Fueling Your Ford: A Deep Dive into Powerstroke Injectors

Why Ford Powerstroke Injectors Are Critical to Your Diesel's Performance

Ford Powerstroke injectors are the heart of your diesel fuel system, responsible for delivering precise amounts of fuel into the combustion chamber at the exact moment needed. Whether you're running a stock 7.3L workhorse or a modern 6.7L Scorpion engine, your injectors directly impact everything from fuel economy to towing power.

Quick Answer: What You Need to Know About Ford Powerstroke Injectors

Engine Compatibility: Different Powerstroke engines use different injector technologies (7.3L & 6.0L use HEUI, 6.4L & 6.7L use Common Rail)

Common Issues: Rough idle, hard starting, white/black smoke, poor fuel economy, loss of power

Stock Replacement Cost: Sets of 8 typically range from $800 to $1,600

Performance Upgrades: Available in various sizes (155cc to 205cc or 50% to 200% over stock)

When to Replace: Every 100,000 to 200,000+ miles depending on maintenance and fuel quality

Installation: Requires specialized tools and proper bleeding procedures; best done as complete sets

For diesel professionals, understanding injector technology isn't just about keeping trucks running—it's about minimizing costly downtime and maximizing the return on every gallon of fuel.

The injector's job sounds simple, but modern Powerstroke injectors fire multiple times per combustion cycle, adjusting spray patterns and timing thousands of times per minute. They operate under extreme pressure—up to 36,000 PSI in newer 6.7L engines—while maintaining tolerances measured in microns.

When injectors fail, the symptoms cascade quickly. A rough idle can deteriorate into misfires, fuel dilution in your oil, and eventually catastrophic engine damage. The 6.0L Powerstroke, for example, uses Hydraulic Electronic Unit Diesel Injectors (HEUI) that rely on high-pressure engine oil to actuate. When seals fail or contamination enters the system, the entire high-pressure oil circuit can be compromised.

This guide breaks down everything you need to know about Powerstroke injectors across all engine generations. We'll walk through the different technologies, help you diagnose failing injectors, explain how to choose the right replacement or upgrade, and outline the critical installation steps.

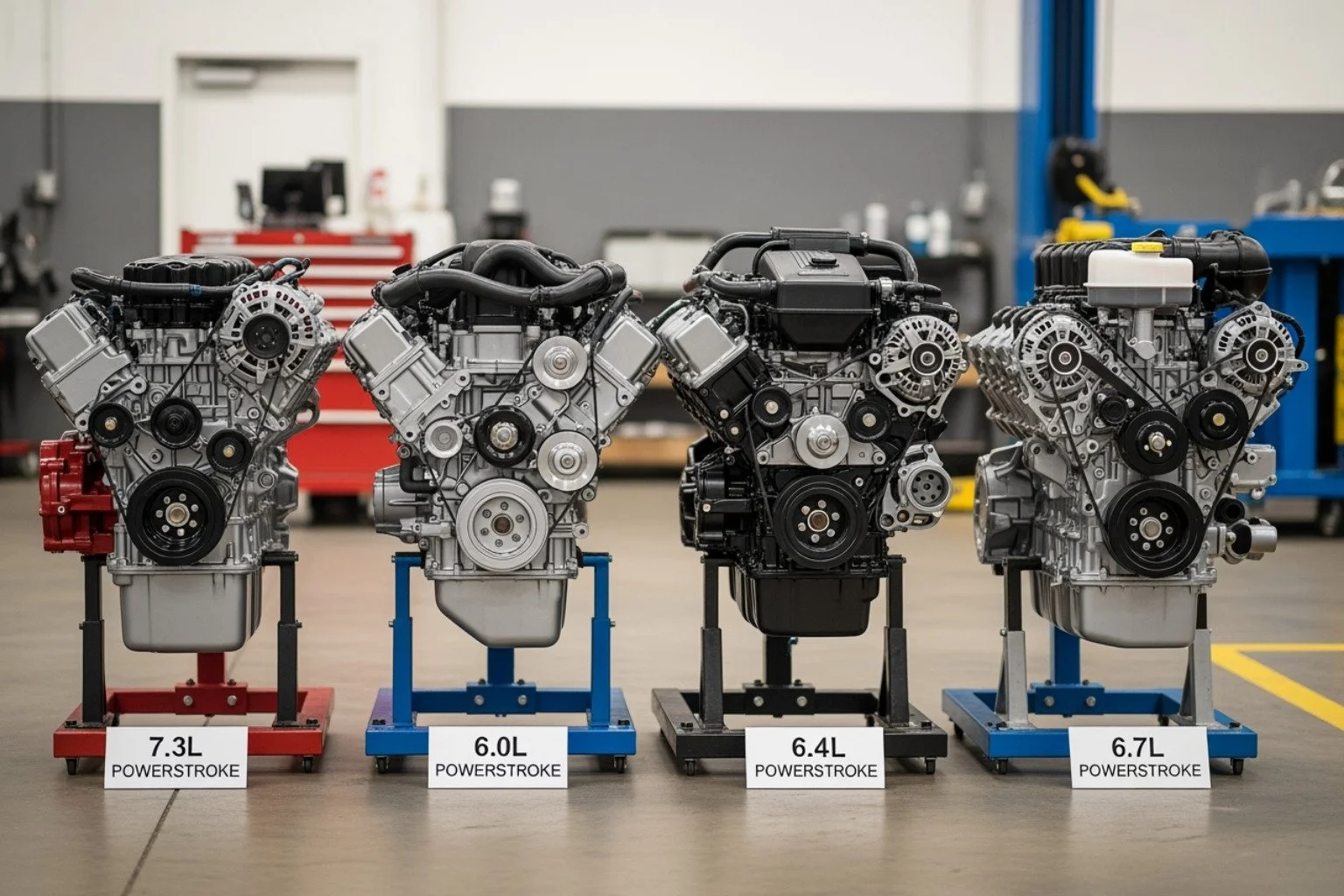

Understanding the Evolution: Powerstroke Injector Types by Engine

The Ford Powerstroke has evolved significantly since its debut, with each generation introducing new fuel injection technology. Understanding these differences is essential for anyone maintaining, repairing, or upgrading these engines.

Let's walk through the major Powerstroke generations and their unique injector technologies.

The Workhorse: 7.3L HEUI Injectors (1994.5-2003)

The legendary 7.3L Powerstroke used a Hydraulic Electronic Unit Injector (HEUI) Fuel System. This system was revolutionary, using high-pressure engine oil (up to 3,000 PSI) from a High-Pressure Oil Pump (HPOP) to actuate an intensifier piston inside the injector. This piston multiplies the fuel pressure by approximately 7:1, forcing diesel fuel through the nozzle at over 20,000 PSI. The 7.3L injectors are known as "split-shot" injectors, which inject a small pilot shot of fuel before the main injection event to quiet combustion noise and smooth out engine operation. Over its lifespan, the 7.3L used several injector codes (e.g., AA, AB, AD), each with slightly different flow rates to accommodate changes in emissions and power ratings. While these Ford Powerstroke injectors earned a reputation for toughness and longevity, they are not immune to failure. Common issues include worn O-rings leading to oil or fuel leaks, and solenoid failure causing misfires. Fortunately, they are highly rebuildable, and a quality Diesel Injector Repair Kit can be a cost-effective maintenance solution for a tired set.

The Notorious: 6.0L HEUI Injectors (2003-2007)

The 6.0L Powerstroke continued using HEUI technology but with a more refined and temperamental design. The Fuel Injection Control Module (FICM) sends a 48-volt signal to each injector's coil, which opens a spool valve, allowing high-pressure oil to force fuel into the cylinder. You can learn more about this in our guides on How Electronic Unit Injector Works and Electronic Unit Injectors.

These injectors are infamous for an issue called spool valve stiction. This occurs when engine oil breaks down from heat and contamination, forming a sticky varnish on the tight-tolerance spool valve. This varnish prevents the valve from opening and closing smoothly, especially during cold starts, leading to rough running, hard starting, and misfires. Another critical failure point is the FICM itself; if its voltage drops below 45 volts, it won't have enough power to properly actuate the injector solenoids. Clean, high-quality synthetic oil changed at regular intervals is absolutely critical for 6.0L injector longevity, as are frequent fuel filter changes to protect the sensitive fuel inlet screens from contamination.

The Transition: 6.4L Piezo Common Rail Injectors (2008-2010)

Ford abandoned HEUI for the 6.4L, adopting a high-pressure Common Rail Injectors system. This design uses a high-pressure fuel pump to pressurize a single fuel rail that feeds all injectors directly. The 6.4L introduced piezoelectric injectors, which use crystals that expand and contract with voltage for incredibly fast and precise fuel control—far faster than the solenoids used in HEUI systems. This technology, explained in our article What is a Common Rail Injector, allowed for multiple injection events per cycle, helping to meet stricter emissions standards alongside the new Diesel Particulate Filter (DPF). However, this system had a significant flaw. During the DPF's active regeneration cycle, the injectors perform a post-combustion injection to send raw fuel into the exhaust to burn off soot. This process can lead to fuel washing past the piston rings and severely diluting the engine oil. This fuel dilution not only wears out the injectors but can quickly destroy the entire engine. Furthermore, the injector bodies themselves were prone to cracking, leading to high-pressure fuel leaks.

The Modern Powerhouse: 6.7L Piezo Common Rail Injectors (2011-Present)

The current 6.7L "Scorpion" Powerstroke, designed and built in-house by Ford, uses the most advanced piezo common rail injectors to date. These Ford Powerstroke injectors can fire multiple times per combustion cycle (pilot, main, and post-injection), resulting in quieter operation, better fuel efficiency, and cleaner emissions. The technology is detailed in our guides on How do Common Rail Injectors Work and the Diesel Engine Common Rail system.

Ford has refined the 6.7L through several generations:

2011-2014: The first generation featured a Bosch CP4.2 high-pressure fuel pump, which became notorious for self-destructing and sending metal debris throughout the entire fuel system, destroying the injectors, rails, and lines—a repair often costing over $10,000.

2015-2019: Ford addressed some issues with a revised turbocharger and fuel system improvements. The injectors in these model years are highly sought after for performance builds, capable of supporting up to 575 rear-wheel horsepower with proper modifications. Even stock replacement injectors can add 50-70 RWHP while improving fuel economy.

2020-Present: The latest generation saw a major update, including a more robust high-pressure fuel pump (moving away from the problematic CP4.2) and new injectors designed for higher pressures and flow rates to support the increased horsepower and torque ratings of the modern Super Duty.

Is It Time for a Change? Symptoms of Failing Ford Powerstroke Injectors

A diesel engine with failing injectors sends clear signals. Ignoring them is a gamble that can lead to catastrophic engine damage and the kind of repair bills that make grown mechanics weep. Catching these problems early is key to protecting your investment.

Common Warning Signs: Decoding Your Engine's Distress Signals

When Ford Powerstroke injectors begin to fail, your truck will tell you. Be on the lookout for these specific symptoms:

Rough Idle: The engine shakes or vibrates erratically, especially when stopped in gear. It feels uneven, not like a normal diesel vibration.

Hard Starting: The engine cranks for an extended period before firing, or it may fail to start at all, especially on cold mornings. This is often a sign of low rail pressure from a leaking injector or, in a HEUI system, a high-pressure oil leak.

Excessive Smoke: Different colors of smoke mean different things. White smoke that smells like raw diesel, especially on startup, indicates unburnt fuel from a faulty injector. Black smoke under acceleration points to over-fueling, where an injector is delivering more fuel than the engine can burn efficiently.

Poor Performance: A noticeable loss of power, hesitation, and sluggishness, especially when towing or climbing a grade. This is often accompanied by a significant drop in poor fuel economy as the engine struggles to run efficiently.

Misfiring: The engine feels like it's skipping, stumbling, or bucking during acceleration as one or more cylinders fail to fire correctly.

Increased Engine Noise: A new, sharp, metallic knocking or ticking sound that changes with engine RPM can indicate an injector issue, sometimes called "injector knock."

One of the most critical symptoms is a fuel smell in your engine oil. This indicates an injector is likely stuck open or has a cracked body, washing fuel past the piston rings and diluting the oil's protective properties. This can quickly lead to bearing failure and catastrophic engine damage. Our guides on Common Rail Diesel Injector Failure Symptoms and general Diesel Injector Problems cover these issues in more detail.

Diagnostic Steps: From Symptoms to Solutions

Symptoms point to the problem, but confirming injector failure requires data-driven testing to avoid replacing expensive parts unnecessarily.

The Power of a Scan Tool: A professional-grade scan tool is your most powerful diagnostic weapon. It can run an automated power balance test (or cylinder contribution test), which shuts down one injector at a time to measure each cylinder's contribution to engine speed. A cylinder with a failing injector will show little to no RPM drop, pinpointing the culprit.

HEUI-Specific Diagnostics (7.3L & 6.0L): A bubble test is a simple yet effective way to check for compromised internal seals. By connecting a clear hose to the fuel return port on the cylinder head, you can look for air bubbles in the fuel. A steady stream of bubbles indicates combustion gasses are leaking past a bad injector seal into the fuel gallery.

Common Rail-Specific Diagnostics (6.4L & 6.7L): A return rate test is the definitive test for common rail injectors. This involves measuring the amount of fuel each injector leaks internally and sends back to the tank. Excessive return flow indicates a worn injector that is bleeding off rail pressure, causing hard starts and low power. You can learn more about this in our article on How to Check Common Rail Injectors.

Visual Inspection: While internal failures are more common, always check for external leaks. Look for wetness around the injector body where it enters the cylinder head or at the high-pressure line connections.

While some tests can be performed by a skilled DIYer, we strongly recommend working with a Diesel Injector Specialist. They have the specialized equipment, like high-pressure pop testers and flow benches, and the experience to provide a definitive diagnosis, ensuring you only replace what's necessary.

Choosing Your Upgrade: How to Select the Right Injectors

Selecting the right Ford Powerstroke injectors depends entirely on your goals. What works for a daily driver might be wrong for a competition truck. This guide will help you find the perfect injectors for your specific application.

Stock Replacement: Restoring Factory Performance

If your goal is to restore reliable, factory-level performance, stock replacement injectors are your answer. These are built to meet or exceed OEM specifications, bringing your Powerstroke back to its original performance. High-quality remanufactured injectors offer a cost-effective solution without sacrificing quality. They are rebuilt by expert Diesel Fuel Injector Rebuilders, with worn components replaced and each unit tested to strict standards. When looking for the Best Diesel Fuel Injectors for a stock application, prioritize reliability and adherence to OEM specs.

Towing & Daily Driving: Balancing Power and Reliability

For those who tow a fifth-wheel, haul equipment, or just want more confidence on the highway, slightly oversized injectors offer a great balance of performance and reliability. These injectors provide a modest increase in fuel flow, improving low-end torque and adding noticeable horsepower (e.g., 50-70 RWHP on a 6.7L) without sacrificing street manners. To get the most out of these injectors, a custom tune is essential to optimize fuel delivery. A quality lift pump is also recommended to ensure consistent fuel supply. Our Performance Diesel Injectors are designed for these balanced applications.

High-Performance Ford Powerstroke Injectors: Releasing Maximum Power

For competition trucks and drag strip builds, large CC (cubic centimeter) injectors are the starting point for serious power. Measured as a percentage over stock nozzle flow (50%, 100%, 200% over), they deliver significantly more fuel to enable massive power gains. However, these are not simple bolt-on parts. You will need a complete ecosystem of supporting modifications: a larger turbocharger, a full Fuel System Upgrade (lift pump, dual high-pressure pumps), transmission upgrades, and a mandatory custom tune to prevent catastrophic engine damage.

Comparing Injector Size (CC/% Over) vs. Application and Typical HP Gains

This table provides a general comparison to help you visualize your options:

Injector Size (CC/% Over) Primary Use Typical HP Gain (over stock) Required Supporting Mods Stock Stock Replacement 0 None 155cc (6.0L) / 20% Over Towing, Daily Driving 30-70 HP Custom Tuning 175cc (6.0L) / 50% Over Heavy Towing, Mild Performance 70-120 HP Custom Tuning, possibly upgraded turbo/fuel pump 190cc (6.0L) / 100% Over Performance, Racing 120-200+ HP Custom Tuning, Upgraded Turbo, Fuel System, Transmission 205cc (6.0L) / 150%+ Over Extreme Performance 200-300+ HP Custom Tuning, Large Turbo, High-Volume Fuel System, Built Transmission

Note: HP gains are estimates and vary based on engine, tuning, and other modifications.

Budgeting for Your Upgrade: Typical Costs and Core Charges

The Diesel Fuel Injector Cost varies by engine generation, performance level, and whether you choose new or remanufactured units. Expect to buy a complete set of eight. Many injector purchases involve a core charge—a deposit you pay upfront and get back when you return your old injectors. This recycling system helps keep costs down. Always review the Core Return Policy to understand the requirements for receiving your full deposit back.

The Installation Process: A Step-by-Step Overview

Proper installation is just as critical as the parts you choose. A botched installation can cause immediate failure, turning a repair into a recurring headache. Getting it right the first time ensures the longevity and performance of your new Ford Powerstroke injectors.

Essential Tools and Preparation

Before you begin, gather the right tools and prepare your workspace. Cleanliness is paramount, as even a tiny speck of dirt can destroy a new injector.

Specialized Tools: You'll need more than a standard wrench set. This includes a long shank T40 bit (for 6.0L), injector pullers, and a quality torque wrench.

Replacement Parts: Have new O-rings, seals, and any other necessary Fuel Injector Replacement Parts on hand.

Clean Workspace: Ensure your work area is as clean as possible to prevent contamination.

Our guide on How to Replace Diesel Injectors can help you prepare.

Critical Steps for a Successful Installation

While steps vary by engine, the core process is similar:

Safety First: Disconnect the batteries to prevent electrical shorts.

Access Components: Drain fuel/oil rails (HEUI systems) and remove valve covers to access the injectors.

Careful Removal: Use the correct puller to remove old injectors. On a 6.0L, be careful not to drop the hold-down clamp and ensure the tip's compression seal comes out.

Thorough Cleaning: Carefully clean the injector cups and bores in the cylinder head. Any remaining carbon or debris will prevent a proper seal.

Install New Seals: Use fresh O-rings and seals from a quality Diesel Injector Repair Kits. Lubricate them with clean engine oil to prevent tearing.

Proper Seating & Torque: Install the new injectors, ensuring correct orientation. Use a torque wrench to tighten hold-down bolts to the manufacturer's exact specification.

Reconnect: Securely connect the electrical pigtails until they "snap" into place.

Post-Installation: System Bleeding and Initial Run

This final stage is vital for injector health.

Priming and Purging: For common rail systems, cycle the key to let the lift pump prime the system. For HEUI systems (especially the 6.0L), you must purge air from the oil and fuel systems before starting to protect the injectors and IPR screen.

Initial Idle: Once started, let the engine idle to operating temperature while checking for leaks or unusual noises.

Test Drive: Take a gentle test drive, avoiding hard acceleration for the first few miles to allow everything to settle.

Warranty and Special Considerations for Ford Powerstroke Injectors

Understand the warranty before you buy. Quality injectors often come with a 2 or 3-year warranty. Also, be aware of regional regulations; some performance injectors may not be legal in California. Investing in Our Quality Diesel Fuel Injectors ensures you get components that meet rigorous standards for performance and durability.

Frequently Asked Questions about Ford Powerstroke Injectors

We've been working with Powerstroke owners for years, and certain questions come up repeatedly. Here are the answers you need to make smart decisions about your Ford Powerstroke injectors.

How long do Powerstroke injectors typically last?

It depends, but a typical lifespan is 100,000 to 200,000+ miles. The three biggest factors influencing longevity are:

Fuel Quality: Clean, high-quality diesel is essential. Contaminated fuel acts like sandpaper on precision internal components, causing premature wear.

Maintenance: Regular oil changes are critical, especially for 7.3L and 6.0L HEUI systems that use engine oil to actuate the injectors. Frequent fuel filter changes are also non-negotiable.

Driving Habits: Heavy towing and aggressive tuning place more stress on injectors, potentially shortening their life compared to light highway cruising.

Can I replace just one failed injector?

While technically possible, we strongly recommend against it. Replacing injectors as a complete, balanced set of eight is the best practice for several reasons:

Labor Cost: The job is labor-intensive. If one injector has failed, the others have endured the same conditions and are likely near the end of their life. Replacing one now often means repeating the entire job for another failed injector soon.

Performance Imbalance: A new injector will have a different flow rate than the remaining worn injectors. This imbalance can cause rough idling, uneven power delivery, and smoke. The engine's computer can struggle to compensate for mismatched cylinder contributions.

Quality suppliers sell injectors in flow-matched sets to ensure every cylinder performs identically, resulting in a smooth, reliable engine.

Do I need a custom tune when upgrading my injectors?

This is a critical question with a straightforward answer:

For Stock Replacements: No. If you are installing new or remanufactured injectors that match OEM specifications, your truck's factory computer is already programmed for them.

For ANY Size Upgrade: Yes, a custom tune is absolutely essential. Larger injectors deliver more fuel. Without a tune, the engine's computer doesn't know how to manage it. This can lead to excessive black smoke, high exhaust gas temperatures (EGTs), poor fuel economy, and even catastrophic engine damage like melted pistons.

A custom tune adjusts fueling parameters, injection timing, and boost pressure to safely and effectively use the additional fuel. It's not an optional accessory; it's a required part of the upgrade that protects your engine and open ups the performance potential of your new Ford Powerstroke injectors.

Conclusion

Your Ford Powerstroke injectors are the precision instruments that dictate your truck's performance, reliability, and efficiency. We've covered their evolution from the oil-driven Hydraulic Electronic Unit Injector (HEUI) Fuel System in the 7.3L and 6.0L to the advanced piezoelectric Common Rail Injectors in modern 6.4L and 6.7L engines.

Recognizing the warning signs of failure—like rough idle, hard starts, and excessive smoke—and performing proper diagnostics can save you from costly repairs. When it's time for a replacement, choosing the right injectors for your application is key. Whether you need a reliable stock replacement or a high-flow performance set, upgrades require supporting modifications and a custom tune to prevent engine damage.

Finally, proper installation with an emphasis on cleanliness, correct torque, and system bleeding is non-negotiable. At G2 Diesel Products, we understand that your truck is an investment. We specialize in manufacturing high-quality diesel fuel injectors that meet or exceed OEM standards, because we know reliability is paramount. Investing in quality Diesel Engine Parts is the smartest decision you can make to keep your Powerstroke running strong for years to come.