What the Heck Are Electronic Unit Injectors Anyway?

Understanding the Powerhouse Behind Your Diesel Engine

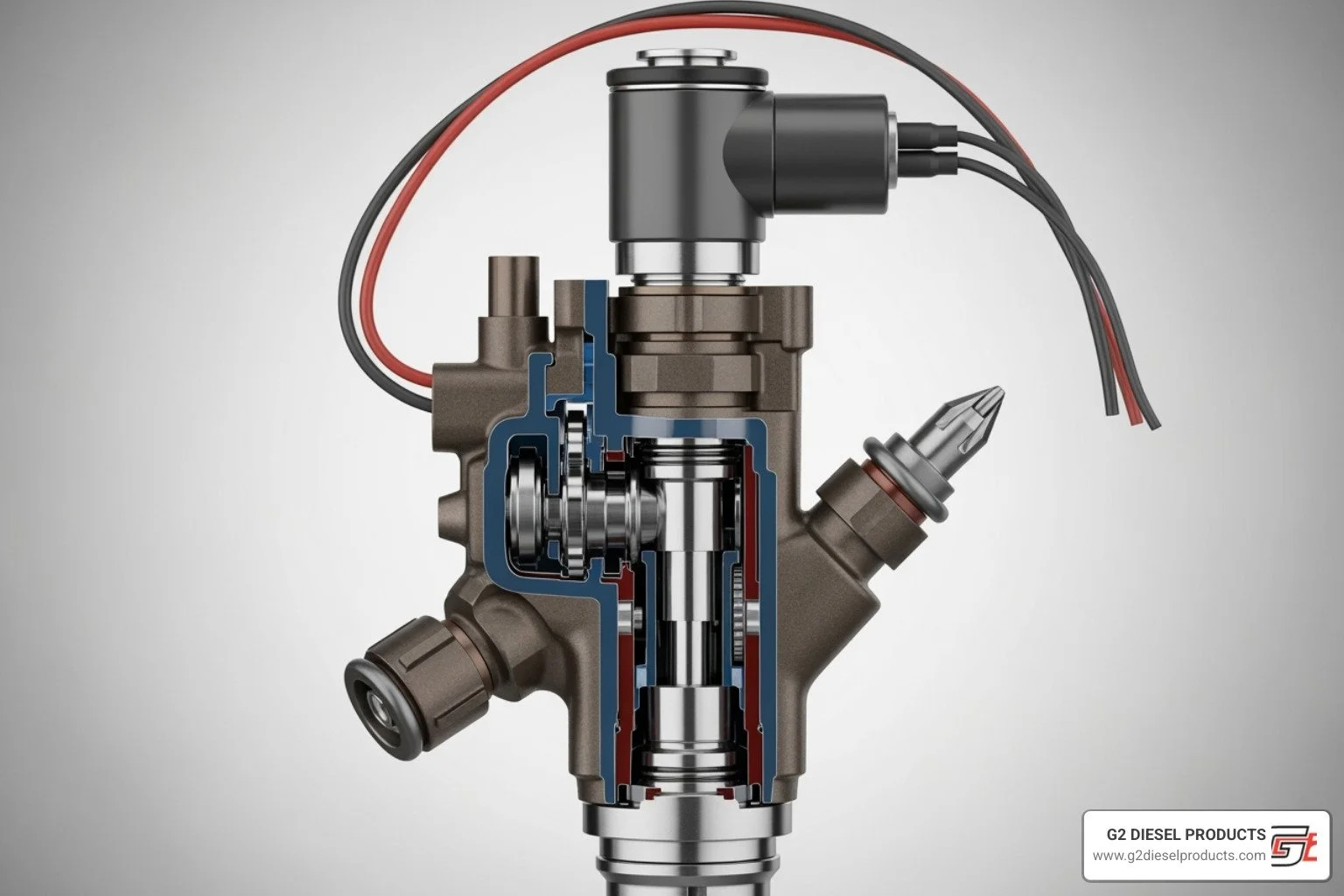

Electronic unit injectors (EUIs) are the high-tech heart of many modern diesel engines, combining a fuel pump and injection nozzle into a single, electronically controlled component. These sophisticated fuel delivery systems are a key reason why heavy-duty trucks can run smoothly while meeting strict emissions standards.

What Electronic Unit Injectors Do:

Deliver fuel with pinpoint accuracy to each cylinder

Generate high pressure up to 2,200 bar for optimal fuel atomization

Control injection timing electronically for maximum power and efficiency

Reduce emissions through precise fuel metering

Combine the pump and injector in one compact, camshaft-driven unit

EUIs emerged in the 1990s to meet tougher emissions regulations and demands for better fuel economy. Unlike older mechanical systems, EUIs use an Engine Control Unit (ECU) and fast-acting solenoid valves to control exactly when and how much fuel gets injected. This allows an EUI to adjust injection timing and quantity thousands of times per minute based on engine speed, load, and temperature.

For fleet managers, this means better fuel economy, more power, cleaner emissions, and longer engine life. Understanding how EUIs work helps you make smarter decisions about maintenance and parts sourcing for your Volvo, Mack, Kenworth, and Paccar trucks.

From Mechanical to Electronic: The Evolution of the Unit Injector

The unit injector concept, which combines the fuel pump and injector at each cylinder, dates back to the early 20th century. These early mechanical systems were robust and could generate impressive pressures up to 2,200 bar, but they had a major limitation: they were driven entirely by the engine's camshaft. This meant injection timing was fixed, offering no flexibility for different operating conditions like climbing a hill or cruising on a flat highway.

As environmental regulations tightened, the diesel industry needed a smarter solution. This led to the electronic unit injector (EUI), which added a computer brain to the mechanical muscle.

For a deeper dive into the technical workings, check out our guide on How Electronic Unit Injector Works.

What is a Conventional Unit Injector (UI)?

A conventional unit injector is a purely mechanical, camshaft-driven device. A lobe on the camshaft pushes a plunger inside the injector, pressurizing fuel and forcing it into the combustion chamber. The design is simple and eliminates long, high-pressure fuel lines. However, because the camshaft dictates the timing, fuel is delivered at the same point in the engine cycle every time. This fixed injection timing limited the engine's ability to adapt, hindering both efficiency and emissions control.

The Leap to Electronic Unit Injectors (EUI)

The leap to electronic control revolutionized the unit injector. The Engine Control Unit (ECU) became the conductor, gathering data from sensors monitoring engine speed, load, and temperature to make split-second decisions about fuel delivery.

The key innovation is the solenoid valve. Controlled by the ECU, this lightning-fast electronic gate determines precisely when fuel pressurization begins and ends. This allows for variable injection timing, where the ECU can adjust both the timing and quantity of fuel injected to match the engine's exact needs.

The benefits are significant: optimal combustion for maximum horsepower and improved fuel economy, along with a dramatic reduction in harmful emissions. For fleet operators, this means trucks that run cleaner, more efficiently, and with better performance across all conditions.

How Electronic Unit Injectors Work: A Four-Phase Breakdown

An electronic unit injector is a marvel of precision engineering, generating immense pressures up to 2,200 bar (roughly 32,000 psi). A constant stream of low-pressure fuel (under 500 kPa) circulates through the injector, a crucial process that both cools the unit and lubricates its precisely machined internal parts, ensuring durability over hundreds of thousands of miles.

Key Components of Electronic Unit Injectors

Every EUI relies on four essential components working in concert:

Plunger Pump: The mechanical muscle, driven by the engine's camshaft to create the force needed to pressurize fuel.

Solenoid-Operated Spill Valve: The electronic brain of the injector. Controlled by the ECU, this fast-acting valve determines the start and end of the injection event.

Injector Nozzle: The business end, featuring microscopic spray holes designed to create the perfect fuel spray pattern for optimal combustion.

Engine Control Unit (ECU): The master computer that monitors engine parameters and tells the solenoid valve exactly when to act.

The Four Phases of EUI Operation

The entire injection process happens in milliseconds, cycling through four distinct phases. This rapid, controlled dance is what makes EUIs so effective.

Phase 1: Fill: As the plunger moves down, the fuel chamber fills with low-pressure fuel, preparing for the injection event.

Phase 2: Spill: The plunger begins its upward stroke, but the spill valve remains open, allowing fuel to circulate back to the return line without building pressure.

Phase 3: Injection: The ECU energizes the solenoid, snapping the spill valve shut. Pressure builds instantly, forcing fuel through the nozzle into the cylinder in a fine, atomized spray.

Phase 4: Pressure Reduction: The ECU de-energizes the solenoid, the spill valve opens, and pressure drops immediately, ending the injection. The injector then resets for the next cycle.

This four-phase process repeats continuously, with the ECU making constant adjustments to timing and duration to optimize engine performance.

EUI vs. The World: A Fuel System Comparison

As diesel technology evolved to meet demands for better fuel economy and lower emissions, several advanced fuel systems emerged. Electronic unit injectors (EUIs) were a major step forward, but they competed with other technologies like Hydraulic Electronic Unit Injectors (HEUI) and Common Rail systems. Each system takes a different approach to achieving precise, high-pressure fuel delivery.

Feature Electronic Unit Injector (EUI) Hydraulic Electronic Unit Injector (HEUI) Common Rail Pressure Generation Camshaft-driven plunger, integrated pump/injector Engine oil pressure acts on intensifier plunger Separate high-pressure pump, common rail reservoir Control Mechanism Solenoid-operated spill valve, ECU controlled Solenoid-operated spool valve, ECU controlled Solenoid/Piezo-electric valve, ECU controlled Max Pressure Up to 2,200 bar Up to ~1790 bar (~26,000 psi) Up to ~2070 bar (~30,000 psi) or more Pros High pressure, no high-pressure lines, robust High pressure independent of engine RPM, flexible Highest pressure, multiple injections, quiet, flexible Cons Camshaft reliance (limits timing flexibility) Oil contamination issues (stiction), complex oil system Sensitive to fuel quality/contamination, higher system complexity

EUI vs. HEUI (Hydraulic Electronic Unit Injector)

While both are types of unit injectors, EUIs and HEUIs generate pressure differently. EUIs use the mechanical force of the engine's camshaft. HEUI systems use a hydraulic approach, employing pressurized engine oil to act on an intensifier plunger inside each injector. This multiplies the oil pressure to create high fuel pressure, offering the advantage of high pressure independent of engine speed.

However, HEUI systems were prone to a problem called stiction, where degraded engine oil would cause internal valves to stick, leading to rough starts and misfires. This maintenance challenge led many manufacturers to move away from the technology.

Learn more about these hydraulic systems in our guide on the Hydraulic Electronic Unit Injector (HEUI) Fuel System.

EUI vs. Common Rail

The Common Rail system represents a fundamental shift in design. Instead of creating pressure at each injector, a single high-pressure pump supplies fuel to a shared rail, or reservoir, that maintains constant high pressure (often near 30,000 psi). The injectors then act as fast-switching valves controlled by the ECU.

This design offers incredible flexibility in injection timing. The ECU can command multiple, precise injection events (pilot, main, and post-injections) within a single combustion cycle. This results in reduced noise, lower emissions, and improved efficiency, making Common Rail the dominant technology in today's market for new engines.

While Common Rail leads new designs, EUIs remain robust workhorses in many existing heavy-duty applications. They are proven, reliable components on many engine platforms still in service today.

Keeping Your Engine Healthy: EUI Failure, Diagnosis, and Prevention

Electronic unit injectors are robust, but they operate in a harsh environment and require proper care. A failing EUI can severely impact engine performance, fuel economy, and emissions. Fortunately, most problems are preventable, and understanding the warning signs can save you from costly downtime.

For a breakdown of potential costs, see our guide on Diesel Fuel Injector Cost.

Common Causes of EUI Failure

Most EUI failures can be traced back to a few key culprits:

Contamination: Water and debris are the primary enemies. Water in fuel causes corrosion and can damage the injector tip. When mixed with sulfur compounds in diesel fuel, it can form corrosive acids. Dirt and other small particles act like sandpaper, wearing down the precisely machined internal components and causing leaks.

High Fuel Temperatures: Excessively hot fuel loses viscosity and cannot properly lubricate the injector's moving parts, leading to accelerated wear.

Internal Wear and Tear: Over millions of cycles, components like the plunger, barrel, and solenoid valve naturally wear out. Carbon can also build up on the nozzle tip, distorting the spray pattern and hurting combustion efficiency.

Diagnosing a Faulty EUI

Your engine will give you warning signs when an EUI is struggling. Look out for these common symptoms:

Engine Misfires: A noticeable stumble or roughness, especially under load.

Excessive Smoke: Black smoke indicates incomplete combustion, while white smoke often points to unburnt fuel from a faulty injector.

Rough Idling: The engine may shake or vibrate more than usual at idle.

Loss of Power: Sluggish acceleration and a feeling that the engine is working harder than normal.

Decreased Fuel Economy: A noticeable drop in MPG over several fill-ups.

Frequent DPF Regeneration: A sign of increased soot production from poor combustion.

If you notice these symptoms, professional diagnosis is key. Technicians use specialized tools to pinpoint the faulty injector, saving time and money. Our Diesel Injector Testing Services can help you accurately identify issues. Prevention through clean fuel and regular filter changes is your best defense against EUI failure.

Who's Using EUIs? Engines and Manufacturers

Despite the rise of newer fuel systems, electronic unit injectors remain vital components in demanding applications worldwide. Their robust design and high-pressure capability make them a trusted choice for heavy-duty work.

You'll find EUIs powering:

On-highway trucks: Many heavy-duty trucks from the late 1990s through the 2010s, including models from Volvo, Mack, Kenworth, and Paccar.

Locomotives and marine engines: Large diesel engines in trains and boats rely on EUIs for power and reliability.

Stationary power generation: Industrial generators and equipment often use EUIs for consistent performance.

Major Engine Manufacturers and Vehicle Types

Many major engine manufacturers have used electronic unit injectors. Volvo and Mack are prominent users in their heavy-duty engines, valuing the durability and performance of EUIs. Other notable users include Detroit Diesel (Series 60), Caterpillar (MEUI systems), Cummins (CELECT systems), Scania (PDE systems), and Electro-Motive Diesel (EMD) in their locomotive and marine engines.

At G2 Diesel Products, we specialize in injectors for these workhorses. Check out our selection of On-Highway Electronic Unit Injectors and VCE Electronic Unit Injectors.

A Closer Look: The Volvo D13 EUI

The Volvo D13 engine, found in many Volvo and Mack trucks, is a prime example of EUI technology in action. In the D13, EUIs are integrated into the cylinder head, driven by an overhead camshaft. The engine's ECU precisely controls each injector to deliver the optimal amount of fuel at the perfect time. This ensures the power, fuel economy, and emissions compliance required for demanding, everyday hauling.

For more details, read our guide: Precision Injection: A Guide to Volvo D13 Fuel Injectors. If you need a replacement, we offer the Volvo D13 Construction EUI Fuel Injector.

Frequently Asked Questions about Electronic Unit Injectors

Here are answers to some of the most common questions we hear about electronic unit injectors.

How do you test an electronic unit injector?

Testing an EUI properly requires specialized equipment. While a technician can perform an on-vehicle cylinder cutout test to identify a misfiring cylinder, a definitive diagnosis involves removing the injector and testing it on a dedicated test bench. These benches measure fuel delivery, solenoid response time, spray pattern, and check for internal leaks to verify performance against OEM specifications.

Are EUI and common rail injectors interchangeable?

No, they are not interchangeable. An EUI is an integrated pump and injector driven by the camshaft. A common rail injector is a valve that gets fuel from a separate, high-pressure rail. Their designs and operating principles are fundamentally different, and attempting to swap them could cause severe engine damage.

Why do some heavy-duty trucks still use EUIs instead of common rail?

While common rail is prevalent in new engines, EUIs remain a strong choice in many heavy-duty applications for several reasons:

Proven Reliability: EUIs have a long and successful track record in demanding environments.

High-Pressure Capability: They generate the very high injection pressures needed for large diesel engines.

Cost-Effectiveness: For established engine platforms, continuing with a proven EUI design is often more economical than a complete redesign for common rail.

Design Simplicity: The EUI system eliminates the need for separate high-pressure lines and a common rail, simplifying some aspects of the engine's fuel system.

The Final Word on Electronic Unit Injectors

Electronic unit injectors represent a pivotal engineering achievement in the history of diesel engines. By combining a high-pressure pump and a precision injector into a single, electronically controlled unit, they enabled a new era of power, efficiency, and emissions control.

With injection pressures up to 2,200 bar and the ability to adjust fuel delivery thousands of times per minute, EUIs brought a level of precision that purely mechanical systems could not match. While common rail technology leads many new engine designs, EUIs are far from obsolete. They continue to power countless Volvo, Mack, Kenworth, and Paccar trucks on the road today, proving their durability and performance mile after mile.

For fleet managers and owner-operators, understanding this technology is key to smart maintenance. The most critical factor in ensuring long life and reliability from an EUI system is the use of quality replacement parts. The internal tolerances of an injector are measured in microns, and compromising on quality can lead to poor performance, reduced fuel economy, and costly downtime.

At G2 Diesel Products, we understand that your trucks are your livelihood. We are committed to manufacturing electronic unit injectors that meet or exceed OEM standards, providing the reliability you need with the quick lead times that keep your fleet moving.

Don't let a failing injector sideline your business. Equip your trucks with parts you can trust.

Shop for high-quality EUI injectors for your Volvo, Mack, or Kenworth truck