might be the culprits.

Check engine lights are your truck's way of waving a flag and saying, "Hey, pay attention!" Modern engines are smart enough to detect when injectors aren't performing properly. They monitor flow rates, response times, and balance between cylinders. When that orange light appears with injector-related codes, it's time to schedule a diesel fuel injector cleaning service.

When to Schedule a Diesel Fuel Injector Cleaning Service

Smart fleet managers don't wait for problems – they prevent them. We've found that scheduling diesel fuel injector cleaning service every 15,000 to 30,000 miles keeps most trucks running smoothly, but your specific situation might call for different timing.

Severe duty cycles accelerate the cleaning timeline significantly. If your trucks spend their days in stop-and-go city traffic, idling at job sites, or making short runs that never let the engine fully warm up, you're looking at the shorter end of that range. Construction equipment and delivery trucks often need attention every 15,000 miles because they rarely get those long highway runs that help keep injectors clean.

Fuel quality issues can throw your maintenance schedule out the window entirely. Maybe you filled up at a questionable truck stop, or water got into your fuel system during a storm. Perhaps you've noticed your fuel looking cloudy or smelling off. When fuel quality is suspect, don't wait for your scheduled maintenance – get those injectors checked immediately.

Seasonal storage creates its own set of challenges. Equipment that sits for months develops varnish and gum deposits faster than you'd expect. If your trucks or equipment hibernate during certain seasons, plan for injector service before storage and inspection when you bring them back to life.

The bottom line? Performance changes should never be ignored. If your truck isn't pulling like it used to, if fuel economy is sliding, or if that smooth idle has turned rough, don't wait for your next scheduled maintenance. Early intervention with professional cleaning often prevents those expensive injector replacements that nobody wants to budget for.

Diesel Fuel Injector Cleaning Service: Professional Methods & Workflow

When your injectors need professional attention, understanding what happens during a diesel fuel injector cleaning service helps you choose the right provider and know what to expect. We've seen too many truck owners get burned by shops that cut corners or don't have proper equipment.

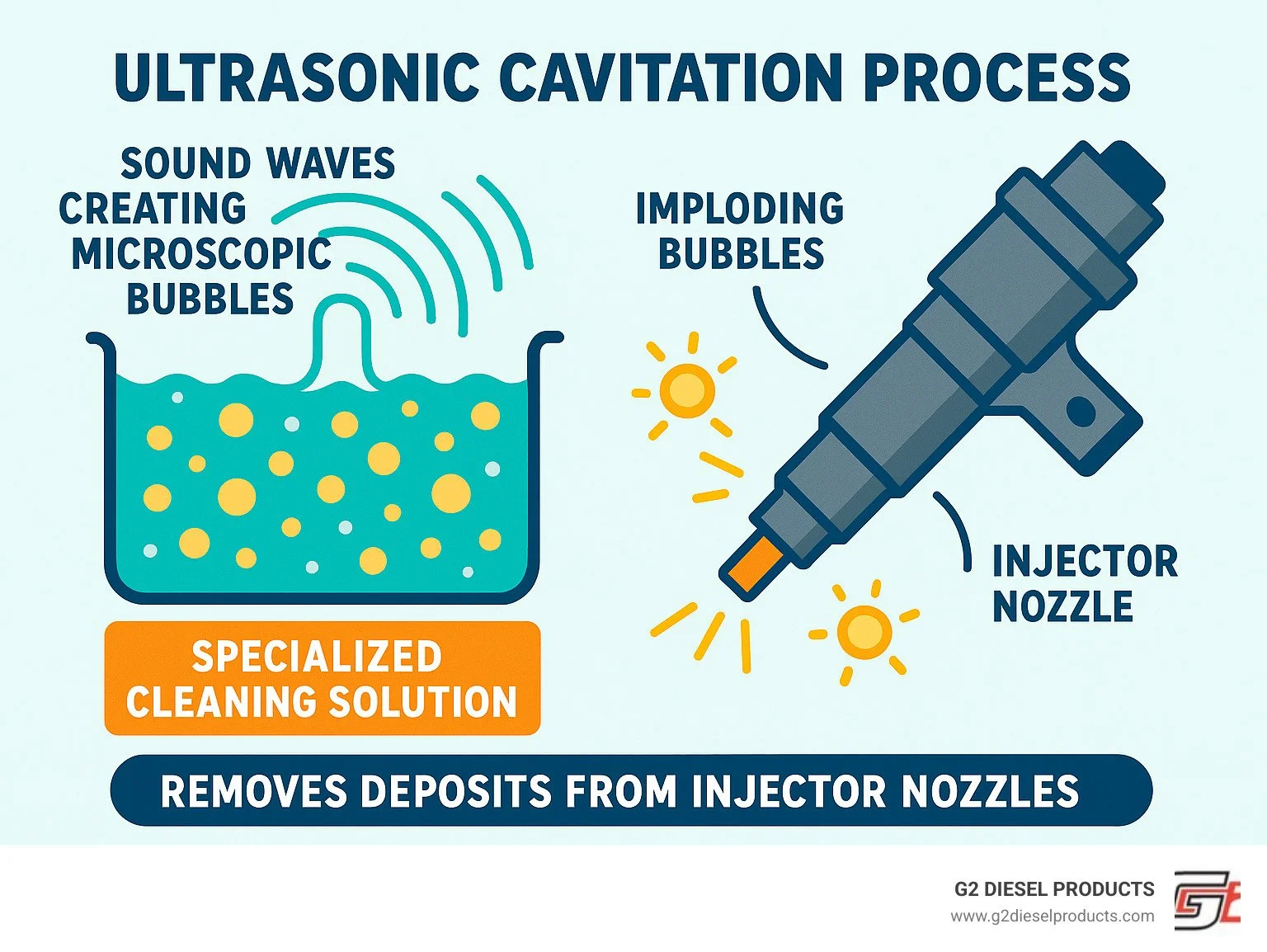

The heart of professional cleaning is the ultrasonic bath process. Think of it like a microscopic pressure washer that reaches places no brush or chemical can touch. High-frequency sound waves create millions of tiny bubbles in heated cleaning solution. When these bubbles collapse, they generate incredible cleaning force that blasts away even the most stubborn carbon deposits.

But ultrasonic cleaning is just the beginning. Back-flushing removes all the loosened debris that the sound waves dislodged. Many shops skip this step to save time, but it's like washing dishes without rinsing – you're leaving contamination behind.

Flow bench testing separates the pros from the pretenders. Real testing equipment measures exactly how much fuel each injector flows and documents the spray pattern quality. You'll get a data sheet showing before and after results, proving the cleaning actually worked.

Smart shops always replace seals during the process. Those tiny O-rings and gaskets get brittle over time, and removing injectors often damages them. Fresh seals prevent costly leaks and ensure your injectors seat properly when reinstalled.

Most professional services complete the entire process in 24-48 hours, including all testing and documentation. That's pretty impressive when you consider how thorough the process is.

Download and print our Injector Service Form

Here's how different cleaning methods stack up:

Cleaning Method Cost Range Effectiveness Downtime Testing Included On-Car Chemical Lower 60-70% 2-4 hours Limited Off-Car Ultrasonic Higher 90-95% 24-48 hours Complete DIY Additives Lowest 30-50% None None

Ultrasonic vs Chemical Diesel Fuel Injector Cleaning Service

The difference between ultrasonic and chemical cleaning is like comparing a power washer to a garden hose. Both use water, but the results are dramatically different.

Ultrasonic cavitation creates forces exceeding 10,000 PSI in spaces smaller than a human hair. Those microscopic bubbles implode with incredible violence, literally tearing deposits away from injector surfaces. It's the only method that can reach into the tiniest passages that control spray pattern quality.

Professional shops heat their cleaning solution to 140-160°F because warm solvents work better. The combination of heat, ultrasonic energy, and specialized chemicals creates the perfect storm for deposit removal. It's like the difference between washing dishes in hot versus cold water.

During cleaning, technicians pulse the injectors 25,000-30,000 times while they're submerged. This opens and closes the pintle valve repeatedly, ensuring every internal surface gets exposed to the cleaning action. Static soaking just can't match this thorough approach.

Chemical-only systems rely on solvents to dissolve deposits, but they lack the mechanical scrubbing action of ultrasonics. While cheaper, they typically restore only 60-70% of original performance compared to 90-95% for ultrasonic methods.

Modern eco-friendly cleaning fluids prove you don't need harsh chemicals to get excellent results. These biodegradable solutions clean effectively while protecting both technicians and the environment. Nobody wants to create hazardous waste just to clean injectors.

Typical Diesel Fuel Injector Cleaning Service Timeline & Turnaround

Knowing the cleaning timeline helps you plan downtime and avoid nasty surprises. Good shops follow proven procedures that balance thoroughness with reasonable turnaround times.

Initial testing comes first, measuring flow rates, spray patterns, and electrical characteristics before any cleaning begins. This baseline data shows which injectors need help and identifies any that are beyond saving. You don't want to waste money cleaning an injector that should be replaced.

The actual cleaning cycle takes 4-6 hours for most injectors. Heavily contaminated units might need multiple cycles to get fully clean. Shops that rush this process are basically stealing your money – proper cleaning can't be hurried.

Post-cleaning verification proves the work was successful. Technicians re-measure everything they tested initially, documenting the improvement and ensuring injectors meet factory specifications. Only injectors that pass these tests should go back in your engine.

Careful packaging and shipping protect your investment during transit. Professional services use proper packaging and expedited shipping to minimize total turnaround time. Most provide tracking information so you know exactly when to expect your injectors back.

Total turnaround typically runs 24-48 hours excluding shipping time. Local shops might offer same-day service for emergencies, though this usually requires advance scheduling and costs extra.

On-Car vs Off-Car Cleaning Explained

The choice between on-car and off-car cleaning often comes down to convenience versus quality. While on-car cleaning sounds appealing, the limitations are significant.

On-car chemical cleaning connects pressurized solvent systems to your fuel rail while the engine runs. It's quick and convenient, but the cleaning solution can't reach all internal passages. Think of it like trying to clean a straw by pouring soap down one end – some areas just won't get clean.

Hydrolock risk makes on-car cleaning genuinely dangerous. If cleaning fluid gets into cylinders, you're looking at catastrophic engine damage. We've heard horror stories of engines requiring complete replacement after cleaning fluid caused hydrolock. That's an expensive way to clean injectors.

Off-car bench service gives technicians complete access to injector internals. Removed injectors can be thoroughly cleaned, tested, and inspected without any risk to your engine. It's more work upfront but delivers far better results.

Parts inspection during off-car service catches problems before they cause failures. Technicians can examine pintle valves, filter baskets, and other internal components, replacing worn parts to ensure reliable operation. This preventive approach saves money long-term.

Filter basket replacement is only possible with off-car service. These internal screens trap contaminants but get clogged over time. Replacing them during cleaning ensures maximum flow capacity and prevents rapid re-contamination.

Injector Types & Special Considerations

Not all injectors are created equal, and different types require specialized knowledge and equipment. Understanding your injector type helps ensure you choose a qualified service provider.

Common rail injectors are the most complex, operating at pressures exceeding 30,000 PSI with sophisticated electronic controls. These high-tech units need specialized equipment for proper testing and calibration. Not every shop can handle them properly.

Electronic unit injectors combine injection pump and injector functions in one unit. Cleaning these requires understanding both hydraulic and electronic systems. The process must address fuel passages and electronic components without damaging sensitive circuits.

Mechanical injectors use simpler spring-loaded designs but still need proper procedures. These workhorses are common in older engines and marine applications. They're generally tougher but can suffer from stuck valves if deposits accumulate.

Marine injectors face unique challenges from saltwater exposure and extended idle periods. Corrosion and varnish formation happen faster in marine environments, requiring specialized cleaning solutions and procedures. Many marine units also operate at different pressures than automotive injectors.

Industrial injectors often work in harsh conditions with extended service intervals. Construction equipment, generators, and stationary engines accumulate severe deposits due to poor fuel quality or continuous operation. These applications often need more aggressive cleaning procedures.

More info about Common Rail Injectors

Budget & Value: What Does Local Cleaning Cost?

Let's talk numbers – because when it comes to diesel fuel injector cleaning service, understanding costs helps you make smart maintenance decisions that protect your bottom line.

Professional cleaning delivers incredible value compared to replacement. While new injectors can cost hundreds or even thousands of dollars each, professional restoration costs a fraction of that amount. You're essentially getting near-new performance at a significant discount.

Most professional services price their work per injector, with volume discounts making fleet maintenance more budget-friendly. When you bring in a complete set, many providers offer reduced pricing that recognizes the efficiency of processing multiple units together. These savings can add up quickly for fleet operators managing several vehicles.

Warranty coverage separates quality services from budget operations. Reputable providers stand behind their work with meaningful guarantees – typically covering their restoration for a full year. The best services even offer no-charge policies if they can't restore your injectors to acceptable performance levels.

Watch out for hidden fees that can surprise you at billing time. Always ask what's included upfront. Some services charge separately for flow testing, seal replacement, or detailed reporting – services that should be standard. Others add expedited processing fees or special handling charges that weren't mentioned initially.

Shipping costs affect your total investment, especially if you're using a distant provider. Factor in both directions when comparing services. Some providers offset this with free return shipping or flat-rate programs that make budgeting easier.

DIY Kits vs Professional Shops

The temptation to save money with do-it-yourself solutions is understandable, but the reality rarely matches the promise. Tank additives represent the most basic approach – they're useful for ongoing maintenance but struggle with serious contamination that's already built up.

These fuel-borne cleaners face limited reach challenges. They can only clean surfaces that fuel naturally contacts during operation. Compare this to ultrasonic cleaning that creates cavitation bubbles reaching into microscopic passages that determine spray quality. It's like trying to clean a clogged drain with soap instead of a drain snake.

The biggest problem with DIY approaches? No flow data to prove they worked. Without before-and-after testing, you're flying blind. Professional services provide quantitative proof of improvement – actual numbers showing restored flow rates and spray patterns.

Safety hazards accompany many DIY cleaning methods. Pressurized systems and chemical solvents pose real risks to untrained users. We've heard stories of damaged injectors and dangerous situations when people attempt procedures without proper equipment or training.

Warranty risks add another layer of concern. Some manufacturers require professional service for warranty compliance. Using unapproved methods could void coverage on expensive injectors that still have warranty protection remaining.

More info about Diesel Injector Repair Kits

Choosing a Reputable Service Provider

Finding the right diesel fuel injector cleaning service provider protects your investment and ensures quality results. Not all cleaning services are created equal, and choosing poorly can cost you more than the original problem.

Certified technicians make all the difference. Look for providers with factory training or industry certifications. Experienced technicians understand the subtle differences between injector types and can spot problems that automated equipment might miss. They know when an injector needs replacement versus restoration.

Flow bench proof separates professional operations from basic cleaning shops. Any reputable provider should gladly show you their testing equipment and explain their procedures. If they can't demonstrate flow testing capability, keep looking. This equipment represents a substantial investment that distinguishes real professionals from operators just running parts through cleaning tanks.

Customer reviews tell the real story about service quality. Check online feedback, ask for references, and talk to other fleet operators about their experiences. Pay attention to patterns – consistent praise for turnaround times and communication indicates reliable service, while recurring complaints about delays or poor results reveal potential problems.

Performance guarantees protect your investment while demonstrating the provider's confidence in their work. The best services guarantee specific performance improvements or offer refunds for injectors they cannot restore. These commitments indicate they have proven procedures and stand behind their results.

Turnaround pledges help you plan maintenance schedules effectively. Reliable services provide realistic timeframes and consistently meet their commitments. Frequent delays or missed deadlines suggest operational issues that could leave your vehicles down longer than planned.

Frequently Asked Questions about Diesel Injector Care

How often should I book a diesel fuel injector cleaning service?

The answer isn't one-size-fits-all, but we've found that most diesel engines benefit from diesel fuel injector cleaning service every 15,000-30,000 miles. Think of it like changing your oil – the right interval depends on how hard you work your engine.

If your truck spends its days in stop-and-go traffic, idling at job sites, or making short delivery runs around the city, you're looking at the shorter end of that range. These conditions don't let your engine get hot enough to burn off deposits naturally, so they build up faster. We typically recommend 15,000-mile intervals for these tough jobs.

Highway haulers have it easier. If you're running consistent speeds on the interstate, your engine stays hot and burns cleaner. You can often stretch cleaning intervals to 30,000 miles without problems. Just keep an eye on your fuel economy – it's usually the first thing to suffer when injectors start getting dirty.

Fuel quality plays a huge role too. If you're buying fuel from reputable truck stops with good turnover, you can probably stick to standard intervals. But if you're forced to use questionable fuel or you've had water contamination issues, don't wait for the calendar to tell you it's time.

Can every injector be restored or will I need replacements?

Here's the good news: professional cleaning can bring about 95% of injectors back to life. But just like that old work boot with a hole worn clear through the sole, some injectors are beyond saving.

The biggest factor is physical damage. If metal particles have scored the precision surfaces inside your injectors, or if extreme heat has warped components, no amount of cleaning will fix that. It's like trying to clean a scratched CD – the damage goes deeper than surface dirt.

Age and mileage definitely matter, but they're not automatic disqualifiers. We've seen 500,000-mile injectors clean up beautifully, and we've seen relatively low-mileage ones that were ruined by poor maintenance. The key is whether the internal wear surfaces are still within specifications.

Sometimes it comes down to economics. If an injector needs major internal repairs on top of cleaning, replacement might make more sense. Any reputable service will give you an honest assessment rather than trying to clean something that's better off replaced.

The electrical side can fail too, especially on newer common rail systems. If the solenoid coils are damaged or the control circuits have failed, cleaning won't help. But mechanical wear is usually the bigger concern with high-mileage injectors.

What should I do before shipping my injectors for cleaning?

Getting your injectors ready for shipping is pretty straightforward, but doing it right prevents headaches later. Think of it like packing a birthday present for your grandmother – you want it to arrive in perfect condition.

Packaging is critical. Wrap each injector individually in bubble wrap or foam padding. These are precision instruments, and even small dings can affect performance. Never let injectors rattle around loose in a box together – they'll beat each other up during shipping.

Don't forget the small stuff that matters. Include all the O-rings, seals, and mounting hardware that came off with the injectors. Even if the service replaces seals (which most do), having the originals ensures proper fit. Those little filter baskets are especially important – they tell the technician a lot about what's been happening in your fuel system.

Paperwork saves time and prevents mistakes. Fill out service forms completely and accurately. Include your contact information, vehicle details, and any specific symptoms you've noticed. If your truck has been hard starting or smoking, mention it – this information helps technicians understand what they're dealing with.

Choose tracked, insured shipping for your own peace of mind. These injectors represent a significant investment, and stuff does occasionally get lost in transit. Priority mail with insurance usually offers the best balance of speed and protection.

If you need expedited service, say so upfront when you arrange the cleaning. Most shops can accommodate rush jobs, but they need advance notice to schedule properly. Clear communication prevents the "I needed these back yesterday" phone calls that stress everyone out.

Conclusion

Professional diesel fuel injector cleaning service delivers impressive results that make it one of the smartest maintenance investments you can make. When you consider that cleaning can restore up to 95% of your injectors' original performance at a fraction of replacement cost, the value becomes crystal clear.

The ripple effects of clean injectors extend far beyond the immediate performance boost. Your engine breathes easier with restored power flowing smoothly through every cylinder. Fuel economy improves noticeably, putting money back in your pocket with every mile. And those annoying regeneration cycles? They happen far less frequently when your injectors are atomizing fuel properly.

Lower emissions aren't just good for the environment – they're good for your bottom line. Clean-burning engines produce fewer particulates, which means your DPF stays cleaner longer. This translates to reduced maintenance costs and less downtime for regeneration cycles that eat into your productivity.

Cost savings compound over time in ways that might surprise you. Beyond the obvious fuel savings, clean injectors reduce stress on your entire engine. This means longer intervals between major repairs and extended overall engine life. For fleet operators, these savings multiply across every vehicle in your operation.

Choosing the right service provider makes all the difference between mediocre results and exceptional restoration. Certified technicians with proper flow-bench equipment deliver the thorough cleaning your injectors deserve. Don't settle for shortcuts when your engine's performance depends on precision.

The beauty of preventive maintenance lies in its simplicity. Regular cleaning prevents the gradual performance decline that's easy to ignore until it becomes expensive to fix. Stay ahead of problems rather than chasing them, and your diesel engine will reward you with years of reliable service.

At G2 Diesel Products, we've seen how proper maintenance transforms engine performance. Our experience manufacturing precision diesel fuel injectors for major truck brands gives us deep appreciation for the engineering excellence these components represent. Whether you're maintaining existing injectors or need quality replacements, the goal remains the same: keeping your diesel running at peak efficiency.