Is Your Engine Misfiring? Unraveling the Mystery of Fuel Injector Problems

When your engine starts sputtering, losing power, or guzzling fuel, Fuel injector problems are often the silent culprit. For fleet managers, these issues translate into costly downtime and unexpected repair bills. Pinpointing the exact cause can be tricky, but knowing the tell-tale signs is the first step to getting your trucks back on the road.

If you suspect injector trouble, look for:

- Engine Misfires or Rough Idling

- Poor Fuel Economy

- Check Engine Light (CEL)

- Loss of Power or Hesitation

- Unusual Exhaust Smoke

- Fuel Smell

This guide explains what fuel injectors do, how they fail, and the smartest way to fix or prevent problems—especially in the heavy-duty diesel engines that keep freight moving.

The Heart of Your Engine: What is a Fuel Injector?

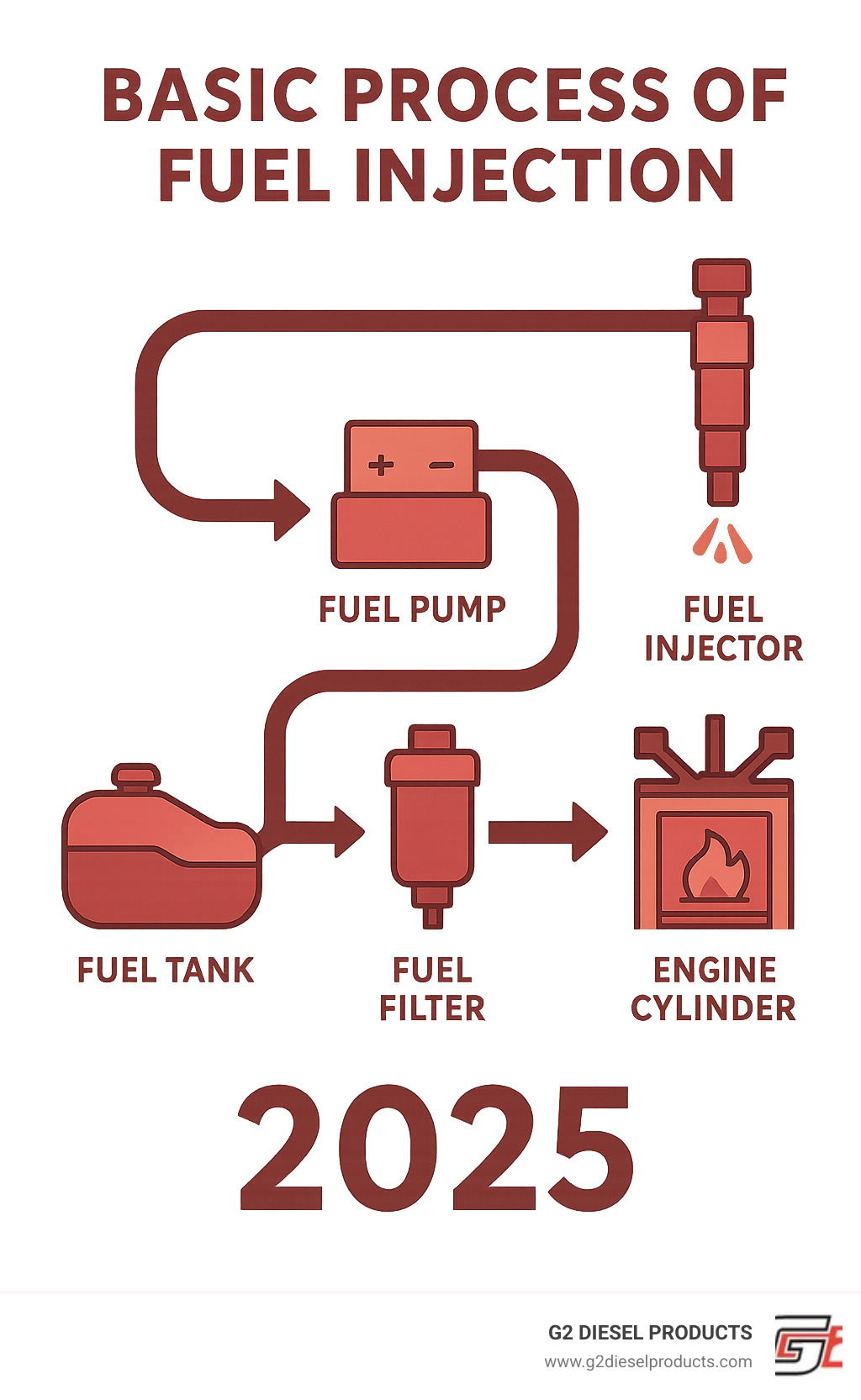

Think of your engine as a finely tuned orchestra, and fuel injectors are the precise instruments that deliver the perfect notes of fuel to keep the whole performance running smoothly. At their core, these are precision-engineered valves, tiny marvels that spray a super-fine, atomized mist of fuel right into your engine's combustion chamber. This isn't just a simple squirt; this precise delivery is absolutely critical for achieving optimal power, getting the best fuel efficiency, and keeping harmful emissions in check.

Unlike the old carburetor systems our grandparents might remember, which were a bit like a garden hose spraying fuel, modern injection systems are more like high-tech laser nozzles. They offer vastly superior performance, giving you more power and better fuel economy. However, with that precision comes a bit more sensitivity. This means they're also more susceptible to issues like contamination or wear, which can quickly lead to fuel injector problems. They work in perfect harmony with your fuel filter and fuel pump, ensuring your engine always gets the exact right mix of fuel and air it needs to purr.

Gasoline vs. Diesel Injectors

While both gasoline and diesel engines rely on these clever injectors, the job of a diesel injector is a whole different ballgame. It's like comparing a gentle stream to a roaring waterfall!

Gasoline injectors typically operate at much lower pressures. They often spray fuel into the intake manifold, where it has a moment to mix with air before it even enters the combustion chamber, ready to be ignited by a spark plug.

Diesel injectors, on the other hand, live a much tougher life. They operate under immense pressure – we're talking thousands of pounds per square inch! This is because diesel engines use what's called compression ignition. There's no spark plug involved; instead, the fuel ignites from the sheer heat generated by compressing the air inside the cylinder. Because the fuel is injected directly into that incredibly hot, high-pressure environment, diesel injectors need to be built incredibly robust and durable. It’s truly a testament to engineering!

Curious to learn more about how these powerhouses work? You can dive deeper into the mechanics by exploring How Do Common Rail Injectors Work and finding the clever design behind How Electronic Unit Injector Works.

Key Types in Heavy-Duty Trucks

When it comes to the workhorses of the road – heavy-duty trucks – two main types of fuel injection systems dominate the scene: Common Rail Injectors and Electronic Unit Injectors (EUI).

Common Rail systems are quite popular for their efficiency. Imagine a single, super high-pressure pump feeding fuel into a shared "common rail." From this rail, individual injectors then precisely distribute the fuel to each cylinder. This setup allows for multiple, incredibly precise injection events within a single combustion cycle. The result? Better fuel economy, smoother engine operation, and reduced emissions. We know these systems inside and out, offering top-notch components like our VCE Common Rail Fuel Injectors.

Then there are Electronic Unit Injectors (EUIs). These are brilliant because they integrate both the injector and the high-pressure pump into a single, compact unit for each cylinder. This clever design eliminates the need for high-pressure fuel lines running between a separate pump and the injector, which can simplify the overall system. Both Common Rail and EUI systems are absolutely vital to the performance of specific engine models, such as those found in the Paccar MX Fuel System and the powerful Detroit DD15 DD16 Injectors. Understanding these distinctions is truly crucial for correctly diagnosing and effectively addressing any fuel injector problems that might pop up.

Is Your Engine Trying to Tell You Something? Common Symptoms of Bad Fuel Injectors

Your hardworking truck provides clear warning signs when fuel injector problems start brewing. Ignoring them can lead to reduced performance, costly repairs, and even engine damage. Watch for the following:

Universal Warning Signs

- Check Engine Light (CEL) – common codes include P0087, P0201–P0212.

- Rough Idle or Vibrations – a “bucking” feeling when stopped.

- Engine Misfires or Stalling – especially under load.

- Loss of Power / Poor Acceleration – sluggish throttle response.

- Reduced Fuel Economy – filling up more often than usual.

- Fuel Smell – a leaking injector is also a fire hazard.

- Hesitation or Surging – inconsistent fuel delivery.

- Failed Emissions Test – incomplete combustion raises emissions.

Diesel-Specific Smoke Signals

- White Smoke – excess fuel or low cylinder heat; often a worn injector.

- Black Smoke – too much fuel or restricted airflow.

- Blue Smoke – burning oil; injector wash-down can contribute.

- Engine Knock – improper spray pattern causes detonation.

Uncovering the Culprits: The Top Causes of Fuel Injector Problems

Fuel injectors are designed to last 50,000–100,000 miles, yet several factors can cut that lifespan short. Knowing the causes lets you stop trouble before it starts.

1. Fuel Contamination – The #1 Enemy

Modern high-pressure common-rail systems operate at microscopic tolerances, so even tiny debris is destructive.

- Poor-Quality Fuel – dirt or weak detergent packages leave sticky deposits.

- Water in Fuel – promotes rust and knocks out the fuel’s natural lubrication.

- Microbial Growth (Diesel Bug) – forms a slimy sludge that clogs filters.

- Rust & Sediment – flakes from aging tanks end up in injector tips.

- Accidental DEF Contamination – Diesel Exhaust Fluid inside the fuel system spells instant failure.

For specific heavy-duty challenges, see our insight on Mack Truck Injector Problems.

2. Clogging & Buildup

Even with clean fuel, deposits form over time.

- Carbon Deposits – combustion by-products restrict spray holes.

- Heat Soak – hot shut-downs solidify waxy fuel components at the tip.

- Additive Imbalance – the wrong (or missing) detergents accelerate varnish.

Once heavily clogged, the only reliable fix is professional off-engine cleaning—learn more about how to clean common-rail diesel injectors.

3. Mechanical or Electrical Failure

- Internal Wear or Corrosion – water and poor fuel strip protective layers.

- Cracked Injector Body – extreme pressure or heat; requires immediate replacement.

- Solenoid Failure / Bad ECU Signal – injector never opens (or never closes).

- Damaged O-rings & Seals – external leaks raise fire risk and reduce mileage.

- Hydro-Lock Risk – a leaking injector fills the cylinder with fuel, bending rods.

Want a broader background on diesel fuel itself? Check out this quick primer on diesel fuel to see why cleanliness is so critical.

From Diagnosis to Solution: A Practical Guide to Fixing Fuel Injector Problems

Once you suspect injector trouble, take a systematic approach so you repair the right part, not just the symptom.

Step-by-Step Diagnosis

- Visual Inspection – look for external leaks, cracked connectors, or chafed wiring.

- Stethoscope Test – a healthy injector “clicks” every time it opens.

- OBD-II Scan – codes such as P0087 (low rail pressure) or P0201–P0212 (cylinder-specific misfire) narrow the search.

- Balance-Rate or Return-Flow Test – compares fueling of each cylinder on a running engine.

- Leak-Down Test – checks for internal dribble that causes hard starts or hydro-lock.

- Bench Testing & Ultrasonic Cleaning – the gold standard for confirming flow, spray pattern, and restoring performance. We offer full diesel injector testing services.

Fix Options at a Glance

| Option | Best For | Pros | Cons |

|---|---|---|---|

| In-Tank Cleaning Additive | Light deposits, preventive maintenance | Inexpensive; DIY | Limited effectiveness on severe clogging |

| Off-Engine Ultrasonic Cleaning | Moderate clogging, uneven spray patterns | Restores OEM flow; keeps your original injectors | Requires removal; modest labor cost |

| Injector Repair/Rebuild | Worn seals, minor mechanical issues | Cost-effective versus new; extends life | Not possible if body is cracked or solenoid failed |

| Full Replacement | Cracked body, severe wear, electrical failure | Restores like-new reliability; warranty available | Highest parts cost; labor to install |

Prevention Pays Off

- Source fuel from TOP TIER™ suppliers.

- Replace fuel filters on schedule.

- Use a quality additive that contains detergents and lubricity improvers.

- Never run the tank to empty—sediment concentrates at the bottom.

- Schedule periodic professional injector cleaning, especially for high-pressure common-rail engines.

A small investment in maintenance is far cheaper than unexpected downtime. If replacement becomes necessary, G2 Diesel Products can supply precision-engineered injectors for Volvo, Mack, Kenworth, and Paccar applications—often with industry-leading lead times.

Frequently Asked Questions about Fuel Injector Health

We often hear similar questions from our customers about fuel injector problems. It's completely understandable to have these concerns, especially when your livelihood depends on your heavy-duty truck. Here are some of the most common ones we encounter:

Can a single bad fuel injector damage an engine?

Absolutely, yes! It might seem like just one small part, but don't underestimate the power of a single faulty fuel injector to wreak havoc on your engine. Fuel injector problems, even if they start small, can quickly snowball into much bigger, more expensive issues.

Imagine an injector that's leaking. Instead of a precise, atomized spray, it's just dripping fuel into the cylinder. This sneaky drip can wash away the vital lubricating oil from the cylinder walls. Think of it like trying to run your car without enough oil – it leads to extra friction and accelerated wear on those crucial pistons and rings. Worse yet, if too much fuel collects, your engine can suffer from what we call 'hydro-lock.' This is where the piston tries to compress liquid fuel, which, unlike air, simply won't compress. The result? Bent connecting rods or even a cracked engine block. Ouch!

Now, what if an injector gets clogged? Instead of too much fuel, it's not delivering enough. This creates a "lean" condition in that cylinder – too much air, not enough fuel. When this happens, temperatures inside the cylinder can skyrocket, leading to pre-ignition or engine knock. This "knock" isn't just an annoying sound; it puts incredible stress on engine parts and can quickly lead to damaged pistons, burnt valves, or even a blown head gasket. So, yes, one "bad apple" injector really can spoil the whole engine, leading to a costly ripple effect.

What is the average cost to fix fuel injector problems?

The question everyone wants to know: "How much will this cost me?" The truth is, fixing fuel injector problems can range from a very small investment to a more significant one, depending on exactly what's wrong and what kind of vehicle you have.

For minor issues, like slight carbon buildup, you might start with a bottle of quality fuel injector cleaner that you simply add to your fuel tank. This is often the most budget-friendly first step.

If the problem is more stubborn, or if your injectors are partially clogged, professional off-engine ultrasonic cleaning is often a fantastic solution. This involves removing the injectors and giving them a deep, thorough clean to restore their performance. Many experts agree this is often the "only true and tested way to properly clean fuel injectors." While it requires a bit more time and effort, it's a very effective way to restore performance without full replacement.

However, if an injector is truly broken – perhaps it's mechanically worn out, has internal corrosion, or is even cracked – then replacement is necessary. This is typically the most expensive option, as it involves the cost of new parts and the labor to install them. But remember, investing in high-quality replacement parts is an investment in your truck's future and reliability. For more in-depth information, you can check out our guide on diesel fuel injector cost.

Are certain trucks more prone to injector issues?

It's true that all fuel injectors, regardless of the truck they're in, will eventually experience wear and tear. They work incredibly hard! However, when it comes to heavy-duty diesel trucks, there's a bit more to consider.

Modern diesel engines, especially those with high-pressure common rail (HPCR) systems, are marvels of engineering. They're incredibly efficient, but this precision comes with a trade-off: they are extremely sensitive to fuel quality and contamination. Their tiny internal tolerances mean that even microscopic particles or a little bit of water can cause fuel injector problems pretty quickly.

This sensitivity means that while no truck is immune, specific models like the Volvo D13, or any engine design with particular vulnerabilities in its fuel system, truly benefit from diligent maintenance and top-notch fuel. These workhorses of the road, which power so much of our economy, demand that extra bit of care. Proactive maintenance and choosing high-quality components are key to keeping them running strong and avoiding those complex, costly fixes. For more detailed insights, you can read about precision injection in Volvo D13 fuel injectors.

Conclusion: Proactive Care for Peak Performance

We've journeyed through the ins and outs of fuel injector problems, from early warning signs to major failures. The takeaway is simple: proactive maintenance saves money, protects your engines, and keeps your fleet on schedule.

When cleaning or repair no longer make sense, trust G2 Diesel Products for high-quality, precision-engineered injectors built for Volvo, Mack, Kenworth, and Paccar trucks. Our quick lead times, innovative designs, and customer-specific packaging help you get back on the road—fast.

Ready to boost uptime and cut fuel costs? Explore our lineup, including Cummins XPI Injectors, or call us today to learn how we can power your fleet’s success.