Unlocking the Mystery: How Your Car's Fuel Injectors Deliver Power

The Heartbeat of Your Engine

How injectors work is fundamental to understanding modern engine performance. They are the unsung heroes of your engine, working tirelessly behind the scenes. While carburetors relied on crude mechanical principles, modern fuel injectors are electronically controlled valves that deliver fuel with incredible precision.

Heres the process in a nutshell: The Engine Control Unit (ECU) signals the injector, an electromagnetic solenoid activates a valve, and pressurized fuel sprays through a nozzle. This atomizes the fuel into a fine mist ideal for combustion. The ECU then cuts power, closing the valveall in a fraction of a second.

This precision delivers a triple benefit that every fleet manager values:

Improved engine performance

Better fuel economy

Superior emissions control

For fleet operators managing Volvo, Mack, Kenworth, and Paccar trucks, understanding injector operation is essential for maintaining uptime, controlling costs, and ensuring regulatory compliance.

The Core of Combustion: What is a Fuel Injector?

At its core, a fuel injector is a precision-engineered, electronically controlled valve. Its primary function is to deliver exactly the right amount of fuel, at exactly the right moment, in exactly the right form for optimal combustion.

Think of it as the world's most sophisticated spray bottle. When the ECU sends a signal, an electromagnetic solenoid lifts a needle valve, allowing pressurized fuel to rush through a nozzle. The magic happens during atomization, where the injector forces fuel through tiny holes under enormous pressure, creating a fine mist that mixes perfectly with air for a clean, powerful burn.

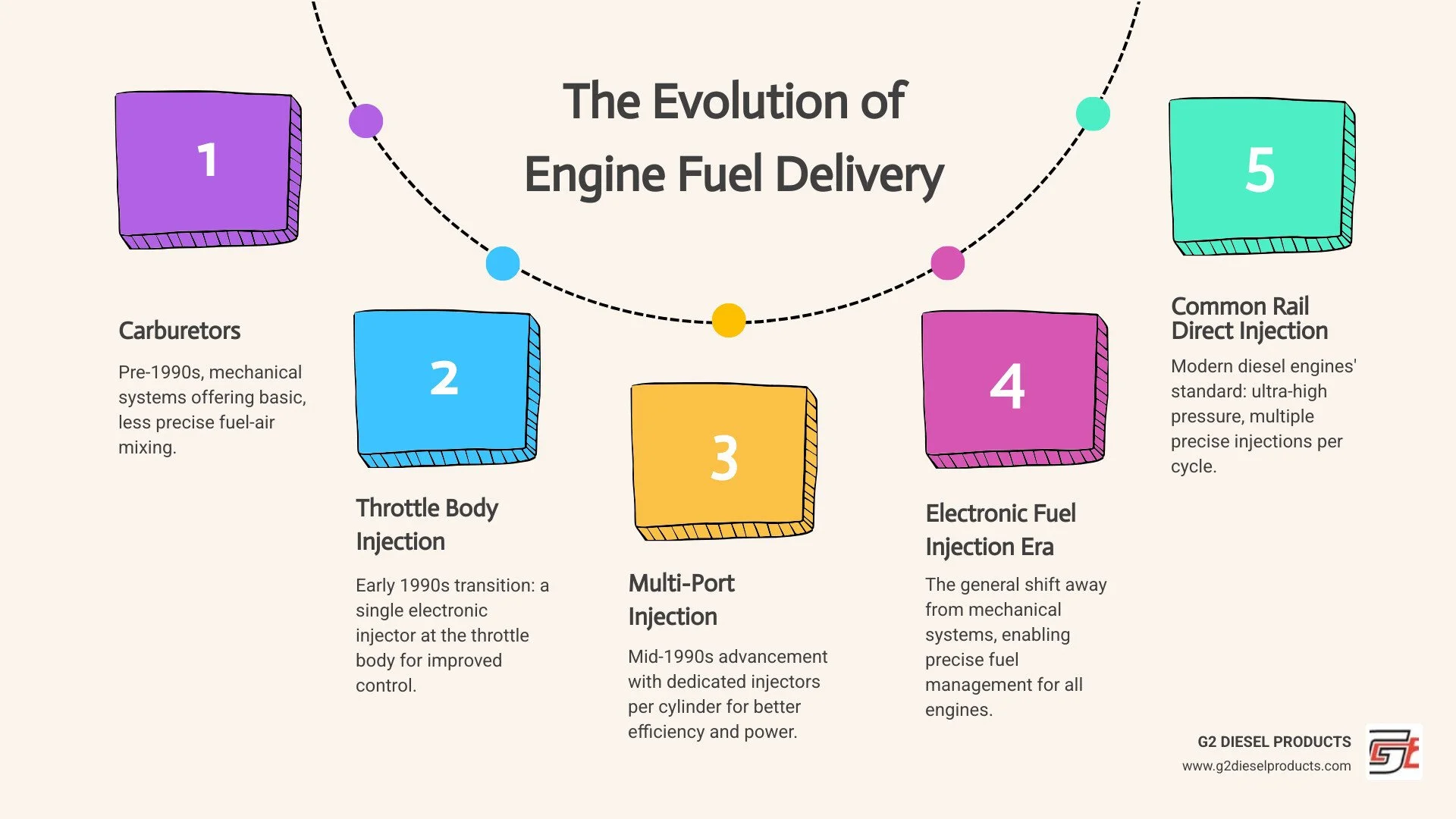

From Carburetors to Precision Injection

This technology is a massive leap from older carburetors. The switch to electronic fuel injection introduced computer precision, leading to:

Improved Power: Every drop of fuel is used efficiently.

Better Fuel Efficiency: Nothing is wasted.

Reduced Emissions: Complete combustion means fewer pollutants.

This precision also made modern catalytic converters possible, as they require the exact air-fuel mixture that only injectors can consistently provide.

The Complete System: How Injectors Work with the Engine

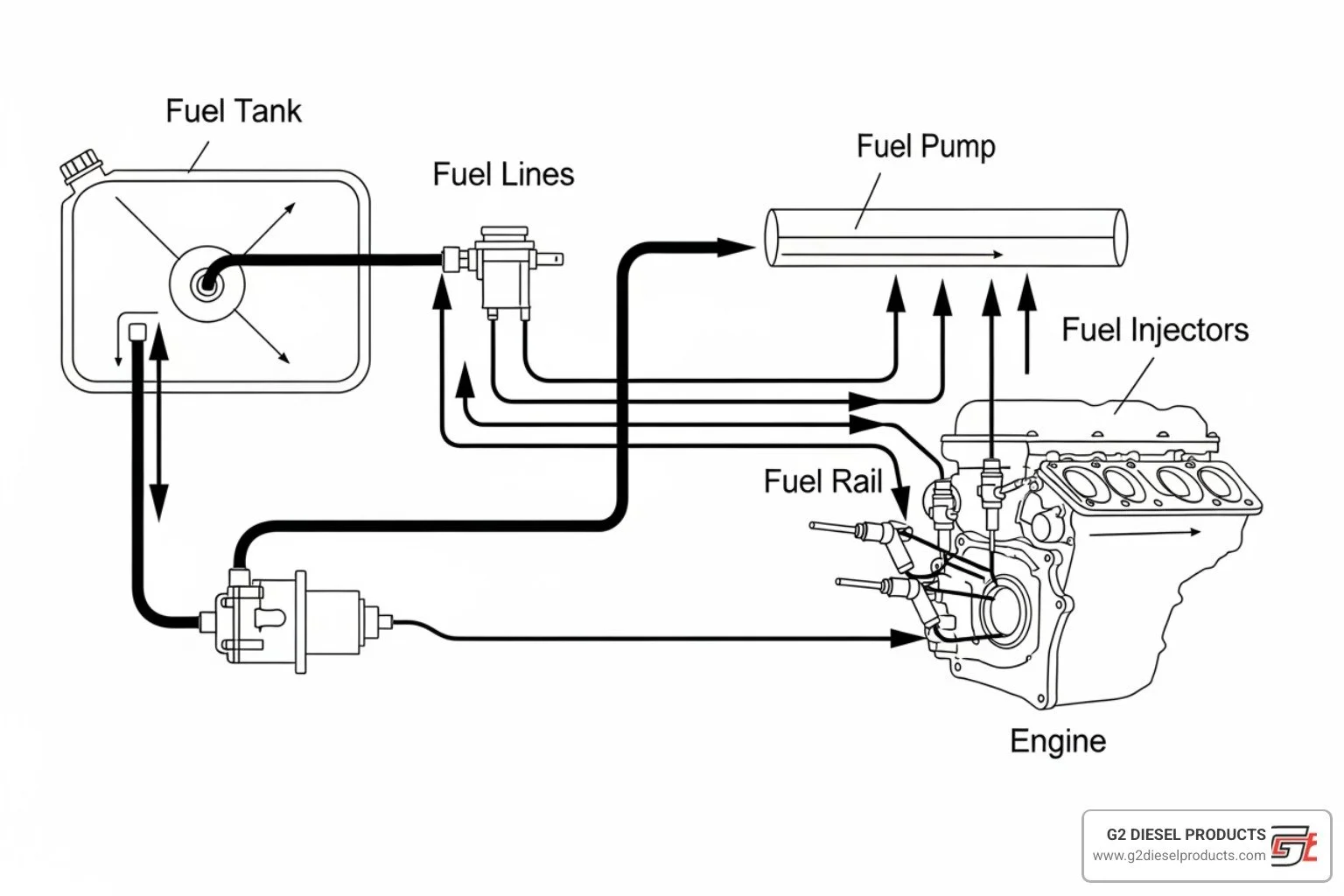

Fuel injectors are part of a larger, coordinated system designed to deliver fuel flawlessly from the tank to the engine.

The journey starts when the fuel pump pressurizes fuel from the fuel tank. This high-pressure fuel travels through fuel lines to the fuel rail, a distribution hub that feeds all the injectors. A fuel pressure regulator ensures the pressure remains constant.

The Brains of the Operation: The ECU and Sensors

The Engine Control Unit (ECU) processes thousands of data points per second from sensors like the Mass Airflow Sensor, Oxygen Sensor, and Throttle Position Sensor. Using this data, the ECU calculates the exact duration each injector should stay open—a measurement known as pulse width.

The Fuel Delivery Process

Pressurization: The fuel pump creates immense pressure (up to 30,000 PSI in modern diesels).

Distribution: Fuel waits in the pressurized fuel rail, ready for the ECU's command.

Injection: The ECU fires the injectors in a precise sequence and duration.

Atomization: Fuel sprays into the cylinder as a fine mist, mixing with air.

Combustion: The air-fuel mixture ignites, creating the power that moves your truck.

This sequence repeats thousands of times per minute, with a typical diesel injector firing over 138,000 times per hour on the highway.

Types of Fuel Injection Systems

Different injection strategies have evolved to meet specific engine design requirements, with each new system bringing improved performance.

Direct vs. Indirect Injection

Indirect injection sprays fuel into the intake manifold or a pre-chamber. Direct injection (DI) shoots fuel straight into the combustion chamber, giving engineers superior control and making it the standard for all modern diesel engines.

Diesel Fuel Injectors: How They Work in Modern Engines

Diesel injectors operate at pressures exceeding 30,000 PSI to atomize thick diesel fuel for compression ignition.

Common Rail Technology is the gold standard for Volvo, Mack, Kenworth, and Paccar trucks. It uses a single, high-pressure fuel rail to feed all injectors, allowing the ECU to command multiple, precisely timed injection events within a single combustion cycle. This capability is crucial for maximizing power, ensuring durability, and meeting strict emissions standards.

Another approach is the Electronic Unit Injector, which combines the pump and injector into a single unit for each cylinder. While effective, common rail systems are now more prevalent in modern applications.

Keeping the Power Flowing: Injector Problems and Maintenance

Understanding how injectors work includes knowing what can go wrong and how to maintain them for peak engine health.

An injector lifespan is typically 50,000 to 100,000 miles, heavily influenced by fuel quality and regular maintenance. For fleet managers, injector problems mean downtime and lost revenue.

Common Symptoms of a Failing Injector

Check Engine Light: The ECU is often the first to detect an injector problem.

Rough Idle: An uneven vibration or shaking when the truck is stationary.

Engine Misfires: A jerky, hiccupping sensation while driving.

Poor Acceleration: The truck feels sluggish or struggles to maintain speed.

Decreased Fuel Economy: A noticeable drop in MPG is a clear red flag.

Hard Starting: The engine cranks longer than usual before firing up.

Diagnosing and Maintaining Your Injectors

The most common culprits behind injector failure are clogged nozzles, fuel leaks, electrical faults, and internal deposit buildup. Professional cleaning using ultrasonic technology can restore many injectors to like-new performance.

Regularly changing your fuel filters is the cheapest and most effective insurance against premature injector failure—it's the first line of defense in protecting your investment.

The Bigger Picture: Injectors, Fuel Economy, and Emissions

Modern fuel injectors strike a balance between power, fuel efficiency, and environmental responsibility. By mastering the precise air-fuel ratio, injectors enable complete combustion, which maximizes fuel efficiency and reduces harmful emissions.

How Injectors Improve Fuel Economy

Precision eliminates waste. By atomizing fuel into a fine mist and delivering it at the perfect moment, injectors ensure every drop is converted into energy. This optimized combustion means your engine works smarter, not harder, translating directly to significant financial savings at the fuel pump.

The Role of Injectors in Emissions Control

Clean emissions start with clean combustion. The precise fuel control from injectors is essential for catalytic converter efficiency. In diesel engines, advanced systems use multiple injection pulses to control combustion temperatures, crucial for reducing NOx formation while minimizing particulate matter.

Frequently Asked Questions about Fuel Injectors

Here are answers to the three most common questions we hear from fleet managers and owner-operators.

How long do fuel injectors typically last?

The typical lifespan is 50,000 to 100,000 miles, but this can vary significantly. The three biggest factors influencing longevity are fuel quality, adherence to regular maintenance schedules, and your primary driving habits (e.g., highway cruising vs. stop-and-go city driving).

Can a clogged fuel injector be cleaned?

Yes, absolutely. For most clogs and deposit buildup, professional ultrasonic cleaning is a highly effective and cost-efficient solution that can restore an injector to like-new performance. However, if an injector has internal mechanical wear or an electrical failure, replacement is the only option. A professional evaluation can help you decide between replacement versus cleaning.

Does fuel injection increase horsepower?

Yes. A properly functioning fuel injection system can add 10 to 20 horsepower compared to older or failing systems. This power gain doesn't come from using more fuel, but from using it more efficiently. Improved atomization and optimized air-fuel ratios lead to a more complete and powerful combustion, extracting maximum energy from every drop of fuel.

Conclusion: The Precision Power of Modern Fuel Injection

After this deep dive, it's clear that how injectors work is a story of remarkable precision. These critical components sit at the intersection of power, efficiency, and environmental responsibility, revolutionizing what we expect from modern engines.

For fleet managers of advanced diesel engines in Volvo, Mack, Kenworth, and Paccar trucks, reliable injectors are the foundation of your operation's profitability. They are essential for delivering outstanding engine performance and exceptional fuel efficiency while meeting strict emissions standards.

At G2 Diesel Products, we specialize in manufacturing high-quality diesel fuel injectors for the demanding world of heavy-duty trucking. We understand that when you manage a fleet, reliability isn't just a feature—it's everything. We are proud to lead innovation within the diesel parts industry, delivering products that meet the exacting standards of today's sophisticated engines.

For fleet operators ready to experience the difference that expertly engineered injectors can make, explore our range of SMART F2P Injectors. Because when it comes to keeping your operation moving, precision matters.