Inject Your Ride with Power: A Buyer's Guide to Fuel Injectors

Why Diesel Fuel Injectors Are Critical for Fleet Performance

When you buy diesel injectors, you are making a direct investment in the heart of your engine's fuel delivery system and, by extension, the profitability of your entire operation. These are not just simple parts; they are high-precision components that govern every single drop of fuel entering the combustion chamber. Their performance directly dictates your engine's power output, fuel efficiency, and long-term reliability. For a fleet manager, the health of their injectors translates directly to the bottom line. A failing injector can increase fuel consumption by 10% or more, a staggering cost when multiplied across a fleet of trucks covering thousands of miles. With leading suppliers selling over 175,000 injectors annually and maintaining customer satisfaction rates above 96%, it's evident that savvy fleet managers prioritize quality and reliability above all else.

To make an informed purchase, consider this essential checklist:

Engine Compatibility: This is the absolute first step. You must match the injector to your truck's exact make, model, year, and engine size (e.g., Volvo D13, Mack MP8, Cummins ISX). An incorrect injector won't just fail to work; it can cause severe engine damage.

New vs. Remanufactured: This is a crucial decision balancing cost and assurance. New injectors offer the latest technology and the longest warranties, while high-quality remanufactured units provide OEM-level performance at a more accessible price point.

Core Charges: If you opt for remanufactured injectors, you must budget for the refundable core deposit. This is a standard industry practice that ensures a steady supply of rebuildable cores, keeping costs down for everyone.

Supplier Reputation: Don't purchase from just anywhere. Look for established suppliers with verifiable customer reviews (aim for 4.9+ star ratings), deep technical knowledge, and accessible support staff.

Warranty Coverage: A strong warranty is a sign of a quality product. Seek a minimum of one year of protection with unlimited mileage, and be sure to understand the terms regarding parts and labor.

Part Number Verification: The most reliable way to ensure you get the right part is to verify the OEM part number, which is often stamped on the body of your old injector or can be found in your service manual.

Modern diesel engines in trucks from manufacturers like Volvo, Mack, Kenworth, and Paccar operate under immense stress. Their injectors must atomize fuel at pressures exceeding 30,000 PSI with microsecond precision. Whether your engine requires older mechanical injectors, Electronic Unit Injectors (EUI), or the latest Common Rail systems, selecting the correct, high-quality component is the key to optimizing combustion, minimizing harmful emissions, and maximizing your truck's uptime on the road.

The Heart of Your Diesel Engine: Understanding Fuel Injectors

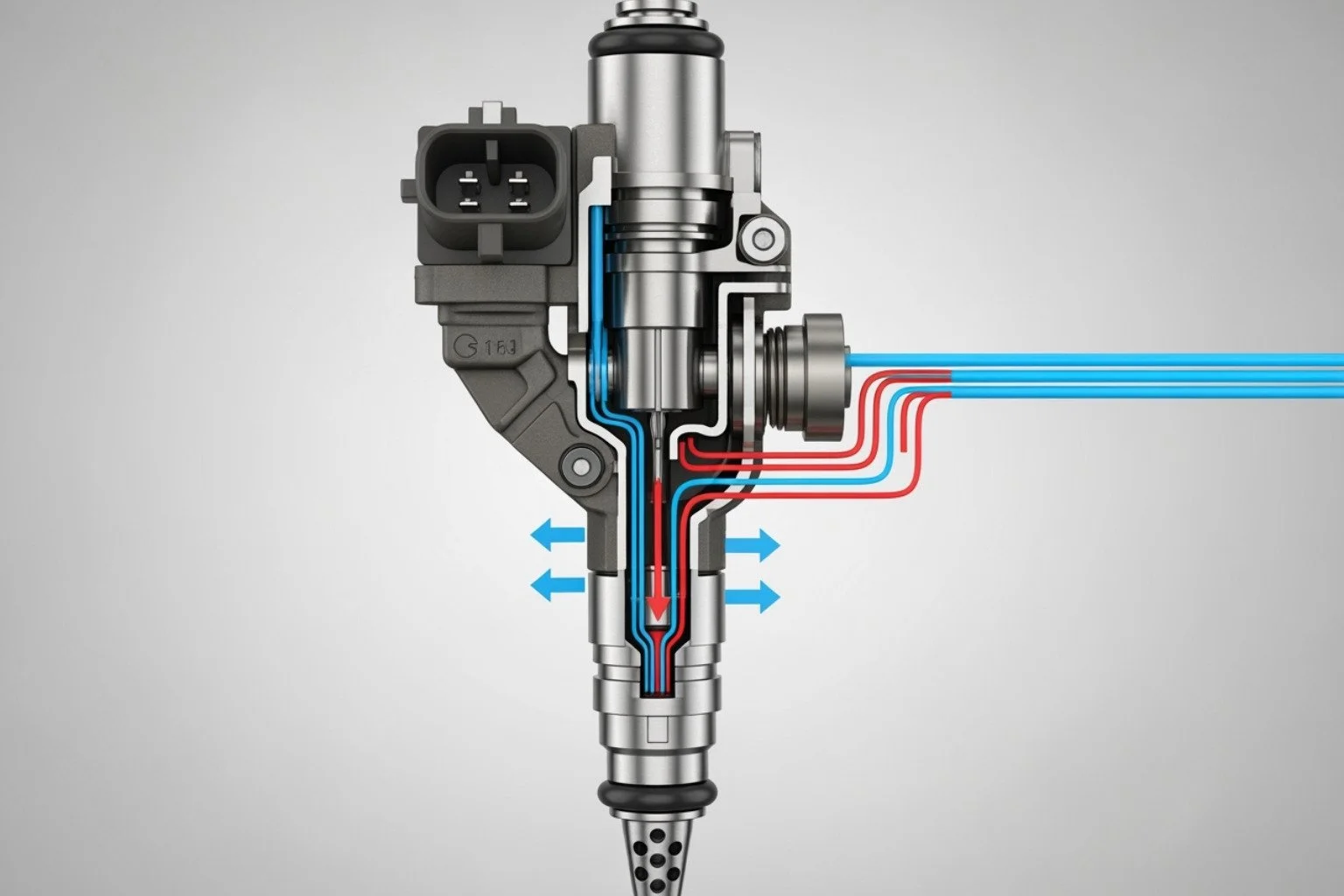

A diesel fuel injector is a marvel of electromechanical engineering, acting as the final, critical gatekeeper between your fuel system and the engine's combustion chamber. It functions in an environment of incredible hostility, withstanding pressures that can exceed 30,000 PSI (over 2,000 bar) and searing temperatures, all while opening and closing thousands of times per minute. Its primary function is fuel atomization—the process of converting liquid diesel into an ultra-fine, cone-shaped mist. This is crucial because liquid fuel burns poorly; only by atomizing it into microscopic droplets can you maximize the surface area exposed to the compressed, heated air in the cylinder, enabling a rapid, complete, and powerful combustion event.

This entire sequence is masterfully orchestrated by the Engine Control Unit (ECU). The ECU acts as the engine's brain, constantly analyzing data from dozens of sensors—monitoring engine speed, load, coolant temperature, and air pressure—to calculate the precise timing and duration of each injection event, down to the microsecond. This precision is the cornerstone of modern diesel performance, directly influencing fuel economy, horsepower, torque, and emissions. Advanced common rail systems take this a step further, capable of performing multiple distinct injections within a single combustion cycle. These can include a small pilot injection to quiet combustion noise, the main injection for power, and a post injection to help regenerate the diesel particulate filter (DPF). For a deeper dive, see How Injectors Work and learn more about Diesel Engine Common Rail systems.

Key Components and Materials

To survive its harsh operating environment, every injector is constructed from incredibly durable materials like hardened stainless steel and specialized high-strength alloys. Understanding its key components is vital when you buy diesel injectors.

Nozzle: The business end of the injector, featuring microscopic holes (typically 5 to 8) precision-drilled to create a specific spray pattern custom to the engine's combustion chamber design.

Needle Valve: A tiny, fast-acting valve housed within the nozzle. It seals against a seat to stop fuel flow and lifts to allow injection. Wear on this component, measured in microns, can cause leaks and poor performance.

Solenoid or Piezo Actuator: This is the 'switch' that activates the injector. A solenoid is an electromagnet that lifts the needle valve when energized by the ECU. A Piezo actuator uses stacks of ceramic crystals that expand instantly when voltage is applied. Piezo actuators are up to five times faster, allowing for more precise control and multiple injection events.

Injector Body: The robust outer casing that houses all internal components, provides passages for fuel flow, and mounts the injector securely to the engine's cylinder head.

Plunger and Barrel: Found in EUI systems, this assembly is driven by the camshaft to generate the high fuel pressure within the injector itself.

High-Pressure Seals: A combination of copper washers and specialized O-rings that are absolutely critical for sealing the injector in the cylinder head, preventing combustion gases from escaping and fuel or oil from leaking.

Decoding the Tech: Types of Diesel Fuel Injectors

When you set out to buy diesel injectors, you'll find that the technology has evolved significantly over the years. The type you need is dictated entirely by your engine's design. The three primary categories are Mechanical Injectors, Electronic Unit Injectors (EUI), and Common Rail Injectors, with the latter two often distinguished by their use of Piezo versus Solenoid technology.

Mechanical Injectors

The original workhorse of the diesel world, mechanical injectors are the simplest in design and are typically found in older diesel engines from the 1990s and earlier. They operate on a purely hydraulic principle. A separate injection pump generates pressure, and when that pressure, acting on the injector, becomes strong enough to overcome the force of a calibrated internal spring, the needle valve pops open and fuel is sprayed.

Pros: They are incredibly durable, relatively inexpensive, and simple to understand.

Cons: They lack the fine control of electronic systems. Injection timing and pressure are largely fixed, leading to less efficient combustion, higher emissions, and more engine noise.

Electronic Unit Injectors (EUI)

EUIs represented a major technological leap forward and were a mainstay in engines from the mid-1990s through the mid-2000s, such as the Detroit Diesel Series 60 and early Volvo/Mack powerplants. An EUI is a self-contained unit that functions as both a high-pressure pump and an injector. Driven by a dedicated lobe on the engine's camshaft, a plunger inside the EUI pressurizes the fuel. The ECU then sends an electrical signal to a solenoid on the injector, controlling precisely when and for how long the fuel is injected. This design eliminates the need for high-pressure fuel lines and allows for much greater control over fueling compared to mechanical systems. You can learn more about How Electronic Unit Injector Works. For specific applications, consider VCE Electronic Unit Injectors.

Common Rail Injectors

The current gold standard in diesel technology, Common Rail Injectors are used in virtually all modern diesel engines found in Volvo, Mack, Kenworth, Paccar, and other heavy-duty trucks. In this system, a belt- or gear-driven high-pressure pump pressurizes fuel and delivers it to a single, shared tube—the "common rail"—which acts as a pressure accumulator. This rail maintains a constant, extremely high pressure (often 25,000-35,000 PSI) that is available to all injectors at all times. Each injector is an electrically-actuated valve (either solenoid or piezo) that the ECU can open and close with incredible speed and precision. The key advantage is that injection pressure is completely independent of engine speed. This allows for high atomization pressure even at low RPMs, resulting in better torque, quieter operation, significantly improved emissions, and superior fuel economy. For a detailed explanation, see How Do Common Rail Injectors Work. When replacing them, VCE Common Rail Fuel Injectors are a reliable choice.

Is It Time for a Change? Signs of Failing Diesel Injectors

Recognizing the early warning signs of a failing diesel injector is crucial for any truck owner or fleet manager. Ignoring these symptoms can lead to cascading failures, including catastrophic engine damage, expensive after-treatment system repairs, and significant, costly downtime. When an injector's internal components wear or become clogged, it can no longer deliver the right amount of fuel at the right time, triggering a variety of performance issues. The most common warning signs include a noticeable engine misfire, a rough or vibrating idle, a sudden drop in poor fuel economy, an illuminated check engine light, and hard starting, particularly in cold weather. A persistent raw fuel smell in or around the engine bay is a critical warning sign of an external leak, which poses a serious fire risk.

For a full breakdown, see Fuel Injector Problems Diesel. If you're dealing with excessive noise, Diesel Injector Noise Reduction may offer solutions.

Performance-Related Symptoms

Loss of Power and Hesitation: If the engine feels sluggish, struggles to pull grades, or stutters during acceleration, it's often due to one or more cylinders not receiving the correct fuel charge.

Decreased Mileage: This is a direct hit to your wallet. Poor fuel atomization from a worn nozzle or incorrect injection timing means you're burning more fuel to produce the same amount of power.

Failed Emissions Test: Incomplete combustion dramatically increases harmful pollutants like particulate matter (soot). This not only harms the environment but can also lead to failed inspections, fines, and costly repairs to your DPF and SCR systems, which are not designed to handle raw fuel or excessive soot. Compliance with regulations from bodies like the Environmental Protection Agency (EPA) is mandatory.

Audible and Visual Clues

Engine Knocking: A sharp, metallic tapping or knocking sound can be caused by an injector that is firing at the wrong time (over-advanced timing) or is stuck open, a condition known as "fuel knock."

Excessive Smoke: The color of the smoke from the exhaust is a key diagnostic clue. White smoke (especially at startup) indicates unburned, vaporized fuel from a misfiring cylinder or leaking injector. Black smoke signals over-fueling from an injector with a worn nozzle or one that's stuck open. Blue smoke suggests the engine is burning oil, which can happen if an injector's O-ring seals have failed.

Visible Fuel Leaks: Any sign of wetness or diesel fuel pooling around the injector body, fuel lines, or where the injector enters the cylinder head requires immediate attention.

Professional Diagnostic Tests

While the symptoms above are strong indicators, a professional technician can confirm the issue with specific tests:

Cylinder Cutout Test: Using diagnostic software, a technician can deactivate one injector at a time. If disabling a cylinder causes no change in the engine's idle, that cylinder's injector is the likely culprit.

Injector Return Flow Test: This test measures the amount of fuel that bypasses the injector internally and returns to the tank. Excessive return flow is a definitive sign of internal wear.

Scan for DTCs: A check engine light will be accompanied by Diagnostic Trouble Codes (DTCs). Codes like P0201-P0212 (Injector Circuit Malfunction) or P0299 (Turbo Underboost, which can be caused by poor combustion) can point directly to the problem.

For Mack owners, some issues may be more common. Reviewing Mack Truck Injector Problems can help with diagnosis.

Your Complete Guide to Choose and Buy Diesel Injectors

When the time comes to buy diesel injectors, making a well-informed choice is paramount to restoring your truck's performance and ensuring its long-term reliability. The process involves more than just finding the cheapest part; it requires careful consideration of new versus remanufactured units, stock versus performance models, and a clear understanding of warranties and core policies. Finding the Best Diesel Fuel Injectors is about finding the optimal balance between your budget, your performance requirements, and your engine's specific needs.

Key Factors Before You Buy

Engine Compatibility: This cannot be overstated. You must know your truck's make, model, year, and specific engine (e.g., Cummins ISX15, Paccar MX-13). For many engines, you may also need the Engine Serial Number (ESN) or CPL (Critical Parts List for Cummins) to identify the exact injector build. Different builds can have unique spray patterns or flow rates, and installing the wrong one can lead to poor performance or even piston damage.

OEM Part Numbers: This is the most foolproof method for a perfect match. The original equipment manufacturer (OEM) part number is usually stamped or etched directly onto the injector body. Cross-reference this number with the supplier to guarantee compatibility.

Stock vs. Performance Needs: For most fleet and commercial applications, a stock replacement that restores factory performance is the right choice. However, some owners may opt for Performance Diesel Injectors, which are modified to flow more fuel for increased horsepower and torque. Be aware that performance injectors often require supporting modifications like a larger turbocharger, custom ECU tuning, and an upgraded fuel system, and may impact emissions compliance.

Budget and Value: While upfront cost is a factor, the true value lies in longevity and performance. Understand the factors that influence Diesel Fuel Injector Cost and view the purchase as an investment in uptime and fuel efficiency, not just an expense.

New vs. Remanufactured: A Detailed Look

New Injectors: These are brand new units, typically from the OEM (like Bosch, Delphi, Denso) or a high-quality aftermarket manufacturer. They offer the absolute highest level of reliability, incorporate the latest engineering updates, and come with the most comprehensive warranties. They are the premium choice for mission-critical applications where maximum peace of mind is required.

Remanufactured Injectors: A high-quality remanufactured injector is not simply a "rebuilt" or used part. It is a used injector core that has undergone a rigorous, factory-level restoration process. This includes complete disassembly, ultrasonic cleaning of all components, and meticulous inspection of critical surfaces under high magnification. All wear items—such as the nozzle, control valve, seals, and O-rings—are discarded and replaced with brand-new parts. The injector is then reassembled and calibrated on a specialized test bench to ensure its fuel delivery, timing, and spray pattern meet or exceed strict OEM specifications. This process, performed by reputable Diesel Fuel Injector Rebuilders, results in a product that can perform as well as a new one for a fraction of the cost.

Core charges are an integral part of the remanufacturing ecosystem. You pay a refundable deposit when you purchase the part. This deposit is refunded to you in full once you return your old, rebuildable injector (the "core"), ensuring a sustainable supply of parts for the industry.

Where to Reliably Buy Diesel Injectors Online

Supplier Reputation: Choose a specialist in diesel parts, not a general auto parts store. Look for companies with a long track record, positive industry reputation, and ASE-certified technicians on staff.

Customer Reviews: Look for consistently high ratings (4.8 stars or higher) and read what other customers say about product quality, shipping speed, and customer service.

Transparent Warranty Policies: A reputable seller will have a clear, comprehensive warranty policy. Look for at least a one-year, unlimited mileage warranty and understand the claim process.

Expert Technical Support: The ability to call and speak with a knowledgeable expert who can help you verify fitment, diagnose issues, or walk you through an installation question is invaluable.

Shipping and Inventory: Downtime costs money. Choose a supplier with a large in-stock inventory who can offer fast, reliable shipping options to get you back on the road quickly.

To start your search, explore options at Diesel Fuel Injectors For Sale.

Protecting Your Investment: Installation and Maintenance

You've done your research and selected the right parts, but the job is only half done. The way you install and maintain your new components is just as critical as the quality of the parts you buy diesel injectors. A shocking number of premature injector failures are not due to a faulty part, but to contamination or errors during the installation process. Protecting your investment requires meticulous attention to detail from start to finish.

This means following precise torque specifications, maintaining a surgically clean work environment, and properly priming the fuel system before the first start. The quality of the fuel and filtration you use going forward is equally paramount, as contamination is the number one killer of high-pressure fuel systems. For detailed instructions, see How to Replace Diesel Injectors. For Paccar engines, knowing How to Prime a Paccar PX-9 Fuel System is essential.

The Importance of Proper Installation

Maintain Absolute Cleanliness: Before removing the old injectors, thoroughly clean the valve cover and the area around the injectors to prevent any dirt, dust, or debris from falling into the open injector bore or cylinder. Even a microscopic particle can destroy the precision sealing surfaces of a new injector.

Clean the Injector Bore: After removing the old injector, the injector bore (or cup/sleeve) in the cylinder head must be carefully cleaned of all carbon buildup. Any remaining carbon can cause the new injector to seat improperly, leading to compression leaks and poor performance.

Always Use New Seals: Never reuse old copper washers or O-rings. These are single-use components designed to crush and form a perfect seal. Quality Diesel Injector Repair Kits will include all necessary new seals.

Use Correct Torque Specifications: Use a calibrated torque wrench for everything—the injector hold-down clamp, the fuel lines, and the valve cover. Over-tightening can distort the injector body and cause it to bind internally, while under-tightening will lead to fuel or compression leaks.

Prime the Fuel System: Never start the engine with a dry fuel system. This can cause the new injectors to fire without the lubrication and cooling provided by diesel fuel, leading to immediate damage. Follow the OEM procedure for priming the system to purge all air.

Long-Term Care and Maintenance

Prioritize Fuel Filtration: Your fuel filters are the only defense your injectors have against contaminants. Use high-quality filters with the correct micron rating and change them according to the manufacturer's schedule—or more frequently if you operate in dusty environments or suspect poor fuel quality.

Use Quality Fuel and Additives: Purchase diesel from high-volume, reputable stations to avoid water and debris. Using a quality multi-function Diesel Fuel Injector Cleaner additive can help prevent deposit buildup on nozzle tips, add lubricity to protect internal parts, and improve cetane for better combustion.

Manage Water Contamination: Regularly drain your fuel-water separator. Water in the fuel system will cause corrosion and can instantly damage injector tips when it flashes to steam under high pressure.

Protect Your After-treatment System: Healthy injectors are key to a healthy DPF and SCR system. A leaking or over-fueling injector will send excess soot and unburned fuel downstream, rapidly clogging the DPF and potentially damaging the SCR catalyst, leading to thousands of dollars in repairs. For specific cleaning techniques, refer to How to Clean Common Rail Diesel Injectors.

Frequently Asked Questions about Diesel Injectors

When preparing to buy diesel injectors, fleet managers, owner-operators, and technicians often have similar questions. Getting clear answers is key to making a confident and correct purchase. Here are detailed answers to the most common inquiries.

What is the typical price range for diesel fuel injectors?

The price of a diesel injector varies significantly based on several key factors. The engine application, the type of injector technology, and the choice between new and remanufactured are the biggest drivers of cost. As a general guide:

Mechanical Injectors: Typically range from $150 to $300 per injector.

Electronic Unit Injectors (EUI): Usually fall in the $300 to $600 range.

Common Rail Injectors: Being the most complex, these are often the most expensive, ranging from $400 to $800+ per injector. For remanufactured units, you must also factor in a refundable core charge, which can range from $100 to $400 per injector depending on its value and scarcity.

Can I replace just one failing injector?

While it is technically possible to replace only the single injector that has failed, it is strongly discouraged by industry experts. Diesel injectors in an engine wear at a very similar rate because they have operated under the same conditions for the same number of hours. If one has failed due to high mileage and wear, the others are likely near the end of their service life as well.

Furthermore, injectors are manufactured and calibrated to be installed as matched sets. They are designed to deliver an identical amount of fuel with identical timing. Installing one brand-new, peak-performance injector alongside older, worn injectors creates an imbalance in the engine. The ECU will struggle to compensate for the different flow rates, leading to a rough idle, persistent vibrations, poor fuel economy, and uneven stress on internal engine components like pistons and bearings. For long-term reliability and smooth engine operation, the best practice is always to replace all injectors as a complete set.

What is a core charge and how does it work?

A core charge is a refundable deposit paid at the time of purchase for a remanufactured part. It is not an extra fee but a financial incentive to ensure you return your old, used part (the "core"). This process is the lifeblood of the remanufacturing industry.

The process is straightforward:

You purchase the remanufactured injector and pay the part price plus the core charge.

The supplier ships the remanufactured part to you, often including a prepaid return shipping label in the box.

After you install the new part, you place your old core into the same packaging.

You ship the core back to the supplier using the provided label.

Once the supplier receives the core and verifies that it is in a rebuildable condition (i.e., not cracked, fire-damaged, or missing major pieces), they issue a full refund of the core charge. This system ensures a sustainable and affordable supply of parts for the entire diesel industry.

How long do diesel injectors last?

The lifespan of a diesel injector can vary dramatically based on factors like fuel quality, maintenance schedules, and operating conditions. However, a general estimate for a heavy-duty commercial truck (Class 8) is between 500,000 and 800,000 miles. For light and medium-duty diesel trucks, the expected lifespan is typically shorter, often in the range of 100,000 to 200,000 miles. Regular use of quality fuel filters and fuel additives can significantly extend an injector's life.

What is the difference between "remanufactured" and "rebuilt"?

These terms are often used interchangeably, but they can mean very different things. Remanufactured implies a rigorous, industrial process where the part is completely disassembled, cleaned, inspected, and all wear components are replaced with new parts before being reassembled and tested to meet or exceed original OEM specifications. Rebuilt, on the other hand, can be a looser term. It may simply mean that the specific component that failed was replaced, without a full disassembly or replacement of other wearing parts. When you buy diesel injectors, always look for high-quality remanufactured parts from a reputable supplier to ensure the best performance and longevity.

Conclusion

You are now equipped with the comprehensive knowledge needed to confidently buy diesel injectors that will keep your fleet running at peak performance and efficiency. We've journeyed from the fundamental principles of how an injector works and the evolution of its technology, to diagnosing failure symptoms, navigating the critical choice between new and remanufactured parts, and understanding the immense importance of proper installation and maintenance. This detailed roadmap empowers you to make decisions that protect your assets and your bottom line.

The central theme is undeniable: quality and precision matter. Investing in high-quality injectors from a reputable supplier is a direct investment in superior engine performance, tangible fuel savings, and long-term operational reliability. For a fleet, this translates to more power on the road, lower cost-per-mile, and a significant reduction in unplanned downtime and costly roadside breakdowns. Furthermore, healthy injectors ensure cleaner combustion, which is essential for maintaining compliance with emissions regulations and preserving the health of expensive after-treatment systems. By combining a smart purchase with meticulous installation and diligent maintenance, you create a formula for success.

For owners of Volvo, Mack, Kenworth, and Paccar trucks who demand the utmost in reliability and performance, G2 Diesel Products offers innovative solutions like their Smart F2P Injectors. With decades of specialized experience in the heavy-duty diesel industry, they understand that your truck is your livelihood. Their commitment to quality and expert support ensures you get the right parts quickly, minimizing downtime and maximizing your earning potential. Here's to many more miles of efficient, powerful, and reliable diesel operation.