New, Reman, or OEM Choosing the Right Injectors for Your Cummins 8.9L

Why Choosing the Right Injectors is Critical for Your Cummins 8.9L Fleet

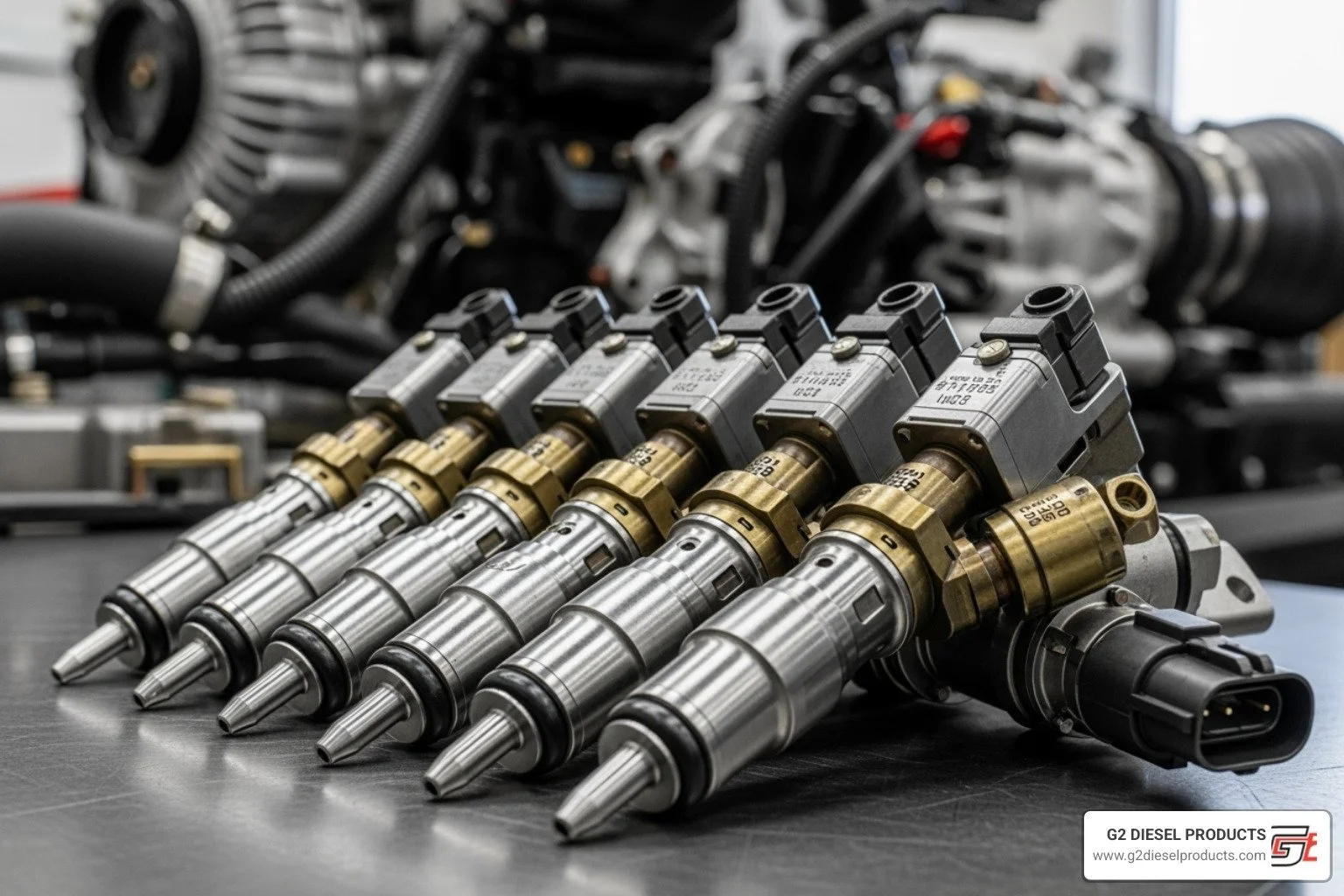

Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series are the heart of fuel delivery in one of the most popular medium-duty diesel engines on the road. For fleets of transit buses, motorhomes, or medium-duty trucks, the right injectors directly impact engine reliability, fuel economy, and the bottom line.

Quick Reference: Key Injector Options for Cummins 8.9L Engines

New OEM Injectors: Highest cost, latest technology, full warranty coverage.

Quality Remanufactured: A cost-effective option built to OEM specs with environmental benefits.

Part Number Critical: The Engine Serial Number (ESN) is required for correct fitment.

System Type Matters: CAPS (pre-2003) and HPCR/XPI (2003+) systems use different injectors.

The Cummins ISL, an 8.9-liter powerhouse, has been a staple since 1999, delivering 280-450 horsepower and a service life of 500,000 miles with proper care. However, injector choice can make or break that reliability promise.

A major evolution occurred in 2003 when Cummins transitioned from the CAPS (Cummins Accumulator Pump System) to the more sophisticated HPCR (High-Pressure Common Rail) system. This fundamentally changed fuel delivery to meet tighter emissions standards.

Choosing the wrong parts can be costly. One forum user found this out the hard way, spending over $12,000 on repeated injector failures from a poor-quality rebuilder. In contrast, others report original equipment lasting well beyond 300,000 miles with proper maintenance and quality replacements.

Understanding the Cummins ISL/L9 Engine and Its Fuel Systems

To properly service Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series, it helps to understand the engine itself. The Cummins ISL is a workhorse that has proven itself for over two decades.

This 8.9-liter inline 6-cylinder diesel debuted in 1999, replacing the L10 engine. It hit a sweet spot of power and practicality, delivering serious performance while being over 300 pounds lighter than its predecessor. It is built for durability with a forged-steel crankshaft, forged-steel connecting rods, and a 24-valve cylinder head secured with six head bolts per cylinder.

As emissions regulations like the EPA 2010 standards tightened, the ISL evolved into the L9. This evolution introduced advanced technologies like a variable-geometry turbocharger (VGT) and the XPI (Xtra-High Pressure Injection) fuel system to maintain performance while cutting emissions. With a power range of 280 to 450 horsepower and an expected 500,000-mile service life, choosing the right injectors is paramount.

For a deeper dive, see our resource on Diesel Engine Common Rail or learn More about the Cummins ISL engine.

The Early Years: Cummins Accumulator Pump System (CAPS)

Before 2003, ISL engines used the Cummins Accumulator Pump System (CAPS). This electronically controlled system employed mechanically actuated injectors and met the emissions standards of its time without requiring EGR or DPF systems, simplifying maintenance.

The Modern Era: High-Pressure Common Rail (HPCR) and XPI

Around 2003, stricter emissions regulations prompted the switch to the High-Pressure Common Rail (HPCR) injection system—a game-changer for Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series. HPCR systems use fully electronic injectors capable of multiple, precise injection events per combustion cycle. The result is dramatically improved fuel efficiency, better performance, and cleaner emissions.

Cummins later refined this with its XPI (Xtra-High Pressure Injection) technology. Operating at ultra-high pressures, XPI provides extremely accurate fuel delivery and atomization for cleaner combustion, quieter operation, and superior power. To meet EPA 2010 standards, these engines integrate aftertreatment systems such as EGR (Exhaust Gas Recirculation), diesel particulate filters (DPF), and selective catalytic reduction (SCR). The DPF alone can reduce particulate matter by well over 90%, while SCR with DEF achieves near-zero NOx emissions.

For a detailed explanation, visit our guide on How Do Common Rail Injectors Work.

Spotting Trouble: Signs, Causes, and Diagnosis of Failing Injectors

Even robust Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series wear out. Catching problems early can save thousands, preventing a minor replacement from becoming a major engine rebuild. Common culprits for failure include fuel contamination, internal wear, electrical issues, or clogged nozzles. For a comprehensive look at these issues, see our resource on Fuel Injector Problems Diesel.

Common Symptoms of a Bad Injector

Excessive Smoke: White smoke indicates unburnt fuel (injector stuck open), black smoke suggests over-fueling, and blue smoke points to oil burning, possibly from fuel dilution.

Engine Misfires and Rough Idle: A shaking or "skipping" engine feeling, especially at idle, often means one or more cylinders aren't getting the correct amount of fuel.

Power Loss and Poor Acceleration: The engine feels "lazy" or "sluggish" because compromised fuel delivery prevents it from generating full power.

Increased Fuel Consumption: A leaking or stuck-open injector delivers more fuel than needed, directly impacting your bottom line.

Hard Starting: The engine struggles to build sufficient fuel pressure for ignition, especially in cold weather.

Engine Knocking: A distinct metallic knocking sound can indicate improper combustion due to injector timing or spray pattern issues.

Fuel in the Oil: A diesel smell on the dipstick is a serious sign that fuel is leaking past piston rings and diluting your engine oil.

Check Engine Light: Modern engines will often trigger a fault code related to the fuel system.

Top Causes of Injector Failure

Fuel Contamination: Water, dirt, rust, and other debris are the number one cause of failure, corroding and scoring delicate internal components.

Metal Particles: In ISL engines, microscopic metal particles from normal wear in the cylinder head can circulate in the fuel and cause catastrophic injector damage.

High Mileage and Normal Wear: After 300,000 to 500,000 miles, the immense pressure and heat cycles will eventually wear out even the best-built injectors.

Incorrect Installation: Contamination during installation, or improper torque on bolts and fuel lines, can cause brand-new injectors to fail quickly.

Electrical Failures: HPCR injectors rely on electronic controls. Oil contamination in the wiring harness under the valve cover is a known issue that can cause intermittent failures.

How to Effectively Diagnose Injector Issues in an ISL/L9

Diagnosing Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series requires a methodical approach.

Scan Tool Diagnostics: Use a Cummins-compatible tool to read fault codes, monitor live data (fuel rail pressure, cylinder balance), and perform active tests.

Cylinder Cutout Test: This software test shuts off individual injectors one by one. If there's no change in engine performance when an injector is cut out, you've likely found the faulty cylinder.

Return Flow Rate Testing: Measures how much fuel each injector sends back to the tank. Excessive return flow indicates an internal leak.

Visual and Electrical Inspection: Check for external fuel leaks, damaged connections, and oil saturation in the injector wiring harness.

Professional Bench Testing: For definitive answers, have the injectors removed and tested at a specialized facility. This provides accurate measurements of spray patterns and flow rates. G2 Diesel Products offers comprehensive Diesel Injector Testing Services. Learn more about the process in our guide on How to Check Common Rail Injectors.

Start with simple, non-invasive tests and work your way up. Addressing warning signs early always costs less than waiting for a catastrophic failure.

The Big Decision: New vs. Remanufactured Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series

When your Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series need replacement, you face a key decision: brand new OEM or quality remanufactured units? The choice impacts your budget, long-term reliability, and warranty. Both are excellent options when sourced from a reputable supplier. For a broader look at costs, see our guide on Diesel Fuel Injector Cost.

Option 1: Brand New OEM Injectors

New OEM injectors from Cummins represent the latest in design and technology. While they have the highest upfront cost, they come with a full manufacturer warranty and the peace of mind that you are installing factory-fresh components. For critical applications where downtime is unacceptable, the guaranteed performance and comprehensive warranty can be worth the premium investment.

Option 2: Quality Remanufactured Injectors

There is a world of difference between a "rebuilt" injector and a professionally remanufactured one. True remanufacturing involves completely disassembling the injector, cleaning every part, and replacing all wear components (nozzles, plungers, seals) with new, high-quality parts. This process restores the injector to meet or exceed original performance standards. The result is a reliable, like-new injector at a fraction of the cost of an OEM unit. For more details on the process, visit our resource on Diesel Fuel Injector Rebuilders.

Comparing New vs. Remanufactured Injectors

Feature Brand New OEM Injectors Quality Remanufactured Injectors Cost Highest upfront investment Significantly more affordable Warranty Full manufacturer warranty Typically 1-year or mileage-based, varies by rebuilder Performance Guaranteed optimal performance, latest specs Restored to OEM performance or better, rigorously tested Availability Readily available, direct from manufacturer Readily available, relies on core supply Environmental Higher resource consumption for new production Eco-friendly, reduces waste and conserves materials

Finding the Right Part Number for your Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series

Installing the wrong part can lead to poor performance or severe engine damage. Your Engine Serial Number (ESN) is the key to identifying the correct injector. The ESN reveals your engine's build year, emissions configuration, and fuel system type (CAPS or HPCR/XPI), which is critical for selecting the right part.

Common part numbers include 5579409, 5579409PX, and 2872331, but variations exist. At G2 Diesel Products, we use your ESN to ensure complete compatibility. Our team specializes in providing the correct Cummins ISL/L9 Reman Fuel Injectors for your exact application, eliminating guesswork and costly mistakes.

Maximizing Injector Lifespan and Engine Performance

Getting the most from your Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series requires more than just buying quality parts; it demands proper maintenance and installation. A well-maintained ISL engine can reach its 500,000-mile service life, but that depends heavily on how you treat its injectors. For guidance on the replacement process, check out our resource on How to Replace Diesel Injectors.

What is the Typical Lifespan and How Can I Extend It?

Injector lifespan can range from 150,000 miles to well over 350,000 miles, depending on care. To extend it:

Use Quality Fuel and Filters: Modern injectors have micron-level tolerances. Stick to the recommended filter change intervals (e.g., for ISL9, primary every 20 k miles/500 hrs, secondary every 40 k miles/1,000 hrs) to protect them from damaging particles.

Perform Regular Oil Changes: Fuel dilution from leaking injectors can degrade oil and accelerate engine wear. Follow the recommended oil change schedule (e.g., for ISL9, every 20 k miles/500 hrs).

Avoid Excessive Idling: Long idle times lead to incomplete combustion, causing carbon buildup on injector tips that disrupts spray patterns and reduces efficiency.

Follow the Maintenance Schedule: Adhering to the full OEM maintenance schedule—including overhead adjustments and DPF service—supports overall engine health. For professional upkeep, consider a Diesel Fuel Injector Cleaning Service.

The Critical Role of Cleanliness During Installation

When working with Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series, cleanliness is absolutely critical. Common-rail systems operate at extreme pressures where a single speck of dirt can destroy a precision component.

Before installation, thoroughly clean the injector bores in the cylinder head to ensure proper seating. Use only lint-free rags and clean tools. Adhere strictly to torque specifications for hold-down bolts and fuel-line connections to prevent leaks or component damage. A few extra minutes of preparation can prevent thousands of dollars in repairs.

Potential Consequences of Using Faulty Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series

Ignoring a failing injector can lead to catastrophic engine damage:

Piston Damage: An improper spray pattern can create hot spots on the piston crown, leading to melting or cracking.

Cylinder Washing: Leaking fuel washes away the protective oil film from cylinder walls, causing rapid wear on rings and liners.

Crankcase Dilution: Fuel leaking into the oil pan thins the oil, destroying its lubricating properties and causing accelerated wear on bearings and other critical components.

DPF and Aftertreatment Damage: Excess soot from poor combustion clogs the DPF, while raw fuel can damage expensive aftertreatment components.

Promptly addressing injector issues is not just maintenance—it is financial protection for your engine.

Frequently Asked Questions about Cummins ISL/L9 Injectors

We hear the same questions from fleet managers and owner-operators about Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series. Here are answers to the three most common concerns.

How does the fuel system (CAPS vs. HPCR) affect which injector I need?

CAPS and HPCR injectors are not interchangeable. They are designed for completely different fuel systems. Pre-2003 ISL engines use the mechanically operated CAPS (Cummins Accumulator Pump System). Engines from 2003 and later use the fully electronic HPCR (High-Pressure Common Rail) or XPI systems, which operate at much higher pressures. The golden rule is to use your Engine Serial Number (ESN) to identify the correct fuel system and corresponding injector for your engine.

Is a remanufactured injector as good as a new one?

Yes, a high-quality remanufactured injector can be just as good as a new one. The key is the rebuilder's process. True remanufacturing is not a simple "rebuild." It involves a complete teardown, rigorous cleaning and inspection, and replacement of all wear parts (nozzles, plungers, seals) with new components. Each unit is then tested on specialized benches to ensure it meets or exceeds OEM specifications for performance, flow rate, and spray pattern. This process provides a reliable, cost-effective alternative to new OEM parts.

What is a core charge and why do I have to pay it?

A core charge is a refundable deposit paid when you buy a remanufactured part. It creates a financial incentive for you to return your old, used part (the "core"). This system ensures a steady supply of rebuildable cores for the remanufacturing industry, which helps keep parts available and prices down for everyone. Once you return your old injector in rebuildable condition (no cracks, fire damage, etc.), your core charge is fully refunded.

Conclusion

Your choice of Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series is a critical decision that protects your investment and keeps your fleet on the road. Whether you opt for brand new OEM injectors or quality remanufactured units, success hinges on three key factors: getting the right part for your ESN, ensuring absolute cleanliness during installation, and adhering to a consistent maintenance schedule.

Your injectors work under immense pressure. They require quality fuel, clean filters, and proper installation to perform reliably. Neglecting these basics can lead to expensive downtime and repairs, regardless of the quality of the injector itself.

At G2 Diesel Products, we have the expertise to ensure your Cummins ISL / L9 Injectors – 8.9L Diesel Engine Series perform at their best. We provide more than just parts; we offer a partnership with diesel fuel injection specialists dedicated to your success.

Ready to get your Cummins ISL or L9 running like new? Find the right injectors for your Cummins ISL/L9 application and experience the G2 Diesel Products difference. Your engine and your bottom line will thank you.