Smoke Signals and Stumbles: Decoding Common Rail Injector Problems

Why Recognizing Common Rail Diesel Injector Failure Symptoms Matters

For any fleet manager or owner-operator, a down truck is a money-losing truck. The common rail diesel engine is the heart of your operation, but its high-performance injectors are precision instruments under immense stress. An injector failure isn't a minor hiccup; it's a potential chain reaction leading to engine-wide destruction. Understanding your engine's warning signs—strange noises, smoke, power loss—is your best defense. This guide will help you catch these issues before they become budget-breaking disasters.

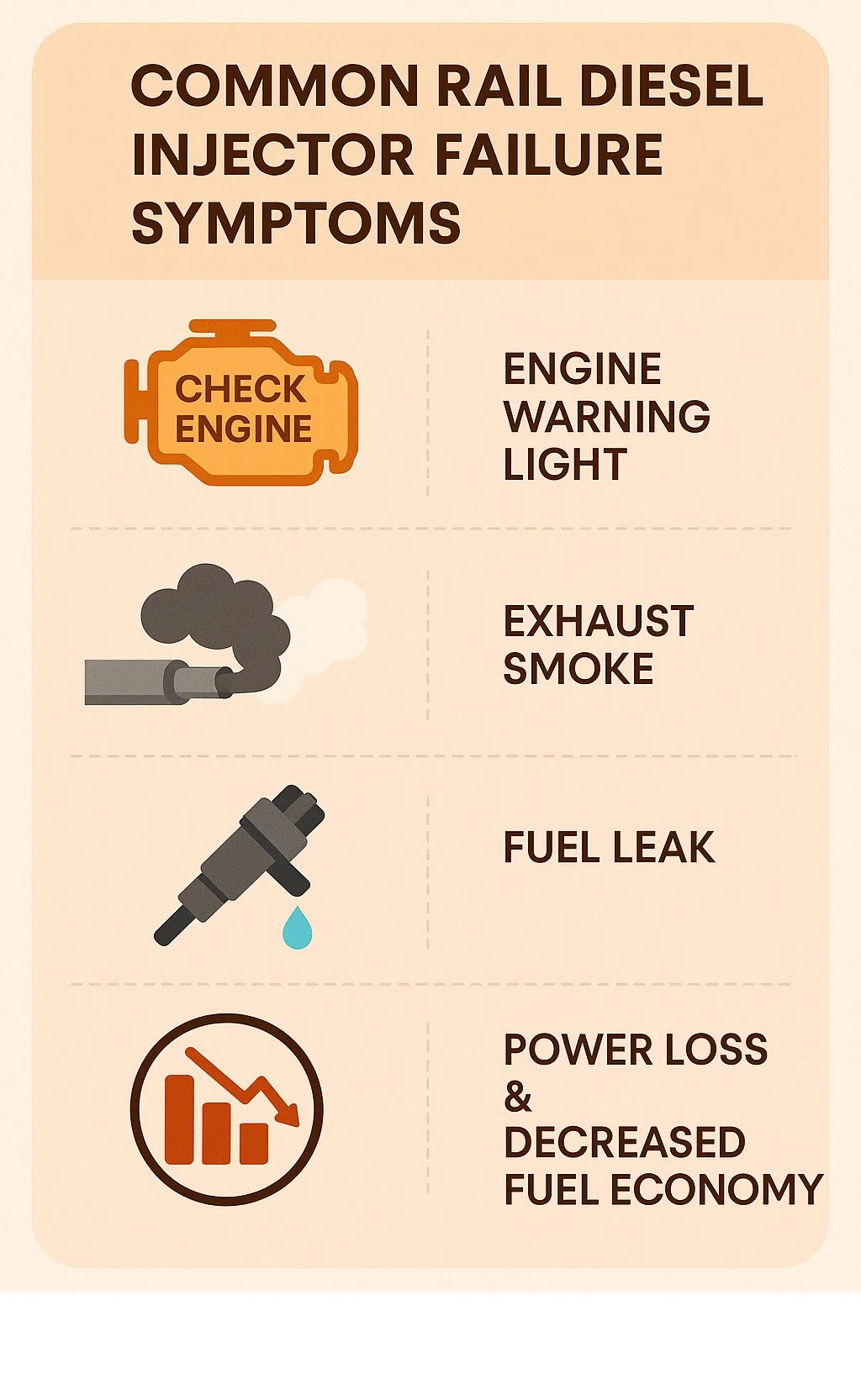

Recognizing common rail diesel injector failure symptoms can mean the difference between a quick repair and catastrophic engine damage. Spotting these warning signs early is essential for minimizing downtime and avoiding costly repairs.

Key symptoms to watch for:

Engine misfires, rough idling, and hesitation: A noticeable shake or shudder, especially at idle or low speeds, often accompanied by a hesitation when you press the accelerator. This points to an inconsistent fuel supply from one or more injectors.

Excessive black, white, or blue exhaust smoke: Each color tells a story. Black smoke signals too much fuel (a rich mixture), white smoke points to unburnt fuel, and a blue haze can indicate oil consumption, sometimes related to injector issues.

Noticeable loss of engine power and declining fuel economy: Your truck may feel sluggish, struggle to pull loads, or require more fuel to cover the same distance. This happens as the ECU tries to compensate for a failing injector, often wasting fuel in the process.

Audible engine knock or rattling sounds: A sharp, metallic knocking sound (detonation) can occur when fuel ignites at the wrong time due to a faulty injector spray pattern or timing.

The smell of raw diesel fuel or visible leaks: A strong fuel odor in the cab or around the engine bay is a clear sign of an external leak, potentially from a cracked injector body or a failed seal.

Illuminated Check Engine Light (CEL): The engine's computer often detects imbalances or electrical faults in the injection system, triggering the CEL and storing specific diagnostic trouble codes (DTCs).

Modern common rail systems operate under extreme pressures exceeding 30,000 PSI with tolerances as small as 1-2 microns. These precision instruments fire multiple times per combustion cycle, which provides incredible performance but also increases vulnerability to contamination and wear.

Contaminated fuel is the leading cause of injector failure. Water, particle debris, and heat soak create a perfect storm for expensive repairs. Since sub-micron particles can cause significant damage and injectors may cycle over a billion times in their service life, understanding failure symptoms is critical for any fleet manager.

The Telltale Signs: Primary Common Rail Diesel Injector Failure Symptoms

Your truck communicates problems through performance issues, strange sounds, and visual warnings. These signs can tell you what's happening inside your Diesel Fuel Injector. Learning to decode these messages helps you catch problems before they become expensive disasters.

Engine Stumbles, Misfires, and Rough Idling

When an injector fails, it creates an uneven fuel supply, leading to incomplete combustion. This causes the engine to misfire, creating a noticeable stumbling or shaking sensation, especially at idle. The sensation can range from a subtle, intermittent vibration felt through the steering wheel to a violent shaking that makes the entire cab shudder. When cold, the engine might struggle to find a stable idle, with the tachometer needle bouncing erratically. The symptom often worsens under load, such as when accelerating or climbing a grade, as the demand for precise fuel delivery increases. Ignoring this can lead to increased stress on engine mounts. Your truck's computer will often detect the issue and activate the Check Engine Light (CEL), storing fault codes like P0201 through P0208 that can help pinpoint the problematic cylinder.

Noticeable Loss of Power and Poor Fuel Economy

Failing injectors often lead to a frustrating loss of power. You may experience sluggish acceleration, reduced towing capacity, or unpredictable power delivery known as engine surge. To maintain performance, the engine's computer (ECU) will try to compensate by adjusting fuel delivery, which usually means over-fueling other cylinders. This results in increased fuel consumption and poor miles per gallon (MPG). For trucks with modern emission controls, faulty injectors also create more soot, forcing the Diesel Particulate Filter (DPF) into more frequent and shorter regeneration cycles. This forced regeneration cycle itself consumes extra fuel, creating a vicious loop of inefficiency. You're not only losing power but also paying more at the pump and putting extra strain on your emissions system. In severe cases, the ECU may trigger a 'limp mode,' drastically reducing engine power to prevent catastrophic damage, signaling a critical fault that requires immediate attention.

Unmistakable Smoke Signals from the Exhaust

Your exhaust pipe provides clear visual clues about injector health. Each color of smoke tells a different story:

Black smoke indicates an engine running too rich. This is most noticeable under heavy acceleration. A stuck-open injector dumps excess fuel into the cylinder, which can't be fully burned. This wastes fuel and creates extreme temperatures that can damage pistons and turbochargers.

White smoke, especially during cold starts, signals unburnt fuel escaping the exhaust. This smoke has a sharp, acrid smell of unburnt diesel and is often most prevalent on a cold start. It's caused by poor fuel atomization from a bad spray pattern or internal leaks. If it persists after the engine warms up, it signals a serious injection problem.

Blue haze at idle often points to dripping injectors that have lost their precision. While classically a sign of burning oil from worn rings, a dripping injector can also be the culprit. The dripping fuel washes lubricating oil off the cylinder walls, causing it to burn. This creates two problems: a faulty injector and accelerated engine wear.

These visual clues are among the key 5 Signs that Indicate Diesel Injector Failure.

Audible Clues and Unusual Smells

Your ears and nose can be reliable diagnostic tools. A sharp engine knock (detonation) occurs when fuel ignites at the wrong time, creating dangerous pressure spikes. A loud rattling on a cold start can also signal internal injector problems. A distinct fuel smell in the cabin or around the engine points to physical leaks from seals or cracked injector bodies. A rotten egg smell is a unique indicator of microbial infestation in the fuel, which can clog injectors with biological growth.

Behind the Breakdown: The Most Common Causes of Injector Failure

Modern injectors are precision instruments susceptible to wear and contamination. Understanding the root cause is crucial for effective repair and prevention of Fuel Injector Problems.

The #1 Culprit: Fuel Contamination

Fuel contamination is the leading cause of injector failure. Common rail systems operate with clearances as small as 1 micron, making them extremely sensitive to impurities. Contaminants aren't a single entity; they come in several destructive forms:

Hard Particles: This includes silica (dirt) and metal shavings from fuel tanks or system wear. These act like liquid sandpaper, eroding microscopic injector surfaces like the nozzle needle and valve seat. This erosion causes internal leaks and poor spray patterns.

Water: Exists as 'free' water (settled) or 'emulsified' (suspended). It causes rust and, under injector pressure, flashes to steam ('explosive erosion'), blasting metal from the injector tip.

Microbial Growth: 'Diesel bugs' are bacteria and fungi living at the water-fuel interface. They form a slime that clogs filters and injector passages, starving the engine of fuel.

Asphaltenes (Soft Particles): These are waxy, tar-like substances in low-quality fuel. Heat and pressure cause them to form hard carbon deposits ('coking') on injector nozzles, disrupting the spray pattern and causing smoke.

The importance of fuel filtration cannot be overstated. Modern systems use multi-stage filtration, and using the finest micron fuel filter available for your system is a small investment that pays huge dividends. For more guidance, see our guide on Diesel Fuel Injector Maintenance.

Internal Wear, Heat, and High Mileage

Even the most robust materials have limits. High operating pressures in common rail systems can exceed 30,000 PSI. Combined with multiple firings per cycle (up to five times per stroke), the workload on modern injectors is immense, causing them to wear much faster than older designs. A commercial vehicle injector may open and close over a billion times during its service life.

Heat soak occurs when the engine is shut down, and residual heat bakes fuel left in the injector, creating deposits that clog passages and cause parts to stick. High mileage wear is inevitable, often becoming noticeable around 75,000 to 87,000 miles. Nozzle and valve set erosion develops over time, with ball seat erosion being a common issue as injectors age. Learn more about Common Rail Injector failure – the common causes and signs.

Installation Errors and Mechanical Damage

Improper installation can quickly destroy a new injector. Improper torque can damage the injector body or cylinder head, while missing or damaged sealing washers can have catastrophic consequences. The copper sealing washer prevents hot combustion gases from escaping past the injector. If this seal fails, escaping gases can contaminate engine oil with carbon, potentially blocking the oil pickup and starving the engine of lubrication.

This carbon buildup can also seize the injector in the cylinder head, making future removal extremely difficult. Other issues like cracked nozzles or brittle O-rings damaged during installation can cause fuel leaks and allow air into the system. Proper installation techniques are covered in our resource on Diesel Injector Maintenance and Repair.

Cause Primary Symptoms Preventative Action Water Contamination Rough Idle, Corrosion, White Smoke Use Water Separator, Drain Filters Particle Contamination Misfire, Black Smoke, Power Loss High-Quality Filters, Clean Fuel Improper Installation Fuel Leak, Engine Knock, Black Smoke Follow OEM Specs, Proper Torque Heat Soak Deposits Rough Idle, Hard Start, Poor Economy Quality Fuel, Injector Cleaner High Mileage Wear Hard Start, High Return Rates, Knock Regular Maintenance, Quality Parts

Old vs. New: Why Modern Common Rail Systems Are More Vulnerable

Technological advancements bring new challenges. Here’s how Diesel Engine Common Rail technology differs from older systems and why it impacts injector longevity.

The Pressure and Precision Game

Older diesel systems were robust, operating at modest pressures (around 300-400 bar) with larger fuel passages that were more forgiving of impurities. They were simple and built for harsh conditions.

Modern common rail systems are engineering marvels that operate at extreme pressures exceeding 2,000 bar (over 30,000 PSI). This pressure is needed for the ultra-fine fuel atomization required for cleaner emissions and better fuel economy. However, this precision comes with vulnerability. The tolerances in modern injectors are incredibly tight—as small as 1-2 microns, about 30 times thinner than a human hair. A microscopic particle can jam these components.

Furthermore, modern injectors fire multiple times per combustion cycle (2-5 times), delivering pre-, main-, and post-injection events. This increased firing frequency can double or quadruple the wear on internal components compared to older single-shot injectors.

The Role of the ECU and Electronics

The Engine Control Unit (ECU) orchestrates the entire injection process. Modern systems use either solenoid or piezoelectric injectors, both controlled electronically. Piezoelectric technology allows for faster, more precise control but is also more sensitive to electrical issues.

The ECU controls injection timing and duration with incredible precision, factoring in dozens of variables to meet strict emission standards while delivering power. However, a faulty ECU can mimic injector failure symptoms like misfires or black smoke, leading to misdiagnosis. Mechanics might replace good injectors when the real culprit is the electronics.

Electrical failures, such as short circuits or damaged wiring, add a layer of complexity not present in older mechanical systems. A voltage spike can damage an injector's coil, and sensitive piezoelectric injectors require specialized diagnostic equipment. This complexity means diagnosing common rail diesel injector failure symptoms requires sophisticated scan tools and electrical testing. For more details, see our guide on how Common Rail Injectors Work.

Diagnosis and Prevention: Your Action Plan

Ignoring symptoms leads to costly damage. Proactive diagnosis and maintenance can save you time and money.

How Mechanics Diagnose Common Rail Diesel Injector Failure Symptoms

Accurate diagnosis is the first step. Mechanics use a systematic approach to identify the root cause of common rail diesel injector failure symptoms.

OBD-II Scan Tools: These tools read fault codes from the truck's computer. Codes like P0087 (low fuel rail pressure) or P0201-P0208 (injector circuit malfunction) provide initial clues.

Injector Balance Rate Tests: On a scan tool, a technician can view the 'balance rates' or 'fuel mass deviation' for each cylinder. A healthy engine will show values near zero. A positive value (e.g., +4.0 mm³) indicates the ECU is adding fuel to that cylinder to compensate for a lack of power, often due to a weak or clogged injector. A negative value (e.g., -4.0 mm³) means the ECU is pulling fuel because that cylinder is running too rich, which could point to a leaking or stuck injector. These readings provide a non-invasive way to quickly identify the problem cylinder.

Back Leak (Return Flow) Test: This physical test is often the definitive diagnostic step. The mechanic disconnects the return lines from each injector and attaches clear tubes or graduated vials. The engine is then run at idle for a specific period (e.g., one minute). A healthy injector will have a very small, specified amount of return fuel. A failing injector, with internal wear and leakage, will return a significantly larger volume of fuel. If one vial fills up much faster than the others, that's the faulty injector. Excessive return flow from multiple injectors can also point to a worn-out high-pressure pump that can't maintain rail pressure.

Rail Pressure Testing: Checking fuel rail pressure during cranking and running can reveal issues with the high-pressure pump or excessive leakage from injectors.

Electrical Tests: A multimeter can check coil resistance on solenoid injectors. Piezoelectric injectors require specialized tools for electrical diagnosis.

For more on these techniques, see our guide on Diesel Injector Testing and Diagnosis.

The Consequences of Ignoring the Signs

Ignoring injector failure symptoms can lead to a cascade of expensive problems. Unburnt fuel can wash oil from cylinder walls ("cylinder wash"), accelerating wear on pistons and rings. This fuel can also contaminate the engine oil (oil dilution), reducing its ability to lubricate and causing widespread engine wear. Debris from a failing injector can damage the high-pressure pump, and excessive soot from incomplete combustion can clog the DPF filter. The worst-case scenario is catastrophic engine failure, requiring a complete rebuild or replacement.

How to Prevent Common Rail Diesel Injector Failure Symptoms

Most injector failures are preventable with proper maintenance.

Use High-Quality Fuel: Source fuel from reputable, high-turnover stations to avoid contaminants and deposits.

Regular Fuel Filter Changes: Filters are your first line of defense. Follow manufacturer service intervals, or change them more often in dusty conditions.

Maintain Fuel/Water Separators: Regularly drain accumulated water from the separator to prevent it from reaching the injectors.

Use Quality Fuel Additives: A multi-function diesel additive can be a powerful preventative tool. A good additive package should include detergents to clean injector nozzles, lubricity improvers to protect the fuel pump and injectors from wear (especially with ULSD fuel), cetane boosters for cleaner combustion, and water demulsifiers to help your water separator work more effectively. Using a quality additive regularly can significantly extend the life of your entire fuel system.

Perform Regular Oil Changes: Clean oil is essential for protecting all engine components. Stick to recommended service intervals.

Avoid Aggressive Tuning: Increasing rail pressure beyond factory specs puts excessive stress on injectors and shortens their lifespan.

Practice Good Driving Habits: Avoid prolonged idling, which causes carbon buildup. Regular highway driving helps keep the system clean.

Use Fuel System Cleaners: A quality diesel fuel system cleaner can remove deposits and prevent new ones from forming. Learn more in our article on How to Clean Common Rail Diesel Injectors.

Frequently Asked Questions about Common Rail Injector Failure

Here are answers to some of the most common questions we receive from fleet managers and truck owners about common rail diesel injector failure symptoms.

What specific symptoms indicate an injector is stuck open vs. just leaking?

This is a critical distinction, as a stuck-open injector requires immediate attention.

A stuck-open injector continuously floods the cylinder with fuel. Symptoms are severe and include excessive black smoke, a no-start condition, severe engine knock, and rapid oil dilution as fuel washes past the piston rings.

A leaking or dripping injector is more subtle. Symptoms include white or blue smoke at idle, hard starting (especially when cold), a rough idle, and the smell of diesel fuel around the engine.

How does the ECU contribute to or report on injector failure?

The ECU controls all aspects of fuel injection and plays a key role in both masking and reporting failures. When an injector weakens, the ECU can compensate by increasing its pulse width (the time it stays open) to maintain power. This can hide early symptoms for a period.

Once the ECU can no longer compensate, it will log fault codes. Codes like P0201-P0208 point to an injector circuit malfunction in a specific cylinder, while P0087 indicates low fuel rail pressure. It's also important to note that each new injector has a unique trim code that must be programmed into the ECU to ensure it performs correctly.

Can improper installation really cause immediate failure?

Yes, absolutely. Installation mistakes can ruin a new injector instantly. Incorrect torque can deform the injector body or crack the cylinder head. However, the most common and destructive error involves the copper sealing washer that sits between the injector and the cylinder head.

If this washer is missing, damaged, or improperly seated, hot combustion gases will leak past the injector. This can cook the injector, create heavy carbon buildup that seizes it in place, and contaminate the engine oil. This contamination can lead to catastrophic engine damage in a very short time. Proper installation is not just important—it's critical.

Conclusion: Protecting Your Investment

Your diesel engine is the heartbeat of your operation. When common rail diesel injector failure symptoms appear, they are warning signals that, if heeded, can save you thousands of dollars. The cost of replacing a single injector is a fraction of a complete engine rebuild.

The smart approach is to stay alert to the warning signs, maintain your fuel system religiously, and address problems before they escalate. Most injector failures are caused by contaminated fuel, which is preventable with proper filtration and quality fuel sources.

Modern common rail systems deliver incredible performance, but their precision makes them vulnerable. There is no room for shortcuts in maintenance or repairs. When it's time for a replacement, quality matters more than ever. At G2 Diesel Products, we understand the demands of heavy-duty trucking. Our VCE Common Rail Fuel Injectors are engineered for Volvo, Mack, Kenworth, and Paccar trucks, built to deliver the reliability your operation depends on.

Your investment in quality components today protects your business tomorrow. Don't let injector problems sideline your operation.

Find the right high-performance diesel fuel injectors for your truck and keep your engine running strong for years to come.