Step-by-Step Injector Replacement for Your Mack MP7 (Mechanic Not Included!)

Why Your Mack MP7 Injectors Matter More Than You Think

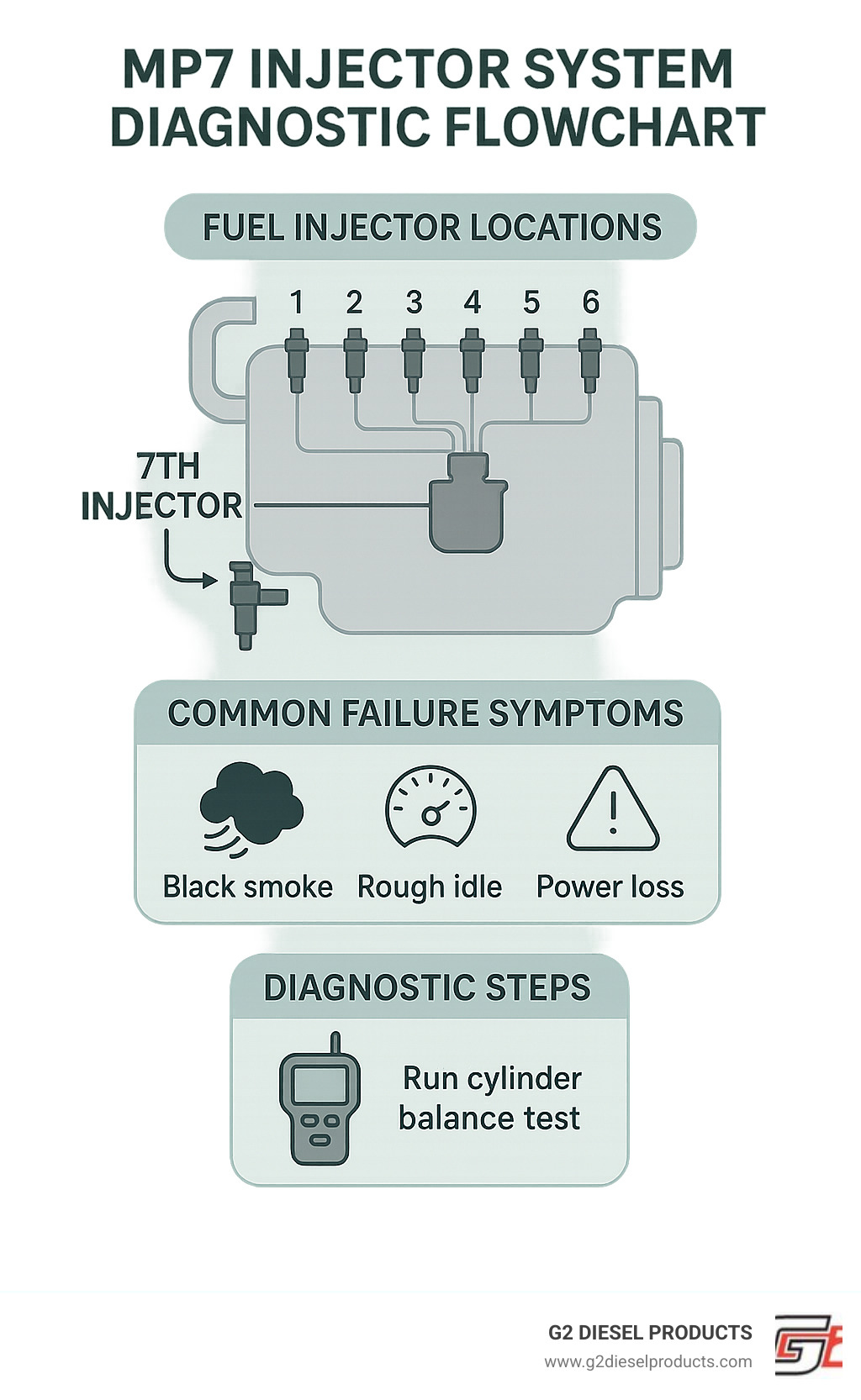

When your injector for mp7 2013 mack truck starts failing, you'll know it fast. Black smoke rolling from the exhaust. Engine misfires that shake the whole cab. Power loss that turns highway merging into a prayer. One forum user put it perfectly: "Hopefully somebody can lead me in the right direction here" - after replacing cylinder #4's injector and still seeing balance test readings climb to +56 while other cylinders sat near zero.

Quick Answer for MP7 Injector Issues:

- Common symptoms: Black smoke, rough idle, power loss, poor fuel economy

- Diagnostic step: Run cylinder balance test with Tech Tool

- Key warning: Values over +50 indicate severe overfueling

- Don't assume: Other issues can mimic injector failure (boost sensors, intake leaks)

- Replacement cost: Varies by part quality and labor

- Special note: 7th injector is separate from main fuel injectors

The 2013 Mack MP7 uses Electronic Unit Injectors (EUI) that both inject fuel and build injection pressure. When they fail, they don't just affect one cylinder - they can trigger a cascade of problems throughout your fuel and emissions systems.

But here's what most people miss: not every engine problem that looks like a bad injector actually is one. Boost pressure sensors, cracked intake manifolds, and fuel delivery issues on the suction side can all create identical symptoms. That's why proper diagnosis saves you from throwing expensive parts at the wrong problem.

Is It Really the Injector? Common Symptoms and Accurate Diagnosis

Before you start tearing into your engine, let's make sure you're chasing the right ghost. Misdiagnosis can turn a straightforward repair into an expensive learning experience.

Telltale Signs of a Failing MP7 Injector

When an MP7 injector fails, the symptoms are hard to ignore and get progressively worse.

- Engine misfire and rough idle: You'll feel a stumble or shake as the engine struggles to fire on all cylinders, especially at idle or under load.

- Significant power loss: Your truck will feel sluggish and struggle to pull hills like it used to.

- Excessive smoke: Black smoke indicates over-fueling from a bad injector. White smoke can mean unburnt fuel is passing through the exhaust, while blue smoke can point to oil burning, sometimes caused by fuel washing down cylinder walls from a leaking injector.

- Fuel smell in engine oil: When an injector leaks internally, diesel can seep past piston rings and contaminate your oil. This dilutes its lubricating properties and can cause serious engine damage.

- Engine knocking: Loud knocking noises under load can signal improper combustion timing, another potential injector-related issue.

For a deeper dive into these problems, check out our comprehensive guide on Mack Truck Injector Problems.

Pinpointing the Problem: Diagnostic Steps for Your 2013 Mack MP7

Proper diagnosis saves time and money. Follow these steps to pinpoint the problem.

Start by checking for fault codes using Tech Tool or similar diagnostic software. These Diagnostic Trouble Codes (DTCs) can point you to the problem cylinder or system.

The cylinder balance test is your most valuable tool. This test measures each cylinder's contribution to the engine's power. A cylinder that's over-fueling will show a high positive value as it tries to do more work than its share.

For example, one 2013 Mack MP7 owner found cylinder #4 climbing rapidly to +56 while others sat near zero. That's a clear sign of an over-fueling injector.

Positive values typically indicate over-fueling, while negative values can signal under-fueling or mechanical issues. Ideally, all cylinders should read close to zero.

Don't skip mechanical tests. A compression test can rule out major mechanical failures like bad valves or piston rings. Also, perform a visual inspection for fuel in the coolant or excessive smoke.

Don't Be Fooled: Other Issues That Mimic Injector Failure

Many issues can mimic a bad injector. Before committing to a replacement, rule out these common culprits.

| Symptom | Bad Injector | Bad Boost Sensor | Suction-Side Air Leak |

|---|---|---|---|

| Black Smoke | High | Possible (low air) | Possible (lean mix) |

| Rough Idle | High | Possible | High |

| Power Loss | High | High | High |

| Poor Fuel Economy | High | Possible | High |

| Hard Starting | Possible | Low | High |

| Misfire Codes | High | Low | Possible |

| Engine Knock | Possible | Low | Possible |

Boost pressure sensor issues are notorious. A faulty sensor causes the ECM to make bad decisions about fuel delivery based on incorrect air readings, creating symptoms identical to injector failure.

Cracked intake manifolds, as discussed in this forum discussion on erratic power loss, can create air leaks that disrupt manifold pressure and cause intermittent power loss.

Charge air cooler leaks also reduce boost pressure, leading to inefficient combustion and a weak, sluggish engine.

Worn camshaft lobes or valve train issues can affect valve timing and lift, leading to poor cylinder breathing and symptoms that look exactly like injector trouble.

The key is methodical diagnosis. Test and verify before replacing parts. Understanding your Truck Fuel Systems will save you from expensive guesswork.

The Complete Guide to Replacing an Injector for MP7 2013 Mack Truck

Once you've confirmed a bad injector, it's time for the replacement. This process requires patience and attention to detail, but following these steps will ensure a successful repair.

Tools and Parts You'll Need

Gathering the right tools and parts beforehand prevents frustration and ensures the job is done correctly.

- Torque wrench: Absolutely essential for proper installation.

- Injector puller tool: A model like the 88800387 makes the job easier and safer for your engine.

- Injector bore cleaning kit: This is a pro-level step you shouldn't skip.

- Socket set: You'll need both standard and deep sockets.

- Safety glasses and gloves: High-pressure diesel fuel is a serious hazard.

- New Electronic Unit Injector (EUI) from G2 Diesel Products: We manufacture high-quality diesel fuel injectors that meet or exceed OEM specifications.

- New injector O-rings: Cheap insurance against future leaks.

- New injector copper or stainless steel sleeve (cup): Keep one handy. Early MP7 copper cups were prone to cracking; upgrading to stainless steel is a smart move.

For more details on what you might need, check out our guide on Fuel Injector Replacement Parts.

Preparation and Safety First

Take your time to do this right the first time.

- Disconnect both battery terminals to prevent electrical accidents.

- Relieve the fuel system pressure. This is a non-negotiable safety step. High-pressure diesel can penetrate skin and cause serious injury. Consult your service manual for the exact procedure.

- Clean your work area thoroughly to prevent contamination.

- Take photos and label everything as you disassemble. This will be a huge help during reassembly.

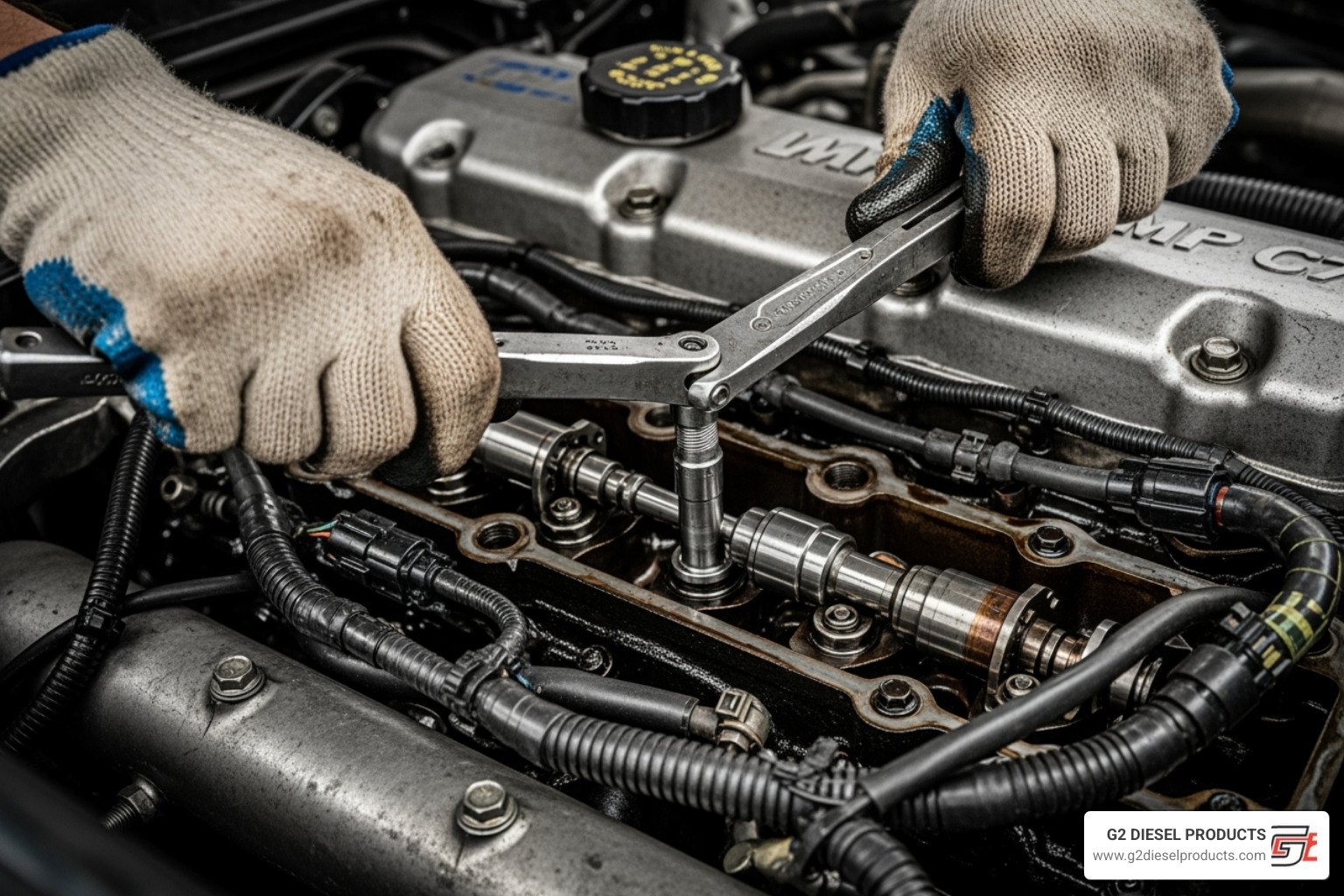

The Removal Process: Getting the Old Injector Out

Follow these steps to remove the old injector.

- Remove the valve cover and any components blocking access, like the air cleaner and air inlet pipe.

- Remove the rocker arm assembly for the bank you're working on. If your truck has jake brakes, their housings will also need to come off.

- Disconnect the injector electrical harness carefully.

- Remove the injector hold-down bolt.

- Use your puller tool to extract the injector. Position the tool, engage it with the injector, and work the pulling mechanism steadily to avoid damaging the cylinder head.

Cleaning and Inspecting the Injector Bore and Cup

This is a critical step for a lasting repair. Do not cut corners.

- Clean the injector bore carefully. Use your cleaning kit to remove all carbon buildup, debris, and old O-ring material. The bore must be spotless for the new injector for mp7 2013 mack truck to seat and seal properly.

- Inspect the injector cup (sleeve) thoroughly for cracks or damage. This sleeve separates the injector from the engine's coolant passages. A crack can lead to coolant in the combustion chamber or fuel in the coolant.

- If the cup is damaged or you're upgrading to stainless steel, remove the old sleeve carefully. A flat-head screwdriver can work, but be patient.

- Check the cylinder head for cracks around the injector bore.

For professional-grade cleaning services, consider our Diesel Fuel Injector Cleaning Service.

Installation and Torque Specifications

With the bore clean, you can install the new injector.

- Lubricate the new O-rings with clean engine oil to ensure a proper seal and prevent damage.

- Carefully slide the new injector into its bore. You should feel it click into place. Confirm the injector ports align with the fuel line ports in the head.

- Push the injector firmly until it's fully seated, then install the hold-down bolt. This is where your torque wrench is crucial. For Mack MP7 EUI injectors, torque the hold-down bolt to 25 ft-lbs (34 Nm) plus an additional 120 degrees of rotation. Always verify with your service manual.

- Reinstall the rocker arm assembly and check the valve lash according to Mack's specifications.

- Reassemble everything in reverse order: rocker arms, jake brake housings, valve cover, and air intake components.

- Prime the fuel system to remove air before starting the engine. Your manual will have the specific procedure. The engine should start within 20-30 seconds of cranking.

Want to understand more about how these sophisticated components work? Check out our article on How Electronic Unit Injector Works.

Beyond the Injectors: Understanding the MP7 Fuel and Emissions Systems

A 2013 Mack MP7 features a complex fuel and emissions system. Understanding related components can help you avoid future issues and keep your truck humming.

The "Ghost in the Machine": Suction-Side Fuel Delivery Problems

Suction-side fuel delivery problems are maddening to diagnose because they mimic faulty injectors. An air leak on the suction side of the fuel pump can starve the engine of fuel, causing hard starting, engine stumbling, sudden power loss, and poor throttle response.

The fuel bucket test is the best way to diagnose these issues. Run your engine from a clean bucket of diesel, bypassing the truck's fuel tank and lines. If the symptoms disappear, the problem is in your suction-side fuel system.

One frustrated owner found this exact scenario after replacing multiple components. The moment they ran their Mack MP7 from an external bucket, all their problems vanished.

Common leak points often hide in plain sight:

- Fuel/water separator O-rings that have hardened or cracked.

- Cracked filter housings with hairline fractures.

- Loose fittings anywhere between the fuel tank and pump.

- A cracked pick-up tube inside the fuel tank.

For a fascinating deep-dive into one mechanic's journey through this exact nightmare, check out this real-world example of a fuel delivery problem.

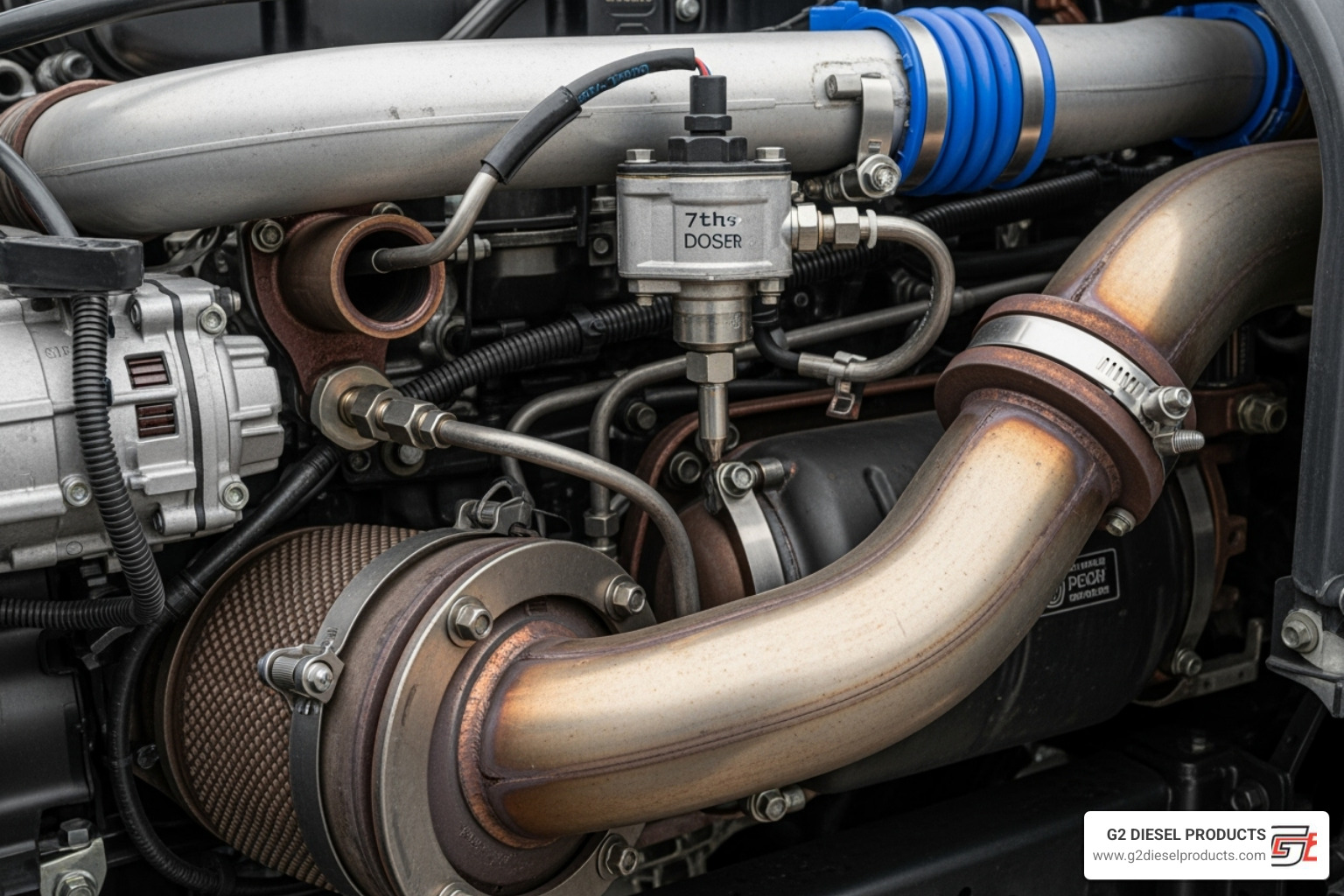

What is the '7th Injector' on a Mack MP7?

It's important to distinguish between the six main fuel injectors and the '7th injector,' which serves a completely different purpose and often causes confusion.

The 7th injector—officially the Aftertreatment Fuel Injector (AFI)—is not part of the engine's main fuel system. It is located downstream in the exhaust system.

Its function is to support the Diesel Particulate Filter (DPF). When the DPF gets clogged with soot, the 7th injector sprays diesel into the hot exhaust stream. This raises the temperature inside the DPF and burns off the soot in a process called regeneration.

Symptoms of failure are different from a main fuel injector. Look for DPF fault codes, failed regeneration cycles, or excessive white exhaust smoke from unburnt fuel in the exhaust.

Troubleshooting and repair for the 7th injector is a separate process that involves checking its functionality and the health of the entire DPF system. It is not related to replacing a main engine injector for mp7 2013 mack truck.

For detailed information about this unique component and what you can expect for replacement costs, our comprehensive guide on What Does The 7th Injector Cost For A Mack Truck covers everything you need to know.

Frequently Asked Questions about Mack MP7 Injectors

Should I replace all six injectors at once?

This question keeps truck owners awake at night - and for good reason. When you're staring at a repair estimate that could hit thousands of dollars, the "replace them all or just one" decision feels overwhelming.

Here's the honest truth: replacing all six injectors at once is a significant investment but can be the smartest move for high-mileage engines. Think of it like this - if one injector gave up the ghost after 400,000 miles, its five siblings have been working just as hard in the same harsh conditions. They're probably not far behind.

The case for replacing all six becomes even stronger when contaminated fuel caused the failure. Bad diesel doesn't discriminate - if it damaged one injector for mp7 2013 mack truck, it likely compromised the others too, even if they're not showing symptoms yet. You might save money upfront by replacing just one, but you could find yourself back under the hood in six months with another failure.

On the flip side, replacing only the faulty injector makes sense for lower-mileage engines or when the failure was clearly isolated - maybe a manufacturing defect or a freak mechanical issue. If your truck has under 300,000 miles and proper maintenance records, a single replacement often does the trick.

The decision ultimately comes down to your truck's history, your budget, and how much downtime you can afford. Nobody wants to play injector roulette, but sometimes it's the practical choice.

What are injector cups and why do they fail so often?

Injector cups - also called sleeves - are those little metal rings that seem to cause big headaches. These seemingly simple components have one of the toughest jobs in your engine: they seal the injector from the cooling passages while enduring extreme heat, pressure, and vibration.

Think about what these cups go through every day. They experience temperature swings from cold startup to blazing combustion chamber heat, all while dealing with high-pressure fuel injection and constant engine vibration. It's like asking a gasket to survive in a blast furnace while someone pounds on it with a hammer.

Early MP7 engines used copper cups, which were notorious for cracking. Many mechanics learned this the hard way after multiple comebacks. The good news? Later models and replacement kits use more durable stainless steel cups that hold up much better to the abuse.

But here's the kicker - improper installation kills more cups than anything else. If they're not seated correctly or the bore isn't perfectly clean, they'll fail faster than you can say "warranty void." When cups fail, you'll see telltale signs like coolant loss, white smoke from burning coolant, or that dreaded fuel-in-coolant mixture that makes your heart sink.

Do I need to reprogram the ECM after replacing an injector?

This is where things get a bit technical, but stick with me. For a 2013 Mack MP7 with Electronic Unit Injectors, ECM reprogramming isn't always mandatory, but it's absolutely worth doing.

Your truck's computer is pretty smart - over time, it learns each injector's personality and makes tiny adjustments to optimize performance. When you swap in a new injector, the ECM might still be compensating for the old, faulty one. It's like your GPS trying to steer with outdated maps.

Even if your engine fires right up after the replacement, the ECM could be holding onto old fault codes or adaptive parameters. Clearing these codes and updating the system ensures your new injector gets a fresh start and can perform at its best.

The process involves connecting your diagnostic tool to check for stored codes related to the failed injector and clearing them out. If your software offers injector calibration or reset procedures, running those helps the ECM properly recognize and fine-tune the new component.

Will your truck run without reprogramming? Probably. Will it run optimally without it? That's less certain. For the best fuel efficiency, power, and emissions control, taking the extra step to update the ECM is smart insurance on your repair investment.

Your Next Step for a Healthy Mack MP7

Diagnosing and replacing a faulty injector for mp7 2013 mack truck is a major accomplishment that saves you money and downtime. A successful repair depends on methodical diagnosis, careful workmanship, and high-quality parts. Using diagnostic tools like the cylinder balance test is crucial to avoid replacing the wrong components.

Understanding how the fuel suction side can mimic injector failure and knowing the difference between your main fuel injectors and the 7th injector in the aftertreatment system will save you from costly mistakes and unnecessary repairs.

Your truck depends on precision-engineered components. When one injector for mp7 2013 mack truck fails, it affects the entire engine's balance and performance. That's why we are passionate about manufacturing diesel fuel injectors that meet and exceed OEM specifications.

At G2 Diesel Products, we understand your truck is your livelihood. That's why we've dedicated ourselves to creating premium remanufactured injectors that deliver the reliability and performance your Mack MP7 deserves. Our Harrisburg, PA facility specializes in diesel fuel injectors for Volvo, Mack, Kenworth, and Paccar trucks, combining innovative manufacturing with quick lead times and customer-specific packaging.

Ready to get your truck back on the road with confidence? We have the quality parts and expertise to keep your MP7 running strong.

Find the right injectors for your Mack truck

More info about Our Quality Volvo Mack Kenworth Paccar Diesel Fuel Injectors