Demystifying the Common Rail Injector: A Deep Dive

Understanding the Heart of Modern Diesel Technology

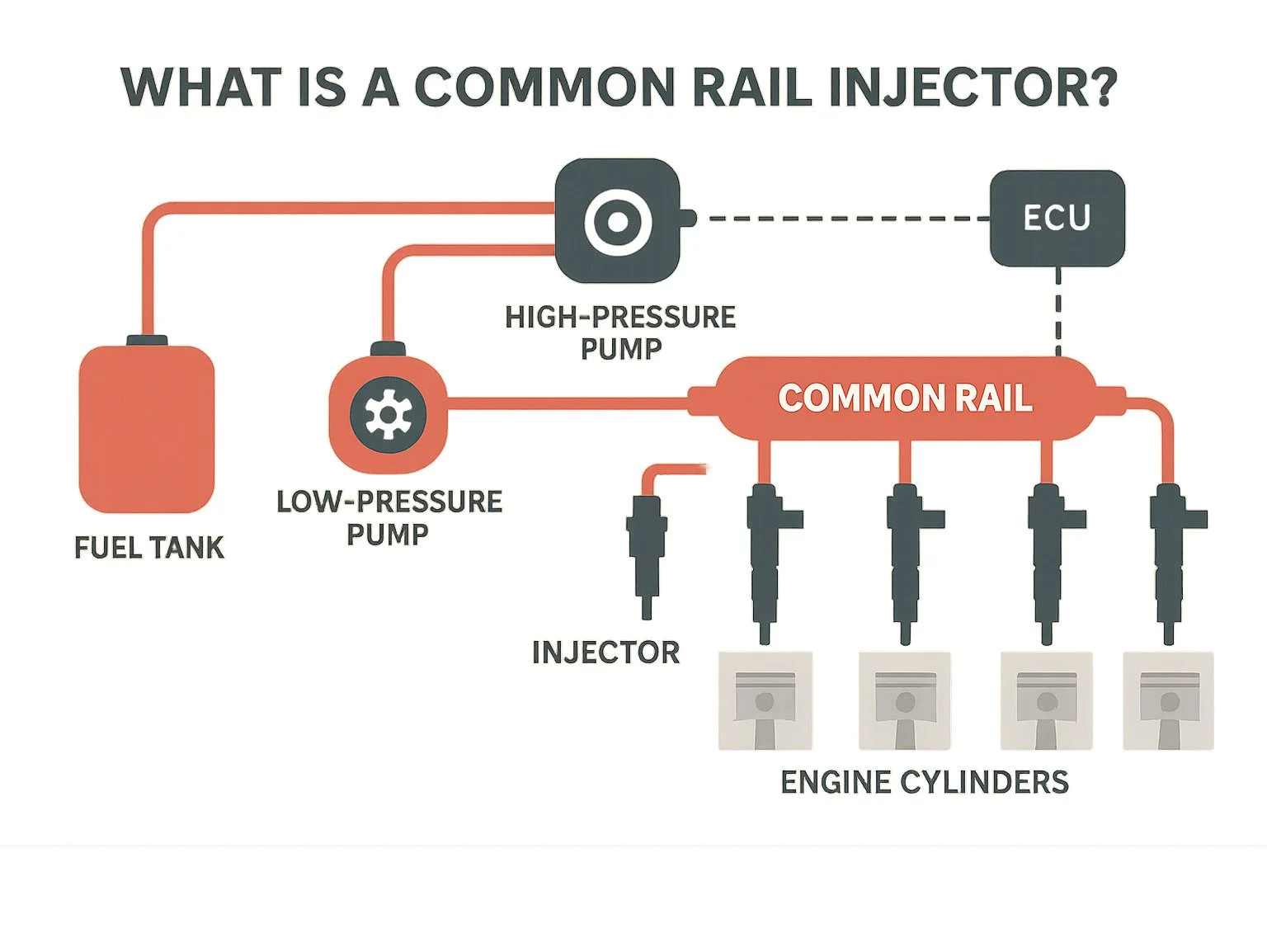

The question what is a common rail injector delves into the single most transformative component in modern diesel engine technology. In essence, it is a highly sophisticated, electronically controlled fuel injector that, unlike its predecessors, does not create its own pressure. Instead, it acts as an ultra-fast valve, receiving a constant supply of extremely high-pressure fuel from a shared reservoir, or "common rail." It then precisely meters and injects this fuel directly into the engine's combustion chamber at immense pressures, often exceeding 29,000 PSI (2,000 bar).

This technology was the critical breakthrough that allowed diesel engines to meet the stringent emissions regulations of the 21st century, such as the EPA 2007/2010 standards in North America and Euro IV, V, and VI standards in Europe. It single-handedly changed the public perception of diesel engines, transforming them from loud, smoky, and unrefined workhorses into quiet, clean, and remarkably efficient powerplants.

Key characteristics of common rail injectors that enable this transformation:

Extreme High-Pressure Operation: Modern systems operate between 1,800-2,500 bar (26,000-36,000+ PSI), with future systems pushing even higher. This extreme pressure is essential for creating an ultra-fine fuel mist (atomization) for cleaner, more complete combustion.

Full Electronic Control: Every aspect of the injection process is managed by the Engine Control Unit (ECU), allowing for a level of precision that is impossible with mechanical systems.

Shared, Constant Fuel Supply: All injectors are fed by a single high-pressure rail, which ensures that injection pressure is independent of engine speed. This means perfect atomization is available at idle, full load, and every point in between.

Multiple Injection Events: The injector can fire several times in a single combustion cycle (as many as 3-7 times). This capability is the secret to reducing engine noise, lowering emissions, and maximizing power.

Microsecond Precision Timing: The ECU can command injections with incredible speed and accuracy, optimizing performance and efficiency in real-time based on dozens of sensor inputs.

For fleet managers and owner-operators of heavy-duty trucks, understanding this technology is not just an academic exercise—it's fundamental to maximizing uptime and minimizing operational costs. The performance, fuel efficiency, and reliability of modern Volvo, Mack, Kenworth, and Paccar trucks are all direct results of the advanced common rail systems they employ. Mastering its principles and maintenance requirements is key to keeping your fleet on the road and profitable.

What is a Common Rail Injector and How Does It Work?

At its core, the common rail system's genius lies in its fundamental design principle: the separation of pressure generation from the injection event. In older mechanical systems, these two functions were inextricably linked; the engine's rotation directly drove a pump that created a pressure pulse for each injection. This meant low engine speed resulted in low injection pressure, leading to poor fuel atomization, inefficiency, and higher emissions. The common rail system completely decouples these processes, allowing for optimal fuel delivery under all possible operating conditions.

The process begins with a high-pressure fuel pump, which is mechanically driven by the engine. This pump draws diesel fuel from the tank (via a low-pressure lift pump) and compresses it to extreme pressures, often exceeding 2,000 bar (nearly 30,000 PSI). This highly pressurized fuel is then fed into the "common rail," a robust, reinforced tube that acts as a high-pressure accumulator. This rail stores the fuel, maintaining a near-constant pressure that is instantly available to all of the engine's injectors, regardless of whether the truck is idling at a stoplight or pulling a heavy load up a steep grade.

Each electronically controlled injector is connected to this common rail via a dedicated high-pressure line. The entire operation is orchestrated by the Engine Control Unit (ECU), the sophisticated computer that serves as the system's brain. The ECU continuously analyzes data from dozens of sensors—monitoring everything from accelerator pedal position and engine RPM to boost pressure, coolant temperature, and exhaust gas composition. Based on this torrent of information, the ECU's complex algorithms determine the precise moment and duration for each injection. When it's time to inject fuel, the ECU sends a precise electrical signal to the injector, causing it to open for a few milliseconds (thousandths of a second) and spray the exact quantity of atomized fuel required. This precise, electronically controlled fuel metering is the cornerstone of modern diesel efficiency. For more technical details, check out our comprehensive guide on How Common Rail Injectors Work.

The Core Components and Their Function

Understanding what a common rail injector is requires knowing its critical supporting cast. Each component plays a vital role in the system's performance and reliability:

High-Pressure Fuel Pump: This is the muscle of the operation. Typically a radial piston pump (like the Bosch CP3 or CP4), it is engineered to generate and sustain the immense pressures required by the system, compressing fuel up to 2,500 bar (over 36,000 PSI).

Fuel Rail: More than just a pipe, the rail is a sophisticated pressure vessel forged from high-strength steel. It must safely contain the enormous fuel pressure while dampening pressure waves from the pump and injectors. It also houses a pressure sensor that provides critical feedback to the ECU.

Fuel Injectors: These are the final actors—the ultra-fast, electronically controlled valves that deliver fuel into the cylinder. With microscopic tolerances, they are responsible for creating the fine fuel mist essential for efficient combustion.

Engine Control Unit (ECU): The brain of the system. This powerful computer processes millions of calculations per second, using sensor data to make split-second decisions about fuel timing, quantity, and pressure to optimize power, economy, and emissions.

High-Pressure Lines: These are not ordinary fuel lines. They are specially engineered from thick-walled steel to safely connect the high-pressure pump to the rail and the rail to each injector, withstanding the constant high-pressure pulses.

Fuel Filter: A component of paramount importance. Given the microscopic clearances inside the injectors, even the smallest particle of dirt or drop of water can cause catastrophic damage. A high-quality, multi-stage filtration system is essential for protecting the entire system, as the fuel also serves to cool and lubricate the injector's internal parts.

This system's ability to maintain constant high pressure allows the ECU to command multiple, distinct injection events during a single combustion cycle:

Pilot Injection: A small, preliminary spray of fuel that ignites just before the main charge. This smooths the start of combustion, pre-heats the chamber, and dramatically reduces the sharp pressure spike that causes the classic "diesel clatter," resulting in a much quieter engine.

Main Injection: This is the primary event that delivers the bulk of the fuel for power generation. The ECU precisely times and meters this injection to produce maximum torque and efficiency based on the current engine load and speed.

Post-Injection: One or more small injections that occur after the main power stroke. These are not for creating power but are used to burn off any remaining soot in the cylinder and, crucially, to raise the exhaust gas temperature to help regenerate the Diesel Particulate Filter (DPF) in the aftertreatment system.

This precisely choreographed sequence of events, managed in microseconds, is what makes modern diesel engines simultaneously powerful, quiet, clean, and efficient. You can see this process in action in this animation explaining common rail functioning.

The Evolution of Fuel Injection: Common Rail vs. Traditional Systems

To truly appreciate the revolutionary nature of the common rail injector, it's essential to understand the limitations of the technologies it replaced. For decades, diesel engines relied on purely mechanical fuel injection systems. While often robust and reliable, these systems were fundamentally constrained by their design.

Early systems used mechanical inline pumps or distributor (rotary) pumps. In these setups, a camshaft within the pump, driven by the engine, would force a plunger to create a high-pressure pulse of fuel. This pulse was sent through a steel line to a simple, spring-loaded mechanical injector, which would pop open when the pressure overcame the spring force. The critical limitation was that injection pressure was directly proportional to engine speed. At low RPMs, pressure was low, leading to poor atomization, incomplete combustion (black smoke), and inefficiency. Timing adjustments were crude and extremely limited.

A significant step forward came with Electronic Unit Injectors (EUI) and Hydraulic Electronic Unit Injectors (HEUI). These systems combined the high-pressure pump and the injector into a single unit for each cylinder, eliminating the high-pressure lines. They were actuated by the engine's own camshaft, but with electronic control over the timing. This was a major improvement, but pressure was still linked to engine speed, and the mechanical constraints of the camshaft limited the ability to perform multiple injections.

The common rail system shattered these limitations. By completely separating pressure generation (the high-pressure pump) from the injection event (the electronically controlled injector), it gave engine designers unprecedented freedom. High pressure was now always available, and timing could be controlled with digital precision, independent of the engine's mechanical rotation. This paved the way for the modern clean diesel engine. You can dive deeper into this journey with A brief history of the common rail system.

Comparing Common Rail vs. Mechanical Injection

Feature Common Rail System Traditional Mechanical System (Pumps & Unit Injectors) Pressure Control Independent of engine speed; constant high pressure available at all times. Dependent on engine speed; pressure rises and falls with RPM. Injection Timing Infinitely flexible; fully controlled by the ECU for real-time optimization. Mechanically fixed or very limited; tied to camshaft profile. Multiple Injections Yes (pilot, main, post); allows for precise shaping of the combustion event. No / Very limited; typically a single injection event. Noise Level Significantly quieter due to pilot injection smoothing combustion. Louder, with characteristic "diesel clatter" from abrupt combustion. Emissions Dramatically lower NOx and Particulate Matter (PM) due to better atomization and injection control. Higher emissions due to less efficient combustion, especially at low speeds. Efficiency Higher fuel efficiency across the entire operating range. Lower efficiency, particularly at off-peak RPMs.

The Common Rail Injector's Role in This Evolution

The common rail injector was the linchpin of this revolution. Its most critical role was enabling heavy-duty diesel engines to meet the wave of stringent global emissions standards that began in the late 1990s and continue today. The precise control over fuel quantity and the ability to perform multiple injections were the tools engineers needed to slash harmful pollutants. High-pressure atomization drastically reduces Particulate Matter (PM), or soot, by ensuring more fuel is burned in the cylinder. Pilot injections lower the peak combustion temperature, which in turn significantly reduces the formation of Nitrogen Oxides (NOx), a major contributor to smog.

This technological leap also unlocked innovative strategies for efficiency, most notably engine down-speeding. Because common rail systems maintain maximum injection pressure and efficiency even at low engine speeds, manufacturers could design engines to produce peak torque at much lower RPMs. This allows heavy-duty trucks to cruise on the highway at 1,000-1,150 RPM instead of the 1,400-1,500 RPM of the past, drastically reducing fuel consumption and engine wear. This strategy is simply not feasible with older injection systems.

Key milestones, such as Hino's first mass-production common rail truck in 1995 and Alfa Romeo's first common rail passenger car in 1997, marked the beginning of a new era. Today, every modern heavy-duty truck from manufacturers like Volvo, Mack, Kenworth, and Paccar relies on this evolutionary technology to deliver the power, efficiency, and clean operation that the modern freight industry demands.

The Anatomy of a Common Rail Injector: Key Types and Components

A common rail injector is a marvel of micro-engineering, one of the most precisely manufactured components in any vehicle. It operates under immense pressure and heat, with internal moving parts that have tolerances measured in microns (millionths of a meter). Understanding its internal anatomy reveals why fuel quality and proper maintenance are so critical. For a detailed look, see our guide on Common Rail Injectors.

Inside the Injector: A Symphony of Precision Parts

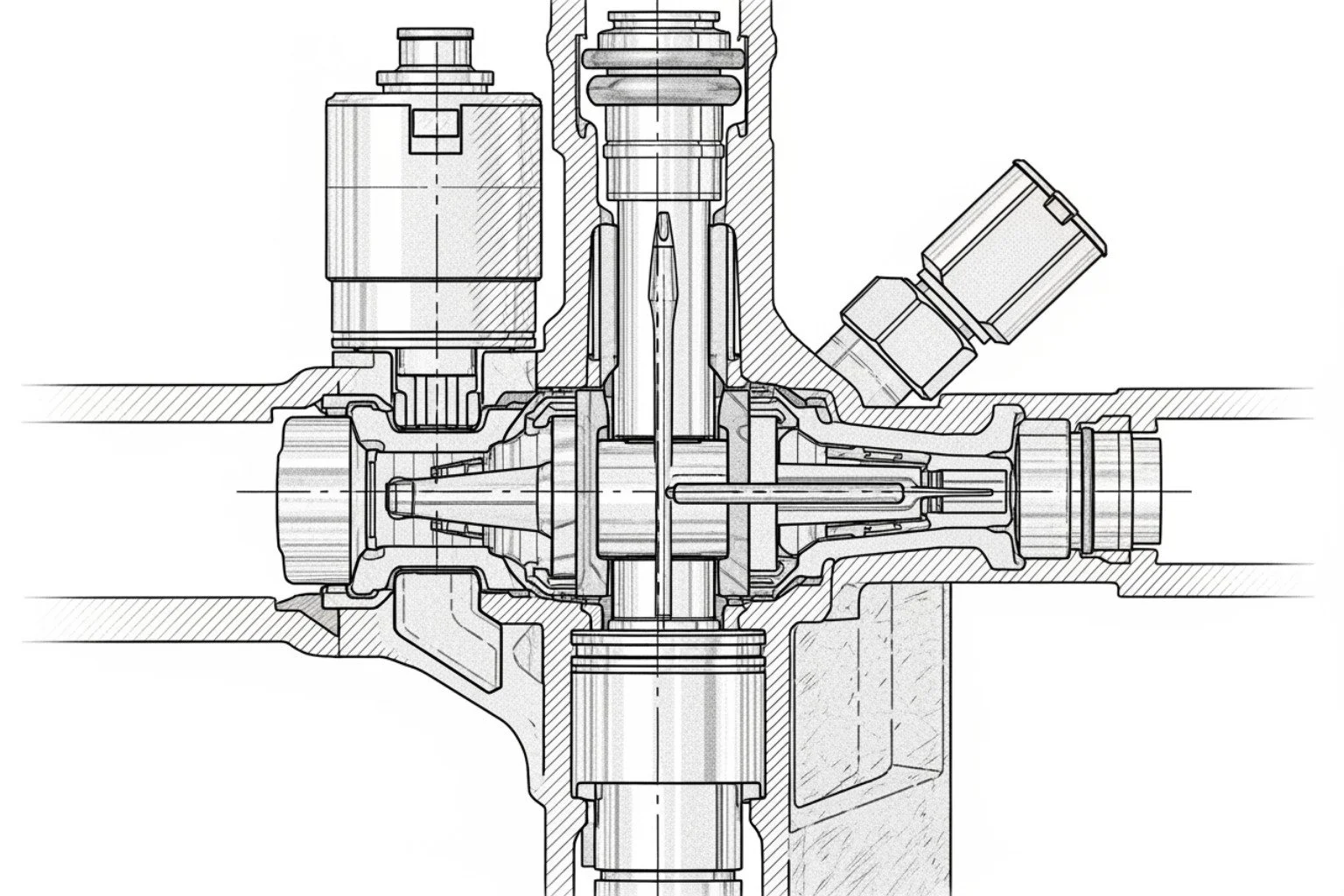

While designs vary between manufacturers like Bosch, Denso, and Delphi, most common rail injectors share these core internal components:

Injector Body: The outer casing that houses all the components and provides the high-pressure fuel passages.

Nozzle Assembly: This is the business end of the injector. It consists of a nozzle body and a needle valve. The needle is held shut by spring pressure and high-pressure fuel acting on its top surface. The tip of the nozzle contains multiple, microscopic spray holes (typically 5 to 8 in modern truck injectors), angled precisely to create the optimal spray pattern for the specific engine's combustion chamber. The design of these holes is critical for fuel atomization, which directly impacts fuel economy and emissions.

Control Valve: This is the heart of the injector's operation. It's a small, internal valve that is opened by the actuator (solenoid or piezo). When it opens, it releases the fuel pressure from above the nozzle needle. This pressure imbalance allows the high-pressure fuel from the side passages to lift the needle, starting the injection. When the control valve closes, pressure builds back up on top of the needle, snapping it shut and ending the injection instantly.

Actuator (Solenoid or Piezo): This is the trigger, the component that receives the electrical signal from the ECU to begin the injection process by opening the control valve.

Solenoid Injectors: The Proven Workhorse

Solenoid injectors, which represent the first and second generations of common rail technology, are still widely used and highly effective. They utilize a simple and robust principle: electromagnetism. The actuator consists of a coil of wire (the solenoid) wrapped around a magnetic pin connected to the control valve.

When the ECU sends an electrical current to the coil, it generates a powerful magnetic field. This field instantly pulls the pin upwards, opening the control valve. This action is indirect; the solenoid doesn't lift the main nozzle needle itself but rather the tiny control valve that uses the fuel's own hydraulic pressure to actuate the needle. This is why they are often called servo-hydraulic injectors. When the ECU cuts the current, the magnetic field collapses, a spring returns the control valve to its seat, and the injection stops. Solenoid injectors are celebrated for their proven reliability and cost-effectiveness, and they were the technology that first enabled the multi-injection strategies that made modern diesels possible.

Piezo Injectors: The High-Speed Specialist

To meet ever-tightening emissions standards and push efficiency further, engineers needed even faster and more precise injectors. The answer was the piezo injector. So, what is a common rail injector with piezo technology? It replaces the electromagnetic coil with a "piezo stack."

This actuator is built from hundreds of paper-thin layers of a special crystalline ceramic. This material exhibits the piezoelectric effect: it expands instantly and with great force when an electrical voltage is applied. This expansion happens in microseconds, up to five times faster than a solenoid can actuate. In many designs, this piezo stack acts directly on the nozzle needle, eliminating the hydraulic servo mechanism and reducing moving mass. This incredible speed and precision allow for:

More Injection Events: Piezo injectors can perform five to seven (or more) injection events per cycle, compared to a solenoid's typical three to five. This allows for even finer control over the combustion process.

Better Injection Shaping: The speed allows the ECU to precisely shape the rate of injection, starting and stopping the flow with near-perfect accuracy. This further reduces noise, emissions, and fuel consumption.

Piezo injectors represent third-generation technology and beyond. While more complex and costly, their superior speed and control are essential for the most advanced diesel engines to achieve peak performance and meet the strictest environmental regulations.

The Best Advantages of Common Rail Technology

Common rail technology didn't just incrementally improve diesel engines; it fundamentally redefined their capabilities. The combination of constant high pressure and precise electronic control unlocked a new level of performance, efficiency, and refinement that was simply unattainable with older mechanical systems. For a comprehensive look, explore How a common rail diesel engine works.

Improved Performance and Fuel Efficiency

One of the most significant benefits is a dramatic increase in power and torque, with some common rail systems delivering up to 25% more output than the conventional systems they replaced. The secret lies in vastly superior fuel atomization. By injecting fuel at pressures over 36,000 PSI, the injector nozzle creates a microscopic mist of incredibly fine droplets. These tiny droplets have a massive surface area, allowing them to mix with the air in the cylinder almost instantly and burn far more completely. This means more chemical energy is converted into mechanical work from every single drop of fuel, directly translating to better fuel economy—a critical factor in the total cost of ownership for any commercial fleet.

Furthermore, this technology enables superior torque curve shaping. Because injection pressure is high and constant regardless of engine speed, the ECU can deliver powerful, efficient combustion even at very low RPMs. This allows engineers to design engines with a broad, flat torque curve, providing strong pulling power from just above idle. This characteristic is the key enabler of engine down-speeding, a strategy where heavy-duty trucks cruise at lower RPMs (e.g., 1,000-1,150 RPM). This not only boosts fuel economy by 2-3% but also significantly reduces engine noise, vibration, and wear on internal components, leading to longer engine life.

Reduced Emissions and Quieter Operation

Common rail technology provided the solution to diesel's two most notorious historical problems: noise and emissions. The harsh, clattering sound of old diesels was caused by a long ignition delay—a lag between when fuel was injected and when it violently exploded. The pilot injection strategy of common rail systems solves this. A tiny amount of fuel is injected and ignited just before the main charge, creating a smoother, more controlled combustion event. This eliminates the abrupt pressure spike, resulting in an engine that is remarkably quiet, often comparable to a gasoline engine at idle.

This precise control is also the key to clean emissions. The superior atomization from high pressure drastically reduces the formation of Particulate Matter (PM), or soot. Any remaining soot can be managed by a post-injection event. This late injection of fuel doesn't produce power but instead raises the temperature of the exhaust gas. This is critical for the operation of the Diesel Particulate Filter (DPF), as it helps to passively burn off the trapped soot (regeneration) or initiate an active regeneration cycle. Similarly, the controlled combustion from pilot injections helps lower peak temperatures in the cylinder, which is the primary method for reducing the formation of harmful Nitrogen Oxides (NOx). This level of control allows modern diesel engines to meet the world's strictest emissions standards, making them a clean and viable technology for the future.

Maintenance and the Future of Common Rail Systems

For any fleet manager or owner-operator, the sophisticated nature of a common rail system means that proper maintenance is not just a recommendation—it is an absolute necessity for ensuring reliability, performance, and profitability. While these systems are designed for durability, their microscopic tolerances leave no room for error. Neglect can lead to costly, fleet-grounding failures.

Maintenance: The Key to Longevity and Profitability

1. Fuel Quality: The Non-Negotiable Foundation The single most critical factor for common rail system health is the fuel that runs through it. The system's one unyielding demand is for exceptionally clean, high-quality diesel fuel.

Contamination: The clearances inside an injector's control valve and nozzle are often less than 5 microns. A single grain of sand or piece of dirt can score these precision surfaces, causing internal leaks, poor spray patterns, or complete seizure. Always source fuel from reputable, high-volume suppliers.

Water: Water is a deadly enemy. It causes corrosion on the finely machined internal parts and, under the system's immense pressure, can flash to steam, causing explosive damage to injector tips. Ensure your vehicle's water separator is drained regularly.

Lubricity: The fuel itself acts as the primary lubricant for the high-pressure pump and injectors. Low-quality or out-of-spec fuel can lack the necessary lubricity, leading to premature wear and failure.

2. Filtration: Your System's Bodyguard High-quality, multi-stage fuel filtration is your first and best line of defense. Adhere strictly to the manufacturer's recommended service intervals for changing both primary (frame-mounted) and secondary (engine-mounted) fuel filters. Using cheap, low-quality filters is a false economy that puts your entire multi-thousand-dollar fuel system at risk. For more tips, see our guide on How to Clean Common Rail Diesel Injectors.

3. Recognizing the Signs of Trouble Early diagnosis can prevent a minor issue from becoming a major repair. Be alert for these common symptoms of a failing injector:

Excessive Smoke: Black smoke indicates over-fueling (leaking injector), while white smoke can indicate unburnt fuel (misfiring injector).

Rough Idle or Misfire: An injector that isn't delivering the correct amount of fuel can cause the engine to shake or stumble, especially at idle.

Loss of Power and Poor Fuel Economy: If an injector's spray pattern degrades, combustion becomes inefficient, wasting fuel and reducing power.

Hard Starting: Leaking injectors can cause the fuel rail to lose its prime pressure when the engine is off, making it difficult to start.

Engine Knock: A loud, metallic knocking sound can indicate an injector is stuck open, dangerously over-fueling a cylinder.

If you notice these symptoms, seek professional diagnosis and service immediately. Common rail systems operate at lethally high pressures, and proper diagnosis requires specialized scan tools and testing equipment. Our article on How to Check Common Rail Injectors can help you identify potential issues early.

Future Trends and Common Acronyms

The evolution of common rail technology is far from over. Engineers continue to push the boundaries of what's possible:

Increasing Injection Pressures: Research is actively pushing towards 3,000 bar (43,500 PSI) and beyond. This requires new breakthroughs in material science and sealing technology but promises even finer atomization for higher efficiency and near-zero emissions.

Advanced ECU Logic: Engine computers are becoming more powerful, incorporating artificial intelligence and model-based control to predict and adapt injection strategies in real-time for unparalleled efficiency.

Integration with Hybrid Systems: Common rail systems are being seamlessly integrated with electric hybrid powertrains, allowing the diesel engine to operate only in its most efficient range.

Fuel Flexibility: Systems are being adapted to run efficiently on a wider range of alternative and renewable fuels, such as HVO (Hydrotreated Vegetable Oil) and other paraffinic diesels.

You'll encounter various acronyms for this technology, including CRDI (Common Rail Direct Injection), TDI (Turbocharged Direct Injection), and CDI (Common-rail Direct Injection). Major engine brands like Duramax, Cummins (XPI), and Power Stroke all use their own branded versions of this fundamental technology.

Frequently Asked Questions about Common Rail Injectors

Here are detailed answers to some of the most common questions fleet managers and technicians have about what is a common rail injector.

What pressure does a common rail injector operate at?

Modern heavy-duty common rail systems typically operate at pressures between 1,800 and 2,500 bar (which translates to a staggering 26,000 to 36,000 PSI). To put that in perspective, it's over 1,000 times the pressure in a typical car tire. This immense pressure is the key to achieving superior fuel atomization—breaking the diesel fuel into a microscopic mist. This fine mist mixes more thoroughly and rapidly with the air in the cylinder, leading to faster, more complete, and cleaner combustion. This directly improves fuel efficiency, increases power output, and reduces harmful emissions. Future systems are already being developed to operate at pressures approaching 3,000 bar (43,500 PSI) to push these benefits even further.

How many times can a common rail injector fire in one cycle?

A key advantage of the common rail injector is its ability to fire multiple times during a single combustion cycle, a feat impossible for older mechanical systems. While it varies by system generation and operating conditions, it's common to see 3 to 5 distinct injection events. Advanced piezo injectors can perform 7 or more injections per cycle. Each injection has a specific purpose: a 'pilot' injection to quiet the engine and reduce NOx, a 'main' injection for power, and one or more 'post' injections to burn off soot or help regenerate the DPF. This multi-injection strategy gives engineers precise control over the entire combustion process, allowing them to fine-tune the engine for optimal power, efficiency, and low emissions in real-time.

Can a common rail injector be used in a gasoline engine?

Yes, the fundamental principle has been successfully adapted for gasoline engines in a technology called Gasoline Direct Injection (GDI) or Turbocharged Gasoline Direct (TGDI). While the core concept is the same—a high-pressure rail feeding electronically controlled injectors that spray fuel directly into the combustion chamber—the operating parameters are different. GDI systems operate at much lower pressures than diesel systems (typically 100-350 bar, or 1,500-5,000 PSI), as gasoline is more volatile and doesn't require such extreme pressure to atomize. However, GDI offers similar benefits over traditional port fuel injection, including improved fuel efficiency, increased power density, and better emissions control.

What is the difference between a common rail injector and a unit injector (EUI)?

The primary difference is how and where high pressure is created. In a unit injector (EUI) system, the high-pressure pump and the injector are combined into a single device for each cylinder, which is mechanically driven by the engine's camshaft. Pressure is created within the injector itself just before injection. In a common rail system, pressure generation is centralized. A single high-pressure pump supplies fuel to a shared rail, and the injectors act only as electronically controlled valves to release that pressure. This separation makes the common rail system more flexible, quieter, and capable of maintaining high pressure at any engine speed.

How long do common rail injectors typically last?

In a well-maintained heavy-duty truck, a set of high-quality common rail injectors can last between 500,000 and 1,000,000 miles (800,000 to 1,600,000 kilometers). However, this lifespan is heavily dependent on several factors: fuel quality, filtration effectiveness, and operating conditions. An engine that experiences frequent contamination, poor filtration, or excessive idling may see a significantly shorter injector life. Regular maintenance is the key to maximizing their lifespan.

What are the main causes of common rail injector failure?

The top causes of failure are almost always related to fuel quality and maintenance. The most common culprits are:

Fuel Contamination: Microscopic dirt, debris, or metal particles that score the injector's internal precision surfaces.

Water in Fuel: Causes corrosion and can damage the nozzle tip through explosive vaporization.

Normal Wear and Tear: Over hundreds of millions of cycles, the nozzle needle and seat will eventually wear, degrading the spray pattern.

Electrical Failure: The internal solenoid or piezo actuator can fail, though this is less common than mechanical wear from contamination.

Conclusion

The journey to fully understand what is a common rail injector takes us deep into the core of modern diesel innovation. It is far more than just a component; it is the key enabler of a paradigm shift in engine technology. By decoupling fuel pressurization from injection timing, the common rail system has allowed diesel engines to make monumental leaps in performance, torque, and refinement. This technology has almost single-handedly transformed the diesel engine, making it cleaner, quieter, and more fuel-efficient than was ever thought possible, allowing it to meet the environmental and performance demands of the 21st century.

For fleet managers and owner-operators of Volvo, Mack, Kenworth, and Paccar trucks, the common rail injector is a cornerstone of daily operations and long-term profitability. Its incredible precision and power come with a critical responsibility: a commitment to meticulous maintenance. The system's health, and by extension your vehicle's uptime, is directly tied to the quality of the fuel you use and the diligence of your filtration service schedule. In an industry where downtime is measured in lost revenue, a healthy fuel system is not an expense but an investment in reliability.

At G2 Diesel Products, we live and breathe this technology. We understand the immense pressures and microscopic tolerances these components endure every second your engine is running. That is why we are dedicated to manufacturing top-tier, heavy-duty injectors that meet or exceed OEM specifications. Our relentless focus on quality, precision engineering, and robust materials ensures that every injector we produce delivers the exceptional reliability and peak performance your fleet demands, keeping your trucks on the road, your drivers productive, and your business moving forward.

For robust and reliable diesel fuel injectors that keep your fleet running strong, explore our Volvo, Mack, Kenworth, and Paccar diesel fuel injectors. Because when your trucks are your livelihood, you deserve components that work as hard as you do.