Power Up Your Diesel: The Best Injectors for Performance and Reliability

The Heartbeat of Your Engine's Performance

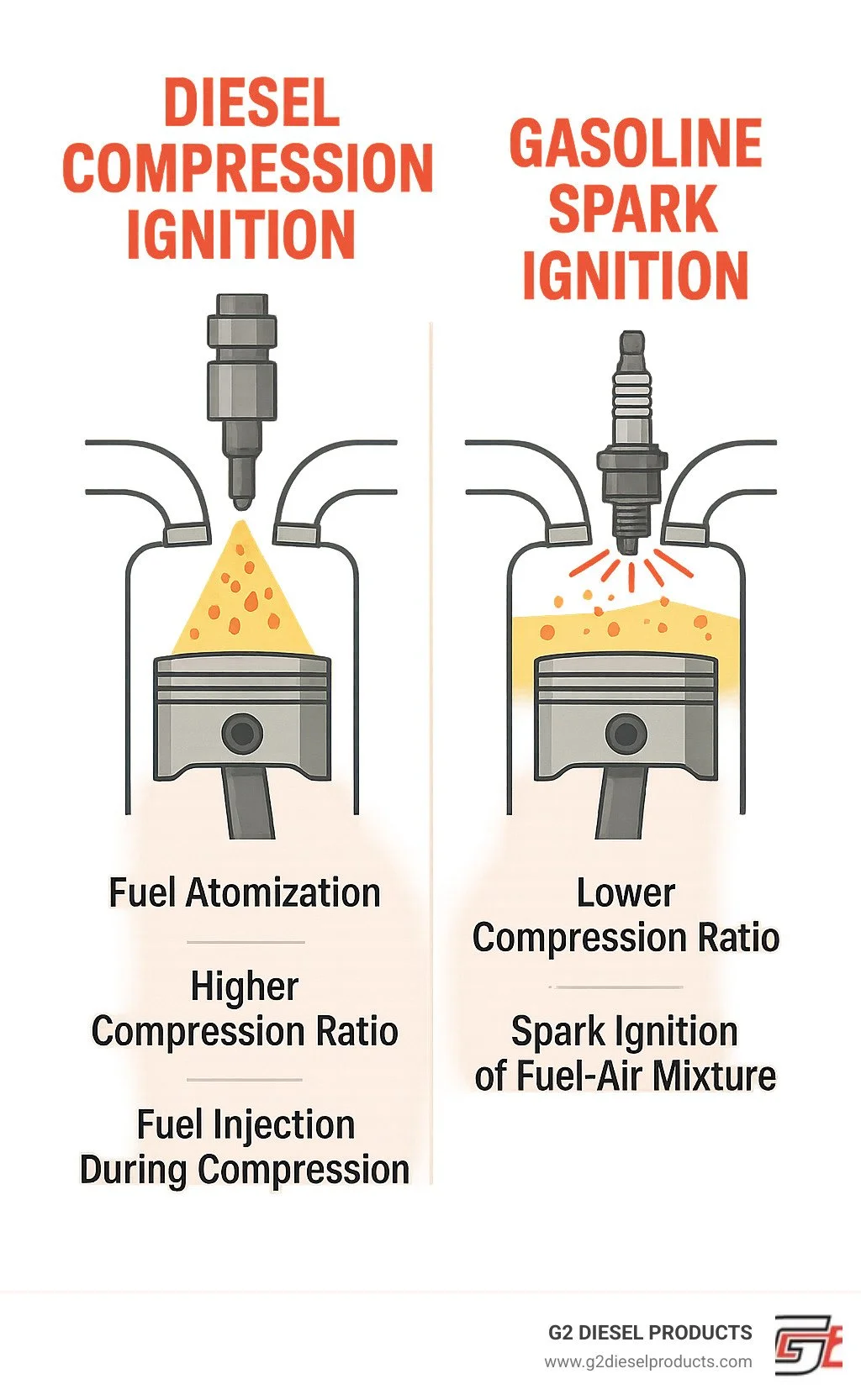

Diesel fuel injectors are precision components that deliver atomized fuel into your engine's combustion chambers. These critical parts are key to engine power, fuel efficiency, reliability, and emissions, creating the perfect fuel-air mixture for compression ignition.

Key Features of Modern Diesel Fuel Injectors:

High-pressure delivery - Operating at 1,600-2,200 bar for optimal atomization

Precision timing - Multiple injections per cycle (2-5 times) for performance and emissions control

Advanced materials - Stainless steel and high-strength alloys for durability

Electronic control - ECU-managed for precise fuel metering

Types available - Common rail, HEUI, unit injectors, and piezo technology

Modern diesel engines use compression ignition, where intense heat and pressure ignite atomized fuel without spark plugs. This process requires injectors that can withstand extreme temperatures (up to 1,000°F) and maintain micro-precision tolerances.

For example, modern piezo injectors act up to five times faster than older solenoid types. This speed directly improves fuel economy, reduces emissions, and ensures smoother engine operation.

Whether you're managing a fleet of Volvo, Mack, Kenworth, or Paccar trucks, understanding injector technology helps you make informed decisions about maintenance, repairs, and replacements that keep your equipment running efficiently.

Understanding the Technology: How Diesel Fuel Injectors Work

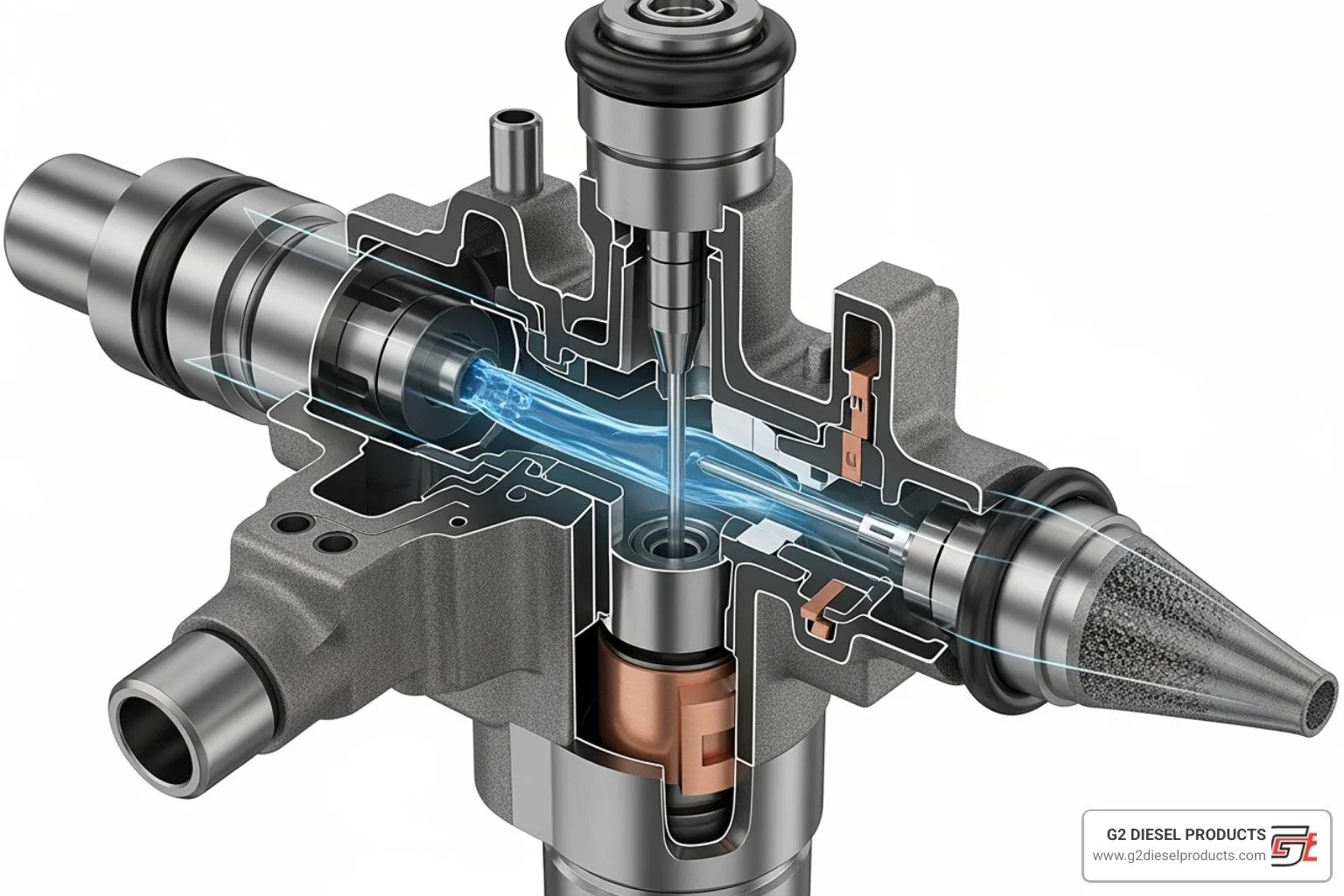

A diesel fuel injector is a precision instrument critical to your engine's performance. These components perform three vital tasks: delivering fuel at immense pressures, atomizing that fuel into a fine mist, and timing each injection with split-second accuracy.

They accomplish this at pressures up to 37,000 psi and speeds of 2,000 times per minute. The Engine Control Unit (ECU) sends electrical signals to each injector, dictating the precise timing and fuel quantity. This isn't just dumping fuel; it's creating microscopic droplets that mix perfectly with superheated, compressed air for clean, powerful combustion.

Perfect atomization means every drop of diesel burns completely, giving you maximum efficiency and minimal emissions. Poor atomization leads to wasted fuel, black smoke, and reduced power. For a deeper dive into how these systems boost your engine's capabilities, check out More on injector technology from G2 Diesel Products.

Key Types of Diesel Fuel Injectors

Diesel fuel injector technology has evolved significantly. Understanding the different types helps in making informed maintenance and replacement decisions.

Mechanical injectors were the original workhorses. These robust systems used spring and fuel pressure for timing but lacked the precision for modern emissions and economy standards.

Unit Injector Systems (EUI) combined the pump and nozzle into one unit per cylinder. This allowed for higher injection pressures and improved reliability, though repairs became more complex.

Hydraulic Electronic Unit Injectors (HEUI) use electronically controlled engine oil pressure to drive injection. This system offers precise control over both timing and fuel quantity.

Common Rail Injectors are the current gold standard. A high-pressure pump feeds a shared fuel rail, allowing the ECU to control each injector independently for multiple, precise injections per cycle. This flexibility enables a small pilot injection to reduce noise, a main injection for power, and a post-injection to clean the exhaust system, dramatically improving fuel economy and cutting emissions.

To understand the mechanics behind these systems, visit How Common Rail Injectors Work.

The Evolution of Injector Technology

The journey from mechanical to electronic diesel fuel injectors was driven by stricter emission standards and demands for better fuel economy.

Solenoid injectors were the first step into electronic control, using electromagnetic coils to open valves in about 160 microseconds. Then came piezo injectors, which use piezoelectric crystals that expand or contract with electricity. Responding in just 100 microseconds, they are up to five times faster than solenoid injectors, directly improving engine performance.

The biggest breakthrough was multiple injections per cycle. Instead of one large fuel dump, modern piezo injectors can deliver 2-5 precisely timed injections. This may include a pilot injection to reduce noise, a main injection for power, and post-injections to optimize emissions control.

At G2 Diesel Products, we stay at the forefront of this innovation, ensuring our remanufactured diesel fuel injectors for Volvo, Mack, Kenworth, and Paccar trucks incorporate the latest technological advances.

Materials and Manufacturing: What Makes a Quality Injector?

Diesel fuel injectors operate under extreme pressure (37,000 psi) and heat (1,000°F), making premium materials and precision manufacturing essential.

Materials: High-strength alloys and stainless steel are chosen for their ability to withstand thermal cycling, resist corrosion, and maintain integrity under pressure.

Manufacturing: Quality injectors are built to tolerances measured in microns (a human hair is about 70 microns wide). These micro-tolerances are critical for components like control valves and spools to seal perfectly.

Nozzle Quality: Premium nozzles undergo processes like extrude honing to optimize flow and ensure consistent spray patterns. The nozzle holes are precision-drilled, as even tiny variations affect performance.

Durability: All internal components, from washers to O-rings, must meet original equipment specifications to ensure a perfect seal and instant response.

At G2 Diesel Products, we understand that quality is non-negotiable. Our commitment to excellence shows in every component we manufacture for Volvo, Mack, Kenworth, and Paccar applications. Learn more about our dedication to quality at Our Quality Volvo Mack Kenworth Paccar Diesel Fuel Injectors.

Diagnosing Problems: Is It Time for a Replacement?

Knowing the early warning signs of a failing diesel fuel injector can save you from costly repairs and keep your truck running smoothly.

Your truck's ECU can flag injector issues with diagnostic codes for low rail pressure or failed cylinder contribution tests. More frequent Diesel Particulate Filter (DPF) regeneration cycles can also point to a faulty injector causing excess soot. Catching these issues early is crucial to prevent power loss or engine damage.

For a deeper dive into the tell-tale signs of trouble, check out Fuel Injector Problems Diesel.

Common Symptoms of Failing Diesel Fuel Injectors

When diesel fuel injectors begin to fail, your truck will let you know. Watch for these common red flags:

Engine Misfires or Rough Idle: A faulty injector can cause a cylinder to misfire, leading to a shaky, uneven engine idle.

Excessive Smoke:

Black smoke: Often indicates over-fueling from an injector stuck open or with a poor spray pattern.

White smoke: Can point to unburnt fuel passing through the exhaust, possibly from an injector failing to atomize fuel correctly.

Grey smoke: Similar to black smoke, indicating unburnt fuel, often with a strong, unpleasant smell.

Poor Fuel Economy: If your truck is suddenly guzzling fuel, a leaking or inefficient injector could be the culprit.

Hard Starting: A struggling injector can make the engine crank longer than usual before starting, especially in cold weather.

Engine Knocking: A distinct knocking sound can occur if an injector is sticking, leading to improper combustion.

Fuel Smell in Oil: A strong diesel smell in your engine oil may indicate a leaking injector. This is a serious sign, as fuel dilutes engine oil, causing premature wear.

Clogged DPF Filters: Faulty injectors can create excess soot, clogging the DPF and causing more frequent regeneration cycles.

Top Causes of Injector Failure

Understanding why diesel fuel injector failures occur is key to prevention.

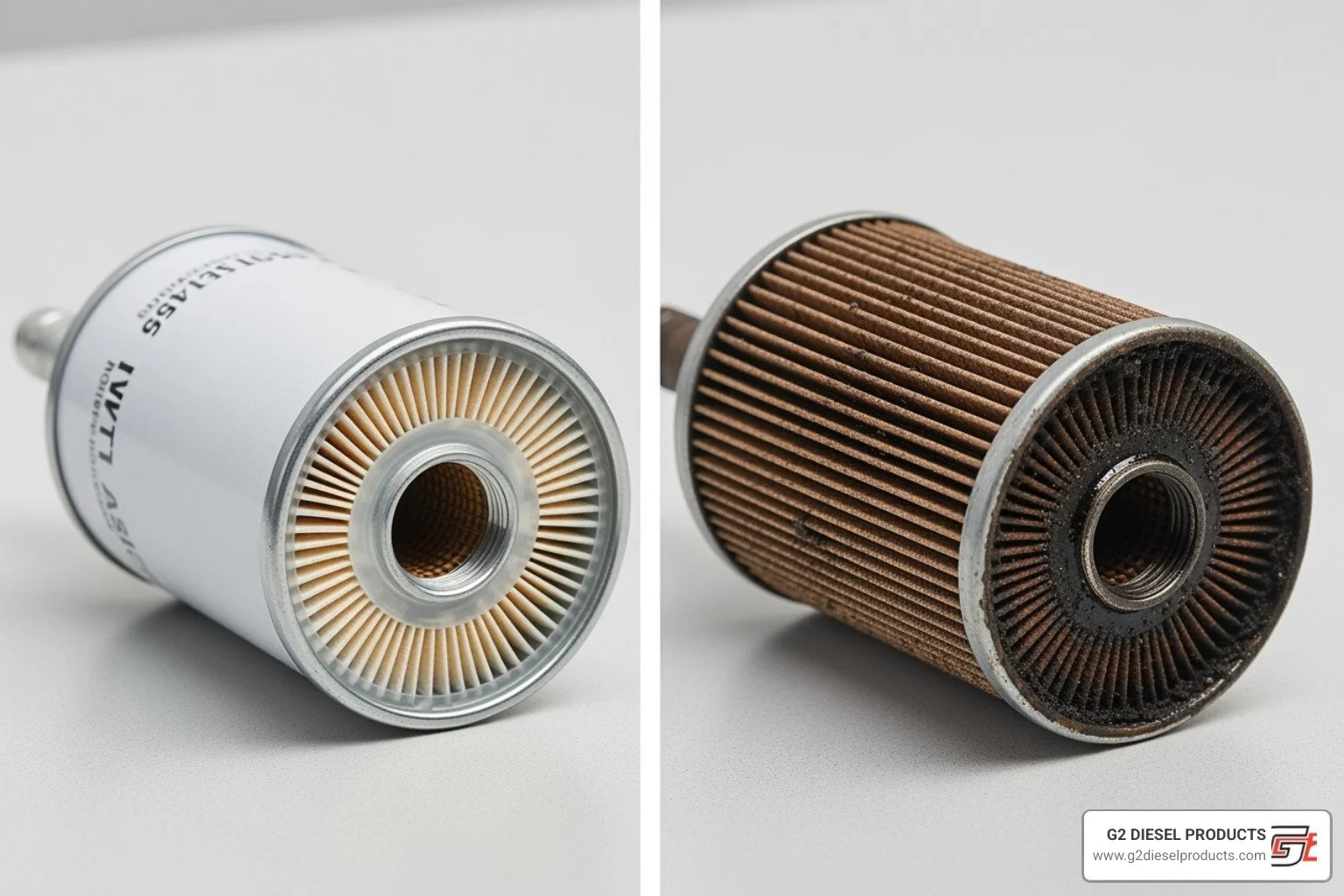

Fuel Contamination: This is the primary cause of injector failure. Water, dirt, rust, and microbial growth can corrode components, abrade surfaces, and clog nozzles. Even microscopic particles can cause significant damage.

Low Lubricity Fuel (ULSD): Ultra-Low Sulfur Diesel (ULSD) is cleaner for the environment but has less natural lubricity than older fuels. This can cause increased friction and wear on internal injector components unless a lubricity additive is used. The HFRR Test (ASTM D-6079) measures fuel lubricity, with a wear scar limit of 520 microns in the US.

Deposits (Coking): Fuel can leave behind deposits over time.

External Coking: Deposits on the nozzle exterior disrupt the spray pattern, reducing power and fuel economy.

Internal Diesel Injector Deposits (IDIDs): These deposits form inside the injector on critical moving parts. In high-pressure systems with tight tolerances, they can cause injectors to stick, seize, or respond slowly.

High Mileage Engine Wear: Like any mechanical part, injectors are subject to wear and tear over thousands of hours of operation. Springs can weaken, and seals can degrade.

Incorrect Installation: Improper installation—using incorrect torque settings, missing washers, or damaging seals—can cause leaks and premature failure.

Understanding these root causes empowers you to take preventative measures. For more insights into why these critical components fail, you can read more at Why Diesel Fuel Injectors Fail.

Maintenance and Solutions: Extending Injector Life and Restoring Power

When your diesel fuel injectors show signs of wear, the right maintenance can extend their life or restore performance. Acting early is key to avoiding major repairs. At G2 Diesel Products, our advanced diagnostic equipment helps pinpoint the exact problem, so you're not guessing.

You can learn more about the sophisticated tools used in modern injector diagnosis at Diesel Injector Testing Equipment.

Prevention and Maintenance Best Practices

Keeping your diesel fuel injectors healthy requires consistent attention to a few key areas.

Use High-Quality Fuel: Stick with reputable fuel stations to avoid sediment and contaminants that can damage your fuel system.

Change Fuel Filters Regularly: Replace filters according to your maintenance schedule to catch contaminants before they reach your injectors.

Use a Fuel Additive: A quality fuel additive can restore lubricity to ULSD fuel and help prevent harmful deposits from forming. Learn more at Diesel Fuel Injector Cleaner.

Drain Your Water Separator: Periodically drain the water separator on your fuel filter to prevent condensation buildup and corrosion.

Get Professional Testing: Proactive diagnostic testing can identify injector issues before they affect performance. This allows you to schedule maintenance instead of dealing with a roadside breakdown. For comprehensive services, check out Diesel Injector Testing Services.

Repair, Rebuild, or Replace? Making the Right Choice

When a diesel fuel injector fails, you can repair, remanufacture, or replace it. The best choice depends on your situation and budget.

Repair: Minor issues like a failed O-ring or clogged nozzle can sometimes be fixed with a Diesel Injector Repair Kit. However, this is not a solution for internal wear.

Remanufacture: This is the best value for most owners. The process involves completely disassembling the failed injector, cleaning every part, and replacing all worn components with new, OE-quality parts. The injector is then reassembled and tested to meet exact specifications. At G2, we use new nozzles in every remanufactured injector to ensure optimal fuel atomization and service life. The core charge system, where you get a refund for returning your old injector, helps keep costs down. Our network of expert Diesel Fuel Injector Rebuilders maintains the highest standards.

Replace: New injectors offer maximum reliability and warranty coverage but are the most expensive option.

For Volvo, Mack, Kenworth, and Paccar applications, we recommend our remanufactured diesel fuel injectors. They meet or exceed OEM specifications while offering significant cost savings compared to new parts, providing reliable performance that keeps your truck on the road.

Frequently Asked Questions about Diesel Injectors

Here are answers to some of the most common questions we hear from truck owners and fleet managers about diesel fuel injectors.

How much do diesel fuel injectors cost?

The cost of diesel fuel injectors varies based on several factors:

Injector Type: Modern common rail and piezo injectors are more complex and costly than older mechanical types.

Engine Application: Injectors are specific to each engine model for Volvo, Mack, Kenworth, and Paccar trucks.

New vs. Remanufactured: A new OEM injector typically costs more than a high-quality remanufactured unit, which can offer the same performance for less.

Core Charge: When buying remanufactured injectors, you pay a refundable deposit (core charge) that you get back when you return your old injector.

Labor Costs: Installation requires specialized tools and knowledge, so be sure to factor labor into your budget.

Investing in quality injectors pays for itself through better fuel efficiency, improved performance, and the avoidance of major engine damage. For a deeper dive into cost considerations, check out Diesel Fuel Injector Cost.

Can I replace just one faulty injector?

While technically possible, we strongly recommend replacing injectors in sets, especially in modern common rail systems. Here’s why:

Similar Wear: Injectors wear at similar rates. If one fails at high mileage, the others are likely near the end of their service life. Replacing just one may mean another repair visit soon.

Cylinder Balance: A new injector flows differently than worn ones, creating an imbalance that your engine's ECU must compensate for. This can lead to rough idling, vibration, and uneven combustion.

Cost-Effectiveness: Replacing injectors as a set saves on labor costs from multiple service visits and provides peace of mind that your entire fuel system is refreshed.

For most high-mileage engines, set replacement is the most reliable and financially sound approach. If you're curious about the process, you can learn more at How to Replace Diesel Injectors.

What's the difference between OEM and quality aftermarket injectors?

Understanding the difference helps you make an informed choice.

OEM (Original Equipment Manufacturer) injectors are made by the same company that supplied them for your new truck. They are built to the engine manufacturer's exact specifications.

Aftermarket injectors is a broad category. It ranges from low-quality knockoffs to premium remanufactured units that meet or exceed OEM standards. The key is to choose a quality supplier.

High-quality remanufactured injectors offer the best of both worlds. At G2 Diesel Products, our remanufactured diesel fuel injectors for Volvo, Mack, Kenworth, and Paccar trucks are built using OE-quality components and tested to meet or exceed original specifications. This provides the same performance and reliability as a new OEM part but at a significantly lower price.

The bottom line is that quality matters more than the label. Whether you choose OEM or aftermarket, ensure your supplier uses proper manufacturing processes, quality components, and thorough testing procedures.

Conclusion: Find the Right Injectors for Your Diesel Engine

Diesel fuel injectors are remarkable components, critical to your engine's power, efficiency, and reliability. From delivering fuel at 37,000 psi to atomizing it thousands of times per minute, they directly impact your truck's performance and your bottom line.

When injectors work perfectly, your engine runs smoothly and efficiently. When they fail, you'll see the signs in rough performance, excessive smoke, and poor fuel economy.

The key takeaways are clear:

Quality matters. The choice of technology, materials, and manufacturing precision is crucial.

Prevention is key. Using quality fuel, changing filters, and performing professional testing can save you thousands in repairs.

The right partner makes all the difference. When it's time for a replacement, choose a supplier you can trust.

At G2 Diesel Products, we understand what Volvo, Mack, Kenworth, and Paccar truck owners need. Our remanufactured diesel fuel injectors are precision-restored to meet or exceed OEM standards. We use brand-new nozzles in every unit because that's where performance begins. We test every injector under real-world conditions because your livelihood depends on reliability.

You deserve injectors that deliver consistent performance, mile after mile. Our quick lead times and customer-specific packaging ensure you get the right parts when you need them.

Ready to experience the difference that quality diesel fuel injectors can make? Your Cummins engine deserves the precision and power that only high-performance components can deliver. Find the right high-performance XPI injectors for your Cummins engine today.