Diesel Power Unleashed: Performance Injectors Roundup

Why Performance Diesel Injectors Are Essential for Maximum Engine Power

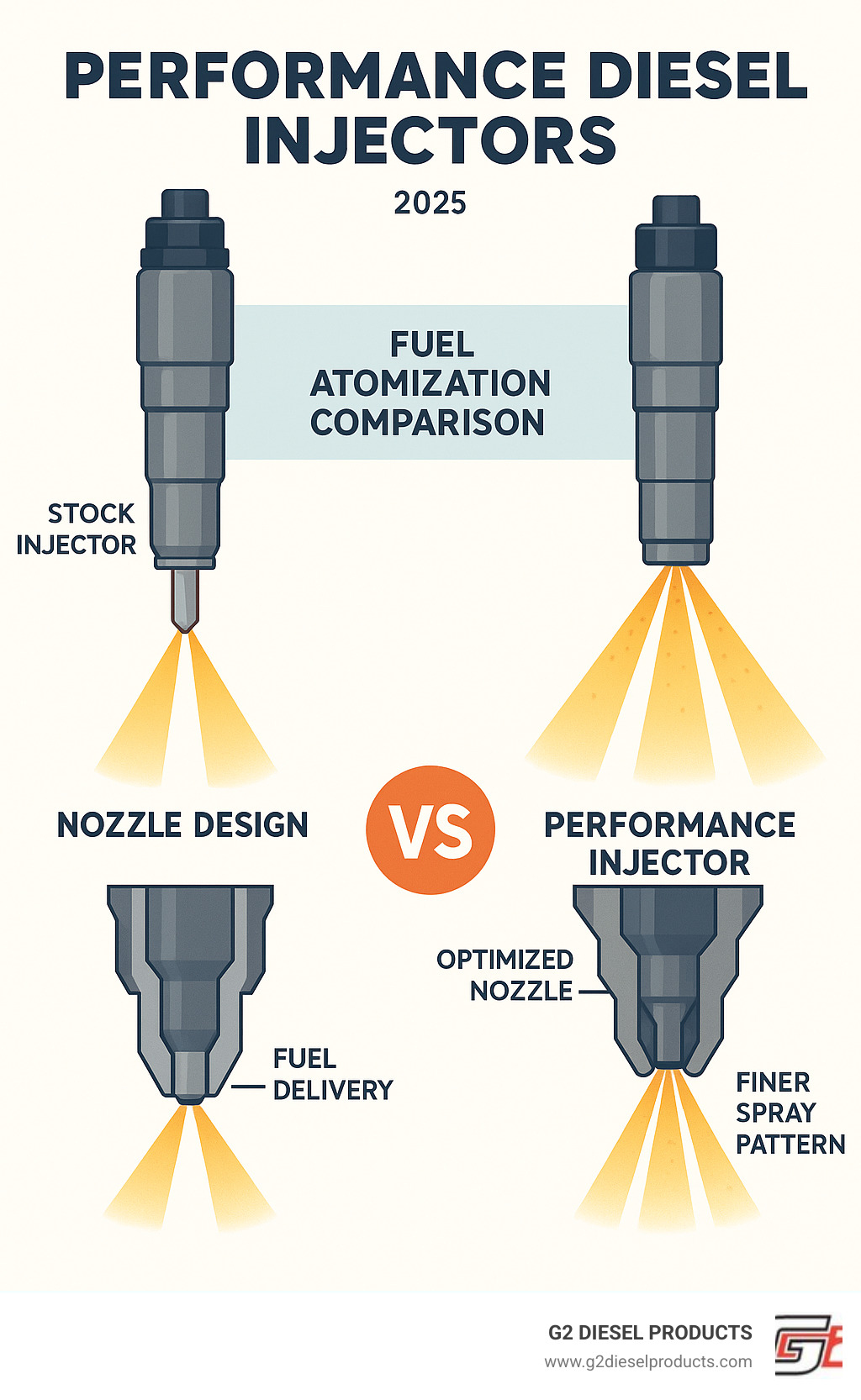

Performance diesel injectors are precision-engineered fuel delivery components that replace stock injectors to increase horsepower, improve fuel efficiency, and improve overall engine performance. Unlike standard OEM injectors, these upgraded units feature larger flow capacities, advanced materials, and optimized spray patterns that enable your diesel engine to produce significantly more power and torque.

Key benefits of performance diesel injectors:

- Power gains: 25% to 200% increase over stock output

- Flow rates: Available from modest upgrades to 300% over stock

- Improved atomization: Better fuel spray for cleaner combustion

- Improved durability: Stainless steel and high-strength alloy construction

- Better throttle response: More precise fuel delivery timing

Modern diesel engines rely on precise fuel injection to achieve optimal combustion. When you upgrade to performance injectors, you're essentially open uping your engine's potential by delivering more fuel at higher pressures with better timing control. This translates to increased horsepower and torque, whether you're pulling heavy loads or seeking maximum performance.

The technology behind these injectors has evolved dramatically. From mechanical P7100 systems to advanced Common Rail designs, performance injectors now feature SAC style nozzles, extrude honing processes, and flow matching to within 1% variance per set. These precision manufacturing techniques ensure consistent performance across all cylinders.

For fleet managers and commercial truck operators, performance injectors offer a compelling value proposition. Beyond the immediate power gains, these upgrades often improve fuel economy through better combustion efficiency while reducing emissions. The improved durability of performance injectors, constructed from stainless steel and high-strength alloys, means extended service life compared to standard replacements.

What Are Performance Diesel Injectors and How Do They Improve Your Engine?

Diesel injectors are the finely tuned valves that let exactly the right amount of fuel enter the combustion chamber at precisely the right moment. Stock units handle this job well enough for everyday driving, but they’re built around strict emissions targets and conservative power levels.

Performance diesel injectors lift those limits. By using stronger alloys, larger flow passages and carefully engineered spray patterns, they push more fuel into each cylinder while atomizing it far more effectively. That single change triggers several benefits:

- Higher horsepower and torque – anywhere from a modest 40 HP bump to well over 250 HP on fully built trucks.

- Sharper throttle response – fuel arrives sooner and more evenly, so the engine reacts instantly.

- Cleaner, more complete combustion – finer mist burns hotter and more uniformly, improving MPG and trimming soot.

- Longer service life – stainless-steel internals laugh off the extra heat and pressure produced in tuned engines.

OEM vs. Performance in one glance

| Feature | Stock Injector | Performance Injector |

|---|---|---|

| Flow rate | Sized for factory tune | +25 % to +300 % over stock |

| Materials | Standard steel | High-strength stainless & alloys |

| Spray pattern | Basic cone | Optimized multi-hole, SAC or VCO |

| Consistency | ±5 % set variance | ≤1 % set variance |

| Goal | Meet emissions, reliability | Maximize power & efficiency |

Because every extra droplet of diesel must be matched with air, serious injector upgrades almost always require supporting mods (bigger turbo, better lift pump) and an ECU recalibration. Done together, those changes open up the real-world gains the flow numbers promise.

For additional background on the parts that work alongside injectors, see our overview of diesel engine parts.

A Deep Dive into Injector Types and Technologies

Diesel injection has evolved from purely mechanical pumps to lightning-fast electronic systems capable of firing multiple times per power stroke. Knowing which style lives under your valve cover is step one in choosing an upgrade. (For a concise history of the underlying engine, see this Wikipedia introduction to the diesel engine.)

Common Fuel System Architectures

- Mechanical (P7100, etc.) – Cam-driven plungers build pressure and timing mechanically. Simple to tinker with and still a favorite for all-out competition.

- Common Rail – A single high-pressure rail feeds electronically controlled injectors that can pulse several times per cycle. Enables the highest precision and the cleanest emissions. Read more: How Common Rail Injectors Work.

- Electronic Unit Injector (EUI) – Each injector has its own pump, giving cylinder-by-cylinder control and very high pressures. How Electronic Unit Injector Works.

- Hydraulic Electronic Unit Injector (HEUI) – Uses engine-oil pressure to actuate the injector for extreme flexibility. HEUI Fuel System.

What Makes a Performance Injector Different?

- SAC style nozzles hold a tiny reserve of fuel to maintain pressure through the shot, improving consistency.

- Extrude honing polishes internal passages, eliminating turbulence and adding flow without drilling oversized holes.

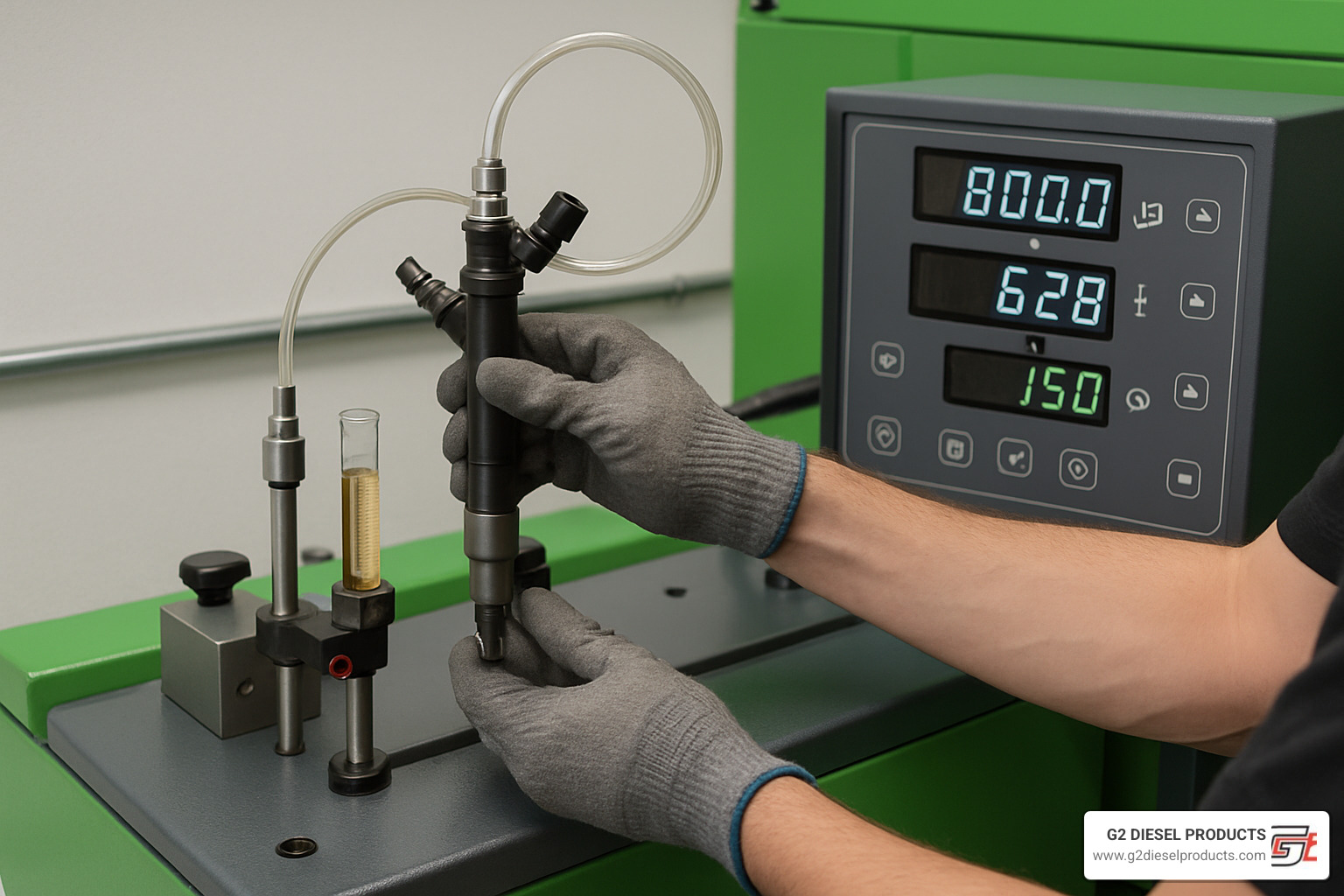

- Flow matching & shot-to-shot testing keep every cylinder within 1 % of the target volume, smoothing idle and boosting reliability.

- Peak & Hold solenoids snap the needle open quickly, reducing latency at high RPM.

These upgrades work together to deliver more fuel, more accurately, in less time—exactly what a tuned diesel demands.

Understanding Performance Diesel Injectors and Their Ratings

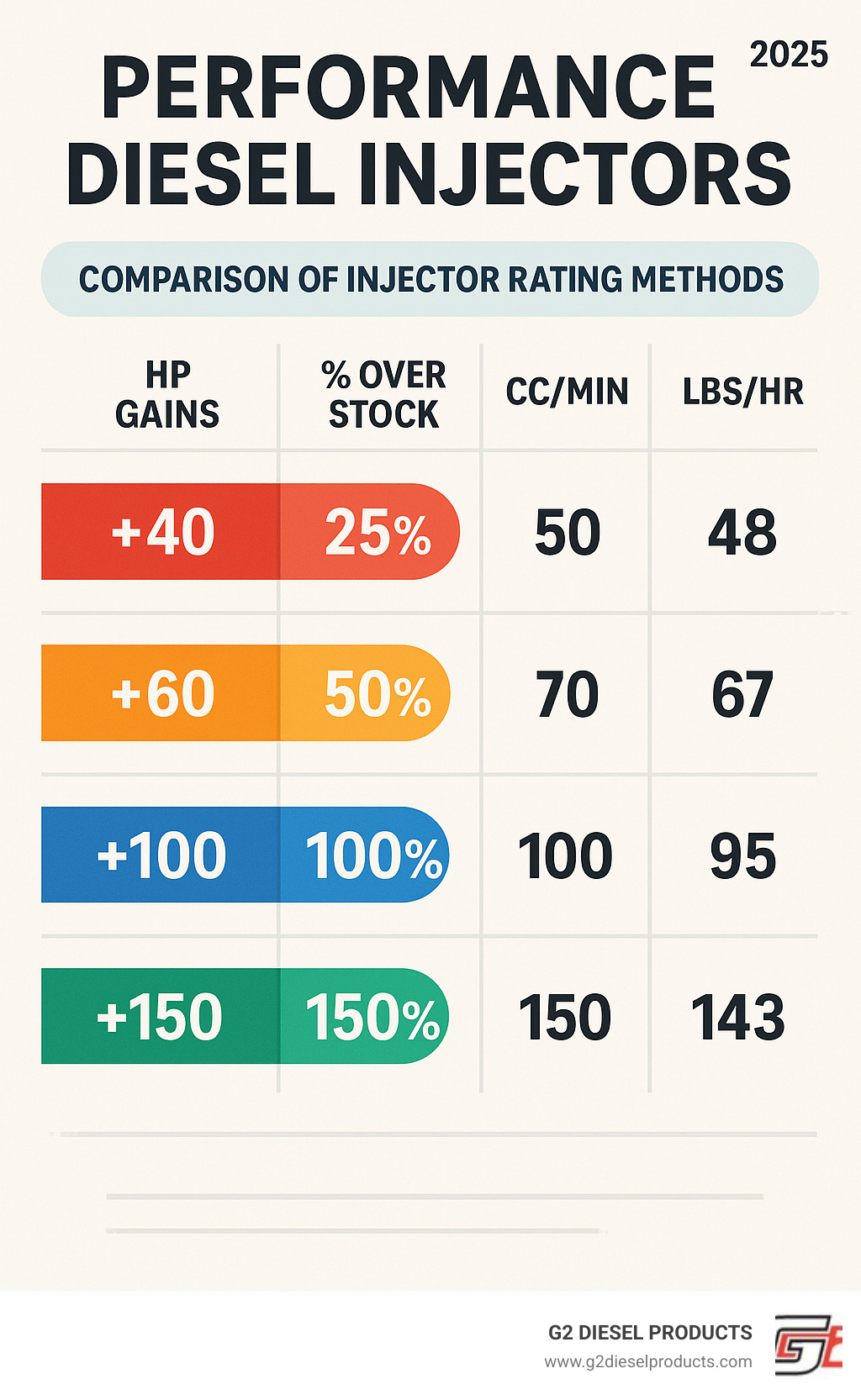

Injector sizing looks complicated at first, but three numbers tell the whole story:

- Horsepower rating – How much extra power the injectors can support with proper air and tuning.

- Percent over stock – A quick reference: +30 % flows 30 % more fuel than OEM.

- CC/MIN or LBS/HR – The exact volume or weight of fuel delivered at test pressure.

Why so many methods? Because each serves a different audience. A weekend tow-rig owner might focus on the horsepower line (“+60 HP sounds perfect”), while an engine builder matching turbos and pumps needs the raw CC figure.

A few practical guidelines keep choices simple:

- Mild street/towing: 20–40 % over stock, generally a drop-in with a conservative tune.

- Serious work/large loads: 50–100 % over stock plus upgraded lift pump and intercooler.

- Competition/race: 100 %+ over stock, bigger turbo(s), built transmission and aggressive ECU maps.

Research and dyno testing show that, when the whole package is matched, power gains of 25 % to 200 % are realistic—a testament to how much factory injectors leave on the table.

For deeper planning guidance, see our full list of diesel engine performance upgrades.

Choosing Your Upgrade: Services and Purchase Considerations

Selecting the right performance diesel injectors feels overwhelming at first, but it doesn't have to be. Think of it like choosing the right tool for the job - you need to match your injectors to your specific goals, budget, and how you actually use your truck.

The biggest mistake we see is truck owners jumping straight to the most aggressive injectors available. Those 300% over stock injectors sound impressive, but they're not the best choice for everyone. A driver who needs reliable daily performance will have very different needs than someone building a competition truck.

Professional guidance makes all the difference here. At G2 Diesel Products, we've helped thousands of truck owners steer these decisions. Our experience with Volvo, Mack, Kenworth, and Paccar engines means we understand exactly what works - and what doesn't - for each application.

Available Services for Your Injectors

Not every injector problem requires buying new parts. Sometimes your existing injectors just need some professional attention to get back to peak performance.

Injector repair often provides the most cost-effective solution. Our diesel injector repair kits can restore performance to worn injectors for a fraction of replacement cost. This approach works particularly well for fleet operators managing multiple vehicles where downtime costs money.

Remanufacturing takes things a step further. Professional diesel fuel injector rebuilders completely disassemble your injectors, replace worn components, and test everything to ensure proper operation. You get like-new performance at a much lower cost than brand new parts.

Professional cleaning addresses one of the most common injector problems - deposit buildup. Our diesel fuel injector cleaning service uses ultrasonic technology and specialized solvents to remove stubborn deposits that affect spray patterns and flow rates. Clean injectors perform better and last longer.

Exchange programs offer the best of both worlds - immediate availability and cost savings. You receive remanufactured injectors right away while returning your old units for credit. This minimizes downtime while keeping costs reasonable.

Bench testing and diagnostics can save you from expensive mistakes. Our diesel injector testing services reveal exactly what's wrong with your injectors before problems cause engine damage. Testing shows flow rates, spray patterns, and other critical parameters that determine injector health.

What to Consider When Buying Performance Diesel Injectors

Warranty coverage should be your first consideration. Performance injectors represent a significant investment, so comprehensive warranty protection is essential. Look for manufacturers who stand behind their products with coverage that includes both parts and labor.

Core return policies affect your total cost more than you might expect. Most performance injectors involve core charges - deposits that get refunded when you return your old injectors. A typical core charge might be $150 per set, refunded when usable cores are returned. Understanding these policies prevents surprise costs at checkout.

Intended use determines everything else about your injector choice. Be honest about how you'll actually use your truck. Street driving requires smooth, consistent performance across all operating conditions. Heavy towing demands reliable power delivery under sustained loads. Competition use prioritizes maximum power output over daily drivability.

Our commitment to quality ensures that every injector we provide meets the highest standards for performance and reliability, regardless of your intended application.

Regulatory and Usage Considerations

Race use only designations apply to some high-performance injectors. These parts require signed waivers acknowledging they're not intended for street use. This designation typically applies to injectors that significantly exceed stock flow rates and may not meet emissions standards.

Emissions compliance gets tricky with performance modifications. While many performance injectors actually improve combustion efficiency and reduce emissions, extreme modifications might not meet all regulatory requirements. The key is finding the right balance between performance and compliance.

State regulations vary significantly across the country. California has particularly strict rules about aftermarket modifications that affect emissions. Other states may have different requirements. Always check local regulations before making significant changes to your truck.

Off-highway use opens up additional options. Trucks used exclusively off-highway may have different regulatory requirements than over-the-road vehicles. This can provide access to more aggressive performance options not available for street use.

Legal responsibilities ultimately rest with you as the truck owner or fleet operator. You're responsible for ensuring your vehicles meet all applicable regulations, including emissions compliance, safety standards, and any industry-specific requirements. When in doubt, consult with professionals who understand both performance modifications and regulatory requirements.

Frequently Asked Questions about Performance Diesel Injectors

How much horsepower can I gain from performance injectors?

The horsepower gains from performance diesel injectors depend heavily on your specific setup and how far you're willing to push your engine. If you're looking for a modest boost that won't require major supporting modifications, you can expect gains in the 40-60 HP range. These smaller upgrades often work well with stock turbochargers and require minimal tuning adjustments.

For those wanting more aggressive power increases, the sky's almost the limit. Race-spec injectors paired with larger turbochargers and custom tuning can support gains of 250 HP or more. We've seen builds that achieve increases from 30% all the way up to over 200% compared to stock output. The key word here is "support" - the injectors enable these gains, but they need help from other components.

Think of it this way: injectors are like the fuel nozzle at a gas station. A bigger nozzle can flow more fuel, but you also need a bigger fuel pump, larger fuel lines, and a tank that can handle the increased flow. Similarly, your engine needs adequate air supply, proper exhaust flow, and most importantly, tuning that knows how to manage all that extra fuel.

A real-world example is our +40HP Performance Injector Kit for 1994-2000 GM 6.5L TD, which delivers exactly what it promises: +40 hp and +60 lb ft torque. These gains are achievable because the injectors are sized appropriately for the engine's other systems.

Do I need a custom tune after installing performance injectors?

Here's the honest answer: for anything beyond the smallest "drop-in" performance injectors (those 5-15hp gains), you absolutely need a custom ECU tune. Skipping this step is like buying a sports car and never taking it out of first gear - you're missing the whole point.

When you install larger injectors, they deliver more fuel per injection event than your engine's computer expects. Without proper tuning, this mismatch leads to poor performance, excessive smoke, dangerously high exhaust gas temperatures (EGTs), and potential engine damage. None of these are things you want to deal with, especially if you're running a commercial operation where downtime costs money.

Modern diesel engines are incredibly sophisticated. They rely on precise fuel delivery timing and quantity to meet emissions standards while delivering optimal performance. Your ECU has been programmed with specific parameters for stock injectors. When you change those injectors, the computer continues operating based on outdated information.

A proper tune optimizes timing and fuel maps to take full advantage of your injector upgrade. It's not just about adding more fuel everywhere - it's about adding the right amount of fuel at the right time under different operating conditions. This is why professional tuning is so important and why we always recommend working with experienced tuners who understand your specific engine platform.

What is a core charge and how does it work?

If you're new to the diesel performance world, core charges might seem confusing at first, but they're actually a pretty clever system that benefits everyone involved. A core charge is essentially a deposit you pay when purchasing remanufactured injectors. Think of it like the deposit you pay on a rental car - you get it back when you return the item in acceptable condition.

Here's how it works in practice: when you buy remanufactured performance diesel injectors, you'll pay the price of the injectors plus a core charge. This charge encourages you to return your old, used injectors (called "cores") to the supplier. Once we receive your usable cores, we refund the deposit. It's that simple.

Typical core charges range from $150 to several hundred dollars depending on the injector type and how many you're buying. The cores need to be complete and rebuildable to qualify for the full refund. If your old injectors are too damaged to remanufacture, you might receive a partial refund or no refund at all.

This system works because it allows manufacturers to rebuild and remanufacture injectors, making high-quality parts more affordable for everyone. Instead of every injector being built from scratch, we can take your old injector, replace the worn components, test it to like-new specifications, and offer it to the next customer at a lower price than a brand-new unit.

The environmental benefits are significant too. Rather than throwing away old injectors, we're reusing the major components and only replacing what's actually worn out. This reduces waste and keeps costs down while maintaining the same quality standards.

From a practical standpoint, core charges help keep quality remanufactured injectors accessible to more truck owners and fleet operators. Without this system, everyone would need to buy brand-new injectors, which would price many people out of performance upgrades entirely.

Conclusion

Performance diesel injectors represent one of the most transformative upgrades you can make to your diesel engine. Think of them as the gateway to your engine's true potential—whether you're hauling heavy loads across the country or pushing the limits on the track, the right injectors can completely change how your truck performs.

The benefits speak for themselves: increased horsepower and torque, improved fuel efficiency, reduced emissions, and improved reliability. It's not just about raw power—though gains from 25% to 200% over stock are certainly impressive. Modern manufacturing techniques like SAC style nozzles, extrude honing, and precision flow matching ensure these improvements are delivered consistently, mile after mile.

Choosing the right injector isn't just about picking the biggest numbers. It requires understanding your specific needs, considering your supporting modifications, and being honest about how you'll use your truck. The rating systems—from horsepower gains to flow rates measured in CC/MIN or LBS/HR—give you the information needed to make smart decisions. But remember, realizing those impressive gains requires proper supporting modifications and professional tuning.

For commercial truck owners running Volvo, Mack, Kenworth, and Paccar vehicles, you're in good hands with G2 Diesel Products. Our deep expertise in these specific platforms, combined with our commitment to innovation and quality, means you get injectors that deliver reliable performance improvements custom to your truck's unique characteristics.

The range of services available—from repair and remanufacturing to professional cleaning and exchange programs—ensures there's an option for every budget and timeline. Understanding warranty policies, core charges, and regulatory considerations helps protect your investment and ensures you get the returns you expect.

Whether you're a fleet operator managing dozens of trucks or an owner-operator who depends on maximum efficiency, the right performance diesel injectors can make a measurable difference in your bottom line. The technology has evolved to provide unprecedented precision and performance, making this an excellent time to consider upgrading your fuel injection system.

Your diesel engine has more potential than you might realize. With the right injectors, proper installation, and professional tuning, you can open up power and efficiency that transforms how your truck performs on the road.