Beyond the Basics: A Deep Dive into Electronic Unit Injector Technology

Why Electronic Unit Injectors Are Critical for Modern Diesel Performance

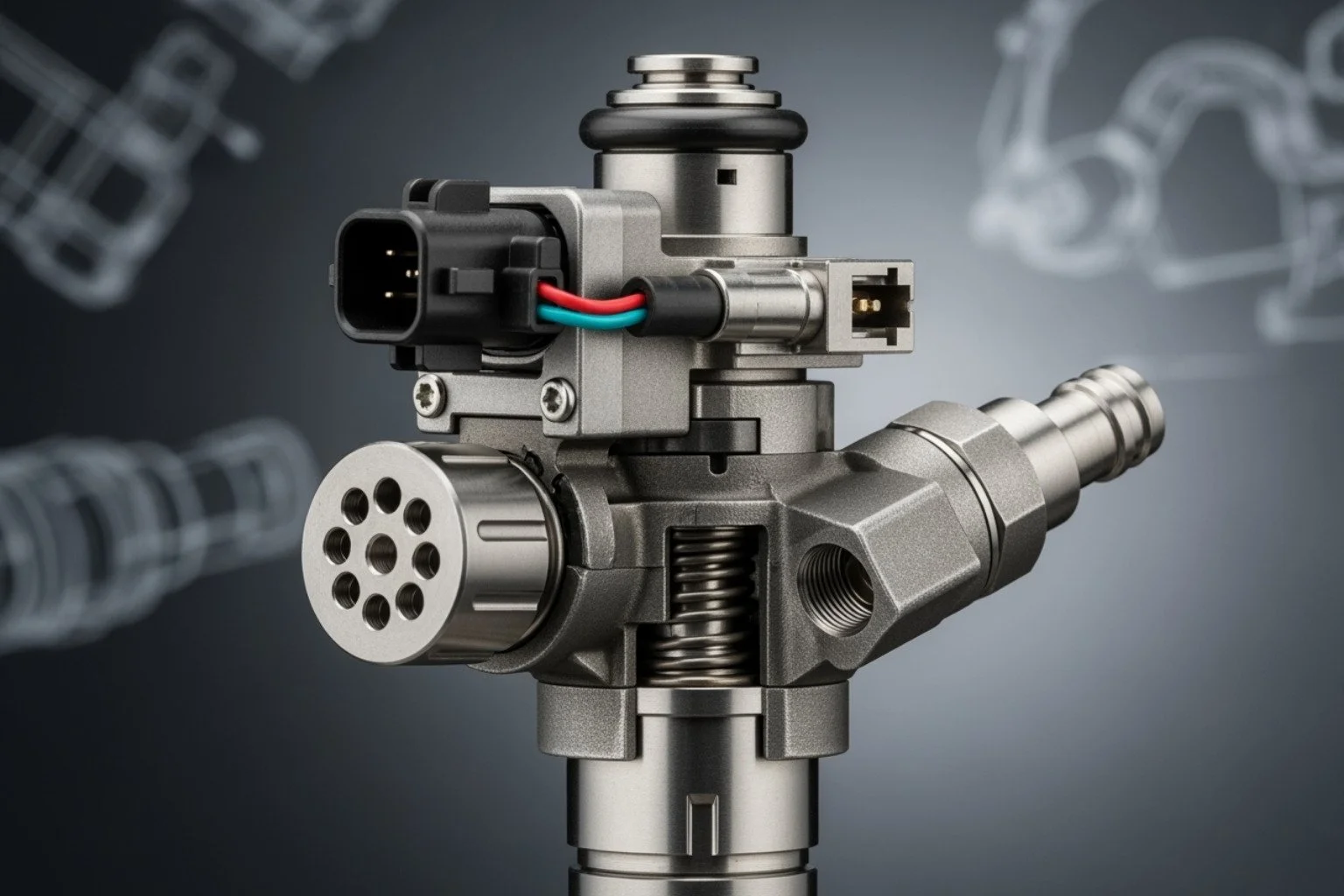

Electronic unit injectors (EUIs) are high-precision fuel delivery systems that represent a monumental leap in diesel engine technology. They integrate a dedicated high-pressure injection pump and an electronically controlled nozzle into a single, compact component for each cylinder. These advanced units have revolutionized diesel engine performance by delivering precisely metered fuel with microsecond timing and at immense pressures, often exceeding 30,000 PSI. This capability is not just an improvement; it's a necessity for meeting the modern demands of fuel economy, emissions control, and power output.

Key facts about electronic unit injectors:

What they are: A highly advanced system where the high-pressure fuel pump and the injector nozzle are combined into a single, compact unit installed directly in the engine's cylinder head. This eliminates the need for vulnerable high-pressure fuel lines and allows for unparalleled control via an electronic solenoid valve.

How they work: A sophisticated four-phase operation (fill, spill, injection, and pressure reduction) is mechanically driven by the engine's camshaft but precisely timed by the Engine Control Unit (ECU), which dictates the exact moment of injection.

Main benefits: The precise control over fuel timing and quantity leads to more complete combustion, resulting in up to 15% better fuel efficiency, a significant reduction in harmful emissions (like NOx and particulate matter), and superior engine power and torque response.

Applications: Their robustness and power make them ideal for the most demanding environments, including heavy-duty trucks, large marine engines, industrial power generation, construction and agricultural machinery, and railway locomotives.

Pressure capability: EUIs generate immense injection pressures, typically up to 2,200 bar (220 MPa or over 30,000 PSI). This extreme pressure is essential for atomizing fuel into an ultra-fine mist, which is critical for efficient combustion.

Durability: Engineered for extreme conditions, these injectors are built for longevity, with many designs rated for up to 20,000 hours of reliable operation, minimizing downtime in critical applications.

The transition from purely mechanical to electronic fuel injection was a paradigm shift. Unlike older systems with fixed timing dictated by camshaft lobes, electronic unit injectors empower the ECU to dynamically adjust when and how much fuel enters each cylinder based on real-time operating conditions.

This level of precision offers tangible, bottom-line benefits: significant fuel savings, lower maintenance overhead, and the ability to comply with increasingly strict global emissions standards, all while delivering the unwavering reliability that heavy-duty industries demand. A thorough understanding of these systems is fundamental to making informed decisions about the maintenance and parts that keep your fleet operating at peak efficiency.

The Evolution of Fuel Injection: From Mechanical to Electronic

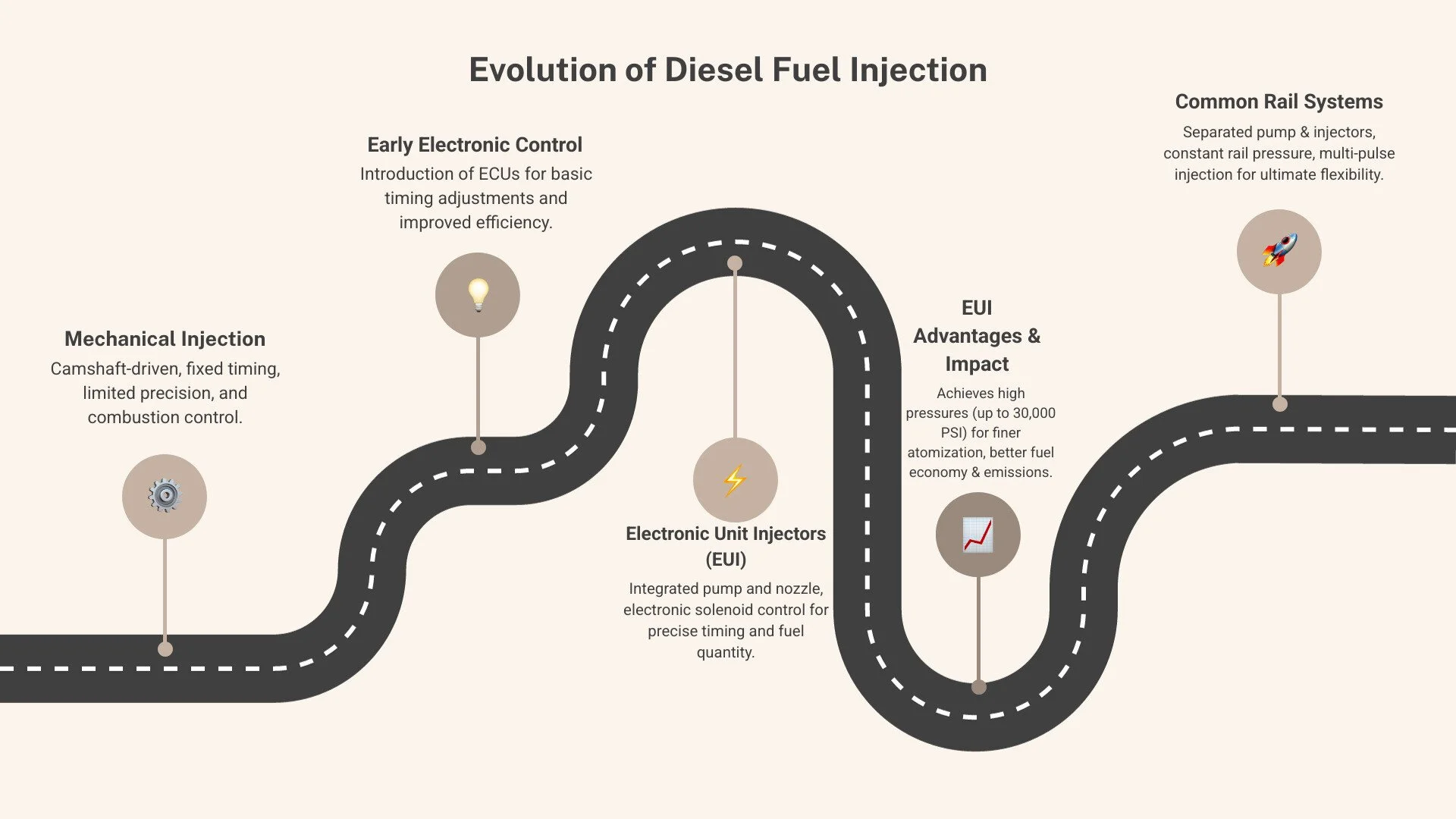

For decades, diesel engines relied on purely mechanical fuel injection systems. Driven directly by the engine's camshaft, these systems were lauded for their simplicity and robustness. However, their core limitation was a lack of adaptability. Injection timing was fixed, mechanically tied to engine rotation, meaning the fuel delivery strategy was the same whether the engine was idling, under full load, or operating in freezing temperatures. This one-size-fits-all approach resulted in significant compromises: unburnt fuel, higher emissions, increased engine noise (diesel knock), and wasted power. As global pressure for better fuel economy and cleaner air intensified, a more intelligent solution was needed.

From Mechanical to Electronic: A Leap in Precision

The game-changer was the integration of electronic control via the Engine Control Unit (ECU). The ECU acts as the engine's brain, sending precise electrical signals to the injectors to control exactly when the injection event starts and how long it lasts. This allows for continuous, real-time adjustments based on a multitude of factors, representing a massive leap from the static timing of mechanical systems. This precision timing enables strategies like multi-pulse injection, leading to more complete and controlled combustion, which directly translates into superior fuel economy, cleaner exhaust, and quieter operation.

Key Components of an EUI System

Each electronic unit injector is a marvel of engineering—a compact, self-contained fuel system that combines a pump, a high-speed control valve, and a multi-orifice nozzle.

Plunger: This hardened steel piston is mechanically driven by a dedicated lobe on the camshaft via a rocker arm. Its downward stroke is what creates the immense hydraulic pressure (up to 30,000 PSI) required for modern diesel injection.

Solenoid Valve: This electrically actuated valve is the gatekeeper of the injection process. It opens and closes in milliseconds in response to commands from the ECU. When closed, it traps fuel, allowing pressure to build; when open, it releases pressure, ending the injection event. Its speed and accuracy are paramount.

Nozzle Assembly: Located at the very tip of the injector, this component is responsible for atomizing the high-pressure fuel. It contains a spring-loaded needle valve and a nozzle with multiple microscopic holes, precisely angled to create a specific spray pattern for optimal mixing with air in the combustion chamber.

Injector Body: The robust housing, machined to exacting tolerances, contains all the internal components. It also features integrated fuel ducts for supplying low-pressure fuel to the injector and returning excess fuel, which critically helps to cool the unit during operation.

Engine Control Unit (ECU): The ECU is the central processor, constantly analyzing data from engine sensors to make split-second decisions about fuel timing and quantity. To learn more about how this electronic brain functions, you can explore this guide on the ECU's role.

EUI vs. HEUI: What's the Difference?

While both are types of electronic unit injectors, EUI and HEUI systems use different methods to generate high pressure. Understanding this distinction is crucial for proper diagnosis and maintenance.

Feature Mechanical Injector Electronic Unit Injector (EUI) Hydraulic Electronic Unit Injector (HEUI) Actuation Method Camshaft-driven plunger Camshaft-driven plunger High-pressure engine oil (hydraulic) Pressure Source Mechanical force from camshaft Mechanical force from camshaft High-pressure oil pump (HPOP) Control Fixed timing, mechanical regulation Electronic solenoid valve (ECU-controlled) Electronic solenoid valve (ECU-controlled) Common Applications Older diesel engines Modern heavy-duty trucks, industrial engines Ford Power Stroke, Caterpillar engines

Standard EUI systems are purely mechanical-hydraulic in their pressure generation. The camshaft directly drives the plunger to create fuel pressure, while the solenoid provides the electronic timing control.

HEUI (Hydraulic Electronic Unit Injector) systems, famously used in engines like the Ford Power Stroke and by Caterpillar, use a different approach. A separate high-pressure oil pump (HPOP) supplies pressurized engine oil to the injectors. This oil acts on an intensifier piston inside the injector, which then pressurizes the fuel. This design decouples injection pressure from engine speed, offering more flexibility at low RPMs. However, it also introduces more complexity and makes the fuel system highly dependent on the quality and cleanliness of the engine oil.

For a deeper look at how HEUI systems leverage engine oil, check out this detailed explanation of the Hydraulic Electronic Unit Injector (HEUI) Fuel System.

How Electronic Unit Injectors Deliver Fuel

An electronic unit injector delivers fuel through a highly synchronized process, a mechanical ballet orchestrated with digital precision by the Engine Control Unit (ECU) and executed in four distinct phases for every power stroke of the engine.

The Brains of the Operation: The Role of the ECU

The ECU is the sophisticated digital mastermind of the entire operation. It functions as a dedicated computer, processing a constant stream of data from a network of sensors across the engine. These include crankshaft and camshaft position sensors (for precise timing), accelerator pedal position (driver demand), intake air temperature and pressure (air density), coolant temperature (engine operating condition), and exhaust gas sensors. By analyzing these inputs against pre-programmed fuel maps, the ECU calculates the optimal fuel quantity and precise injection timing—down to the microsecond—for every single combustion event. It then dispatches a perfectly timed electrical pulse to each injector's solenoid valve, ensuring the engine receives exactly the right amount of fuel at the right moment for maximum efficiency and power.

The Four-Phase Injection Process Explained

Fuel delivery occurs in a rapid, cyclical, four-phase process that repeats thousands of times per minute with incredible accuracy.

Fill Phase: The cycle begins as the camshaft rotates and the rocker arm moves upward, away from the injector's plunger. A spring pushes the plunger up, creating a vacuum in the chamber below it. This suction draws in fresh, low-pressure fuel (typically supplied by a lift pump at around 60-90 PSI) from the fuel gallery in the cylinder head, filling the chamber and preparing it for the next injection cycle.

Spill Phase: The rocker arm begins its downward stroke, pushing down on the plunger and starting to pressurize the trapped fuel. During this phase, the ECU keeps the solenoid valve de-energized, or open. This allows the initially displaced fuel to safely "spill" out of the injector and recirculate back to the fuel tank. This phase is critical as it allows the ECU to precisely control the start of injection by deciding the exact moment to close the spill port.

Injection Phase: This is the moment of truth. The ECU sends a precise electrical current to the solenoid, causing its valve to snap shut in a fraction of a millisecond. With the spill port now closed, the continued downward motion of the plunger has nowhere to push the fuel, causing pressure to build almost instantaneously to extreme levels, often exceeding 30,000 PSI. This immense pressure overcomes the spring force inside the nozzle, lifting the needle and forcing fuel through the microscopic orifices, atomizing it into a fine, combustible mist. The duration for which the ECU keeps the solenoid energized directly controls the amount of fuel injected.

Pressure Reduction Phase: As soon as the required amount of fuel has been delivered, the ECU cuts the current to the solenoid, which immediately reopens the valve. The remaining high-pressure fuel is instantly released, spilling back and causing a rapid drop in pressure within the injector. This sudden pressure drop is crucial for ensuring the nozzle needle snaps shut cleanly, preventing any extra fuel from dribbling into the cylinder, which would cause smoke and emissions.

This highly controlled, four-part cycle is the secret behind the remarkable accuracy and efficiency of electronic unit injectors. To visualize this process in greater detail, our technical guide offers a comprehensive breakdown: How Electronic Unit Injector Works.

The Advantages of Electronic Unit Injectors in Heavy-Duty Engines

In the world of heavy-duty applications, from long-haul trucking to industrial power generation, performance and reliability are non-negotiable. Electronic unit injectors are indispensable in these environments, offering a suite of tangible benefits that directly impact operational costs, environmental compliance, and overall productivity.

Improved Performance and Power

The primary advantage of EUIs is their profound impact on engine performance. By generating extremely high injection pressures—up to 2,200 bar (220 MPa)—they achieve exceptionally fine fuel atomization. This vapor-like fuel spray mixes far more thoroughly and rapidly with the compressed air in the cylinder, leading to faster and more complete combustion. The result is a more powerful and efficient energy release, which translates directly into a noticeable increase in horsepower and a more responsive torque curve. This is critical for a truck hauling a heavy load up a steep grade or for industrial machinery operating under significant strain.

Superior Fuel Economy and Cleaner Emissions

Compared to older mechanical systems, EUIs can improve fuel efficiency by as much as 15%. This remarkable gain is achieved through the ECU's precise fuel metering, which eliminates waste by delivering the exact amount of fuel needed for any given load and speed. This efficiency is further enhanced by advanced injection strategies that are only possible with electronic control. Chief among these is multi-pulse injection. Instead of a single squirt of fuel, the ECU can command the injector to fire multiple times within a single combustion cycle:

Pilot Injection: A small amount of fuel is injected just before the main charge. This initiates a smoother combustion process, significantly reducing the sharp pressure spike that causes the characteristic "diesel knock," leading to a quieter, less stressed engine.

Main Injection: This is the primary charge that delivers the power for the combustion stroke.

Post-Injection: A small, late injection of fuel can be used to raise exhaust temperatures, a critical function for regenerating the Diesel Particulate Filter (DPF) and burning off trapped soot, ensuring compliance with strict emissions regulations like EPA 2010 and Euro VI.

By optimizing the combustion event in this way, EUIs drastically lower harmful emissions, including:

NOx (Nitrogen Oxides): A major contributor to smog and acid rain.

Particulate Matter (Soot): The black smoke often associated with older diesel engines.

Durability and Reliability in Demanding Applications

Heavy-duty equipment operates in harsh conditions and requires components that are both powerful and incredibly durable. Electronic unit injectors are engineered from the ground up to withstand these rigors, with typical service lives designed to reach up to 20,000 hours.

Their integrated design, which combines the pump and injector into one unit, is a key factor in their reliability. This eliminates the long, high-pressure fuel lines found in older systems, which were common points of failure due to vibration and pressure fatigue. This robust, self-contained architecture makes EUIs the preferred choice for a wide range of demanding applications:

Heavy-duty and medium-duty trucks

Marine propulsion and auxiliary engines

Industrial power generators

Large-scale construction and agricultural equipment

Diesel-electric locomotives

Our on-highway electronic unit injectors are specifically designed to keep these essential vehicles on the road, delivering the consistent power and unwavering reliability that fleet operators depend on. On-Highway Electronic Unit Injectors.

Keeping Your EUI System Healthy: Maintenance and Troubleshooting

Proper care and proactive maintenance of your electronic unit injectors are absolutely essential for ensuring engine longevity, optimal performance, and fuel efficiency. Understanding the common failure points and adopting preventative maintenance practices can save you from unexpected and costly downtime.

Common Problems and Failure Points

Even the most robust EUIs operate under immense pressure and heat, making them susceptible to failure over time. The most common culprits include:

Fuel Contamination: This is the leading cause of EUI failure. Water in diesel fuel displaces the fuel's natural lubricating properties, leading to corrosion and scuffing of the plunger and barrel. Abrasive particles like dirt or rust act like liquid sandpaper, eroding the microscopic tolerances of the solenoid valve and enlarging the nozzle orifices, which ruins the spray pattern.

Electrical Issues: The solenoid is a high-wear item. Failures can occur from internal coil shorts, broken wiring, or corrosion at the connector. A faulty solenoid will prevent the injector from firing correctly, or at all, leading to a dead cylinder.

Mechanical Wear: The relentless cycle of high-pressure actuation eventually leads to wear on mechanical components. The plunger and barrel can lose their tight seal, reducing peak pressure, while the nozzle needle and seat can wear, causing leakage or a distorted spray pattern.

Carbon Buildup (Coking): Inefficient combustion or fuel dribbling can lead to hard carbon deposits forming on the injector nozzle tip. This buildup disrupts the spray pattern, reduces fuel atomization, and can cause the nozzle to overheat.

O-Ring and Seal Failure: Degraded rubber or copper seals can cause external fuel or oil leaks. More dangerously, an internal leak can allow high-pressure fuel to enter the crankcase, diluting the engine oil and leading to catastrophic bearing failure.

Wiring Harness Issues: The engine wiring harness can become damaged from heat, vibration, or chafing. A corroded or broken wire between the ECU and the injector will interrupt the command signal, mimicking an injector failure.

Warning Signs of a Failing EUI

Your engine will almost always provide clear warning signs that an electronic unit injector is in trouble. Be alert for any of the following symptoms:

Rough Idling or Misfiring: The engine may stumble, shake, or run unevenly, especially at idle, as one or more cylinders fail to contribute power correctly.

Excessive Black Smoke: This is a classic sign of over-fueling or poor atomization, indicating that fuel is not burning completely.

Loss of Power and Poor Acceleration: The truck may feel sluggish, struggle to pull loads, or have difficulty climbing hills.

Hard Starting: The engine may crank for an extended period before starting, particularly when cold, due to incorrect fuel delivery.

Increased Fuel Consumption: A leaking or inefficiently firing injector will waste fuel, leading to a noticeable drop in your miles per gallon.

Check Engine Light with Fault Codes: The ECU will often detect an issue and trigger the check engine light. Common diagnostic trouble codes (DTCs) include P0201-P0212 (Injector Circuit Malfunction) or codes related to cylinder contribution/balance.

Best Practices for EUI System Maintenance

Fortunately, most EUI problems are preventable with a disciplined maintenance routine:

Use High-Quality, Clean Fuel: Always source diesel from reputable suppliers. Consistently using a high-quality fuel conditioner can improve lubricity, prevent gelling, and help manage moisture.

Change Fuel Filters Religiously: This is your cheapest insurance policy. Adhere strictly to the manufacturer's recommended service intervals, or shorten them if operating in dusty or dirty environments. Pay attention to the micron rating of your filters.

Maintain Strict Oil Change Intervals: Clean engine oil is vital for overall engine health, but it is absolutely critical for HEUI systems, where the oil itself is the hydraulic fluid that actuates the injectors.

Address Leaks Immediately: Any sign of a fuel or oil leak around the injectors or on the engine should be investigated and repaired promptly to prevent more severe secondary failures.

Trust Professional Diagnostics: If you suspect an injector problem, use a qualified technician with the right diagnostic tools. Tests like a cylinder cutout test can quickly isolate a problematic cylinder, while specialized equipment can test injector performance before you resort to costly replacement. Learn more about proper testing procedures in our guide to Diesel Electronic Unit Injector Testing Specs.

Frequently Asked Questions about Electronic Unit Injectors

Here are detailed answers to some of the most common questions we receive from fleet managers and technicians about electronic unit injectors.

Can a faulty EUI damage my engine?

Absolutely, yes. A malfunctioning electronic unit injector is not just a performance issue; it's a direct threat to engine health that can lead to catastrophic and expensive damage if ignored. An injector that is stuck open or leaking excessively can wash the protective oil film from the cylinder walls, causing direct metal-to-metal contact and scoring on the pistons and liners. An injector with a poor spray pattern can lead to unburnt fuel diluting the engine oil in the crankcase. This thinned oil loses its ability to properly lubricate critical components like crankshaft bearings, camshafts, and turbochargers, leading to rapid, widespread engine failure. If you notice any warning signs, it is imperative to get the vehicle diagnosed immediately.

How are EUIs tested for performance?

Testing electronic unit injectors is a multi-step process that requires specialized equipment to get a complete picture of their health. A technician will typically perform several tests:

Electronic Test: Using a diagnostic scan tool, a technician can perform a "cylinder cutout" or "contribution" test, where the ECU deactivates one injector at a time to see how it affects engine speed. A small drop indicates a weak injector. The tool can also read fault codes and test the electrical integrity of the solenoid coil.

Mechanical Test ("Pop Test"): The injector is removed and placed on a testing bench. The test checks the nozzle opening pressure (NOP) to ensure it opens at the correct pressure. It also visually inspects the fuel spray pattern to verify it is a uniform, finely atomized mist. A dribbling, streaming, or uneven spray pattern is a clear sign of a problem.

Flow Testing: The most advanced benches can measure the exact volume of fuel the injector delivers at different pulse widths and pressures, comparing it against OEM specifications to check for wear and proper metering.

This combination of electronic and mechanical testing provides a comprehensive health check. For more details, see our guide on Diesel Electronic Unit Injector Testing Specs.

Is it better to repair or replace a failing EUI?

This is a common dilemma, but for long-term reliability and peace of mind, replacement is almost always the superior option. While simple external components like O-rings and seals can be replaced, the internal parts of an EUI—the plunger, barrel, and nozzle assembly—are manufactured to incredibly tight tolerances, often measured in millionths of an inch. Attempting to repair or rebuild these precision components in a typical shop environment without specialized, climate-controlled equipment and calibration tools is highly likely to fail. A poorly repaired injector may work for a short time but will often lead to repeat failures, costing you more in labor and downtime. Replacing a failing EUI with a high-quality new or professionally remanufactured unit ensures that all components meet strict OEM specifications, providing guaranteed performance and a reliable, long-term solution.

What is the main difference between an EUI and a Common Rail system?

This is a frequent and important question. While both are electronically controlled high-pressure systems, they generate and deliver pressure differently. In an EUI system, each injector is its own high-pressure pump, creating pressure mechanically via the camshaft for each injection event. In a Common Rail system, a single, separate high-pressure pump (like a CP3 or CP4) pressurizes fuel and stores it in a shared fuel rail that feeds all the injectors. The injectors in a common rail system are essentially just electronically controlled nozzles. The key trade-off is complexity: EUI systems are mechanically simpler at the injector level but tie injection pressure to engine speed, while common rail systems offer more flexible pressure control independent of engine speed but add the complexity of a separate high-pressure pump and rail.

Conclusion

In the demanding world of heavy-duty diesel engines, electronic unit injectors represent a pivotal technological leap. They are the backbone of modern diesel performance, providing the raw power, sharp efficiency, and steadfast reliability that commercial and industrial applications depend on. The evolution from simple mechanical systems to these intelligent, high-pressure units has fundamentally reshaped what is possible, enabling engines to meet stringent global emissions standards while delivering up to 15% better fuel efficiency—a critical factor for any fleet's bottom line. With injection pressures soaring to 30,000 PSI and the microsecond precision of ECU control, EUI technology translates directly into tangible benefits: more freight hauled, less fuel consumed, and lower environmental impact.

This advanced technology directly supports fleet operators and their business goals. The ability of an EUI system to make thousands of micro-adjustments every minute ensures peak performance and economy in all conditions, from hauling a full load up a mountain pass to cruising on the highway. Their robust, integrated design also provides the exceptional durability needed for a long and productive service life, minimizing costly downtime and keeping your valuable assets on the road and generating revenue.

To achieve this level of performance, equipping your engine with the highest quality components is not just a recommendation; it's a requirement. At G2 Diesel Products, we understand that your fleet's success is built on the foundation of precision-engineered, reliable parts. From our state-of-the-art facility in Harrisburg, PA, we supply a comprehensive range of premium replacement injectors for leading engine brands like Volvo, Mack, Kenworth, and Paccar, ensuring OEM-level performance and rapid lead times to get you back in service faster.

Ready to experience the difference that superior quality electronic unit injectors can make for your fleet? Shop for high-performance diesel fuel injectors and discover why fleet operators across the country trust G2 Diesel Products for their critical fuel system needs.