Injector First Aid: Top Repair Kits for Diesel Engines

Breathing New Life into Your Diesel Engine

Diesel injector repair kits provide a cost-effective way to restore engine performance without the high cost of complete injector replacement. These kits contain the essential O-rings, seals, gaskets, and internal parts needed to rebuild worn or failing fuel injectors.

Key aspects of diesel injector repair kits:

Components: Kits range from basic seal sets to master rebuild kits with nozzles, valves, and specialized tools.

Applications: Designed for common rail, unit injector, and conventional diesel systems.

Cost Savings: Can be up to 70% less expensive than buying new injectors.

Compatibility: Kits are specific to injector technology and engine models.

Your diesel engine's fuel system is vital for performance and efficiency. When injectors fail, you'll notice symptoms like rough idling, black smoke, poor fuel economy, and hard starting. For fleet managers, minimizing downtime and controlling maintenance costs is a constant challenge. A failing injector doesn't always require an expensive replacement; often, a quality repair kit can restore proper fuel atomization and sealing at a fraction of the cost.

Modern diesel injectors operate under extreme pressures, causing seals and internal components to wear over time. A repair kit addresses these wear points with OEM-quality replacement parts, ensuring a reliable fix.

Is Your Engine Crying for Help? Signs of a Failing Injector

When a diesel engine's smooth hum turns into a cough or sputter, it's often a sign of failing injectors. Catching these warning signs early can save you from costly repairs and breakdowns.

Failing injectors disrupt fuel delivery, causing a domino effect on engine performance. Here are the key symptoms to watch for:

Loss of Power: Your truck may struggle to accelerate or feel sluggish, especially under load. This lost horsepower and torque is a primary indicator of injector issues.

Poor Fuel Economy: If you're burning through diesel faster than usual, faulty injectors are a likely culprit. They may be leaking fuel or creating an inefficient spray pattern, wasting fuel with every combustion cycle.

Excessive Smoke: Black smoke from the exhaust is a classic sign of unburnt fuel escaping the engine. Conversely, white smoke can indicate unvaporized fuel, also linked to injector problems.

Rough Running: Rough idling can make the entire cab vibrate, while engine misfires create a jerky, stuttering sensation as one or more cylinders fail to fire correctly.

Hard Starting: Difficulty starting the engine, especially in cold weather, often points to injectors that aren't delivering enough fuel for ignition.

Fuel Smell: A strong diesel odor around your truck can mean fuel is leaking from worn injector seals or gaskets.

Engine Knocking: A metallic pinging or rattling sound can occur when injectors deliver fuel at the wrong time or in the wrong amount, disrupting the engine's precise combustion timing.

Increased Emissions: Malfunctioning injectors lead to incomplete combustion, which increases harmful emissions and often goes hand-in-hand with visible smoke.

Fortunately, many of these issues can be resolved with a quality diesel injector repair kit before a full replacement is necessary. For a deeper dive into these problems, see our guide on Common Diesel Injector Problems.

What's Inside a Diesel Injector Repair Kit?

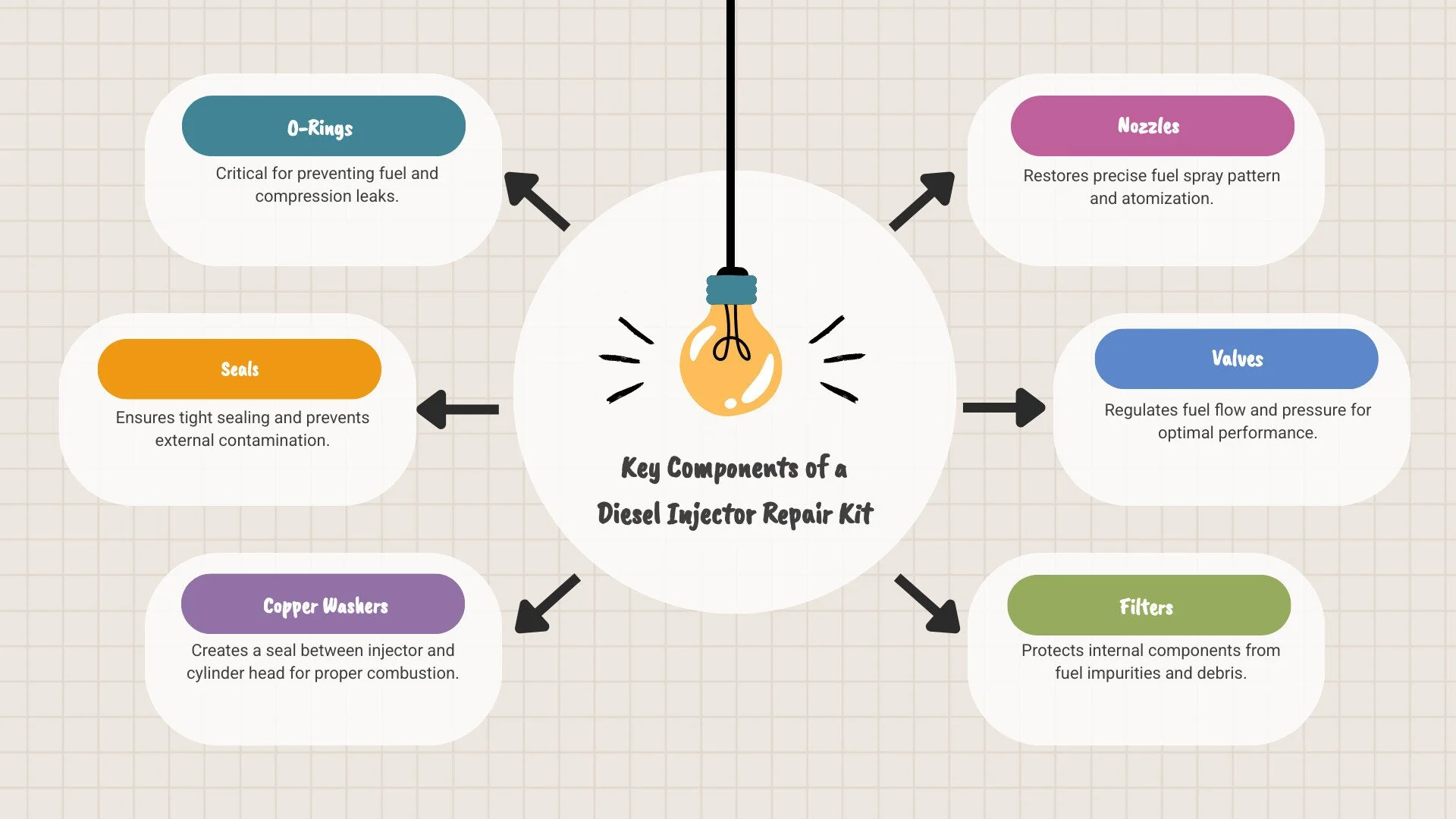

A diesel injector repair kit is like first aid for your engine, containing the necessary components to restore an injector's function without the cost of a new unit. The goal is to fix leaks and restore precise fuel delivery.

Kits typically include O-rings, seals, gaskets, and copper washers. More comprehensive kits also contain nozzles, internal valves, and filters. The exact contents depend on the injector type and the extent of the required repair. For a full overview of components, see our guide on Diesel Injector Replacement Parts.

Understanding the Role of Each Component

Sealing Components: O-rings and copper washers are crucial for preventing fuel leaks and containing combustion gases. A failed seal can waste fuel and lead to a loss of compression.

Internal Components: Nozzles and valves control fuel delivery. The nozzle atomizes diesel into a fine mist for efficient burning. Over time, nozzles can clog or wear, disrupting the spray pattern. Internal valves regulate the timing and amount of fuel injected. Wear on these parts leads to poor performance and higher emissions.

The Difference Between Basic and Deluxe Kits

Repair kits come in different levels to match the repair needs.

Basic Seal Kits: These are ideal for routine maintenance or fixing minor leaks. They contain the essential O-rings, seals, and copper washers to restore sealing integrity when the injector's internal parts are still in good condition.

Deluxe or Master Kits: For more extensive repairs, these kits include everything in a basic kit plus critical internal parts like new nozzles and control valves. They often come with specialized tools such as solenoid sockets or valve extractors, which are necessary for a proper rebuild and prevent damage during disassembly.

A master rebuild kit may include:

A complete set of O-rings and seals

High-pressure copper and sealing washers

A new, matched nozzle

A control valve assembly

Internal filters

Return line components

Specialized removal and installation tools

Bushings and plungers (for unit injectors)

Calibration shims and springs (where applicable)

These deluxe kits provide everything needed for a thorough restoration, addressing both leaks and internal wear.

Matching the Kit to Your Diesel Injector System

Using the right diesel injector repair kit is critical, as different diesel fuel systems have unique designs. You cannot use a one-size-fits-all kit. Injector technology has evolved to improve performance, boost fuel efficiency, and meet stricter emissions standards, leading to several distinct system types.

Understanding which kit matches your system ensures compatibility and restores performance. Our Diesel Fuel Injectors Overview provides more detail, but here’s how kits differ for the primary systems.

Kits for Common Rail (CRDI) Systems

Common rail systems are the modern standard, using a high-pressure rail to store fuel that is delivered to the injectors with electronic precision. This allows for multiple injections per cycle, resulting in better atomization, quieter operation, and lower emissions.

Repair kits for CRDI systems contain components built for extreme pressure and precision. Key parts include:

Control Valves: Regulate fuel flow and injection timing with microscopic accuracy.

Nozzle Nuts: Secure the nozzle while maintaining a high-pressure seal.

Ball Seats: Tiny but essential components for proper valve operation.

High-Pressure Seals: Specialized O-rings and filters designed to prevent leaks and contamination in environments exceeding 30,000 PSI.

Kits for Unit Injector Systems (EUI/HEUI)

Found in many heavy-duty trucks from Volvo, Mack, Kenworth, and Paccar, unit injectors combine the high-pressure pump and the nozzle into a single unit for each cylinder. This design requires a different set of repair components.

Repair kits for EUI/HEUI systems often include:

Plungers and Bushings: Mechanical parts that generate high pressure within the injector and are subject to wear.

Solenoid Assemblies: Control the electronic actuation of the injector.

Specialized Seals: O-rings and seals designed for the unique internal geometry of these combined pump-nozzle units.

Kits for Mechanical and Conventional Injectors

These injectors are the foundation of the diesel industry. Though simpler and operating at lower pressures, they are robust and still widely used. Repair is often more straightforward.

Repair kits for mechanical systems typically focus on:

Nozzle Replacement: The most common repair, as the nozzle tip wears from heat and carbon buildup.

Shims: Used to adjust the injector's opening pressure, which is critical for proper timing.

Springs: Ensure the nozzle valve opens and closes at the correct pressure; they can weaken over time.

Gaskets and Seals: Maintain the integrity of the injector body and prevent external fuel leaks.

The Ultimate Guide to Choosing a Diesel Injector Repair Kit

Picking the right diesel injector repair kit doesn't have to feel like solving a puzzle blindfolded. With a little know-how and the right approach, you can confidently select a kit that'll get your engine purring like new again.

The foundation of any successful repair starts with compatibility. Think of it like dating – you need the right match, or things just won't work out. Your engine model and year are crucial details because even the same manufacturer can make significant changes between model years. A 2015 Volvo D13 might need different components than a 2018 model, despite looking nearly identical on the outside.

The injector part number is your golden ticket to getting exactly what you need. This alphanumeric code is like your injector's fingerprint – unique and specific. Many quality diesel injector repair kits are cross-referenced with original equipment or aftermarket part numbers, making it easy to find the perfect match.

Your vehicle application matters too. A Cummins ISX engine has different requirements than a Detroit Diesel Series 60. At G2 Diesel Products, we specialize in Volvo, Mack, Kenworth, and Paccar trucks, so we understand these distinctions intimately.

Beyond getting the right fit, quality considerations separate the wheat from the chaff. We always recommend OEM-quality or premium aftermarket parts because your injectors work harder than a coffee shop barista during morning rush hour. They're constantly dealing with extreme pressure, heat, and chemical exposure.

The price versus value equation is where many people stumble. That bargain-basement kit might look tempting, but remember – you're investing in your engine's future. A slightly higher-priced kit with superior components and solid warranty coverage often saves money in the long run. Nobody wants to do the same repair twice! For insights on selecting top-quality components, check out our guide to Best Diesel Fuel Injectors.

Why Quality Matters: OEM-Quality and Premium Aftermarket

When we talk about quality in diesel injector repair kits, we're not just throwing around fancy marketing terms. These components live in one of the harshest environments imaginable – inside your engine's combustion chamber area.

Manufacturing tolerances are measured in thousandths of an inch. Imagine trying to thread a needle while wearing oven mitts – that's how precise these components need to be. Even tiny deviations can cause fuel leaks, wonky spray patterns, or premature wear. OEM-quality and premium aftermarket parts are manufactured to meet or exceed these exacting specifications.

Material durability isn't negotiable when you're dealing with diesel fuel, extreme temperatures, and crushing pressure. Quality seals and O-rings use advanced rubber compounds that laugh in the face of fuel exposure and temperature swings. Internal components often feature stainless steel construction and some even sport nickel plating to fight off corrosion like a superhero fights crime.

A solid warranty tells you everything about a manufacturer's confidence in their product. We've seen aftermarket parts backed by 1-year warranties, and some remanufactured products even come with 2-year coverage. That's not just peace of mind – that's protection for your investment. If you're curious about product conditions and what "new" or "used" really means, Learn about product conditions provides helpful clarity.

Choosing quality ensures long-term performance and reliability. Nobody wants to crawl under their truck again in six months because they tried to save a few bucks on inferior parts.

Reading the Fine Print: What to Look for in a Listing

Before you hit that "buy now" button, put on your detective hat and dig into the details. A good product listing is like a good friend – it tells you exactly what you're getting into.

Kit contents verification should be your first stop. Does the listing spell out exactly what's included? Is it a basic seal kit with just the essentials, or a comprehensive package with internal components? Vague descriptions like "complete repair kit" without specifics are red flags. You want detailed lists, not mystery boxes.

The return policy reveals a lot about a seller's character. What happens if the kit doesn't fit or arrives damaged? Look for clear, reasonable policies – something like 30 to 90 days for uninstalled, brand-new condition products shows the seller stands behind their merchandise.

Seller reputation and customer reviews are pure gold. A seller with thousands of positive feedback scores (like 99.5% positive feedback) and detailed seller ratings for accurate descriptions, shipping speed, and communication is worth their weight in diesel fuel. Pay special attention to reviews mentioning product quality and fitment accuracy.

Don't overlook included tools either. Remember those specialized tools we talked about earlier? If your repair needs them and you don't have them, a kit that includes solenoid sockets, extractors, or other specialized equipment can save you time and additional purchases.

Here's what smart buyers check before making their decision:

Compatibility details should include specific engine models, years, and injector part numbers – this ensures the kit fits your vehicle precisely. Component quality descriptions mentioning "OEM-quality," "premium aftermarket," or material specifications like stainless steel and nickel plating indicate durability and performance. Included tools should be clearly listed if specialized equipment is part of the package, saving you from additional purchases. Warranty terms showing length and coverage provide peace of mind and protection against premature failure. Price evaluation should balance cost-effectiveness with reliable, long-lasting repair potential.

Taking a few extra minutes to examine these details means you can confidently choose a diesel injector repair kit that'll serve you well for years to come.

The Repair Process: A Step-by-Step Overview

Installing a diesel injector repair kit is a rewarding but meticulous job. It demands patience, precision, and a focus on cleanliness. These are not simple components, so attention to detail is paramount.

Safety and cleanliness are the golden rules. Always disconnect the battery, relieve fuel system pressure, and wear protective gear. Your workspace and the engine bay must be spotless, as even a tiny speck of dirt can damage the sensitive fuel system. For more on the initial steps, our guide on How to Replace Diesel Injectors is a useful resource.

Preparation and Disassembly

Gather Tools: Collect your repair kit, specialized pullers or sockets, hand tools, a torque wrench, and cleaning supplies.

Clean the Area: Thoroughly clean the engine bay around the injectors to prevent debris from falling into the fuel system.

Disconnect Lines: Carefully relieve fuel pressure, then disconnect and label all fuel lines and electrical connectors.

Remove the Injector: Use a specialized puller if necessary. Some injectors can be stubborn.

Cap Openings: Immediately cap all open fuel ports and lines to prevent contamination.

Disassemble Carefully: Secure the injector on a clean workbench and follow the kit's instructions to disassemble it. Keep parts organized and note their orientation.

Installation of Your Diesel Injector Repair Kit

Clean All Components: Carefully clean every part of the injector to remove carbon and fuel residue. An ultrasonic cleaner is ideal.

Replace Seals and O-Rings: Lightly lubricate new seals with clean diesel fuel to prevent tearing during installation. Never install them dry.

Install New Internal Parts: Handle new nozzles and valves with care. Their precision surfaces are delicate.

Reassemble to Torque Specs: This is critical. Use a calibrated torque wrench to tighten all bolts and components to the manufacturer's exact specifications. Do not guess.

Follow Instructions: The kit's instructions are your roadmap to a successful repair. Follow them precisely.

Potential Risks of a DIY Repair

While DIY repair can save money, be aware of the risks. Modern injectors are complex, high-pressure components.

Complexity: Tolerances are measured in microns, and mistakes can be costly.

Specialized Tools: Many repairs are impossible without specific tools. Attempting a repair without them can damage parts.

Engine Damage: Improper installation can lead to fuel leaks, fire hazards, or catastrophic engine failure.

Contamination: Introducing dirt into the fuel system can cause widespread damage.

Calibration: Some rebuilt injectors require professional calibration to function correctly.

If you feel uncertain at any point, consult a Diesel Injector Specialist. Knowing when to call a professional is a smart decision.

Frequently Asked Questions about Diesel Injector Repair

Deciding how to handle a failing injector involves several common questions. Here are straightforward answers to help you make the right choice.

Is it better to repair or replace a diesel injector?

The decision depends on cost, the extent of the damage, and the injector's age.

Repair is a great option when dealing with minor wear, such as failing seals, clogged nozzles, or minor internal leaks. A diesel injector repair kit can save up to 70% compared to the cost of a new part.

Replace the injector if it has major damage, like a cracked body, severe internal erosion, or electrical failure. If one high-mileage injector fails from wear, others may soon follow, making a full set replacement a wise long-term investment.

For more on costs, review our guide on Diesel Fuel Injector Cost.

How long does a diesel injector repair take?

Time can vary significantly. A simple seal replacement on an easily accessible injector might take a skilled DIYer 1-2 hours per injector. A full rebuild with internal components is more involved, with professionals often quoting 1-4 hours per injector. The biggest variable is access difficulty; some engines require significant disassembly to reach the injectors, adding hours to the job. Rushing often leads to mistakes, so plan accordingly.

How do I know if the repair was successful?

A successful repair will result in noticeable improvements:

Smoother Idle: The engine should run smoothly without shaking or sputtering.

Improved Power: Acceleration should feel crisp and responsive.

Better Fuel Economy: Your mileage should return to normal or improve.

No Smoke or Leaks: The exhaust should be clear, and there should be no signs of fuel leaking around the injector.

Reduced Engine Noise: Any knocking or rattling sounds should be gone.

A post-repair diagnostic scan showing no fuel system fault codes is another good confirmation of a successful job.

Conclusion: The Smart Path to Restored Engine Performance

There's something deeply satisfying about hearing your diesel engine purr like it did when it first rolled off the lot. Throughout this journey, we've explored how diesel injector repair kits can be your secret weapon in the battle against declining engine performance and mounting maintenance costs.

When your injectors start showing their age – through rough idling, black smoke, or that dreaded drop in fuel economy – you don't have to immediately reach for your wallet and prepare for sticker shock. A quality diesel injector repair kit offers a practical middle ground between expensive replacements and living with poor performance.

The math is compelling. We're talking about potential savings of up to 70% compared to new injector replacement, while still achieving the performance restoration your engine craves. Whether you're dealing with the high-pressure precision of common rail systems, the robust mechanics of unit injectors, or the straightforward design of conventional systems, there's a repair solution custom to your specific needs.

But the benefits extend far beyond your bottom line. Restored engine performance means better fuel efficiency, which translates to fewer stops at the pump and reduced operating costs. Lower emissions mean you're doing your part for the environment while potentially avoiding costly compliance issues. Reduced downtime keeps your trucks on the road where they belong – earning money, not sitting in the shop.

The key to success lies in making informed decisions. Understanding your injector system, choosing quality components over cheap shortcuts, and knowing when to tackle the repair yourself versus calling in professional help. Sometimes the smartest investment is in your own knowledge and the right tools for the job.

For fleet managers and owner-operators who demand reliability without compromise, this approach empowers you to take control of your maintenance destiny. You're not just fixing a problem – you're investing in the long-term health and performance of your equipment.

When you're ready to take that next step, trust in proven quality and innovation. For top-tier, reliable diesel fuel injectors and repair kits for Volvo, Mack, Kenworth, and Paccar trucks, G2 Diesel Products delivers the reliability and performance your fleet deserves. We're here to help you keep those diesels running strong, mile after mile, repair after successful repair.