Fuel Injection Systems Explained: What Powers Your Ride?

Why Fuel Injection Systems Are Critical for Modern Engines

Fuel injection is the process of delivering precisely metered fuel into an engine using computer-controlled, high-pressure injectors. This system has completely replaced carburetors in modern vehicles, becoming the standard for both gasoline and diesel engines worldwide.

Key facts about fuel injection:

Precision: Controls exact fuel amounts for optimal combustion

Efficiency: Improves fuel economy by 10-30% over carburetors

Performance: Delivers more power and smoother operation

Emissions: Reduces harmful pollutants to meet strict standards

Universal: Used in all cars manufactured since 1990

The last carburetor-equipped car, the Subaru Justy, rolled off the assembly line in 1990. Since then, fuel injection has become the heart of every modern engine, from compact cars to heavy-duty diesel trucks.

The transition happened because fuel injection offers:

Better fuel atomization - Creates a fine mist for complete burning

Computer control - Adjusts fuel delivery thousands of times per second

Consistent performance - Works reliably in all weather and altitudes

Lower emissions - Meets increasingly strict environmental standards

For fleet managers, understanding fuel injection is crucial. Your Volvo, Mack, Kenworth, and Paccar trucks all depend on sophisticated injection systems that require quality components for reliable operation and minimal downtime.

Whether it's a port injection system in a gasoline engine or a high-pressure common rail system in your diesel fleet, fuel injection technology determines your engine's power, efficiency, and longevity.

The Evolution of Fuel Delivery: From Carburetors to Modern Injection

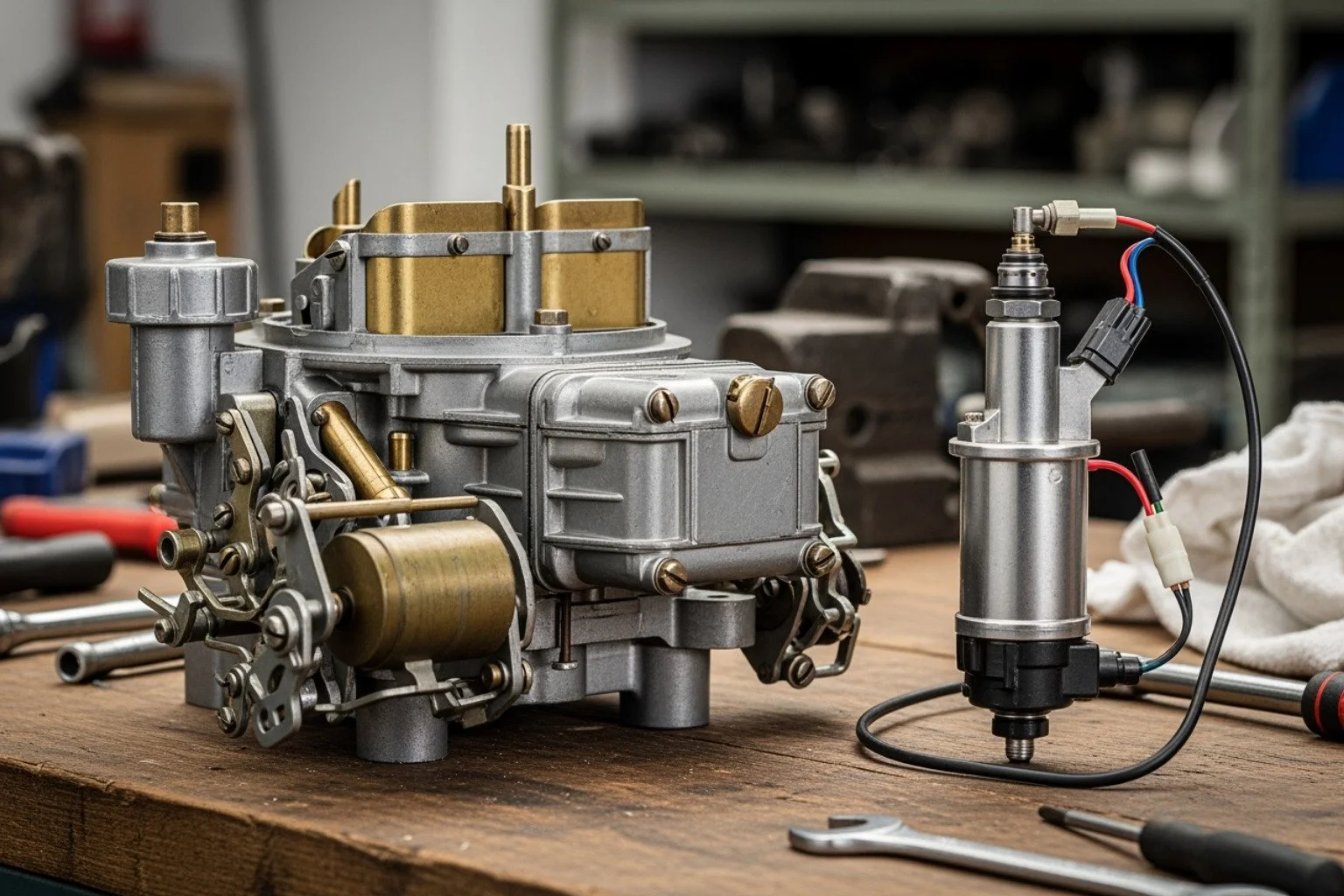

For most of the 20th century, the carburetor was the heart of the automobile engine. This purely mechanical device, a marvel of analog engineering, was responsible for mixing air and fuel before they entered the combustion chamber. While it served its purpose effectively for decades, the carburetor was fundamentally imprecise. It relied on the Venturi effect—a pressure drop created by air rushing through a constriction—to draw fuel into the airstream. This method was susceptible to changes in temperature, altitude, and engine load, making it difficult to maintain the ideal air-fuel mixture under all conditions. As the automotive world demanded greater efficiency and cleaner air, the carburetor's days were numbered.

Fuel injection was not a novel concept born in the digital age. The idea of injecting fuel under pressure dates back to the late 1800s with early diesel engines. However, it was World War II aviation that truly showcased its superiority. Fighter planes equipped with direct fuel injection could perform aggressive aerial maneuvers, including negative-G dives, without the engine sputtering or stalling—a common and dangerous problem for carbureted aircraft where gravity could disrupt fuel flow. The automotive world took notice. In 1954, Mercedes-Benz stunned the public with its 300SL “Gullwing” sports car, the first production passenger vehicle to feature gasoline direct injection, adapting technology proven in the skies for the road.

The real game-changer, however, was the integration of electronics. Pioneering systems like Bosch's D-Jetronic (pressure-sensing) and L-Jetronic (airflow-sensing) in the late 1960s and 1970s marked the beginning of the digital revolution. For the first time, an Engine Control Unit (ECU) could take sensor inputs and make intelligent decisions about fuel delivery. By the 1980s, as microprocessors became more powerful and affordable, electronic fuel injection (EFI) began its takeover, delivering a level of precision that was simply unattainable with mechanical systems.

Why Carburetors Were Replaced

The primary drivers for replacing carburetors were stricter emissions laws and the relentless demand for better fuel economy. In the United States, the Clean Air Act of 1970 and its subsequent amendments set firm targets for reducing pollutants like unburnt hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx). Carburetors, with their inherent inability to consistently maintain the precise stoichiometric air-fuel ratio (14.7 parts air to 1 part fuel for gasoline), simply couldn't meet these new standards. They were analog devices in a world demanding digital accuracy.

Fundamentally, a carburetor creates an inconsistent mixture that varies with engine speed, load, and atmospheric conditions. This led to a host of well-known issues: difficult cold starts requiring a manual or automatic choke, rough idling, hesitation upon acceleration, and a sensitivity to altitude changes that could leave an engine starved for fuel or running too rich. Late-stage carburetors became incredibly complex, with a labyrinth of vacuum hoses and auxiliary devices in a desperate attempt to meet new demands, making them a nightmare to tune and maintain. Fuel injection solved all these problems by using a network of sensors to adapt its strategy in real-time, thousands of times per second.

Key Milestones in Fuel Injection History

The journey to today's sophisticated systems happened in distinct, revolutionary stages:

1950s: Mechanical injection makes its passenger car debut. The 1954 Mercedes-Benz 300SL is the first to feature gasoline direct injection, while the 1957 Chevrolet Corvette offered a mechanical port-injection system as a high-performance option.

1958: The Chrysler Electrojector, one of the very first electronic fuel injection (EFI) systems, is offered on several high-end models. Though complex and rare, it proved that computer-controlled fueling was the future.

1980s: EFI becomes the dominant technology in European and Japanese markets as manufacturers race to meet emissions regulations and consumer demands for performance and efficiency. American manufacturers quickly follow suit.

1990: The last carbureted passenger car sold in the United States, the Subaru Justy, is produced, officially marking the end of the carburetor era in the mainstream market.

1997: Mitsubishi launches the first mass-produced Gasoline Direct Injection (GDI) engine in the Japanese market, reintroducing the concept of in-cylinder injection to the mainstream for improved efficiency.

1999: Alfa Romeo introduces the 156 JTD, the first passenger car to use a common rail diesel injection system. This technology, offering high pressure and precise control, would go on to revolutionize the diesel engine industry, becoming the standard for everything from compact cars to the heavy-duty Volvo, Mack, Kenworth, and Paccar trucks used in commercial fleets today.

Understanding the Core Components of a Fuel Injection System

A modern fuel injection system is a symphony of high-pressure hydraulics and advanced digital electronics, all working in perfect harmony to achieve one goal: efficient combustion. The core principle is straightforward: get the right amount of fuel to the right place at exactly the right time. To achieve this, the system relies on a network of components, each with a critical role to play.

The journey begins in the fuel tank, where an electric, low-pressure fuel pump (often called a lift pump) sends gasoline or diesel through fuel lines toward the engine. Along the way, the fuel passes through at least one fuel filter, a crucial component that traps rust, dirt, and other contaminants that could otherwise damage the high-precision injectors.

For high-pressure systems (like GDI and all diesels), the fuel then arrives at a mechanical, engine-driven high-pressure fuel pump. This pump boosts the fuel pressure from around 50-60 psi to thousands, or even tens of thousands, of psi.

The high-pressure fuel is then supplied to the fuel rail, a manifold that acts as a pressurized reservoir, ensuring that all injectors have a constant supply of fuel ready to be fired. A pressure regulator or sensor monitors the pressure in the rail and bleeds off any excess to maintain a consistent level.

Finally, the fuel injectors—electronically controlled valves—spray a fine, atomized mist of fuel into the engine. The entire performance is orchestrated by the Engine Control Unit (ECU), which processes information from a host of engine sensors.

The Brains of the Operation: The ECU and Engine Sensors

The Engine Control Unit (ECU), also known as the Engine Control Module (ECM), is the powerful onboard computer at the heart of the system. It uses complex software maps and algorithms to calculate the precise amount of fuel needed for every single combustion event. Its primary output is the injector pulse width—the tiny fraction of a second (measured in milliseconds) that each injector is commanded to stay open. To make this calculation, the ECU relies on a constant stream of data from a network of sensors:

Mass Airflow (MAF) Sensor: Positioned between the air filter and the throttle body, this sensor measures the mass of the air entering the engine. This is the most critical input for the ECU's primary fuel calculation, as the computer needs to know exactly how much oxygen is available to match it with the correct amount of fuel.

Manifold Absolute Pressure (MAP) Sensor: Often used in conjunction with or instead of a MAF sensor, the MAP sensor measures air pressure (or vacuum) inside the intake manifold. This data helps the ECU determine the engine's load—how hard it is working.

Throttle Position Sensor (TPS): This sensor is connected to the throttle plate (which is controlled by the accelerator pedal) and reports to the ECU exactly how far the driver has pressed the pedal. This signals driver intent and the demand for power.

Coolant Temperature Sensor (CTS): By monitoring the temperature of the engine's coolant, this sensor tells the ECU whether the engine is cold or at operating temperature. A cold engine is less efficient at vaporizing fuel, so the ECU provides a richer fuel mixture (more fuel) for smooth starting and idling, similar to a carburetor's choke.

Crankshaft and Camshaft Position Sensors: These two sensors work together to tell the ECU the engine's rotational speed (RPM) and the exact position of the pistons and valves. This information is vital for timing the fuel injection events precisely with the engine's intake and combustion strokes.

Oxygen (O2) Sensor(s): Located in the exhaust stream, these sensors act as the system's crucial feedback loop. They measure the amount of unburnt oxygen in the exhaust gases. A high oxygen reading indicates a lean mixture (too little fuel), while a low reading signifies a rich mixture (too much fuel). The ECU uses this real-time data to make constant, minute adjustments (known as fuel trims) to keep the air-fuel ratio perfectly balanced for complete combustion and optimal catalytic converter efficiency.

The Heart of the System: Fuel Pump and Injectors

If the ECU is the brain, the fuel pump and injectors are the heart and arteries. The high-pressure fuel pump is an incredible piece of mechanical engineering, generating immense pressures that can reach over 36,000 psi (2,500 bar) in modern heavy-duty diesel systems. This extreme pressure is essential for atomizing the fuel into a microscopic mist, which increases its surface area and allows it to mix with air and burn more completely and efficiently.

The fuel injector itself is a marvel of precision. It is a fast-acting electromechanical valve. When the ECU sends a precisely timed electrical pulse, a tiny electromagnet (solenoid) or piezoelectric stack inside the injector activates, lifting a plunger or needle valve from its seat. This opens the valve, allowing the highly pressurized fuel to spray out through a precisely engineered nozzle with multiple microscopic holes. This action creates the fine fuel atomization required for clean and powerful combustion. The exact amount of fuel delivered is controlled with incredible accuracy by the injector's pulse width. For fleet managers, the reliability and precision of these components are non-negotiable. Using high-quality, durable parts from specialists is the key to keeping trucks on the road and operating costs down. To learn more, see How Injectors Work.

The Main Types of Fuel Injection Systems

While the term fuel injection is used universally, not all systems are created equal. They have evolved significantly over the decades, with designs tailored to different cost, performance, and emissions requirements. The most fundamental difference between these systems is where the fuel meets the air—either outside the combustion chamber in the intake manifold (an external mixture formation) or directly inside the combustion chamber itself (an internal mixture formation).

Feature Single-Point Injection (SPI) Multi-Point Injection (MPI) Direct Injection (DI) Injector Location Throttle body (before intake manifold) Intake port (one per cylinder) Directly into combustion chamber Precision Low Medium to High Very High Cost Low Medium High Complexity Low Medium High Fuel Atomization Fair Good Excellent Fuel Economy Fair Good Excellent Emissions Control Fair Good Excellent Typical Use Case Older, entry-level engines (now obsolete) Most modern gasoline engines (port-injected) Modern gasoline & all diesel engines

Single-Point Injection (SPI) / Throttle Body Injection (TBI)

Single-Point Injection, most commonly known as Throttle Body Injection (TBI), was the simplest and earliest form of electronic fuel injection to gain widespread use. It was designed as a straightforward, cost-effective replacement for the carburetor. The system uses one or two fuel injectors mounted centrally in a throttle body, which looks very much like the base of a carburetor. These injectors spray fuel into the top of the intake manifold, where it mixes with air before being distributed to the cylinders through intake runners.

While TBI was a definite improvement over carburetors in terms of reliability and cold-start performance, it was still a compromise. Because the fuel had to travel a long and often uneven path to reach the cylinders, fuel distribution was often unequal. Some cylinders would run slightly richer or leaner than others, leading to suboptimal performance and efficiency. This system was a crucial transitional technology used from roughly 1980 to 1995, bridging the gap between the analog and digital eras before being made obsolete by more advanced designs.

Multi-Point Fuel Injection (MPI) / Port Fuel Injection (PFI)

Multi-Point Fuel Injection (MPI), also called Port Fuel Injection (PFI), was the next major evolutionary step. Instead of a central injector, MPI systems assign a dedicated fuel injector to each cylinder, mounting it in the intake manifold right at the cylinder's intake port. This ensures that each cylinder receives a much more precise and equal amount of fuel, creating a better-quality air-fuel mixture just before it enters the combustion chamber.

Early MPI systems used "batch fire," where all injectors would pulse at the same time, once per engine revolution. This was soon refined into "sequential fuel injection" (SFI), a much more precise method where the ECU times the firing of each injector to coincide with the intake stroke of its specific cylinder. This just-in-time delivery prevents fuel from pooling on the back of the intake valve and leads to better fuel atomization, sharper throttle response, increased power, and improved fuel economy. While MPI systems can be susceptible to carbon buildup on the intake valves over time (since the fuel is injected behind them), they remain a robust, reliable, and extremely common technology in gasoline engines today.

Direct Fuel Injection (GDI & Common Rail)

Direct injection is the pinnacle of current fuel delivery technology, moving the point of injection from the intake port directly into the hostile environment of the combustion chamber. This requires injectors and fuel systems built to withstand extreme heat and pressure. The benefits, however, are substantial. Injecting fuel directly into the cylinder provides superior fuel atomization and allows for a significant charge cooling effect, where the vaporizing fuel dramatically cools the air in the chamber. This cooling effect suppresses engine knock (detonation), which in turn allows engineers to use higher compression ratios, resulting in greater thermal efficiency, more power, and better fuel economy from a smaller displacement engine.

In gasoline engines, this technology is known as Gasoline Direct Injection (GDI). In diesel engines, where direct injection has always been a necessity, the dominant system is the Common Rail. This design uses a high-pressure pump to charge a single fuel rail (the "common rail") that feeds all the injectors. This decouples pressure generation from the injection event, allowing for extremely high and stable injection pressures and giving the ECU precise control over injection timing and quantity. This level of control is essential for the power, efficiency, and emissions compliance of modern heavy-duty trucks from manufacturers like Volvo, Mack, Kenworth, and Paccar. You can learn more about these advanced systems at What is a Common Rail Injector?.

Fuel Injection in Petrol vs. Diesel Engines

While both modern petrol (gasoline) and diesel engines rely on fuel injection, the systems are engineered to serve two fundamentally different combustion processes. The core distinction lies in how the fuel is ignited:

Petrol engines use spark-ignition. A relatively low-pressure system prepares a combustible mixture of fuel and air, which is then drawn into the cylinder, compressed, and ignited by a precisely timed high-voltage spark from a spark plug.

Diesel engines use compression-ignition. Air alone is drawn into the cylinder and compressed to an extreme degree, which heats it to a temperature well above the auto-ignition point of diesel fuel. At the precise moment, fuel is injected at immense pressure, and it ignites instantly upon contact with the superheated air—no spark plug is needed.

This difference explains why all diesel engines, even the earliest ones, have required fuel injection. A carburetor, which relies on engine vacuum, is incapable of generating the immense pressures needed to force fuel into a highly compressed cylinder. The pressure differential is staggering: a typical port-injected gasoline system operates at a gentle 40-60 psi, and even modern GDI systems run at 3,000-5,000 psi. In contrast, modern common rail diesel systems operate at pressures routinely exceeding 30,000 psi (over 2,000 bar), with the latest systems pushing toward 45,000 psi. This extreme pressure is necessary to atomize the thicker, less volatile diesel fuel into a microscopic mist, ensuring it mixes with the air and burns completely and cleanly.

Gasoline Direct Injection (GDI)

In the quest for greater efficiency, most modern gasoline engines have adopted Gasoline Direct Injection (GDI). By injecting fuel directly into the combustion chamber, GDI allows for advanced combustion strategies that are impossible with port injection. One such strategy is stratified charge mode, typically used during light-load cruising. The injector creates a small, rich pocket of air-fuel mixture near the spark plug, surrounded by very lean air elsewhere in the cylinder. This allows the engine to run on an overall lean mixture, saving significant fuel. When the driver demands power, the system instantly switches to a homogeneous mode, injecting fuel earlier in the intake stroke to create a uniform, power-rich mixture throughout the cylinder. Furthermore, GDI provides a powerful cooling effect inside the chamber as the fuel vaporizes, which allows for higher compression ratios, boosting thermal efficiency and power output. For more on gasoline, see How Gasoline Works.

Diesel Fuel Injection Systems

Diesel fuel injection is a world of extreme pressures and microscopic precision. The systems found in today's heavy-duty trucks from Volvo, Mack, Kenworth, and Paccar are marvels of engineering, built for immense power and long-haul durability. The extremely high pressures are critical for atomizing the dense diesel fuel for clean, efficient combustion.

The most prevalent design is the Common Rail system. A high-pressure pump pressurizes fuel in a single rail that acts as a shared accumulator for all injectors. This design allows the ECU to control injection events with incredible precision, independent of engine speed. Learn more at How Do Common Rail Injectors Work.

Another design used in some heavy-duty engines is the Electronic Unit Injector (EUI). This system combines the high-pressure pump and the injector into a single, compact unit for each cylinder, actuated by the engine's camshaft. This eliminates the need for high-pressure fuel lines and can generate very high injection pressures. Read more at How Electronic Unit Injector Works.

Modern diesel injectors, controlled by the ECU, can perform multiple injection events within a single combustion cycle. This includes:

A small pilot injection that occurs just before the main charge. This smooths out the combustion process, significantly reducing the characteristic "diesel clatter" and lowering NOx emissions.

The main injection, which delivers the bulk of the fuel to produce power and torque.

One or more post-injections that occur after the main event. These late injections of fuel help burn off soot in the exhaust and are critical for the operation of the Diesel Particulate Filter (DPF) and other emissions aftertreatment systems. This level of precision is what makes modern diesel engines simultaneously powerful, efficient, and compliant with strict emissions laws. Explore our resources on Diesel Fuel Injectors for more information.

Benefits, Maintenance, and the Future of Fuel Injection

The universal adoption of fuel injection was not merely a trend; it was a fundamental leap forward that brought transformative benefits to every aspect of engine operation and vehicle ownership.

Better Fuel Economy: By delivering the precise amount of fuel required for any given load and eliminating waste, fuel injection systems improve mileage by a significant margin, often 10-30% or more compared to their carbureted predecessors.

Increased Power and Torque: Optimized air-fuel mixtures and superior fuel atomization allow the engine to extract more energy from every single drop of fuel, resulting in higher horsepower and torque figures across the entire RPM range.

Lower Harmful Emissions: The ability to maintain a perfect stoichiometric air-fuel ratio allows the catalytic converter to operate at peak efficiency, dramatically cutting pollutants like carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) to meet modern environmental standards.

Improved Reliability and Drivability: Fuel injection systems self-adjust to changes in altitude and ambient temperature, ensuring flawless cold starts, smooth idling, and consistent performance without the need for a manual choke or seasonal adjustments.

Smoother Engine Operation: By ensuring each cylinder receives an equal fuel charge, fuel injection minimizes vibration, engine knocking, and misfires, creating a more refined, quieter, and more pleasant driving experience.

Common Maintenance for Your Fuel Injection System

While modern fuel injection systems are remarkably reliable, they are not immune to problems. Recognizing the early warning signs can prevent costly downtime and cascading failures. Key symptoms to watch for include:

Rough idle or engine shaking and vibrating when the vehicle is stopped.

Engine misfires, which can be felt as a stutter, hesitation, or stumble during acceleration.

Poor acceleration or a general feeling of sluggishness and lack of power, especially under load.

Increased fuel consumption, a direct and painful hit to your wallet or a fleet's operating costs.

Check engine light illuminating on the dashboard, which is the ECU's way of telling you it has detected a fault in the system, often related to the fuel mixture.

The most common culprit behind these issues is clogged injectors. Over thousands of miles, carbon deposits and other contaminants from fuel can bake onto the injector nozzle's microscopic openings. This disrupts the carefully engineered spray pattern, causing the injector to drip or stream fuel instead of atomizing it into a fine mist. This leads to incomplete combustion, which is the root cause of the symptoms above. For GDI engines, a separate issue is carbon buildup on the intake valves, as there is no fuel constantly washing over them to keep them clean.

Preventive maintenance is the best strategy:

Fuel Filter Replacement: This is the single most important maintenance item. Regularly replacing your fuel filters according to the manufacturer's schedule is cheap insurance to protect your expensive pump and injectors from damaging contaminants.

Using Quality Fuel: Consistently using high-quality, Top Tier certified fuels that contain enhanced detergent packages helps prevent deposit formation and keeps the entire fuel system cleaner.

Professional Injector Cleaning: For existing clogs, specialized off-car ultrasonic cleaning and flow-testing can often restore injector performance to factory specifications. For more, see How to Clean Common Rail Diesel Injectors.

Understanding potential issues can help you avoid catastrophic failures. For more guidance, see Troubleshooting Electronic Fuel Injection Problems and our guide to Diesel Fuel Injector Problems.

Future Trends in Fuel Injection Technology

The evolution of fuel injection is far from over. Engineers are constantly pushing the boundaries to squeeze even more efficiency and power from the internal combustion engine. Key trends include:

Dual Injection Systems: A growing number of manufacturers are building engines that feature both a direct injector and a port injector for each cylinder. This hybrid approach uses port injection at low loads to improve mixture formation and keep intake valves clean, while leveraging direct injection under high loads for maximum power and efficiency. The ECU intelligently blends the two systems for optimal results.

Higher Injection Pressures: The push for higher pressures, especially in diesel and GDI systems, is relentless. Pressures approaching 45,000 psi (3,000 bar) and beyond allow for even finer fuel atomization, leading to faster, cleaner, and more complete combustion.

Advanced Piezoelectric Injectors: While traditional injectors use a solenoid (electromagnet), piezoelectric injectors use a crystal stack that expands instantly when voltage is applied. They can open and close up to five times faster than solenoids, allowing for even more precise control and a greater number of multiple-injection events per combustion cycle.

Water Injection: A technology once reserved for racing and aircraft is making a comeback. Injecting a fine mist of water into the intake or cylinder provides a powerful charge-cooling effect, drastically reducing the risk of knock and allowing for higher boost and compression, which translates to more power and lower NOx emissions.

Integration with Hybrid Systems and Alternative Fuels: Fuel injection systems are being adapted to work seamlessly with hybrid-electric powertrains, optimizing engine on/off cycles. They are also being engineered to handle a variety of alternative and synthetic fuels (e-fuels), which will be crucial for the long-term viability of the internal combustion engine.

Frequently Asked Questions about Fuel Injection

Here are straightforward answers to the most common questions we receive about fuel injection systems.

What is the main difference between fuel injection and a carburetor?

A carburetor is a passive mechanical device that uses engine vacuum and the Venturi effect to suck fuel into the airstream. It is imprecise and cannot easily adapt to changing conditions. Fuel injection is an active system that uses a high-pressure pump and computer-controlled injectors to force a precise, atomized mist of fuel into the engine. The key difference is the digital precision and real-time adaptability of fuel injection, which is impossible for a mechanical carburetor to achieve.

What are the signs of a failing fuel injector?

Common signs include the check engine light turning on, a rough or unstable idle, engine misfires (which feel like a hesitation or stuttering), a noticeable loss of power and poor acceleration, and a sudden drop in fuel economy. In some cases, you might also smell raw fuel from the engine bay or see black smoke from the exhaust, indicating an injector is stuck open and dumping excess fuel into the cylinder. These symptoms indicate that one or more cylinders are not receiving the correct amount of fuel for proper combustion.

Can you convert an old car from a carburetor to fuel injection?

Yes, it is a popular upgrade for classic cars. Numerous aftermarket companies offer complete EFI conversion kits. The process typically involves replacing the carburetor with a throttle body injection unit or installing a new intake manifold for multi-point injection. It also requires adding a high-pressure fuel pump, an ECU, an oxygen sensor, and other necessary sensors. The benefits are significant: improved reliability, better fuel economy, easier cold starts, and smoother performance. However, it is a complex and potentially costly project that is best handled by experienced mechanics or skilled hobbyists. This conversion is common for classic gasoline cars, but not necessary for modern diesel trucks, which have always used fuel injection.

What is the difference between a clogged and a bad fuel injector?

A clogged injector is one where performance is compromised by physical carbon deposits blocking the nozzle, which disrupts the spray pattern and flow rate. In many cases, a clogged injector is still mechanically and electrically sound and can be restored to full function through professional off-car ultrasonic cleaning. A bad or failed injector, on the other hand, has an internal mechanical or electrical failure. This could be a burnt-out solenoid coil that no longer opens the valve, a weak or broken internal spring, a worn-out valve seat, or a cracked injector body. A bad injector cannot be fixed by cleaning and must be replaced entirely.

How often should I use a fuel injector cleaner additive?

The effectiveness of over-the-counter fuel injector cleaners is a topic of debate. While using a high-quality cleaner from a reputable brand periodically (e.g., every 5,000-10,000 miles) may help prevent minor deposit buildup in a healthy system, it is not a cure for a severely clogged or failing injector. The best preventative measure is to consistently use high-quality, Top Tier certified fuel, which already contains a higher concentration of effective detergents. If you are already experiencing symptoms of a clogged injector, a bottled additive is unlikely to solve the problem. In such cases, a professional cleaning service or injector replacement is the recommended course of action.

Conclusion

From a mechanical marvel to a digital necessity, fuel injection has revolutionized engine performance. It is the key to the modern engine's balance of fuel efficiency, power, and environmental responsibility. Every time you turn the key, you're witnessing decades of engineering excellence at work.

For fleet managers running heavy-duty diesel engines, the stakes are even higher. Your Volvo, Mack, Kenworth, and Paccar trucks depend on injection systems that can withstand extreme pressures and demanding schedules. A failing injector means downtime, lost revenue, and frustrated customers.

This is where the precision and durability of high-quality components become absolutely critical. The difference between a reliable injector and a substandard one can mean the difference between smooth operations and costly breakdowns.

At G2 Diesel Products, we understand that your livelihood depends on reliability. Our commitment is to manufacture high-quality diesel fuel injectors that deliver consistent performance, mile after mile. The future of fuel injection will continue to evolve, but the need for dependable components will remain constant.

To keep your fleet running strong and ensure every drop of fuel translates into optimal power and efficiency, explore our range of high-quality diesel fuel injectors. When reliability matters most, trust in components designed to meet the rigorous demands of your diesel applications.