Cummins XPI Injectors: Precision Fuel Delivery for ISX15 and X15 Engines

Why XPI Injectors Are Critical for Modern Cummins Diesel Performance

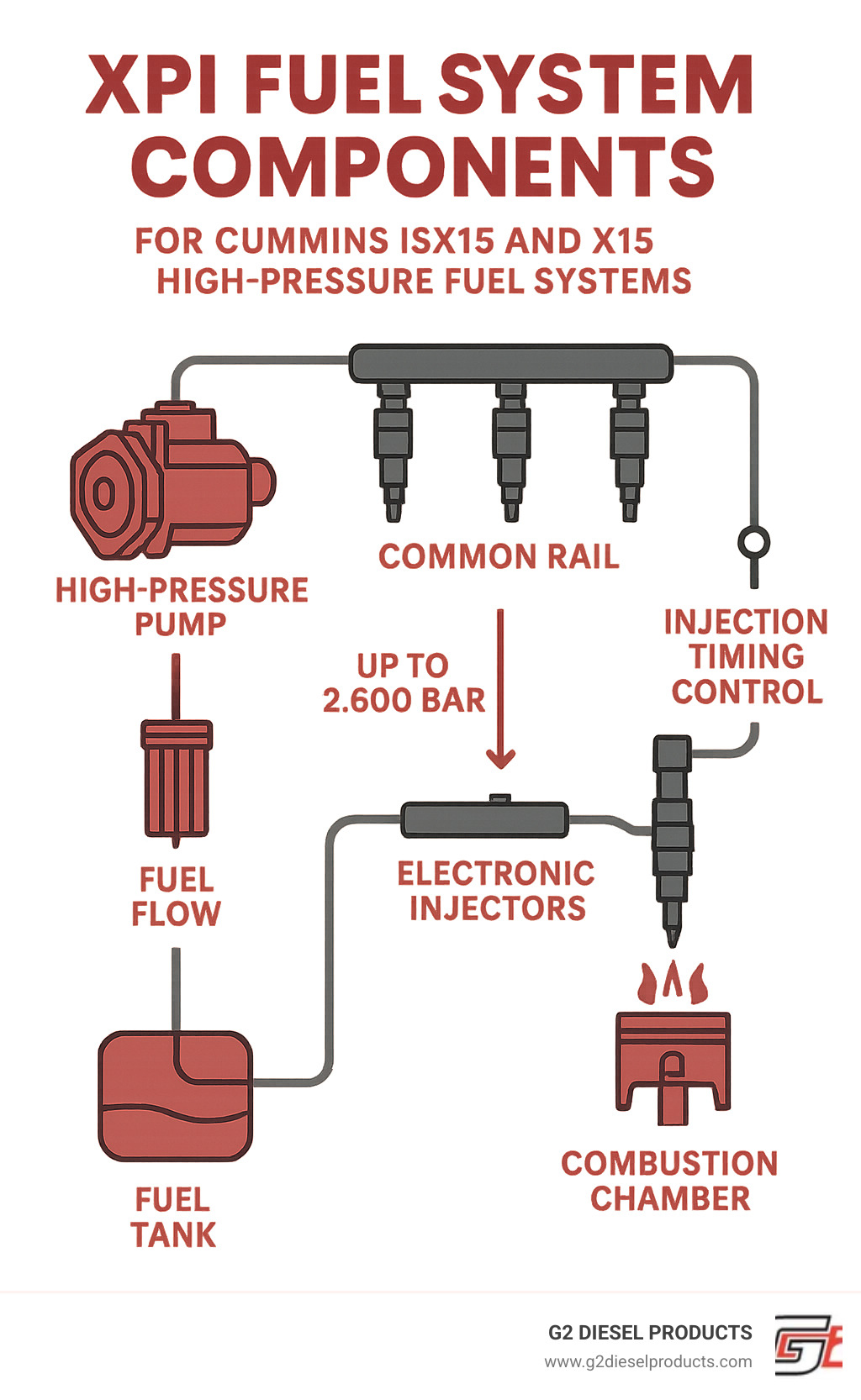

XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems are the core of modern diesel fuel injection, delivering fuel at immense pressures up to 2,600 bar (37,000 psi) via a sophisticated common rail system.

Quick Answer: What You Need to Know About XPI Injectors

- XPI stands for: Xtra-High Pressure Injection, Cummins' advanced common rail fuel system.

- Pressure capability: Up to 2,600 bar for superior fuel atomization.

- Key benefits: Improved fuel economy, reduced emissions, and multiple injection events per cycle.

- Applications: Cummins ISX15 and X15 engines in heavy-duty trucks.

- Unique features: Pressurized spring cavities, leakless design, and pressure-assisted operation.

- Performance gains: Up to 5% efficiency improvement and a 25% reduction in parasitic power consumption.

For fleet managers, understanding XPI technology is essential because these injectors directly impact the bottom line through better fuel economy, lower maintenance costs, and reduced downtime.

The XPI system is a major leap from older Cummins fuel systems. Instead of mechanically timed, cam-actuated injectors, XPI uses electronically controlled solenoid injectors fed by a high-pressure common rail. This allows the Engine Control Module (ECM) to precisely manage injection timing, duration, and pressure for each cylinder. This level of precision is crucial for modern Kenworth, Peterbilt, and Freightliner trucks to meet strict EPA emissions standards while delivering the power your operations demand.

Understanding the XPI Fuel System: The Heart of Cummins ISX15 and X15 Engines

The XPI (Xtra-High Pressure Injection) fuel system in Cummins ISX15 and X15 engines is a significant evolution from older designs. It's a common rail system, meaning all injectors draw fuel from a single, high-pressure source. This contrasts sharply with older Cummins systems like HPI-TP, which used mechanical, camshaft-driven plungers to pressurize fuel at each cylinder individually.

Here's a breakdown of how the XPI system works:

- High-Pressure Fuel Pump: This is the system's powerhouse, pressurizing fuel up to an incredible 2,600 bar (37,000 psi). Cummins offers 1, 2, and 3-cylinder pump models to match specific engine requirements.

- Fuel Rail: This durable metal tube acts as a high-pressure reservoir, distributing the pressurized fuel to each cylinder and ensuring it's ready for immediate injection.

- Solenoid-Actuated Injectors: These are the system's stars. They receive precise electrical commands from the Engine Control Module (ECM), which constantly monitors engine speed, load, temperature, and other parameters to determine the exact fuel needs.

When the ECM signals an injector's solenoid, XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems deliver the right amount of fuel at the perfect moment—a level of precision unattainable with mechanical systems.

How XPI Technology Delivers Superior Performance

The precision of XPI technology translates directly into better performance, fuel economy, and cleaner emissions. Key features include:

- Multiple Injection Events: The system can deliver up to six precisely timed injections per power stroke. Pilot injections initiate smooth combustion and reduce noise, the main injection provides power, and post injections help the aftertreatment system by raising exhaust temperatures. This multi-stage process ensures more complete and efficient combustion.

- Superior Atomization: Injecting fuel at 2,600 bar creates an ultra-fine mist that mixes thoroughly with air. This improved atomization leads to better combustion efficiency, maximizing power from every drop of fuel while producing fewer harmful emissions.

- Pressure-Assisted & Leakless Design: The high-pressure environment helps protect internal components from fuel debris. The system's pressurized spring cavities and leakless design virtually eliminate fuel leakage, improving fuel economy and reducing parasitic power consumption by over 25% compared to typical mid-range injectors.

Combined, these features allow XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems to deliver the performance and efficiency required to keep modern trucks profitable and compliant with today's strict emissions standards.

Key Benefits of Upgrading to XPI Injectors

For a fleet of heavy-duty trucks, XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems are a critical investment that lifts an engine from merely functional to exceptional. The benefits directly impact your operations and profitability.

Performance Gains: Properly functioning XPI injectors deliver more horsepower and torque when it's needed most. Drivers will notice a crisper engine response, making it easier to handle steep grades and merge into highway traffic with confidence.

Fuel Economy: The ultra-high injection pressures create fine fuel droplets that burn more completely. Cummins' claim of up to a 5% efficiency improvement translates to significant savings. For a truck running 100,000 miles a year, that can mean thousands of dollars back in your pocket. The leakless design further boosts efficiency by reducing parasitic power consumption by over 25%.

Durability: XPI injectors feature a pressure-assisted design that makes them highly resistant to fuel debris, a common issue with unpredictable fuel quality on the road. This robust construction means fewer breakdowns, less downtime, and lower maintenance costs over the engine's life.

Emissions Compliance: XPI technology is essential for meeting strict EPA standards. The system's precise control over fuel delivery, including multiple injection events, optimizes combustion to minimize pollutants like nitrogen oxides and particulate matter. This future-proofs your fleet against tightening regulations.

These benefits are interconnected: better atomization improves both performance and emissions, while the leakless design improves both fuel economy and durability. Investing in quality performance diesel injectors with XPI technology pays dividends with every mile.

A Practical Guide to XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems

Properly maintaining XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems is critical. This guide covers identifying the right parts, installation best practices, and tips for ensuring longevity.

Identifying the Right Part: Common XPI Injector Part Numbers

Using the correct part number is non-negotiable for your Cummins ISX15 or X15 engine. Always match the part number to your engine's Serial Number (ESN) to ensure compatibility. Common XPI injector part numbers include:

- OEM 2872405: Find our quality remanufactured version here: Cummins ISX15 XPI Fuel Injector.

- OEM 5579417PX: A common cross-reference.

- OEM 2897320: Our remanufactured version is available here: Cummins ISX 15L XPI Fuel Injector.

- OEM 5579421: Stocked here: Cummins ISX 15L Fuel Injector.

Other cross-reference numbers include 2894920, 2894920PX, 5579415, and 5579415px. When in doubt, consult a professional to avoid costly mistakes.

Installation Best Practices and Potential Challenges

Replacing XPI injectors requires precision. Follow these best practices for a smooth installation:

- Cleanliness is Critical: Work in a spotless area with clean tools. Microscopic debris can cause catastrophic damage to high-pressure components.

- Clean the Injector Bores: Use a proper brush to remove all carbon and debris from the cylinder head bores to ensure the new injector seats correctly.

- Follow Torque Specifications: These are requirements, not suggestions. Use a calibrated torque wrench.

- Hold Down Bolts: Pre-torque to 20 Nm (177 in-lb). Final torque is 80 Nm (59 ft-lb) for AP55100/101/102 models or 65 Nm (48 ft-lb) for AP55103 models.

- Feed Tube Nuts: Pre-torque to 20 Nm (177 in-lb), then final torque to 77 Nm (57 ft-lb).

- Solenoid Nuts: Torque gently to just 2 Nm (18 in-lb) to avoid breaking the terminal.

- Program Trim Codes: Each new injector has a unique calibration code that must be programmed into the ECM using software like Cummins Insite. Skipping this step leads to rough idling, poor fuel economy, and fault codes. Some ISX CM2350 models may only require a fuel injector reset.

For more detailed instructions, see our guide on how to replace diesel injectors. Using specialty tools like an affordable injector puller tool can also simplify the job.

Ensuring Longevity: Maintenance, Lifespan, and Fuel Quality

The lifespan of your XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems depends heavily on maintenance and fuel quality. With proper care, they can last for hundreds of thousands of miles. Quality remanufactured injectors often come with excellent warranty coverage, such as a two-year, unlimited mileage warranty.

Fuel quality is the single most important factor.

- Use ULSD: Modern injectors are designed for Ultra-Low Sulfur Diesel.

- Beware of Contaminants: Water is the biggest enemy, causing corrosion and catastrophic failure. Solid contaminants cause abrasive wear. Ensure your fuel-water separator is working and drained regularly.

- Change Fuel Filters Religiously: This is your primary defense. Follow the manufacturer's schedule and use high-quality filters. It's far cheaper than replacing injectors.

For more tips, explore resources on how to clean common rail diesel injectors and the importance of regular maintenance and fuel filter changes. While a diesel fuel injector cleaning service can sometimes help, replacement is often the most reliable long-term solution.

Troubleshooting and Sourcing XPI Injectors

When you suspect your XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems are failing, knowing the signs and how to diagnose them is key to minimizing downtime. Common symptoms of failing injectors include a rough idle, engine misfires, a sudden drop in fuel economy, excessive exhaust smoke (black, white, or blue), and a noticeable loss of power.

Diagnostic software like Cummins Insite is invaluable for reading fault codes and performing tests to pinpoint the problem. For more details, see our guide on Fuel injector problems in diesel engines.

Diagnosing Issues: Common Fault Codes for XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems

The Cummins ECM logs fault codes that act as a guide to the problem. Key codes related to XPI injectors include:

- Code 1139 & 1144: Injector Mechanical Not Responding - Abnormal Update Rate. These codes suggest a mechanical issue within an injector, such as internal wear or a clog, preventing it from responding to ECM commands.

- Code 1911: Fuel Rail Pressure - Data Erratic, Intermittent, or Incorrect. This points to a problem with the high-pressure system's ability to maintain or report pressure. Causes can range from a faulty sensor or pump to leaks in the system or injector drain line restrictions.

A qualified technician can help you How to check common rail injectors to confirm if the injectors are the root cause.

The Smart Choice: Remanufactured XPI Injectors and Core Policies from G2 Diesel Products

When replacing an injector, high-quality remanufactured XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems from G2 Diesel Products offer the best combination of performance, reliability, and value.

Our remanufacturing process is meticulous. We completely disassemble the injector, replace all wearable parts (including 100% new nozzles) with new OE-equivalent components, and then conduct multi-point testing and calibration on state-of-the-art equipment. Each injector is tested at over 18 crucial points to ensure it meets or exceeds OEM standards. Our ISO 9001:2015 Certified facilities reflect this commitment to quality, which is why we can offer a two-year, unlimited mileage warranty.

Understanding the core charge policy is key to maximizing value. A core charge is a deposit paid at purchase, which is refunded when you return your old, rebuildable injector. To receive a full refund, return the core within the specified timeframe (usually 30-90 days), drained of all fluids, and packaged securely to prevent leaks. Cores that are seized, cracked, or fire-damaged may not receive full credit.

For more details, explore our General information on fuel injectors and our specific core policies.

Frequently Asked Questions about Cummins XPI Injectors

Here are answers to the most common questions we receive about XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems.

What makes the XPI system different from older Cummins fuel systems?

The key difference is precision and control. The XPI system is a high-pressure common rail system using electronically controlled injectors. This allows for multiple, precisely timed injections per engine cycle. Older systems were typically cam-actuated and mechanical, offering only a single injection event with fixed timing. XPI's electronic control results in superior efficiency, lower emissions, and reduced engine noise.

Do I need to program the ECM after installing new XPI injectors?

Yes, in most cases. Each injector has a unique trim code that must be programmed into the Engine Control Module (ECM). This code calibrates the ECM to the specific flow rate of that injector, ensuring balanced power and smooth engine operation. Skipping this step will lead to performance issues and fault codes. A few specific ISX CM2350 engine models may only require an injector reset, but programming is the general rule.

Can I use a remanufactured XPI injector from G2 Diesel Products without sacrificing quality?

Absolutely. A high-quality remanufactured injector is not just a cleaned-up used part. At G2 Diesel Products, our rigorous remanufacturing process involves complete disassembly, replacement of all critical wear parts with new OE-equivalent components (including 100% new nozzles), and extensive multi-point testing to ensure performance meets or exceeds OEM specifications. Our injectors are calibrated in our ISO 9001:2015 Certified facility and backed by a comprehensive warranty, making them a reliable and cost-effective choice for your fleet.

Conclusion

XPI Injectors – For Cummins ISX15 and X15 High-Pressure Fuel Systems are the cornerstone of modern diesel performance. Their advanced Xtra-High Pressure Injection technology provides the precision needed for superior fuel economy, lower emissions, and reliable power.

We've covered how this system works, the importance of using correct part numbers, and the critical steps for installation, including ECM programming. Proper maintenance, especially using high-quality fuel and filters, is your best strategy for ensuring injector longevity. When issues arise, understanding common fault codes can streamline diagnostics.

At G2 Diesel Products, we provide high-quality remanufactured XPI injectors that deliver OEM-level performance and reliability at a fraction of the cost. Our rigorous testing and solid warranty give you the confidence to keep your fleet on the road and profitable.

Don't let failing injectors compromise your engine's potential.

Ready to restore your truck's performance? Find the right Cummins XPI Injectors for your engine at G2 Diesel Products and feel the difference precision fuel delivery makes.