Paccar Fuel System Diagrams: See How It All Connects

Why Understanding Your Paccar Fuel System Diagram Is Critical

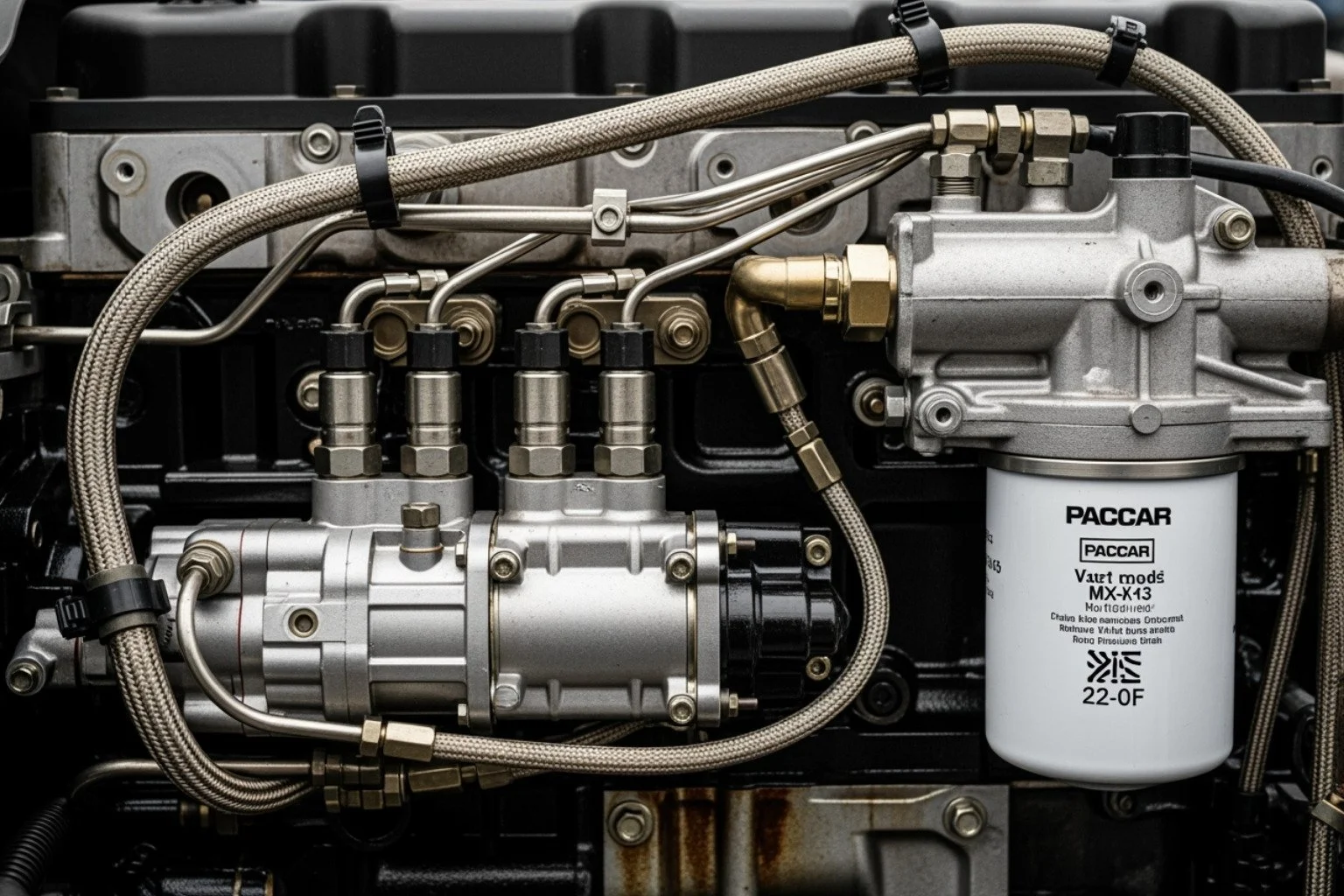

A paccar fuel system diagram is the essential roadmap for your Kenworth or Peterbilt truck's engine, serving as the definitive guide for anyone looking to maintain, diagnose, or repair the heart of their vehicle. It details the precise path fuel travels from the tank to the combustion chamber, outlining every critical component, from filters and pumps to the high-pressure common rail and injectors. For technicians and owner-operators working on the sophisticated MX-11 and MX-13 engines, a clear understanding of this schematic is not just helpful—it's fundamental to achieving efficiency, reliability, and profitability.

The modern diesel engine has evolved far beyond the simple mechanical systems of the past. With the advent of high-pressure common rail (HPCR) technology, Paccar engines now operate with incredible precision and under immense pressures, making visual inspection and guesswork obsolete. The system is logically divided into key circuits: a low-pressure suction and supply circuit (fuel tank, lift pump, primary filter/water separator), a high-pressure delivery circuit (high-pressure pump, common rail, injectors), a sophisticated electronic control system (ECM, sensors, actuators), and a fuel return system. Knowing this layout allows you to logically trace fuel flow, quickly locate components, and accurately diagnose a wide range of issues, from frustrating hard starts and low power complaints to critical fuel leak warnings.

As one veteran diesel technician with over 30 years of experience noted, \"I've never seen a $5,000 high-pressure pump failure that couldn't have been prevented by a 30-second water drain.\" This powerful statement underscores the immense value of preventative maintenance, a practice made intuitive by the fuel system diagram. When you can visualize how a simple task like draining the water separator protects the entire high-pressure circuit—where components operate at over 36,000 psi—the importance becomes crystal clear. These diagrams are invaluable, indispensable tools for keeping your truck on the road, minimizing costly downtime, and ensuring your Paccar engine runs as efficiently as the day it left the factory.

Decoding the Paccar Fuel System Diagram: Components and Flow

Whether you're looking at the schematic for an MX-11 or an MX-13 engine, a paccar fuel system diagram provides a detailed illustration of how diesel fuel completes its journey from a passive liquid in the tank to a power-generating, atomized spray inside the cylinder. A thorough understanding of this flow is the first step toward expert-level maintenance and rapid, accurate troubleshooting. Paccar engines utilize advanced high-pressure common rail technology, and while minor variations exist between model years and specific applications, the fundamental principles of operation are remarkably consistent. The entire system can be understood by breaking it down into two primary circuits: a low-pressure circuit designed to draw, clean, and deliver fuel to the engine, and a high-pressure circuit designed to pressurize, store, and inject that fuel to create power. For a comprehensive look at these systems, see our guide on Paccar Fuel Systems.

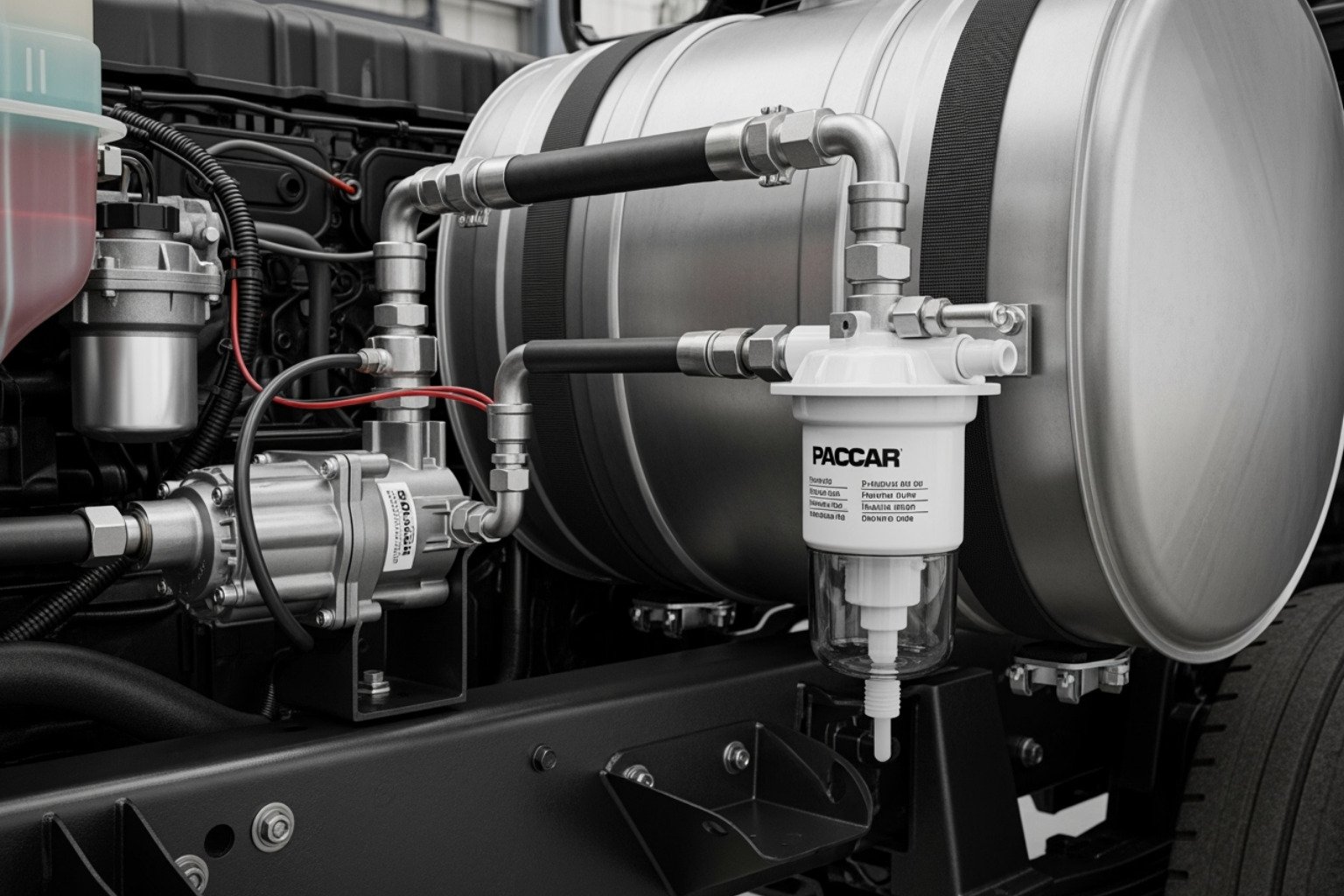

The Low-Pressure Circuit: The Journey to the Pump

The low-pressure circuit, often called the suction or supply side, operates at a relatively modest pressure of 30-75 psi. Its primary job is to prepare a clean, air-free supply of fuel for the extremely demanding high-pressure pump. The journey begins at the fuel tank, where an electric lift pump (sometimes called a transfer pump), typically located on the engine block, draws fuel through a pickup tube. This pump creates the initial pressure needed to push the fuel toward the engine and, crucially, maintains positive pressure to prevent the high-pressure pump from being starved of fuel, which could lead to cavitation and damage. From the pump, fuel is pushed through the primary fuel filter and water separator assembly. This critical first stage of filtration uses a 30-micron filter element to capture larger contaminants like rust, dirt, and algae. Integrated within this housing is the water separator, which uses baffles and a special hydrophobic media to coalesce and separate heavier water from the lighter diesel fuel. A Water-in-Fuel (WIF) sensor is threaded into the bottom of the filter bowl to detect accumulated water and trigger a dashboard warning. Also located on the filter module is a hand priming pump, a manual plunger used to draw fuel through the circuit and purge any trapped air after performing service like a filter change. Special attention must be paid to all suction-side fuel lines and fittings between the tank and the lift pump. Even a minuscule leak here will not drip fuel but will instead draw in air, leading to hard-starting, stalling, and engine misfires.

The High-Pressure Circuit: Creating Power

Once the fuel is cleaned and pressurized by the low-pressure circuit, it enters a world of extreme force. The engine-driven high-pressure pump, a marvel of mechanical engineering, takes the incoming 30-75 psi fuel and intensifies it to an incredible 2500 bar (36,260 psi). This pump is typically driven by the engine's rear gear train and its output is precisely regulated by a fuel metering unit controlled by the ECM. Before this highly pressurized fuel can be used, it passes through a secondary fuel filter for a final, critical stage of cleaning. This filter features a very fine 4-5 micron rating, designed to protect the microscopic tolerances inside the fuel injectors from any damaging particles that may have passed the primary filter. From there, the fuel enters the common rail, a thick-walled steel tube that acts as a high-pressure reservoir or hydraulic accumulator. Its job is to store the pressurized fuel and dampen pressure pulses from the pump, ensuring that a stable, constant pressure is instantly available to all injectors. The electronically controlled fuel injectors are the final actors. When commanded by the ECM, they open a nozzle valve for a few millionths of a second, atomizing the high-pressure fuel directly into the cylinders. They perform multiple injection events per combustion cycle: a small pilot injection to initiate smooth combustion and reduce noise, a main injection for the power stroke, and often a post-injection for emissions control and to help with DPF regeneration. At G2 Diesel Products, we offer precision-engineered injectors like our Reman Paccar MX13 Smart F2P Fuel Injector 2047600 built to meet these exacting demands. As a final safeguard, a mechanical pressure relief valve is mounted on the common rail to vent excess pressure back to the tank in the event of a system malfunction, preventing catastrophic over-pressurization.

The Brains of the Operation: The ECM and Sensors

The entire fuel delivery process is orchestrated by the Engine Control Module (ECM), the powerful onboard computer that serves as the electronic brain of the engine. The ECM constantly analyzes a stream of data from dozens of sensors across the truck to make real-time adjustments to fuel timing, injection pressure, and fuel volume for optimal performance, fuel economy, and emissions compliance under all operating conditions. Key sensors in the fuel system include the fuel pressure sensor on the common rail, which provides the critical feedback loop for pressure control; the fuel temperature sensor, which allows the ECM to compensate for changes in fuel density; and the Water-in-Fuel sensor, which provides an early warning of harmful contamination. The ECM uses this data, along with inputs from the crankshaft position sensor (for engine speed and timing), accelerator pedal position sensor (for driver demand), and various temperature and pressure sensors, to precisely command the high-pressure pump and injectors. This allows for the sophisticated control of multiple injection events, which is the key to how modern Paccar engines can deliver high power and torque while simultaneously meeting stringent environmental standards.

Essential Maintenance for a Healthy Paccar Fuel System

Your paccar fuel system diagram is more than just a diagnostic tool; it's a map to the components that demand regular, proactive attention. Establishing a routine of preventative maintenance is vastly more effective and less expensive than reacting to problems like hard starting, rough idling, or unexpected engine derates. A small investment in regular care will keep your MX-11 or MX-13 engine running reliably and efficiently, especially when operating in challenging conditions like extreme cold or heat. Should you need to prime the system after service, our guide on How to Prime a Paccar PX-9 Fuel System provides a useful overview, though always refer to your specific engine's manual for exact procedures.

Fuel Filtration and Water Separator Service

Your fuel filtration system is the single most important defense for the expensive, precision-engineered components in your high-pressure common rail system. Daily water draining from the primary fuel filter/water separator is the most critical maintenance task you can perform. This simple, 30-second job, done as part of a pre-trip inspection, can prevent thousands of dollars in catastrophic damage to the high-pressure pump and injectors, which rely on diesel fuel for lubrication. The WIF sensor light on your dashboard is a final, urgent warning; do not rely on it as your maintenance reminder. If the light comes on, it means a significant amount of water has already accumulated.

PACCAR's standard two-stage filtration system is designed for maximum protection. It uses a 30-micron primary filter to catch larger debris and separate water, followed by a 4-5 micron secondary filter to capture microscopic particles that could destroy the tight tolerances of the injector nozzles. Adhering to the correct filter replacement intervals is crucial. These intervals vary by application:

Standard/Line-Haul: Every 75,000 miles, 2,250 hours, or 12 months, whichever comes first.

Severe Duty/Vocational: Every 30,000 miles or 6 months.

Using B20 Biodiesel: Every 25,000 miles. Biodiesel is an excellent solvent and can loosen deposits from the fuel tank, clogging filters more quickly. It is also more prone to absorbing water.

When changing filters, absolute cleanliness is paramount to prevent system contamination. First, thoroughly clean the filter housing and the surrounding area before opening the system. When installing the new filter, always use new O-rings and lubricate them with clean diesel fuel or motor oil to ensure a proper seal and prevent tearing. Torque the filter caps to the manufacturer's specification, typically 30 lb-ft, to prevent air leaks or damage to the housing. Crucially, do not pre-fill the new filters with fuel from a can. This common practice on older engines introduces a high risk of pouring unfiltered, contaminated fuel directly into the clean side of the system, bypassing the filter and sending debris straight to the injectors. Instead, install the filters dry and use the hand priming pump to prime the system, drawing clean fuel through the new filters. For the MX-13, PACCAR recommends a specific multi-step priming process to ensure all air is purged. For complete, model-specific details, always consult PACCAR's official Fuel Filter Maintenance reference.

Approved Fuels and Cold-Weather Best Practices

Using high-quality fuel is non-negotiable for the performance and longevity of a modern HPCR system. Always use Ultra-Low Sulfur Diesel (ULSD) that meets ASTM D975 standards. The fuel should have a minimum cetane rating of 42, with a rating of 45 or higher strongly recommended for better starting and performance in cold weather. Biodiesel blends up to B20 (20% biodiesel, 80% diesel) are acceptable, provided the biodiesel portion meets ASTM D6751 standards and is sourced from a BQ-9000 certified producer. However, be prepared for the shorter filter change intervals mentioned above. Paraffinic diesel fuels like Hydrogenated Vegetable Oil (HVO) and Gas-to-Liquids (GTL) that meet the EN15940 standard are also approved. Under no circumstances should you ever use gasoline, alcohol, or kerosene blends, as their poor lubricity will cause immediate and severe damage to the high-pressure pump and injectors, voiding your warranty.

For cold weather operation, take proactive steps to prevent fuel gelling. Use a high-quality winter-blend diesel from your supplier, which is formulated with cold flow improvers. If needed, supplement with a PACCAR-approved anti-gel additive. Always add additives to the tank before filling with fuel to ensure proper mixing. Keep fuel tanks as full as possible, especially overnight, to minimize the surface area where water vapor can condense. Ensure your engine's fuel heater is operational. Finally, practice a proper cool-down idle at around 1,000 RPM for three to five minutes before shutting down the engine. This simple habit allows the turbocharger to cool gradually and prevents residual fuel from "coking" or baking onto the hot tips of the injectors, which can disrupt the spray pattern and harm performance and longevity.

Troubleshooting with a Paccar Fuel System Diagram

When a fuel-related problem arises, your paccar fuel system diagram becomes your most valuable diagnostic tool. It allows you to move beyond guesswork and systematically troubleshoot common issues like hard starting, no-start conditions, low power, excessive smoke, or frequent engine stalling. By showing the intended path of fuel flow and the location of key components, the diagram enables you to form a logical diagnostic strategy, tracing the system from the tank to the injectors to efficiently isolate the root cause of the problem. For additional real-world troubleshooting insights, you can review this Paccar MX-13 Fuel System Q&A.

Common Problems: Air Intrusion and Low Fuel Pressure

Air intrusion and low fuel pressure are, by far, the two most common culprits behind a wide array of fuel system symptoms. Understanding how to diagnose them is a core skill.

Air Intrusion: Air bubbles in the fuel are compressible and disrupt the solid stream of liquid the system is designed for. This causes symptoms like hard starting (especially after sitting overnight), no-starts, a rough or rolling idle, engine misfires, and stalling. A classic sign is an engine that loses its prime and requires manual priming to restart after being shut down. Air almost always enters the system on the suction side—the lines between the fuel tank and the lift pump. The most common entry points are damaged or improperly seated O-rings on the primary fuel filter cap, loose or cracked fuel lines, or worn seals on the hand priming pump. As discussed on forums like The Truckers Report, even a pinhole-sized leak on the suction side can introduce enough air to cause major drivability problems. A common diagnostic technique is to install a clear section of fuel line before the lift pump to visually check for air bubbles.

Low Fuel Pressure: This condition typically results in lack of power, poor acceleration, engine derates, and the inability to pull a heavy load up a grade. The most frequent causes are clogged primary or secondary fuel filters, which should always be the first thing you check. Other causes include a failing electric lift pump that can no longer supply adequate volume or pressure, or a physical restriction in a fuel line (such as a kinked hose or debris in the tank pickup). On the high-pressure side, a sticking pressure relief valve on the common rail can bleed off pressure, or the high-pressure pump itself may be wearing out. Diagnostic trouble codes (DTCs) are essential here, with P0087 (Fuel Rail Pressure Too Low) being the most direct indicator. A technician will use this code as a starting point, then use pressure gauges on both the low and high-pressure circuits to pinpoint where the pressure is being lost.

Understanding Dashboard Warning Lights

Your dashboard is your engine's primary communication interface. Ignoring its warnings can lead to escalating damage and costly repairs. When a fuel system problem is detected, you will likely see one of these lights:

Water-in-Fuel (WIF) Light: This is a critical, time-sensitive warning. It means the WIF sensor has detected a significant volume of water in the primary filter bowl. You should stop the truck safely as soon as possible and drain the separator. Continuing to operate with this light on risks sending water into the high-pressure pump and injectors, which can cause immediate and severe damage.

Check Engine Light (CEL): This amber light indicates the ECM has detected and stored a fault code. It can be triggered by hundreds of potential issues, including many fuel system problems like low fuel pressure, or a malfunctioning sensor or actuator. The truck may enter a limited power "derate" mode to prevent further damage. The fault codes must be read with a diagnostic tool to identify the specific problem.

Stop Engine Light (SEL): This red light, often accompanied by an audible alarm, signals a critical fault that could cause severe and imminent engine damage. This could be triggered by a major fuel system failure (like dangerously low rail pressure that could damage injectors), critically low oil pressure, or severe overheating. Your only response should be to pull over safely and shut down the engine immediately to prevent a catastrophic failure.

Paccar MX-11 vs. MX-13: Key Fuel System Differences

A paccar fuel system diagram for an MX-11 engine and one for an MX-13 engine will appear remarkably similar at first glance, and for good reason. Both engines are built upon PACCAR's highly successful and robust high-pressure common rail technology, a platform capable of generating immense fuel pressure up to 2500 bar (36,260 psi). This shared architectural foundation means the core components—lift pump, two-stage filters, high-pressure pump, common rail, and injectors—and the fundamental principles of fuel flow are nearly identical.

Both the MX-11 and MX-13 engines employ a low-pressure circuit to supply clean fuel, a high-pressure circuit to generate injection pressure, and a sophisticated ECM that precisely controls multiple injection events for power, efficiency, and emissions control. The primary differences between the two are not in the type of technology used, but in the sizing, calibration, and application of that technology. The 10.8-liter MX-11 (producing 355-430 hp) is optimized for weight-sensitive regional haul and vocational applications where fuel economy and payload are paramount. In contrast, the larger 12.9-liter MX-13 (producing 405-510 hp) is engineered for the higher power and torque demands of long-haul and heavy-duty work.

This design philosophy is highly beneficial for fleets and technicians, as maintenance procedures and diagnostic skills learned on one engine are directly transferable to the other. However, it is critical to understand that while the systems are functionally alike, the components are often not interchangeable. The MX-13's higher power output demands a greater fuel volume, meaning its high-pressure pump may have a slightly larger displacement, and its fuel injectors will have a higher flow rate specification. The ECM calibrations are also entirely different, with fuel maps and timing strategies tailored specifically to each engine's displacement and intended duty cycle. Therefore, while the troubleshooting logic remains the same, you must always reference the specific diagram and part numbers for your truck's exact engine model and year. Subtle model year updates can also introduce changes to sensor locations or component designs. For a closer look at each engine's specific system, you can explore our detailed guides on the Paccar MX-11 Fuel System Diagram and the Paccar MX13 Fuel System Diagram.

Frequently Asked Questions about Paccar Fuel Systems

Operators, technicians, and fleet managers frequently have questions about maintaining and troubleshooting these sophisticated fuel systems. Having clear, accurate answers is key to maximizing uptime and minimizing operational costs. Here are some of the most common inquiries we receive.

How often should I drain the water from the fuel separator?

You should drain your water separator daily as a non-negotiable part of your pre-trip inspection. Water constantly accumulates in fuel tanks through condensation, especially in humid climates or with large day/night temperature swings. It is extremely damaging to the entire fuel system, as it causes corrosion and displaces the diesel fuel that lubricates the high-pressure pump and injectors. This simple 30-second task is the single best piece of preventative maintenance you can perform. The Water-in-Fuel (WIF) light on the dashboard is an emergency warning, not a maintenance reminder. By the time it illuminates, water has already reached a dangerous level, putting thousands of dollars worth of components at immediate risk.

What are the first signs of air in the fuel system?

Air is the enemy of a high-pressure fuel system. Since air is compressible and fuel is not, its presence disrupts the precise metering and injection of fuel. The most common signs include:

Hard starting or no-start conditions: The engine cranks but struggles to fire, or won't fire at all. This is especially common after the truck has been sitting for several hours (losing its prime).

Rough, inconsistent idling: The engine shakes or the RPMs fluctuate noticeably at idle.

Engine misfires or stumbling during acceleration: The truck hesitates, bucks, or loses power under load as air pockets pass through the injectors.

Engine stalling: The engine may stall unexpectedly, particularly at low RPMs.

If you experience these symptoms, your first step should be to meticulously inspect all fuel lines, fittings, and seals on the suction side of the system (between the tank and the lift pump) for any potential leak points.

What is the correct procedure for priming the fuel system on an MX-13?

After changing fuel filters or if the system has run out of fuel, you must prime it to remove all air. While procedures can vary slightly by model year, the general process for an MX-13 is as follows:

Ensure both new fuel filters are installed correctly and the caps are torqued to spec.

Turn the ignition key to the \"ON\" position (without starting the engine) to energize the ECM and lift pump.

Locate the manual priming pump on the primary fuel filter module.

Unscrew the plunger and pump it repeatedly until you feel significant resistance. This may take 50-100 strokes or more if the system was completely empty.

Once firm, push the plunger in and tighten it securely.

Cycle the ignition key off, then back on. You may hear the electric lift pump run for a short cycle.

Attempt to start the engine. It may run rough for a few seconds as the last bits of air are purged. If it doesn't start, do not crank for more than 30 seconds. Repeat the priming process.

Can I use fuel additives in my Paccar engine?

PACCAR generally states that additives are not necessary if you are using high-quality diesel fuel that meets ASTM D975 standards. However, they acknowledge their utility in certain situations. Use only reputable, alcohol-free additives. Common types include anti-gel/cold flow improvers for winter operation, cetane boosters to improve combustion quality, lubricity improvers for use with poor quality fuel, and biocides to kill microbial growth (algae) in contaminated tanks. Never use \"performance\" additives that claim to drastically increase horsepower, as they can alter the fuel's properties and potentially harm the system.

Where can I find an official Paccar fuel system diagram for my truck?

Obtaining the correct, VIN-specific diagram is crucial for accurate service. Generic online diagrams are helpful for understanding the basics, but for actual repairs, you need the right information. Here are the best resources:

Authorized Kenworth or Peterbilt Dealer: The service department at your dealer can access and provide official service manuals and diagrams that are specific to your truck's chassis and engine combination.

PACCAR ePortal: This is the primary online resource for dealers and authorized service centers, offering the most comprehensive and up-to-date technical information, including interactive diagrams, based on a truck's VIN.

DAVIE4 Diagnostic Software: The official diagnostic software used by technicians provides interactive diagrams, component locators, and guided troubleshooting procedures for advanced diagnostics.

Technical Service Bulletins (TSBs): PACCAR sometimes releases updated diagrams or service information through TSBs to address known issues or reflect design improvements.

Conclusion

Understanding your paccar fuel system diagram elevates it from a complex schematic on a screen or page into a powerful, practical tool for maximizing your truck's health, performance, and profitability. It provides the crucial context behind essential maintenance tasks, clarifying why daily water draining is non-negotiable and why adhering to strict filter replacement schedules with high-quality parts is the best way to protect the incredibly precise high-pressure pump and injectors from premature and costly failure.

Your MX-11 or MX-13 engine is a masterpiece of modern engineering, operating with astonishing precision at pressures up to 36,260 psi. Such a system demands respect and meticulous care. A deep knowledge of the fuel system, guided by its diagram, empowers you to prevent downtime from common, avoidable issues like air intrusion, fuel contamination, or filter neglect. It allows you to troubleshoot logically, communicate effectively with technicians, and make informed decisions about maintenance and repairs.

At G2 Diesel Products, we are committed to providing parts that uphold the integrity of this sophisticated system. Our Smart F2P Injectors are remanufactured to meet or exceed the exacting OEM standards required by your PACCAR engine. When you need reliable, high-performance replacement parts, you can trust them to integrate seamlessly into your fuel system and restore its peak performance.

The best and most affordable repair is always the one you never have to make. By arming yourself with knowledge and using quality components, you are making a direct investment in your truck's long-term longevity and reliability. Ready to ensure your fuel system operates at its best? Shop our full line of Paccar diesel fuel injectors today.