Pump Up the Power: Why a Fuel System Upgrade is Your Next Move

Why Your Diesel Engine Deserves Better: The Case for a Fuel System Upgrade

For the operator of a heavy-duty diesel truck, the engine is more than just a motor; it's the heart of your livelihood. Whether you're behind the wheel of a Volvo, Mack, Kenworth, or Paccar, you depend on that engine for power, reliability, and efficiency. A fuel system upgrade is one of the most profound investments you can make to transform your diesel engine, open uping its peak potential and safeguarding its health. The fuel system is the engine's circulatory system, the critical lifeline that dictates not just raw power but also long-term reliability and day-to-day operational costs. If you're experiencing symptoms like hard starts, declining fuel economy, or a noticeable loss of power when hauling a heavy load, your stock fuel system is the most likely bottleneck holding your engine back.

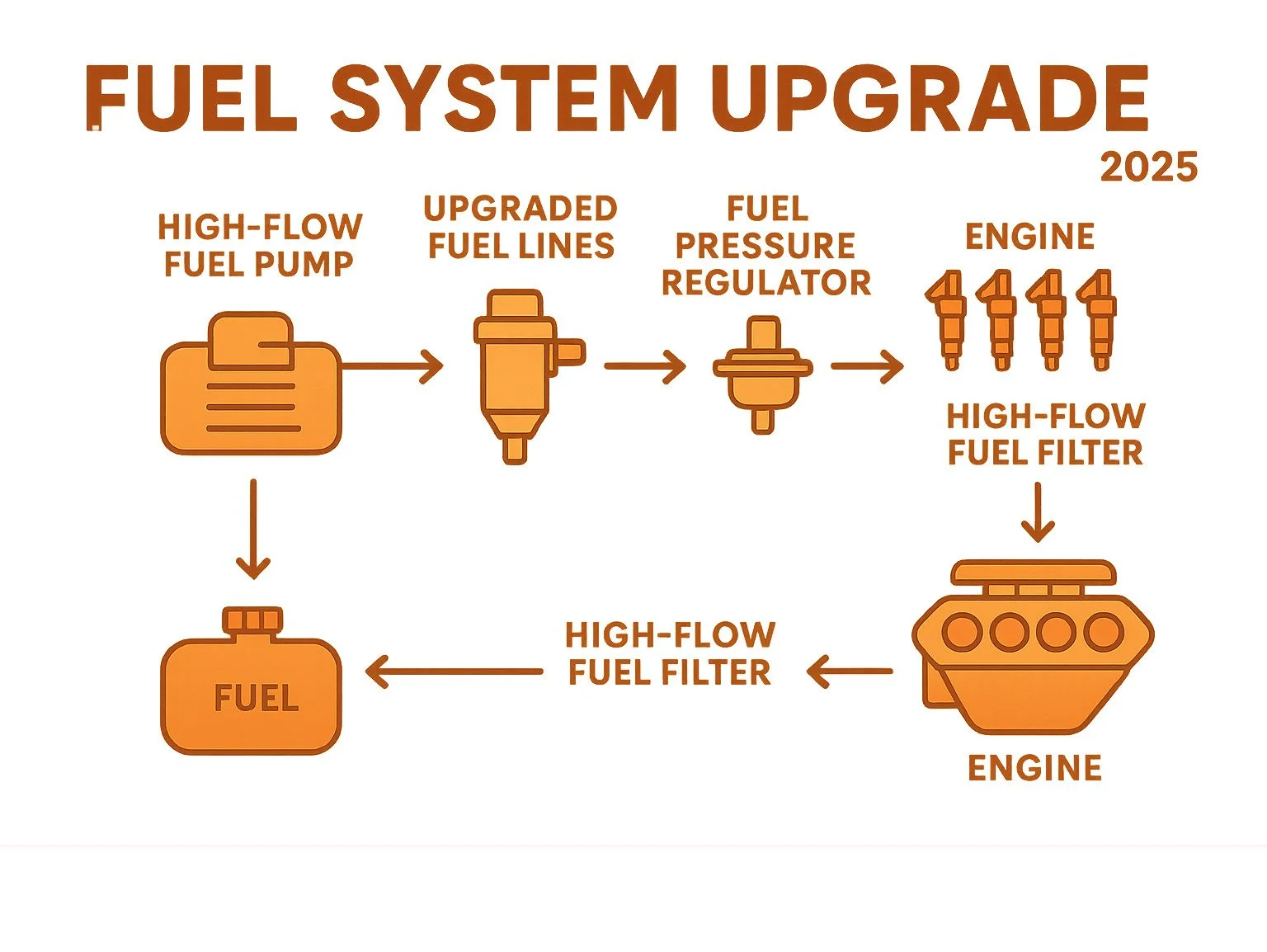

Quick Answer: Key Fuel System Upgrade Components

High-Flow Fuel Pumps: The heart of the upgrade, delivering the necessary volume of fuel to meet increased power demands without a drop in pressure.

Performance Fuel Injectors: The artists, ensuring precise fuel atomization and optimized flow rates for complete and efficient combustion.

Upgraded Fuel Lines: The arteries, built to handle higher pressures and flow volumes safely and without restriction.

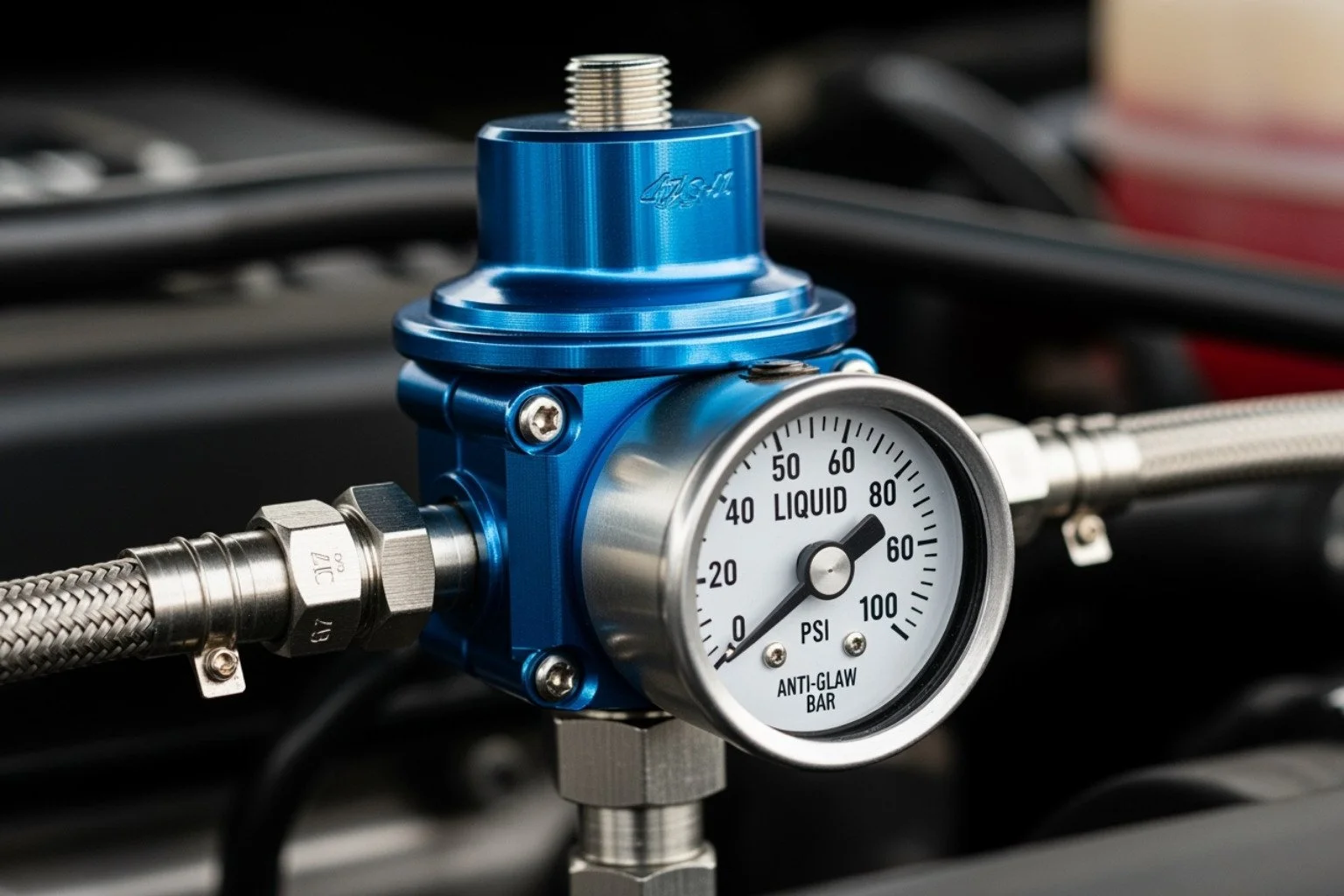

Fuel Pressure Regulators: The brain's regulator, maintaining consistent and stable fuel pressure across all engine loads and operating conditions.

High-Flow Fuel Filters: The guardians, protecting expensive upgraded components from harmful contaminants that can cause catastrophic failure.

Modern diesel engines are marvels of engineering, requiring incredibly precise fuel delivery to operate at peak efficiency. However, factory-installed stock systems are built to a cost and are typically designed with minimal overhead. They are adequate for stock power levels under normal conditions, but the moment you ask for more—through performance modifications, heavy-haul applications, or even just accumulated wear and tear—their limitations become apparent. The key to a successful upgrade is to treat the fuel system as a complete, integrated system, not a collection of unrelated parts. As one industry expert notes, "The key word in fuel system upgrades is 'system.' Taking a holistic approach...can pay off in better performance and control." This philosophy is crucial. When one component is upgraded, the others must be capable of supporting that change. A powerful fuel pump is useless if the injectors can't handle the flow, and high-flow injectors will be starved by a stock pump. True performance is born from harmony.

Is Your Engine Crying for Help? Signs You Need a Fuel System Upgrade

Imagine your truck’s engine trying to communicate with you. At first, it might be a whisper—a slightly longer crank time in the morning. Over time, it can become a scream—a stuttering misfire while climbing a grade. Recognizing these distress signals early is the key to preventing catastrophic failure, saving you from significant repair costs and crippling downtime.

Here are the common signs that your engine is struggling with a failing or inadequate fuel system component, explained in detail:

Hard Starts: Your engine cranks and cranks before finally sputtering to life. This is a classic symptom of insufficient fuel pressure. The system may be losing its prime overnight due to a weak check valve in the pump or a leaking injector, requiring the pump to work much harder to build the necessary pressure for ignition.

Engine Misfires: You feel a rough, stuttering, or shaking sensation from the engine, especially under load. This indicates that one or more cylinders are not firing correctly. Misfires are often caused by inconsistent fuel delivery from a clogged or failing injector, or a fuel pump that can't maintain pressure during high-demand moments, leading to incomplete combustion.

Poor Fuel Economy: You're visiting the pump more often, and your cost-per-mile is climbing. A sudden or gradual drop in MPG is a clear sign that the engine is receiving fuel inefficiently. This could be due to leaking injectors that are dumping excess fuel, or a faulty regulator causing a rich fuel mixture that doesn't burn completely, wasting fuel and money.

Loss of Power: The truck feels sluggish, struggles to get up to speed, and groans on inclines it used to handle with ease. This feeling of being "down on power" is a direct result of fuel starvation. The engine is demanding more fuel to make power, but the fuel system cannot deliver it, effectively choking its performance.

Stalling: The engine dies unexpectedly, either at idle or, more dangerously, while driving. An engine that stalls, especially at low speeds or when coming to a stop, is often suffering from a severe fuel supply issue. This could be a failing pump that cuts out intermittently or a clogged filter that finally blocks flow entirely.

Strong Fuel Smell: A persistent odor of raw diesel fuel around the truck is a major red flag that cannot be ignored. It indicates a leak somewhere in the system—perhaps from a cracked fuel line, a degraded O-ring on an injector, or a faulty seal on the fuel tank. A fuel leak is not just a waste of money; it's an extreme fire hazard.

These symptoms often point to a failing fuel pump, clogged injectors, or a malfunctioning pressure regulator. A weak pump can't supply enough volume or pressure, while clogged injectors or a faulty regulator disrupt the delicate air-to-fuel ratio, leading to misfires and poor performance. One particularly insidious issue is "injector lag," which is caused by insufficient fuel pressure allowing fuel vapor to form in the injector body. This vapor bubble must be compressed before liquid fuel can be injected, delaying the injection timing. This seemingly small delay has huge consequences: increased fuel consumption, reduced power output, and a sharp rise in harmful emissions. If you're noticing these issues, especially with your diesel injectors, we at G2 Diesel Products offer comprehensive Diesel Injector Testing Services in Harrisburg, PA, to accurately diagnose the root cause of the problem.

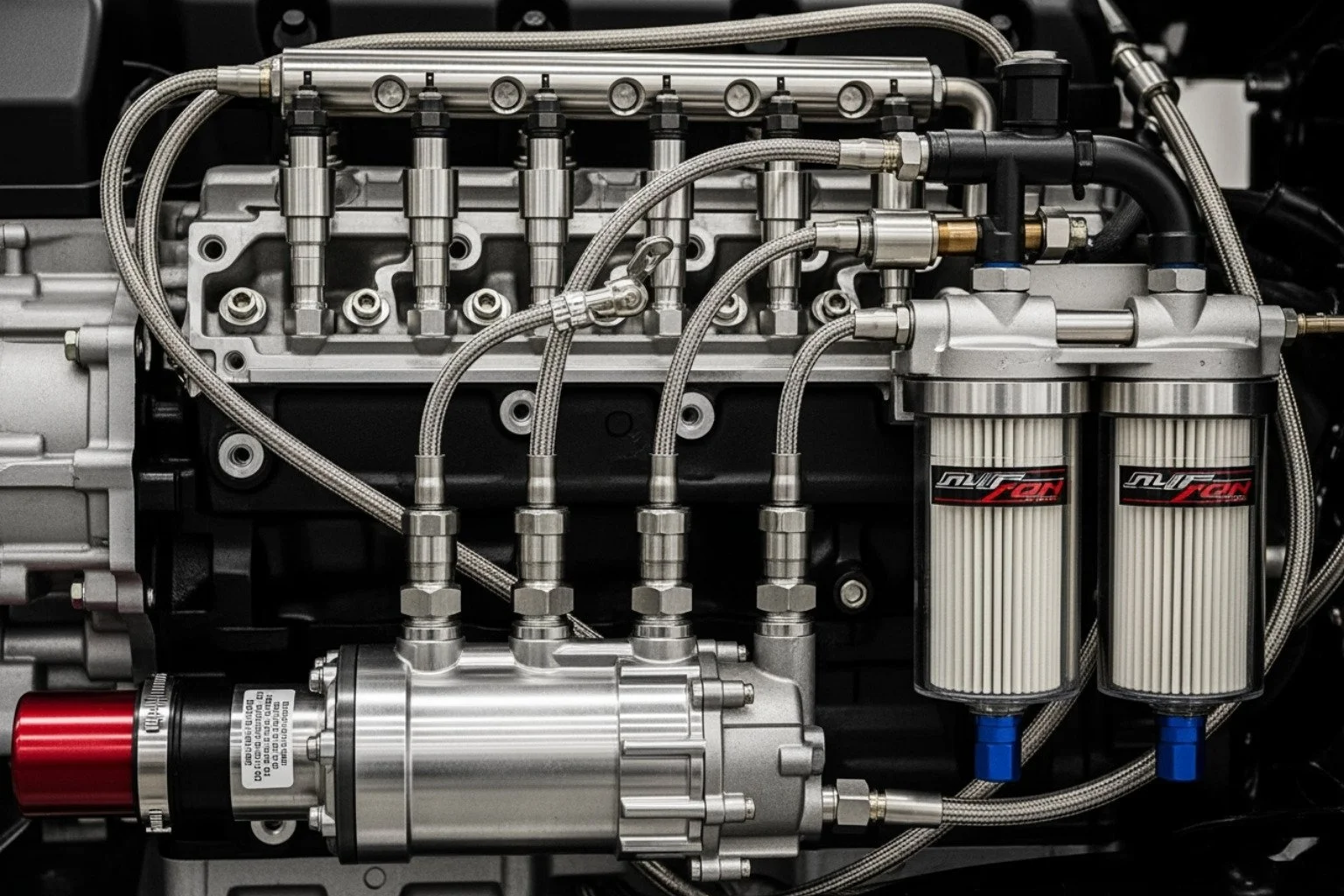

The Heart of Your Engine: A Deep Dive into Fuel System Components

Starting on a fuel system upgrade requires a solid understanding of the key players involved. Think of your engine's fuel system as its circulatory system: a complex network responsible for storing, pumping, filtering, and delivering the precise amount of fuel at the exact right pressure and time. Each component has a critical role, and the failure of one can compromise the entire system.

Fuel Tank: More than just a storage vessel, the tank is the first line of defense. It must be kept free of contaminants like water, rust, and microbial growth (algae), which can wreak havoc on the entire system. For high-performance applications, tanks with proper baffling or a sump are essential to prevent fuel starvation during hard acceleration or on steep inclines.

Fuel Pump: This is the muscle of the system. In diesel engines, you typically have a lift pump that moves fuel from the tank to the engine at low pressure, and a high-pressure pump (like a CP3 or CP4 in common rail systems) that pressurizes the fuel to extreme levels (often over 25,000 PSI). Upgrading the lift pump is often the first step to ensure the high-pressure pump never gets starved for fuel.

Fuel Lines: These are the highways that transport fuel. Stock rubber lines can degrade over time and may not handle the pressure and volume of an upgraded system. Upgrading to larger diameter lines made from braided stainless steel or, even better, PTFE (Teflon), ensures maximum flow and resistance to corrosive modern fuels.

Fuel Filter: This is the system's indispensable guard. A high-quality fuel filter with a fine micron rating is crucial for catching tiny debris that could destroy the microscopic tolerances inside expensive injectors and high-pressure pumps. A good system will also include a water separator, as water is a major enemy of high-pressure fuel components.

Fuel Pressure Regulator: This component maintains a steady, consistent pressure in the fuel rail, regardless of engine load. Without it, fuel pressure would spike when demand is low and plummet when demand is high, leading to erratic performance. Many performance regulators are boost-referenced, meaning they increase fuel pressure as turbo boost increases to ensure the engine never runs lean under power.

Diesel Fuel Injectors: These are the precision artists of the system. They are responsible for spraying a perfectly atomized cone of fuel into the combustion chamber. The timing, duration, and pattern of this spray are critical for power, efficiency, and emissions. Modern injectors use either fast-acting solenoids or even faster piezo-electric crystals to achieve incredible precision.

Engine Control Unit (ECU): This is the brain of the entire operation. The ECU takes in data from dozens of sensors (air flow, engine speed, throttle position, boost pressure, etc.) and uses complex algorithms to calculate the exact moment to fire each injector and for how long. It orchestrates the entire symphony of fuel delivery.

Different Fuel System Types

Diesel fuel systems are built to be incredibly robust to handle pressures that are orders of magnitude higher than gasoline systems. Modern Electronic Fuel Injection (EFI) for diesel has evolved significantly. Systems using Direct injection spray fuel directly into the combustion chamber, offering unparalleled control over performance and efficiency. For a broad primer on the history, see Fuel injection.

At G2 Diesel Products, we specialize in the most advanced diesel injection technologies:

Common Rail Injectors: The current industry standard, these systems use a single high-pressure pump to feed a shared fuel rail that supplies all injectors. This allows the ECU to control injection timing and pressure independently of engine speed, enabling multiple, precise injection events per combustion cycle. The result is quieter operation, lower emissions, and vastly improved performance. (See overview: Common rail).

Hydraulic Electronic Unit Injector (HEUI) Fuel System: Popular in many heavy-duty engines from the 90s and 2000s, these innovative systems use high-pressure engine oil to actuate the fuel injectors. The ECU controls an oil valve, and the pressurized oil acts on an intensifier piston within the injector to generate the extremely high fuel pressures needed for injection. This provides excellent control for demanding jobs. (See background: Unit injector).

The Ultimate Guide to Your Next Fuel System Upgrade

Planning your fuel system upgrade is a project where the details matter immensely. Success hinges on adopting a holistic system approach, ensuring every new component works in perfect harmony with the others. Simply swapping one part for a bigger one is a recipe for disappointment and potential engine damage. Think of your fuel system as a complex highway system designed to move fuel. If you widen one stretch of road (e.g., bigger injectors) but leave the original narrow bridges and on-ramps in place (e.g., stock fuel pump and lines), you haven't solved the traffic problem; you've just moved the bottleneck. Component compatibility is paramount. Mismatched parts can lead to a host of issues, including rough idling, poor acceleration, dangerous lean conditions, or even catastrophic engine failure.

Fuel Pumps: The Driving Force

When you demand more power from your engine, you are fundamentally demanding more fuel. A high-flow fuel pump is the essential foundation of any performance build. Whether you're pulling heavy loads up a mountain pass or pushing for a new record at the track, a performance pump ensures your engine never goes thirsty. However, installing a more powerful pump has knock-on effects. A high-volume pump draws significantly more amperage than a stock unit, which often necessitates upgraded wiring and relays to prevent voltage drops that can starve the pump and hurt performance. Furthermore, an oversized pump can overwhelm the factory pressure regulator, causing excessively high fuel pressure, which leads to a rich fuel mixture, poor performance, and potential damage to the injectors. The key is to calculate your engine's fuel needs based on your horsepower goal and select a pump that provides a safe margin of capacity (typically 15-20% more than your calculated peak demand) without going to wasteful extremes. At G2 Diesel Products, our high-performance fuel pumps are engineered specifically for the demands of diesel applications, ensuring reliable, consistent fuel delivery for your Volvo, Mack, Kenworth, or Paccar truck.

Fuel Injectors: A Guide to Your Next Fuel System Upgrade

If the pump is the heart of the system, the injectors are the precision surgical instruments. Getting injector sizing right is one of the most critical aspects of a fuel system upgrade. When you're planning for more horsepower, your injectors must be able to flow enough fuel to support that goal. Injector flow is typically measured in Liters Per Minute (LPM) or Cubic Centimeters (cc) per minute. A common mistake is to assume that bigger is always better. While modern manufacturing allows larger injectors to have better low-output control than in the past, there is a limit. If the injector's minimum pulse width still delivers too much fuel at idle or low-load conditions, you'll end up with a rich mixture, poor idle quality, fouled plugs, and terrible fuel economy. Matching injectors to horsepower goals requires careful calculation, often based on the engine's Brake Specific Fuel Consumption (BSFC). Our Performance Diesel Injectors are designed with this precision in mind, built to handle the higher pressures and flow demands of modified diesel engines while maintaining control for clean, efficient combustion across the entire RPM range.

Fuel Lines, Filters, and Regulators: The Supporting Cast

These components are the unsung heroes of your fuel system, and ignoring them can undermine your entire investment. As fuel flow increases, line diameter becomes a critical factor. The stock lines on your truck may be perfectly adequate for the factory pump, but they can become a major restriction when you install a high-flow unit. Upgrading to larger lines, commonly sized using the -AN (Army-Navy) standard (e.g., -6AN, -8AN, or -10AN), can dramatically improve flow capacity. For modern fuels, which can be corrosive, PTFE-lined hoses offer superior resistance to degradation compared to traditional rubber. Similarly, a restrictive stock fuel filter can become a significant bottleneck. High-flow fuel filters are designed with more surface area and less restrictive media to protect your upgraded components without impeding performance. Finally, for any turbocharged or boostd application, a boost-referenced fuel pressure regulator is essential. This device is connected to the intake manifold and automatically increases fuel pressure as boost pressure rises (typically at a 1:1 ratio). This ensures that the injectors can overcome the pressure in the cylinder and prevents a dangerous lean condition when the engine is working its hardest. Mismatched parts in this supporting cast lead to poor performance and potential engine damage, which is why we focus on providing a complete suite of components designed to function as a single, integrated unit.

Reaping the Rewards: Benefits of a Properly Tuned System

A properly planned and executed fuel system upgrade is more than just a repair or a modification; it's a change. When all components—the pump, lines, filter, regulator, and injectors—are correctly sized and working in harmony, your engine can finally perform to its true capabilities. The results are often immediate and profound.

Increased Horsepower and Torque: This is the most obvious benefit. With the ability to deliver more fuel efficiently, the engine can generate significantly more power. This isn't just a number on a dyno sheet; it's the real-world ability to merge onto the highway with confidence, hold speed on a steep grade, and reduce trip times.

Improved Fuel Economy: This may seem counterintuitive. How can a system designed to flow more fuel actually save it? The answer lies in efficiency. A high-pressure, high-performance system with superior injectors creates a finer atomization of the fuel. This leads to a faster, more complete combustion process, extracting more energy from every single drop of fuel. While you'll use more fuel at full throttle, your part-throttle efficiency during cruising can be significantly improved with proper tuning.

Improved Engine Reliability: Stock components in a modified engine are living on borrowed time. Pushing them beyond their design limits leads to stress, excessive wear, and premature failure. Upgraded components are specifically engineered to handle higher pressures and flow rates, reducing stress on the entire system and leading to fewer unexpected breakdowns and a longer-lasting engine.

Better Throttle Response: The frustrating delay between pressing the accelerator and feeling the engine respond is often due to a fuel system that can't react quickly enough. A properly designed upgrade provides instant, predictable power, making the truck feel more responsive and easier to drive.

Extended Component Lifespan: High-quality, properly sized components last longer because they are not being pushed to their absolute limit. They operate comfortably within their design parameters, leading to greater durability and a better return on your investment.

Reduced Emissions: More efficient and complete combustion doesn't just produce more power; it also produces fewer harmful byproducts like soot (particulate matter). A well-tuned performance system can often run cleaner than a struggling stock system.

The Critical Role of ECU Tuning

None of these benefits are possible without the final, critical piece of the puzzle: ECU tuning. Your upgraded hardware is like a world-class orchestra with brand-new instruments, but the ECU is the conductor. Without a proper tune to rewrite its instructions, the conductor is still trying to lead a high school band. The ECU must be reprogrammed to understand the new flow rates of the injectors and the capabilities of the new pump. A professional tune optimizes the fuel maps, injection timing, and pressure settings to match the new hardware, allowing you to safely open up the full performance potential of your investment. Skipping this step will, at best, result in poor performance; at worst, it can lead to catastrophic engine damage.

The Consequences of Neglecting Your Fuel System Upgrade

Ignoring your fuel system's needs—or worse, making other performance modifications like a larger turbo or aggressive air intake without upgrading the fuel delivery—is a costly and dangerous mistake. The single biggest risk is catastrophic engine damage. When an engine's demand for fuel exceeds the system's ability to supply it, it runs lean. A lean air-fuel mixture burns significantly hotter, causing exhaust gas temperatures (EGTs) to skyrocket. This extreme heat can melt pistons, warp cylinder heads, and destroy turbochargers. Incorrect fuel pressure, whether too high or too low, also wreaks havoc, leading to poor performance, damaged injector nozzles, and failed solenoids. If you've invested thousands in other modifications, a neglected fuel system becomes the bottleneck that renders those other parts worthless. This leads to dangerous stalling and misfiring, turning your reliable workhorse into an unpredictable liability. The financial impact is severe. Poor fuel economy, frequent repairs, and lost revenue from downtime add up quickly. A catastrophic fuel system failure can easily lead to a repair bill exceeding $10,000. Your fuel system is the foundation of your engine's performance and reliability; it deserves to be treated with the respect it commands.

OEM vs. Performance Parts: Making the Right Choice for Your Truck

When the time comes to replace or upgrade a fuel system component, you face a fundamental choice: stick with Original Equipment Manufacturer (OEM) parts or invest in aftermarket performance parts. The right decision depends entirely on your goals, your budget, and how you use your truck. There is no single "best" answer, only the best choice for your specific application.

Feature OEM Replacement Parts G2 Diesel Products Performance Fuel System Parts Intended Use Restoring factory performance, daily driving reliability High-performance applications, racing, heavy-duty work Power Support Designed for stock power levels and factory specifications Engineered for significantly increased horsepower and torque Cost Generally moderate initial cost Higher initial investment, but superior long-term value for performance Durability Meets factory specifications for a standard service life Often exceeds OEM specifications for demanding conditions and higher stress Installation Complexity Direct-fit, typically straightforward with no modifications needed May require additional supporting modifications or professional installation

When to Choose OEM Replacement

OEM parts are the ideal choice when your primary goal is to restore your truck to its original, factory-specified condition. If a component has failed due to normal wear and tear after many years of reliable service, and you have no plans to increase the engine's power output, an OEM replacement is a dependable and cost-effective solution. For fleet managers overseeing dozens of vehicles, sticking with OEM parts ensures standardization, predictability, and often simplifies warranty claims. OEM components are engineered to work seamlessly with the rest of the stock vehicle, offering a direct-fit installation with no surprises. Our Fuel Injector Replacement Parts are engineered to meet or exceed all OEM standards, ensuring your Volvo, Mack, Kenworth, or Paccar truck maintains the reliable performance it was designed for.

When to Choose a Performance Fuel System Upgrade

A performance fuel system upgrade becomes essential the moment you decide to push your engine beyond its stock limitations. If you are planning a high horsepower build, adding a larger turbocharger, or using aggressive ECU tuning, the stock fuel system will not be able to supply the necessary fuel. It's not an option; it's a requirement. Similarly, for diesel performance applications like competitive truck pulling, drag racing, or even extremely heavy hauling in demanding environments (like logging or high-altitude transport), upgraded components provide the robustness and flow capacity needed to handle the immense stress. Performance parts from a reputable manufacturer like G2 Diesel Products are not just "bigger"; they are engineered with superior materials, tighter tolerances, and advanced designs to improve durability and efficiency under conditions that would destroy stock parts. This investment provides the performance you demand and the peace of mind you need when pushing your equipment to the limit. G2 Diesel Products' performance line is designed to support even the most ambitious diesel builds.

Frequently Asked Questions about Fuel System Upgrades

We understand that a fuel system upgrade is a significant investment. Let's tackle some of the most common questions we hear from truck owners and fleet managers to help you make an informed decision.

How much does a fuel system upgrade cost?

The cost of a fuel system upgrade can vary dramatically, from a few hundred dollars to well over ten thousand. It all depends on your goals and the scope of the project. A simple OEM replacement for a single failed part will be the most affordable option. A basic performance upgrade, such as a high-flow lift pump to improve reliability, might cost between $500 and $1,500 installed. A comprehensive system overhaul for a high-horsepower build—including a high-capacity lift pump, a modified or dual high-pressure pump, larger injectors, new lines, a performance regulator, and custom tuning—can easily range from $5,000 to $10,000 or more in parts and labor. This is not an area to cut corners; the high pressures and tight tolerances in a diesel fuel system demand high-quality components and professional expertise. For a more detailed look at the cost of one of the key components, our Diesel Fuel Injector Cost guide can provide a better sense of what to expect.

Do I need to tune my engine after a fuel system upgrade?

Yes, absolutely and without exception. This is arguably the most critical step in the entire process. Your engine's computer (ECU) is programmed with a precise digital map that is calibrated for the exact flow characteristics of your stock fuel components. When you install parts that flow more fuel, like larger injectors or a higher-pressure pump, the ECU's stock map is no longer valid. Without an ECU tune, the computer will still command the injectors based on the old data, leading to an incorrect air-to-fuel ratio. This will result in poor performance, terrible fuel economy, and, most importantly, can create dangerous conditions that lead to severe engine damage. Professional ECU tuning rewrites the map to match your new hardware, optimizing the air-to-fuel ratio, injection timing, and other parameters to safely realize the full performance gains from your investment.

Can I upgrade just one part of my fuel system?

While you technically can replace a single part, it's crucial to distinguish between a repair and a performance upgrade. If you are simply replacing a failed OEM part with another OEM part to restore stock performance, then yes, a single part replacement is fine. However, if you are seeking to improve performance, a systemic approach is always best. Your fuel system is only as strong as its weakest link. For example, if you install injectors that can flow 30% more fuel but leave the stock fuel pump in place, the pump will be unable to supply enough volume to keep up at high RPMs. This will cause fuel pressure to drop, creating a dangerous lean condition and completely negating the benefit of the new injectors. For performance gains, you must plan your upgrade as a complete, balanced system where each component is matched to the others.

Can I install a fuel system upgrade myself?

This depends on your mechanical experience, your tools, and the complexity of the job. Replacing a simple component like an external lift pump or a spin-on filter might be within the capabilities of a skilled DIY mechanic. However, working on the high-pressure side of a modern diesel fuel system is a different story. These systems operate at incredibly high pressures (up to 30,000 PSI or more), and a leak can inject fuel straight through the skin, causing a severe chemical injury. The work requires specialized tools, an immaculate working environment to prevent contamination, and a deep understanding of how the system functions. For components like high-pressure pumps or injectors, we strongly recommend professional installation to ensure the job is done safely and correctly.

How will a fuel system upgrade affect my truck's warranty and emissions compliance?

This is a critical consideration. In the United States, the Magnuson-Moss Warranty Act states that a manufacturer cannot void your entire vehicle warranty just because you've installed aftermarket parts. However, they can deny a specific warranty claim if they can prove that the aftermarket part caused the failure. Regarding emissions, many high-performance parts are designated for "off-road use only" and may not be legal for use on public roads in your state or country. It is the owner's responsibility to be aware of and comply with all local, state, and federal laws. Before beginning an upgrade, it's wise to research your local regulations and understand the potential impact on your vehicle's warranty.

Conclusion: Open uping Your Engine's Full Potential

Your journey into fuel system upgrades is the first and most important step toward open uping your diesel engine's true potential. As we've explored, a successful upgrade is far more than just a collection of expensive, shiny parts; it is a balanced, systemic process that requires careful planning, component matching, and precise execution. When you respect the fuel system as a complete, integrated unit—where the pump, lines, filters, injectors, and regulator all work in concert—you set the foundation for remarkable success.

The rewards for this diligence are substantial and tangible. You'll experience a significant increase in performance, giving you the power and torque you need for any task. You'll benefit from improved fuel economy as a result of more efficient combustion, saving you money with every mile you drive. And most importantly, you'll achieve improved engine reliability, knowing your engine is not just more powerful, but also more robust and less prone to the kinds of failures that can take a truck off the road. However, this is all contingent on proper planning and, critically, professional ECU tuning to bring it all together. If you miss a connection or create a bottleneck, you risk creating new, more expensive problems instead of solving the old ones.

At G2 Diesel Products, we live and breathe diesel performance. We understand the immense demands placed on your Volvo, Mack, Kenworth, and Paccar trucks in the real world. We are dedicated to providing the highest quality components engineered for the most demanding applications, backed by decades of expertise in diesel fuel injection technology.

Ready to take the next step and transform your truck's performance and reliability? Explore our high-performance SMART F2P INJECTORS. They represent the cutting edge of diesel injection technology and are designed to be the heart of your next fuel system upgrade, delivering the precision, power, and durability that G2 Diesel Products is known for.