Inject Life Back into Your Engine with These Replacement Parts

Why Your Engine's Performance Depends on Quality Fuel Injector Parts

Fuel injector replacement parts are the essential components that keep your diesel engine running smoothly and efficiently. When these critical parts fail, your entire operation can grind to a halt.

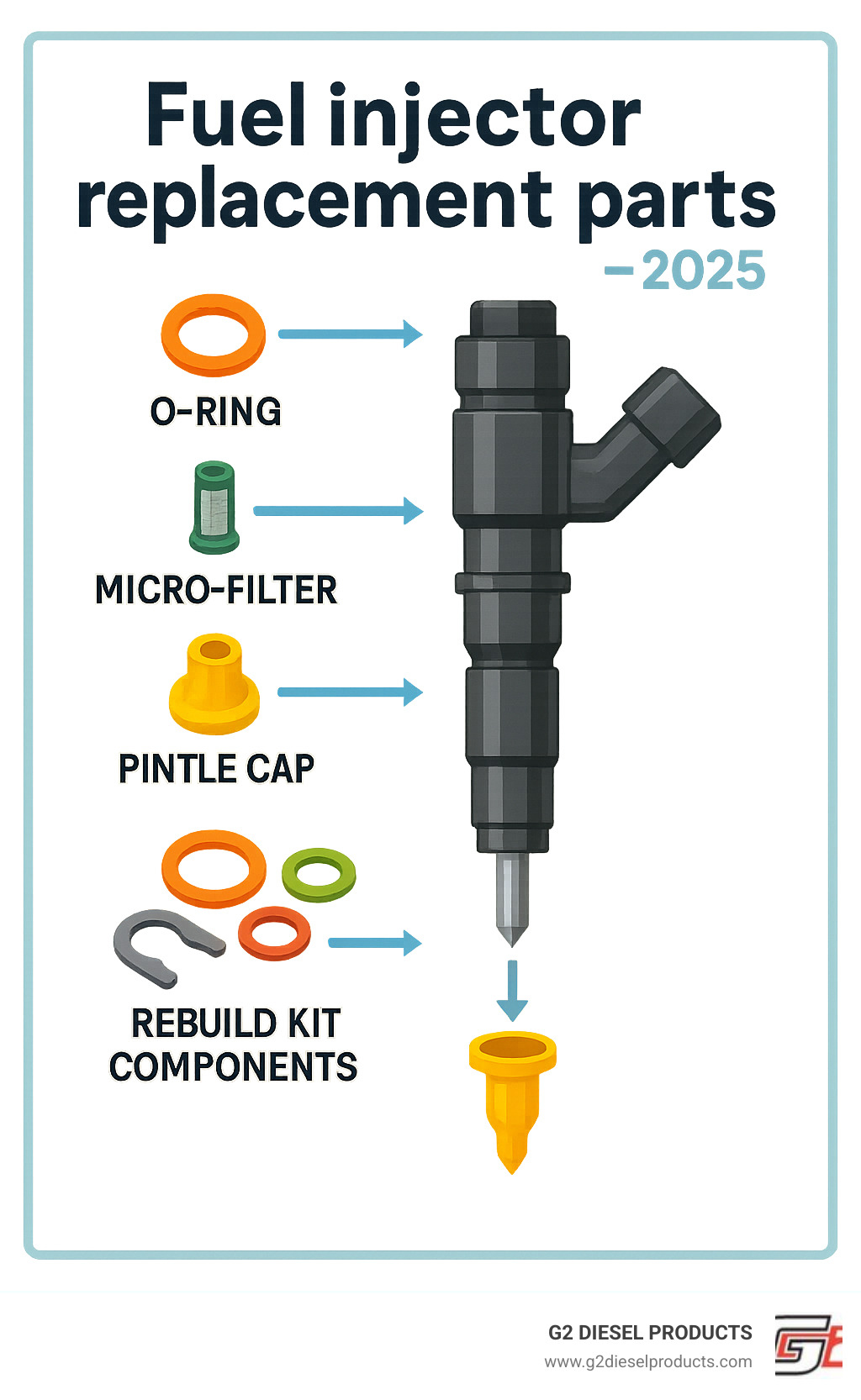

Key fuel injector replacement parts include:

- O-rings and seals - Prevent fuel leaks and maintain proper pressure

- Micro-filters - Block contaminants from reaching fuel nozzles

- Pintle caps - Control fuel spray patterns and atomization

- Spacers and washers - Ensure proper injector positioning

- Retaining clips - Secure injectors in place

- Complete rebuild kits - Contain all necessary sealing components

Your fuel injectors operate under extreme pressure - over 2,000 PSI in modern diesel systems. This intense environment constantly stresses seals, filters, and other components. When these parts wear out, you'll notice rough idling, poor acceleration, decreased fuel efficiency, and black smoke from your exhaust.

The good news? Many injector problems don't require complete replacement. Often, a rebuild kit with fresh seals and filters can restore your injectors to like-new performance at a fraction of the cost.

For fleet managers overseeing Volvo, Mack, Kenworth, and Paccar trucks, understanding these components is crucial. The right parts sourced quickly can mean the difference between minor maintenance and major downtime.

Why You Can't Ignore Failing Fuel Injector Parts

When that check engine light flickers on, it's often a sign of trouble within your fuel system. The small but mighty fuel injector replacement parts are frequently the culprits. These components work under extreme pressure, and over time, seals crack, filters clog, and O-rings wear out. It's not a matter of if they'll need attention, but when.

Common Symptoms and Long-Term Costs

Ignoring the warning signs can turn a minor issue into major engine damage. Be aware of these common symptoms:

- Performance Issues: Look for hard starting, stalling, rough idling, and noticeable power loss, especially when hauling heavy loads.

- Efficiency Drops: A sudden decrease in fuel efficiency and more frequent stops at the pump are clear indicators of a problem.

- Sensory Warnings: Pay attention to fuel odors around the truck, black smoke from the exhaust, or engine knocking sounds.

These symptoms can escalate to more severe problems like oil thinning or hydro lock, which can cause catastrophic engine failure. For a deeper dive into these issues, see our guide on Common Diesel Injector Issues.

Neglecting these parts has serious long-term consequences. Poor fuel atomization leads to carbon buildup on valves and pistons, causing progressive engine damage. Unburnt fuel can destroy expensive downstream components like catalytic converters and oxygen sensors.

Furthermore, a malfunctioning injector increases emissions, which can lead to failed inspections under regulations like those from the U.S. Environmental Protection Agency (EPA). Most importantly, unexpected breakdowns cost more than just repairs; they cost you downtime, contracts, and customer trust. Proactive maintenance with quality parts is a small price to pay for reliability and safety on the road.

A Comprehensive Guide to Fuel Injector Replacement Parts

While the main injector body is built to last, it relies on several smaller fuel injector replacement parts to function correctly. When these wear out, the entire system suffers. Key components include seals, O-rings, micro-filters, pintle caps, spacers, and retaining clips. Fortunately, many issues can be solved with a rebuild kit instead of a full injector replacement.

What's Inside a Fuel Injector Rebuild Kit?

A rebuild kit contains all the essential consumable parts needed to restore an injector's performance. These kits are a cost-effective solution for fleet operators and typically include:

- Upper and Lower O-rings: Seal the injector to the fuel rail and intake manifold, preventing fuel leaks and vacuum issues.

- Micro-filters: Trap microscopic debris that can clog the injector nozzle.

- Pintle Caps: Protect the injector tip and help shape the fuel spray for proper atomization.

- Spacers and Washers: Ensure the injector is positioned correctly for optimal function.

Rebuilding injectors can restore them to like-new performance for a fraction of the cost of new units. Learn more in our guide to Diesel Injector Repair Kits.

Understanding Different Types of Seals and Filters

The quality of materials used in fuel injector replacement parts is critical for longevity and performance.

- Viton O-rings: This specialized synthetic rubber is the industry standard, offering superior resistance to extreme temperatures and harsh diesel fuel chemicals.

- High-Pressure Seals: These are engineered to withstand the immense pressures of modern diesel systems (over 2,000 PSI), preventing leaks under constant stress.

- Micro-filter Baskets: These tiny filters are designed to catch particles as small as 10 microns, protecting the delicate injector nozzle from contaminants.

Always choose parts that meet or exceed OEM specifications and are compatible with modern diesel and biodiesel blends. Investing in quality components prevents premature failure and potential engine damage.

Navigating Different Fuel Systems and Their Specific Parts

Not all fuel injection systems are the same, and using the correct fuel injector replacement parts is critical. Modern heavy-duty diesel engines in trucks from Volvo, Mack, Kenworth, and Paccar use highly advanced systems that operate under extreme pressure, requiring specialized components engineered for durability and precision.

Key Diesel Injection Systems

- Common Rail Systems: These are the cutting edge of diesel technology. A single, high-pressure rail supplies fuel to all injectors, allowing for precise, multiple injection events per cycle. This results in cleaner, more efficient, and powerful engines. The extreme pressures demand perfect seals and components. Learn more about How Do Common Rail Injectors Work.

- Electronic Unit Injectors (EUI): In an EUI system, each cylinder has its own integrated pump and injector unit. This design generates incredibly high injection pressures, delivering immense power but requiring top-quality, robust components to handle the stress.

- Hydraulically Actuated Electronic Unit Injectors (HEUI): This system uses pressurized engine oil to actuate the fuel injector, creating even greater injection pressures. HEUI systems are ideal for heavy-duty applications demanding maximum torque. Our Electronic Unit Injectors are built to withstand these conditions.

Diesel fuel injector replacement parts are purpose-built for an environment where failure is not an option. For operators looking to maximize performance, we also offer Performance Diesel Injectors to get the most out of your engine.

The Critical Choice: Quality, Cost, and Finding the Right Parts

Selecting fuel injector replacement parts is an investment in your truck's reliability and performance. High-quality components ensure precise flow rates and optimal spray patterns, leading to better fuel efficiency, increased power, and lower emissions. At G2 Diesel Products, we are committed to excellence, providing parts that meet rigorous quality standards through processes like laser welding and extensive cycle testing. Learn more about Our Quality Diesel Fuel Injectors.

OEM vs. Remanufactured: Making the Right Choice

You generally have two options: new OEM parts or high-quality remanufactured parts.

- OEM Parts: These are identical to the factory-installed components, guaranteeing perfect fit and performance.

- High-Quality Remanufactured Parts: These are original parts that have been completely rebuilt to meet or exceed OEM specifications, often incorporating design improvements. They offer a compelling balance of quality and cost-effectiveness.

Here's a quick comparison:

| Factor | OEM Parts | High-Quality Remanufactured Parts |

|---|---|---|

| Price | Generally higher | More cost-effective |

| Fitment Guarantee | Exact, original fit | Exact, original fit (rebuilt to OEM specs) |

| Performance | Original factory performance | Restored to or exceeding original performance |

| Warranty | Manufacturer's warranty | Comparable to new (typically 2-3 years) |

| Core Charge Policy | May require a core deposit | Typically requires a core deposit |

For more details, see our guides on Precision Injection: A Guide to Diesel Fuel Injectors and Information on OEM standards.

Breaking Down the Cost

The cost of repair depends on the approach:

- Individual Components: The most economical option for a specific, known failure like a single leaking O-ring.

- Rebuild Kits: A great value, providing all necessary seals and filters to refurbish an injector.

- Complete Injector Replacement: The highest initial cost, but often the best long-term solution for severely damaged or worn injectors.

Investing in quality parts prevents more expensive repairs later. Read more about Diesel Fuel Injector Cost.

When to Call in the Experts

While some repairs are DIY-friendly, complex tasks require professional services. Experts have specialized equipment for:

- Ultrasonic Injector Cleaning: To remove tough carbon deposits.

- Flow and Spray Pattern Testing: To ensure the injector meets OEM specifications for fuel delivery and atomization.

- High-Pressure Testing: To verify performance under extreme operating conditions.

- Advanced Diagnostics: To accurately identify complex issues.

For our customers in Harrisburg, PA, and surrounding areas, using a certified shop ensures your parts are installed correctly. Find certified repair shops near you.

Frequently Asked Questions about Fuel Injector Replacement

Here are answers to common questions about fuel injector replacement parts.

How often do fuel injector parts need to be replaced?

There's no single answer, as replacement intervals depend on several factors:

- Maintenance Schedule: Follow your manufacturer's recommendations for inspection. It's good practice to replace seals and O-rings whenever an injector is removed.

- Mileage: Proactively inspect injector components around the 100,000 to 150,000-mile mark.

- Fuel Quality: Clean, high-quality diesel extends the life of your parts, while poor fuel can clog micro-filters prematurely.

- Driving Habits: Highway driving is less stressful on components than stop-and-go traffic or heavy hauling.

Proactive replacement is key to avoiding unexpected breakdowns.

Is it okay to replace just one fuel injector?

While you can replace a single injector, it's not recommended for high-mileage engines. When one injector fails, the others are likely worn as well. Replacing only one creates an imbalance in fuel delivery, leading to rough idling, poor performance, and reduced fuel efficiency. For consistent performance, it's best practice to replace injectors in matched sets.

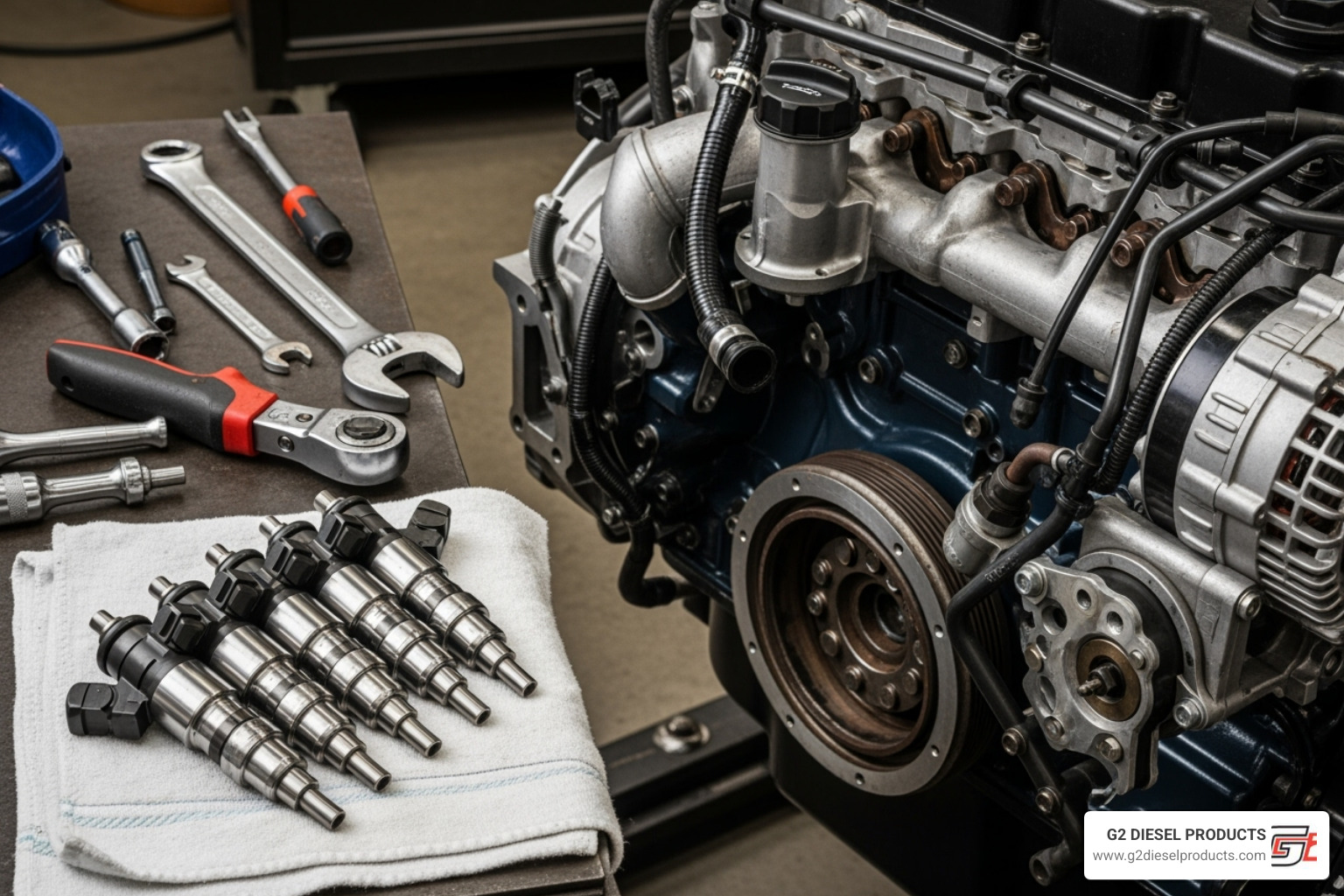

What are the essential tools for replacing fuel injector seals and O-rings?

For a DIY replacement of seals and O-rings, you'll need the right equipment:

- Basic Hand Tools: A quality wrench and socket set.

- Pick Set: To carefully remove old seals without scratching the injector.

- Fuel Injector Puller: A specialized tool to safely extract the injector.

- Seal Installation Tools: To slide new seals on without tearing them.

- Torque Wrench: To tighten bolts to precise manufacturer specifications.

- Safety Gear: Always use safety glasses, gloves, and have shop rags handy.

More complex internal repairs are best left to professionals.

Conclusion: Power Your Engine with Confidence

Your heavy-duty diesel engine's performance hinges on the health of its fuel injection system. From the smallest O-ring to the entire injector assembly, every component plays a crucial role. Recognizing the signs of failure and acting proactively with quality fuel injector replacement parts is the best defense against costly downtime and major repairs.

Whether you opt for a rebuild kit, individual components, or a complete set of remanufactured injectors, choosing quality parts ensures your engine runs with the power, efficiency, and reliability you depend on. The demanding systems in Volvo, Mack, Kenworth, and Paccar trucks require components that meet or exceed OEM standards.

At G2 Diesel Products, we specialize in manufacturing high-quality diesel fuel injectors for these heavy-duty applications. Our commitment to innovation means you get reliable products designed to minimize downtime and maximize performance. Investing in your engine is an investment in your livelihood.

We make the replacement process easy with a straightforward Core Return Policy: Diesel Fuel Injectors. Keep your engine running strong for years to come.