Injector Insights: Finding the Best Fuel Injectors for Your Diesel

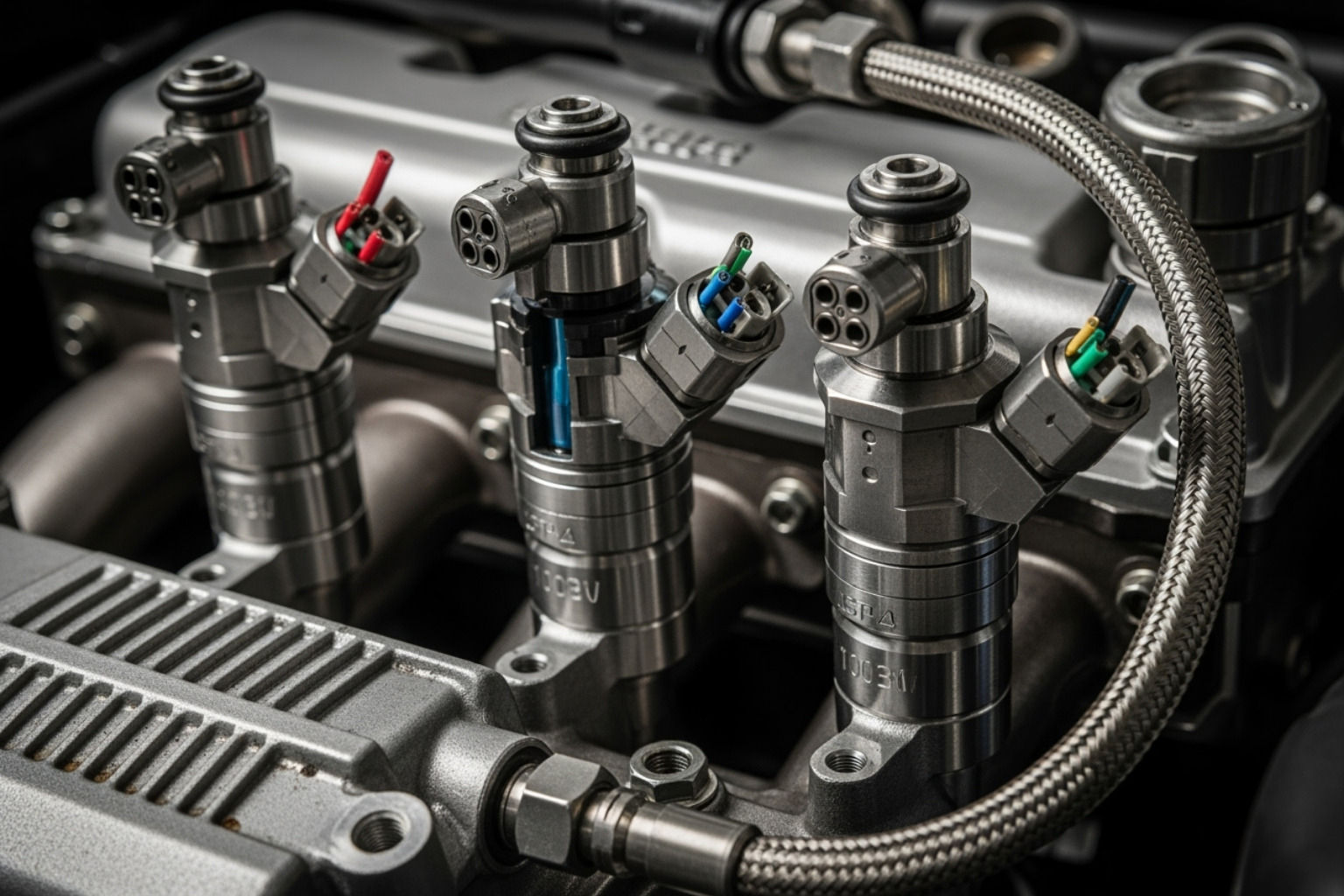

The best diesel fuel injectors are the heart of your engine's fuel system, delivering precise fuel metering, optimal atomization, and reliable performance. (For readers new to the technology, the history and basic principles of the diesel engine provide helpful context.) These precision components determine how efficiently your diesel burns, directly impacting power output, fuel economy, and emissions compliance. For fleet managers, choosing the right injectors means the difference between reliable operation and costly downtime.

Modern diesel engines operate under extreme conditions. Injectors face approximately 140,000 cycles per hour at typical highway speeds, delivering fuel at pressures exceeding 30,000 PSI in common rail systems. This demanding environment requires components built to the highest standards. Poor-quality injectors can cause rough idling, increased fuel consumption, excessive emissions, and even catastrophic engine damage. Conversely, high-performance injectors improve performance, reduce operating costs, and extend engine life.

When selecting injectors, key factors include:

- Engine compatibility (make/model/year)

- Application requirements (towing, highway, performance)

- New vs. OEM-remanufactured options

- Flow rate and material quality

Water contamination remains the biggest threat to injector longevity, as it displaces essential lubrication and accelerates wear. This guide provides the insights you need to make informed purchasing decisions for your Volvo, Mack, Kenworth, and Paccar fleet.

Understanding Diesel Fuel Injector Fundamentals

To appreciate what makes the best diesel fuel injectors, it helps to understand how they function. They don't just dump fuel into the combustion chamber; they carefully measure, time, and atomize every drop for optimal combustion. This entire process is orchestrated by the Engine Control Module (ECM), which constantly monitors engine conditions and tells each injector exactly when to fire and how much fuel to deliver.

The key to efficiency is fuel atomization. When fuel is forced through the injector at pressures that can exceed 30,000 PSI, it breaks into millions of tiny droplets. This creates a fine mist, ensuring an ideal fuel-air mixture for a complete and powerful burn. Poor atomization leads to wasted fuel, reduced power, and higher emissions.

Mechanical Injectors

The original diesel injectors, mechanical injectors, use a simple but robust spring-and-plunger design. When fuel pressure builds enough to overcome the spring's resistance, the plunger lifts and sprays fuel into the cylinder. While known for their exceptional durability, they operate at lower pressures and lack the fine control of modern systems. You'll typically find them in older, pre-emissions diesel engines.

Electronic Unit Injector Systems (EUI & HEUI)

Electronic Unit Injector (EUI) systems represent a major leap forward, combining the fuel pump and nozzle into a single unit for each cylinder. This design allows for much higher injection pressures and gives the ECM precise electronic control over timing and fuel quantity. Our guide on Electronic Unit Injector (EUI) operation explains this in more detail.

Hydraulic Electronic Unit Injector (HEUI) systems take this a step further by using pressurized engine oil to intensify fuel pressure within the injector itself. This clever design achieves superior atomization and fuel control. The Hydraulic Electronic Unit Injector (HEUI) system was a breakthrough that paved the way for cleaner, more efficient engines.

Common Rail Injectors

Common rail injectors are the current gold standard and are found in virtually every modern heavy-duty truck. In this system, a central high-pressure rail supplies fuel to all injectors simultaneously. Each injector then uses a fast-acting solenoid or piezo actuator to precisely control the injection event. The game-changing feature is the ability to perform multiple injections per cycle—a small pilot injection to quiet combustion, a main injection for power, and a post-injection for emissions control. This results in quieter operation, better fuel economy, and cleaner emissions.

When seeking the best diesel fuel injectors for your Volvo, Mack, Kenworth, or Paccar truck, Common Rail Injectors offer the superior performance today's applications demand. You can learn more about how common rail injectors work in our detailed guide.

How to Choose the Best Diesel Fuel Injectors for Your Engine

Selecting the best diesel fuel injectors is a critical investment in your truck's long-term reliability and performance. The right choice ensures smooth operation, while a poor one can lead to expensive breakdowns. While the Diesel Fuel Injector Cost is an important consideration, prioritizing quality and compatibility will save you far more money by preventing downtime and maximizing efficiency.

Key Factors for Selecting the Best Diesel Fuel Injectors

When you're hunting for the best diesel fuel injectors, several crucial factors should guide your decision:

- Engine Compatibility: This is non-negotiable. An injector designed for one engine will not work correctly in another. At G2 Diesel Products, we specialize in precise compatibility for Volvo, Mack, Kenworth, and Paccar trucks, ensuring you get the exact part your engine needs.

- Application: A truck hauling heavy loads up steep grades has different needs than one cruising highways. Select injectors optimized for your primary use, whether it's heavy-duty towing or fuel-efficient long-hauling.

- Flow Rate and Spray Pattern: Stock injectors are designed to meet OEM specifications for performance and emissions. Quality injectors ensure optimal spray patterns for complete combustion, which translates directly into better fuel economy and cleaner emissions.

- Material Quality: The best injectors use stainless steel and high-strength alloys to withstand the extreme pressures and temperatures inside a diesel engine. Inferior materials can lead to premature wear and failure.

- Warranty: A solid warranty shows the manufacturer's confidence in their product. We stand behind our injectors with comprehensive warranty coverage to protect your investment.

Once you've chosen your injectors, knowing How to Replace Diesel Injectors properly is vital for performance.

New vs. Remanufactured: Which is Best for Your Diesel Fuel Injectors?

One of the biggest decisions is whether to choose new or OEM-remanufactured units. Both are excellent options, depending on your needs and budget.

| Criteria | New Injectors | OEM-Remanufactured Injectors |

|---|---|---|

| Quality | Highest, all-new components to OEM specs | OE-level, rebuilt to new specs with genuine parts |

| Performance | Optimal, factory-calibrated | Restored to original performance, often with latest updates |

| Warranty | Comprehensive, often longest | Strong, comparable to new |

| Cost | Highest initial investment | Excellent value, lower than new |

| Core Charge | None | Required, refundable upon core return |

New injectors represent the gold standard, manufactured entirely from fresh components and built to the latest OEM specifications for peak performance right out of the box.

OEM-remanufactured injectors offer a compelling alternative that combines quality with value. This process involves rebuilding used injector cores to original manufacturer specifications, replacing all worn components, and incorporating the latest design updates. These injectors undergo rigorous testing to ensure they meet or exceed original performance and reliability. It's crucial to distinguish these from generic "rebuilt" options, which may cut corners. At G2 Diesel Products, we offer both new and OEM-remanufactured injectors that meet the highest standards, along with all necessary Fuel Injector Replacement Parts.

The Payoff: Benefits of High-Quality & Performance Injectors

Investing in the best diesel fuel injectors isn't just a repair; it's an upgrade that open ups your engine's true potential. Quality injectors orchestrate a precise combustion process that improves every aspect of your truck's performance, paying dividends across your operation.

Improved Engine Performance and Power

High-quality injectors translate directly into performance gains you can feel behind the wheel. This precision results in:

- Increased Horsepower and Torque: Performance injectors deliver fuel with surgical precision, allowing your engine to generate more power when you need it most, whether you're climbing a steep grade or merging onto a highway.

- Improved Throttle Response: Gone are the days of lag. Quality injectors ensure your engine reacts instantly to your inputs, making your truck feel more agile and confident.

- Smoother Power Delivery: When injectors maintain optimal spray patterns and timing, fuel burns consistently across all cylinders. This creates a uniform power output that reduces vibration and makes for a more comfortable drive.

Our Performance Diesel Injectors are engineered to deliver these tangible benefits for Volvo, Mack, Kenworth, and Paccar fleets.

Improved Fuel Economy

This is where the best diesel fuel injectors have the most immediate impact on your bottom line. In heavy-duty trucking, even a modest improvement in fuel efficiency translates to thousands of dollars in annual savings per truck.

- Precise Fuel Metering: The engine gets exactly the fuel it needs and nothing more. Every combustion cycle receives the optimal amount, eliminating the waste that comes from over-fueling.

- Optimal Atomization: When fuel breaks down into a finer mist, it exposes more surface area to oxygen. This leads to more complete combustion, meaning more of your fuel budget converts to miles driven.

- Lower Operating Costs: The combination of precise metering and optimal atomization reduces fuel waste, which directly lowers your operating costs and improves profitability.

Reduced Emissions and Environmental Impact

Quality injectors play a crucial role in achieving cleaner emissions without sacrificing performance.

- Cleaner Burn: Efficient combustion produces fewer harmful byproducts. This means your truck contributes less pollution while maintaining the power you depend on.

- Minimized Soot (Particulate Matter): The black smoke seen from poorly maintained trucks is a result of incomplete combustion. High-quality injectors ensure fuel burns thoroughly, dramatically reducing these emissions.

- Meeting Environmental Regulations: Modern diesel engines must comply with strict emissions standards. Properly functioning injectors are essential for aftertreatment systems to work effectively. Optimized combustion also contributes to Diesel Injector Noise Reduction.

Common Injector Problems and How to Prevent Them

Even the best diesel fuel injectors can fall victim to common issues if not properly maintained. Understanding these problems and how to prevent them is crucial for extending injector life and avoiding costly downtime. Prevention is always better and cheaper than treatment.

When injectors start failing, your truck will provide warning signs. Common symptoms include a rough idle, engine misfiring, excessive smoke from the exhaust, a noticeable drop in poor fuel economy, and an illuminated check engine light. You can find more troubleshooting guidance in our resource on Fuel Injector Problems Diesel.

The #1 Culprit: Fuel Contamination

The primary enemy of fuel injectors is fuel contamination. Your injectors are precision instruments, and even microscopic debris can cause premature wear. The real villain, however, is water contamination. Water displaces the fuel's natural lubrication, creating metal-on-metal contact that dramatically accelerates wear and leads to premature failure. This can also cause internal corrosion on critical components. Other issues include lubricity loss from poor-quality fuel and carbon build-up on the injector nozzle, which disrupts the spray pattern and reduces efficiency.

Prevention and Maintenance Strategies

Fortunately, most injector problems are preventable with smart maintenance practices:

- Use High-Quality Diesel Fuel: This is your first line of defense. Quality fuel contains fewer contaminants and provides better lubricity.

- Regular Fuel Filter Replacement: This is non-negotiable. Follow your truck's maintenance schedule to capture contaminants before they reach your injectors.

- Use a Water Separator: This device is crucial for removing water from fuel. Be sure to drain it regularly.

- Use Quality Fuel Additives: A good Diesel Fuel Injector Cleaner can improve lubricity, prevent gelling, and keep the fuel system clean.

- Professional Testing: Our Diesel Injector Testing Services can identify issues before they become major failures.

- Ensure Proper Installation: Incorrect installation can cause leaks or damage. Always ensure the job is done by trained professionals who know How to Clean Common Rail Diesel Injectors and prepare the injector bore correctly.

Following these practices will significantly extend the lifespan of your injectors and keep your Volvo, Mack, Kenworth, and Paccar trucks running reliably.

Frequently Asked Questions about Diesel Fuel Injectors

Here are answers to the most common questions we receive from fleet managers and owners of Volvo, Mack, Kenworth, and Paccar trucks.

What are the signs of a failing diesel injector?

Your truck will usually give you several clues. The most obvious is the check engine light, but you should also watch for performance issues. Classic symptoms include engine misfires and a rough, shaky idle. You might also notice poor acceleration and a significant increase in fuel consumption. Finally, pay attention to visible smoke from the exhaust: white smoke often means unburnt fuel, while black smoke indicates over-fueling or a poor spray pattern. Diagnosing the specific cause often requires professional Diesel Injector Testing Equipment.

Can you replace just one diesel injector?

While you can replace a single injector, it is generally not recommended. Injectors are designed to work as a balanced set, delivering consistent flow rates and spray patterns. When you install one new injector with several older, worn ones, you create an imbalance that can lead to rough engine operation and uneven power delivery. Furthermore, if one injector has failed due to normal wear and tear, the others have experienced the same mileage and conditions. They are likely approaching the end of their service life as well. For these reasons, we strongly recommend replacing injectors as a complete set to ensure balanced performance and long-term reliability.

How long do diesel fuel injectors last?

The typical lifespan for diesel fuel injectors ranges from 100,000 to 300,000+ miles, but this can vary widely based on several key factors:

- Fuel Quality: This is the single biggest factor. Consistently using clean, high-quality diesel from reputable sources is crucial. Contaminated fuel, especially with water, will drastically shorten injector life.

- Maintenance Practices: Sticking to a regular maintenance schedule makes a huge difference. This includes regular fuel filter changes, proper water separator maintenance, and using quality fuel additives.

- Operating Conditions: A truck that spends most of its time on long highway hauls will typically see longer injector life than one in constant stop-and-go city traffic or pulling heavy loads.

- Injector Quality: Original Equipment or high-quality OEM-remanufactured injectors are built to precise specifications and will outlast cheaper alternatives that may cut corners on materials or quality control.

Conclusion

Choosing the best diesel fuel injectors is a critical investment in your fleet's future, directly influencing everything from daily fuel costs to long-term engine reliability. We've seen how injector technology has evolved to deliver an incredible balance of power and efficiency, and how selecting the right parts for your engine is paramount.

Prioritizing quality—whether you choose new or OEM-remanufactured units—ensures you receive the full benefits of improved performance, better fuel economy, and lower emissions. The value proposition is clear. Perhaps most importantly, proactive maintenance is the best strategy to prevent costly downtime. Protecting your investment from fuel contamination by using quality fuel and changing filters regularly will maximize the lifespan of your injectors.

At G2 Diesel Products, we are dedicated to manufacturing high-quality diesel fuel injectors specifically for Volvo, Mack, Kenworth, and Paccar trucks. Our commitment to innovation, reliability, and customer service means you get products engineered to meet the demanding requirements of your operation.

Make informed decisions, prioritize quality over short-term savings, and maintain your injectors proactively. Your engines—and your bottom line—will thank you for it.

Ready to experience the difference quality makes? Find the right injectors for your heavy-duty truck and see why fleet managers trust G2 Diesel Products to keep their trucks running strong.