Injector Check-Up: Finding Reliable Fuel Injector Testing Near You

Why Professional Fuel Injector Testing Matters for Your Fleet

Fuel injector testing service is the only reliable way to verify that your engine's fuel delivery system is performing at peak efficiency. When your diesel trucks start showing signs of rough idling, poor fuel economy, or increased emissions, professional off-car testing can diagnose exactly which injectors need attention - saving you from costly guesswork and unnecessary downtime.

Key benefits of professional fuel injector testing:

Precise diagnosis - Flow testing reveals exact performance data for each injector

Cost savings - Identify which injectors can be cleaned vs. replaced

Performance restoration - Ultrasonic cleaning restores injectors to OEM specifications

Fuel economy improvement - Properly flowing injectors optimize combustion efficiency

Emissions compliance - Clean injectors reduce harmful exhaust emissions

Extended engine life - Prevent damage from uneven fuel delivery

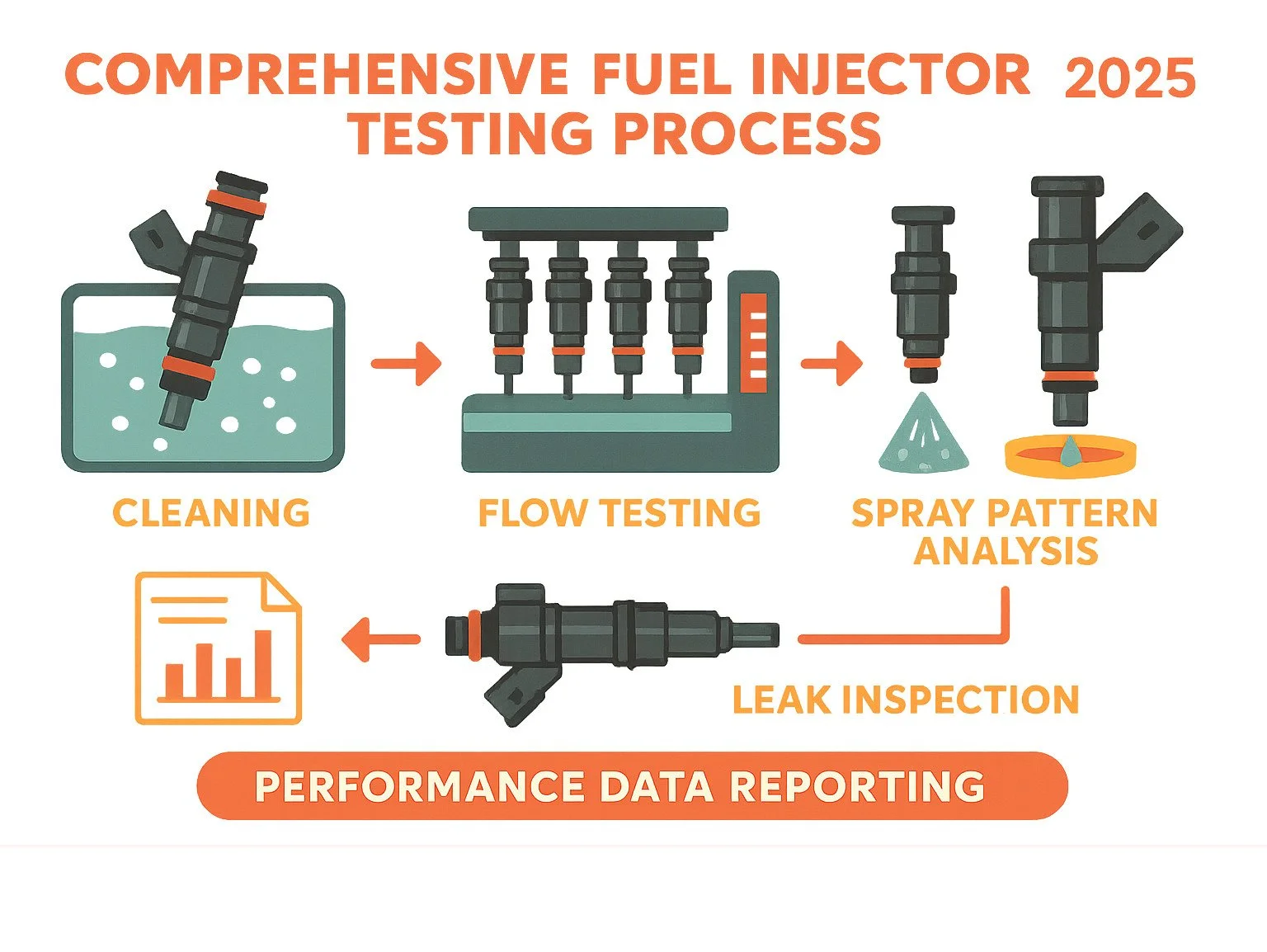

Professional testing involves removing injectors from your vehicle and testing them on specialized equipment. This off-car process includes ultrasonic cleaning, flow rate verification, spray pattern analysis, and leak testing. Most services provide detailed before-and-after data sheets showing exactly how each injector performs.

The testing process typically takes 1-3 business days, with costs varying based on injector type. Diesel injectors require more specialized equipment and testing procedures compared to gasoline injectors, but both benefit significantly from professional service.

As one industry expert noted: "Off-the-car injector cleaning and testing is the only way to verify that each injector is doing its job and allowing each cylinder to operate evenly for peak performance."

Why Your Engine's Performance Hinges on Healthy Injectors

Your diesel engine needs fuel delivered with precision, much like a chef uses exact ingredients. Fuel atomization is crucial—fuel must be a fine mist to mix perfectly with air. When injectors work properly, they create the ideal air-fuel ratio calculated by the Engine Control Unit (ECU) for maximum combustion efficiency. A single faulty injector can disrupt this balance.

Healthy injectors are key to reduced emissions and improved fuel economy, leading to smoother operation, better throttle response, and fewer trips to the pump. For diesel fleets, this precision is even more critical. The high-pressure systems in modern diesels demand injectors that maintain perfect spray patterns under extreme conditions. That's why professional diesel injector testing is so valuable—it provides the data you need for informed maintenance.

Telltale Signs Your Injectors Need a Check-Up

Your truck has a way of telling you when something's not right. The signs of failing injectors often start small but can escalate if ignored.

Rough idle is usually one of the first things you'll notice. Your engine might feel like it's stumbling or shaking more than usual. This happens when cylinders aren't getting consistent fuel.

Engine misfires take this problem to the next level. You'll feel a sudden jolt or hesitation, especially under load, which means the combustion process isn't completing properly.

When you're dealing with poor acceleration, your truck feels like it's holding back. Clogged or failing injectors can't deliver the fuel volume needed for strong performance.

Increased fuel consumption might sneak up on you. You'll notice fuel costs creeping upward as inefficient injectors force your engine to work harder for the same power.

A distinct fuel odor from the truck or exhaust is a red flag for incomplete combustion or a fuel leak, both of which are safety and performance issues.

Failed emissions tests are becoming more common as regulations tighten. Dirty or malfunctioning injectors directly contribute to higher pollutant levels, which will show up on emissions tests.

And of course, there's the check engine light. While this light can indicate many issues, persistent fuel system or misfire codes often point straight to injector problems.

The Hidden Costs of Neglecting Injector Maintenance

Here's where things get expensive fast. What starts as a minor performance issue can snowball into major repair bills if you don't address injector problems promptly.

Catastrophic engine damage is the most significant risk. When injectors deliver fuel unevenly, some cylinders run too lean (not enough fuel) or too rich (too much fuel). A lean condition creates extreme heat, which can melt pistons, warp cylinder heads, and burn valves. A rich condition, on the other hand, can wash lubricating oil off the cylinder walls, leading to accelerated wear on piston rings and liners. In severe cases, a leaking injector can cause hydrolock—where liquid fuel fills the cylinder—which can bend connecting rods or crack the engine block. These scenarios don't just require a simple fix; they often necessitate a complete and costly engine overhaul.

Your catalytic converter and oxygen sensors are also at risk. These emissions components are at risk from unburned fuel and irregular exhaust from failing injectors. Replacing a catalytic converter can cost thousands.

The cost of new injectors becomes unavoidable if injectors are damaged beyond repair. While professional fuel injector testing service and cleaning can often restore injectors, waiting too long eliminates that option.

For commercial operators, downtime might be the most painful cost of all. Every day your truck is in the shop is lost revenue. Preventive maintenance is far smarter than dealing with emergency breakdowns.

If testing reveals that some injectors can't be saved, it's helpful to understand your options for replacement parts before you're facing an urgent situation.

The Anatomy of a Professional Fuel Injector Testing Service

When your truck shows signs of trouble, you need answers, not guesswork. Off-car service provides a complete physical for each injector in a specialized lab. The process starts with ultrasonic cleaning, where microscopic bubbles scrub away internal carbon and varnish that fuel additives can't touch. After cleaning, each injector is put on a precision test bench.

Flow testing measures fuel delivery under various conditions, while spray pattern analysis looks for a fine, clean-burning mist instead of fuel-wasting dribbles. The service also includes leak testing to ensure a tight seal and a coil resistance test to check electrical response. Unlike just using additives, this professional service provides a detailed before-and-after data sheet with hard numbers on performance. This data is invaluable for maintenance planning. You can see the testing process to get a better feel for what happens.

Key Tests Performed on the Bench

A comprehensive fuel injector testing service puts each injector through a series of precise evaluations.

The leak inspection comes first because if an injector can't hold pressure when closed, other tests are pointless. It checks for internal and external leaks under realistic pressure. A leaking injector wastes fuel and throws off engine timing.

Ohm testing checks the coil's integrity by measuring electrical resistance. Every injector has specific values it must meet; if they're off, the injector won't open and close correctly.

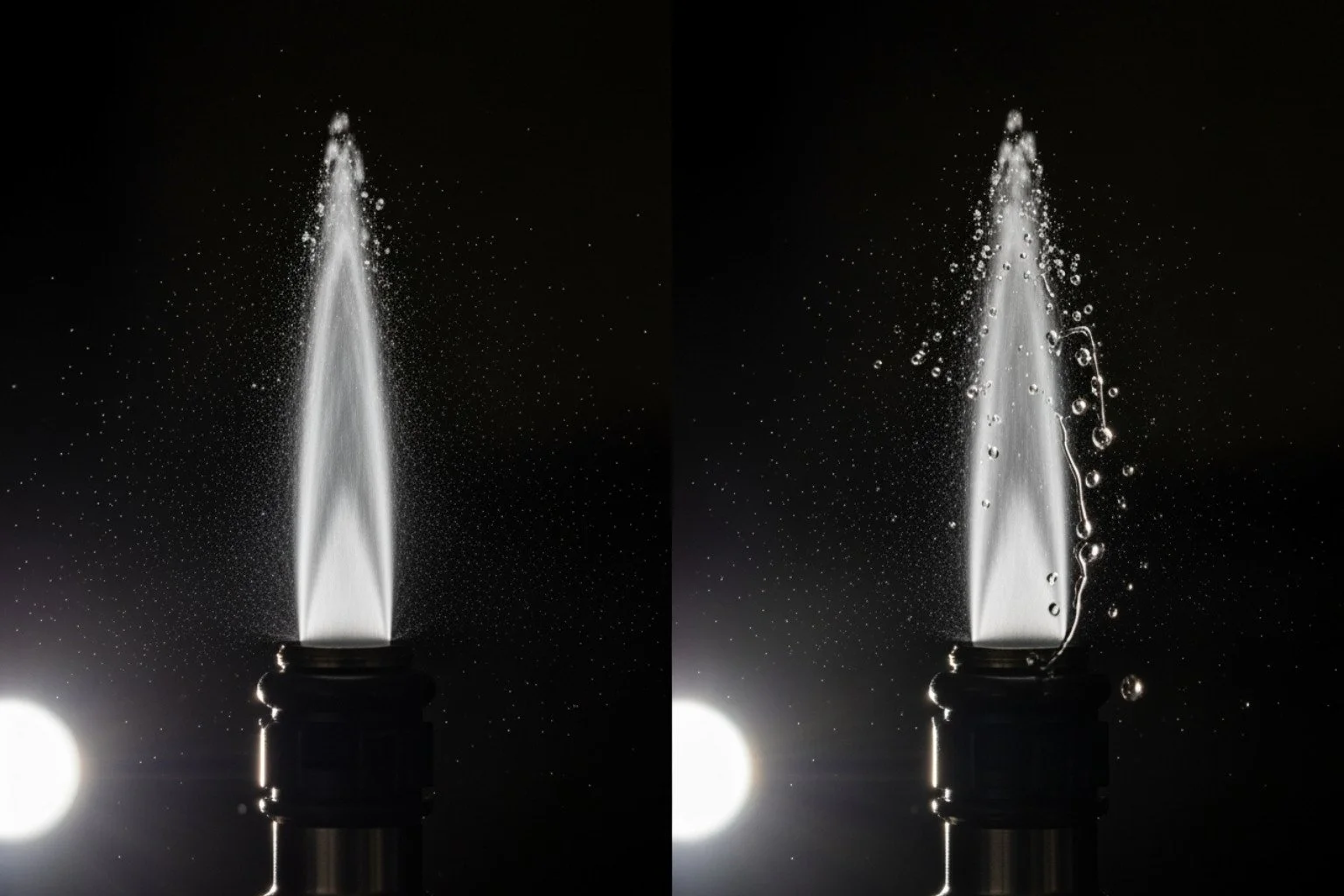

The spray pattern verification is where you can visually see problems. A healthy injector creates a symmetrical cone of finely atomized fuel. Failing injectors might show streams, lopsided patterns, or drips.

Static flow rate testing measures maximum fuel delivery with the injector held wide open. It tells us about overall capacity and if the injector can deliver the volume needed under full load.

The dynamic pulse flow rate test simulates real driving conditions, as injectors pulse on and off rapidly. This test reveals how consistently each injector performs across different pulse widths, just as the engine demands.

Finally, flow matching ensures all injectors in a set deliver similar amounts of fuel. Mismatched flow rates create uneven power delivery. Professional services aim to get all injectors within tight tolerances.

[TABLE] Comparing Off-Car Bench Testing vs. In-Car Diagnostics

Understanding the difference between professional bench testing and typical shop diagnostics helps explain why a fuel injector testing service delivers such different results:

Feature Off-Car Testing (G2 Diesel Products) In-Car Diagnostics Accuracy High (verifies flow/pattern for each injector individually) Moderate (identifies misfires, general cylinder data) Cleaning Deep ultrasonic cleaning of internal components None (at best, fuel additives offer minimal effect) Diagnostics Precise data for each injector's performance (flow, pattern, leaks, electrical) General cylinder data (e.g., which cylinder is misfiring, sensor readings) Cost Moderate per injector for specialized service Varies (shop labor for scanning, potential part replacement without confirmation) Effectiveness Restores to OEM spec, identifies irreparable issues Identifies problem area only, often leads to guesswork replacement

The biggest difference is that in-car diagnostics can tell you something is wrong and roughly where the problem might be. Professional bench testing tells you exactly what's wrong with each individual injector and whether it can be fixed or needs replacement.

In-car scanning might show you that cylinder #3 is misfiring, but it can't tell you if the injector is clogged, leaking, has a bad spray pattern, or is electrically faulty. Professional testing answers all these questions with hard data, eliminating the guesswork that often leads to unnecessary parts replacement.

Note: G2 Diesel Products specializes in professional off-car injector testing and cleaning. Fuel additives are not a substitute for professional service and are not offered or recommended by G2 Diesel Products.

Not All Injectors Are Created Equal: Gasoline vs. Diesel Testing

Gasoline and diesel injectors are engineered for different jobs, and understanding these differences is crucial when seeking a fuel injector testing service. Gasoline engines use two main injector types: Gasoline Port Injection (PFI), which sprays fuel into the intake manifold at modest pressures, and the newer Gasoline Direct Injection (GDI), which injects fuel directly into the combustion chamber at much higher pressures.

Diesel engines, especially in heavy-duty trucks, are in another league. They use Mechanical Diesel Injectors, modern Common Rail Diesel Injectors operating at pressures over 30,000 PSI, or Electronic Unit Injectors (EUI). These differences mean a testing service can't use a one-size-fits-all approach; the equipment and expertise vary dramatically. For diesel fleet managers, understanding diesel testing equipment can save time and money.

What to Expect from a Gasoline Fuel Injector Testing Service

When you bring gasoline injectors in for professional testing, you're entering a well-established process that's been refined over decades. The service handles both top-feed injectors and side-feed injectors with expertise. The process begins with comprehensive baseline testing, followed by ultrasonic cleaning to remove internal carbon and varnish. A quality service also replaces critical wear components. Filter basket replacement ensures unrestricted fuel flow, while new O-ring replacement prevents leaks. Many services also include pintle cap replacement to help shape the spray pattern. Because gasoline injectors operate at lower pressures with simpler mechanisms, the simpler process is often faster and more affordable. Most gasoline injectors respond very well to professional cleaning.

The Specialized Demands of a Diesel Fuel Injector Testing Service

Heavy-duty diesel injectors require specialized expertise due to extreme pressures and higher stakes. High-pressure testing is essential for common rail systems operating over 30,000 PSI, and the equipment must replicate these conditions. You can't test a common rail injector on equipment designed for gasoline systems.

The opening pressure test, or "pop-testing," verifies that mechanical diesel injectors open at the correct pressure to prevent poor atomization. Return flow measurement is critical for common rail systems, as excessive return flow often indicates internal wear. Nozzle condition assessment requires a trained eye to spot microscopic wear that can distort spray patterns.

All this complexity demands specialized test benches—sophisticated computerized systems that can simulate various engine conditions to provide a comprehensive performance profile. For fleet managers, understanding how to check common rail injectors is vital for preventing catastrophic engine failure. There's no room for compromise in your fuel injector testing service.

The Logistics of Service: Cost, Turnaround, and Shipping

Understanding the logistics of a professional fuel injector testing service makes the process smoother. The service cost per injector is almost always significantly less than buying new ones, with the price depending on injector type and parts needed. Many services offer free return shipping for multiple injectors, so it's worth asking about their policies.

Turnaround time is typically fast, often 1-3 days from receipt, as providers understand the cost of downtime. The process starts with a service form detailing your vehicle and symptoms. Proper packaging instructions are crucial to prevent shipping damage. Finally, be aware of the unclaimed items policy and stay in communication.

Preparing Your Injectors for Service

Getting your injectors ready for service is straightforward but important for a smooth process.

Remove from fuel rail: Carefully detach each injector. Shipping them on the rail is bulky and risks damage.

Clean exterior: Wipe off heavy grease and grime. This helps technicians work more efficiently.

Drain all fuel: This is a safety and shipping requirement. Let injectors air dry to prevent spills.

Package securely: Place each injector in a sealed plastic bag. Pack them snugly in a sturdy, cushioned box to prevent damage.

Include service form: This document tells technicians about your vehicle and the problems you're experiencing. You can download an example service form to see what's required.

Understanding Costs and Timelines

Let's talk about the investment. Gasoline injectors generally cost less to service due to their simpler designs. Diesel injectors, especially common rail systems, require more sophisticated testing, making the service more intensive but still far cheaper than buying new.

The standard turnaround is an efficient 1-3 business days. Expedited service may be available for a fee. Return shipping options are typically flexible, with many providers offering trackable methods. Core charges mainly apply to exchange programs, common for diesel applications, where you get a refurbished injector immediately and send yours back.

A key benefit is the transparent before-and-after data you receive, proving the service's value. For more insights, check out our guide on diesel injector cleaning.

Frequently Asked Questions about Fuel Injector Testing

When it comes to fuel injector testing service, we get plenty of questions from truck owners and fleet managers who want to understand exactly what they're investing in. Let's tackle the most common concerns.

Can all fuel injectors be tested and cleaned?

Most gasoline injectors from cars, marine engines, and powersports vehicles can be professionally tested and cleaned. Specialized diesel services, like those at G2 Diesel Products, can handle modern common rail, mechanical, and electronic unit injectors. However, there are some exclusions. Certain older or highly specialized types, like some GDI (Gasoline Direct Injection) and CIS (Continuous Injection System) injectors, can be difficult to service. Due to service provider limitations, it's crucial to ask first. A quick call to confirm they can service your specific injector type will save time and frustration.

How often should I have my fuel injectors tested?

There's no set interval for injector testing. We recommend a symptom-based service approach. Your engine will tell you when it needs attention through warning signs like rough idling or poor fuel economy. Other good times for testing include:

Performance tuning: To ensure proper fueling for modified engines.

High-mileage maintenance: Proactive testing can prevent breakdowns, especially for commercial vehicles.

After an engine rebuild: To ensure the new engine's fuel delivery system is perfect.

What happens if an injector fails the tests?

If an injector cannot be restored, a professional service will provide data sheet confirmation explaining the failure. Reputable services often won't charge for an injector they can't fix. You will then receive a replacement recommendation. Sourcing quality replacements is crucial, especially for diesel trucks where reliability is key. At G2 Diesel Products, we manufacture high-quality diesel fuel injectors for Volvo, Mack, Kenworth, and Paccar trucks. When replacement is necessary, we provide components you can trust. For help selecting the right parts, see our guide on how to Find the best diesel injectors.

Conclusion: The Smart Path to Restored Power and Efficiency

When you step back, it's clear that fuel injector testing service is a smart investment in your vehicle's health. This proactive maintenance is a cost-effective solution that saves you from expensive emergency repairs. Professional off-car testing provides precise data, eliminating guesswork and leading to genuine performance restoration. You'll notice a smoother engine, stronger pulling power, and real fuel savings, along with significant environmental benefits.

Sometimes, an injector cannot be restored. So, what to do if injectors fail? This is where G2 Diesel Products excels. We manufacture high-quality replacements for Volvo, Mack, Kenworth, and Paccar trucks. We understand your livelihood depends on reliability, so we lead the industry in innovation, offering quick lead times and customer-specific packaging.

Don't settle for subpar parts that might leave you stranded. Shop for high-performance diesel fuel injectors that are built to exceed expectations and keep your fleet running strong.