From Factory to Fuel Line: Leading Diesel Injector Manufacturers

Why Choosing the Right Diesel Fuel Injector Manufacturer Matters

Selecting the right diesel fuel injector manufacturer directly impacts your fleet's performance, fuel efficiency, and maintenance costs, marking the difference between reliable operation and costly downtime. While many manufacturers serve the general market, specialized suppliers like G2 Diesel Products focus on specific applications for brands like Volvo, Mack, Kenworth, and Paccar, ensuring a perfect fit and optimal performance.

Modern diesel engines rely on injectors operating at pressures over 30,000 PSI. These precision parts atomize fuel into microscopic droplets while enduring extreme conditions. With the global diesel fuel injection market reaching $25.3 billion in 2022 and growing, the demand for high-quality components is clear.

Fleet managers need parts that fit specific engine models, arrive quickly to minimize downtime, and deliver consistent performance. The difference between a quality manufacturer and a subpar one appears in fuel economy, emissions compliance, and repair frequency.

Quality manufacturing is critical because injector failures can lead to expensive engine damage. Poor atomization causes incomplete combustion, carbon buildup, and reduced power. In contrast, precision-engineered injectors from reputable manufacturers optimize fuel delivery for maximum efficiency and minimal emissions.

Understanding the Core Technology: Injector Types and Components

Modern diesel injectors are sophisticated engineering marvels that deliver fuel with incredible precision. Understanding how they work helps you appreciate why choosing the right diesel fuel injector manufacturer matters so much for your fleet.

Primary Types of Diesel Fuel Injectors

The evolution of diesel injection technology brought better control, improved efficiency, and cleaner emissions with each generation.

Mechanical injectors represent the old-school approach. Operating purely on hydraulic pressure from the fuel pump, they open and spray a predetermined amount of fuel when pressure hits a set point. While they lack finesse, their simplicity makes them extremely durable.

The Hydraulic Electronic Unit Injector (HEUI) Fuel System introduced electronic control by using engine oil pressure, amplified by an intensifier piston, to create high fuel pressure. An electronic solenoid controls oil flow, giving precise control over fuel delivery.

Electronic Unit Injectors (EUI) integrate the fuel pump and injector into one unit per cylinder, eliminating high-pressure fuel lines. A cam-driven plunger creates pressure while an electronic solenoid valve controls injection timing with remarkable accuracy.

Common Rail Injectors are today's gold standard. A single high-pressure pump feeds a shared rail that supplies all injectors, maintaining constant pressure. This allows for multiple injection events per combustion cycle—pre-injection for noise reduction, main injection for power, and post-injection for emissions control. Understanding how Common Rail Injectors work reveals why modern Diesel Engine Common Rail systems are so effective.

Piezo injectors advance common rail technology by replacing solenoids with piezoelectric actuators. These materials expand and contract almost instantly with electricity, enabling incredibly rapid and precise nozzle control for superior fuel atomization and quieter operation.

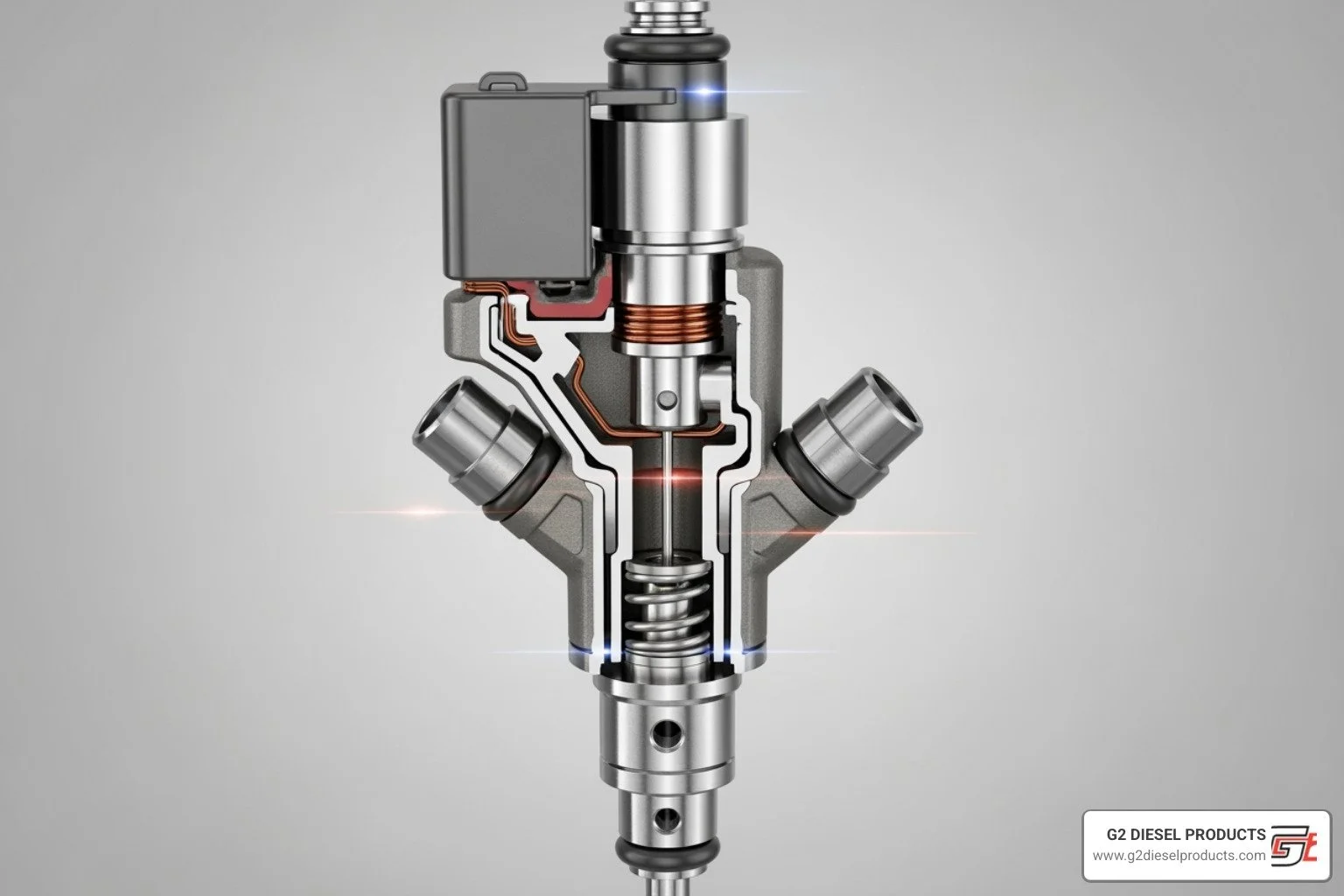

Key Components and Their Functions

Every diesel injector is a masterpiece of precision engineering.

The nozzle is the business end, changing pressurized fuel into a fine mist. Its design—hole size, number, and pattern—directly affects combustion efficiency.

A spring-loaded plunger or needle valve acts as the fuel flow gatekeeper. Its precision fit and smooth movement are critical for proper operation.

The solenoid or piezo actuator is the electronic brain, determining exactly when and for how long injection occurs based on signals from the engine's computer.

The injector body is a robust casing that houses all internal components, protecting them from extreme pressure and temperature.

A control valve precisely manages fuel flow or pressure within the injector to start and stop injection events.

The high-pressure inlet connects the injector to the fuel system, handling pressures that can exceed 30,000 PSI.

When these components wear, Fuel Injector Replacement Parts or comprehensive Diesel Injector Repair Kits can often restore performance. The micron-level precision required in manufacturing these parts highlights why a top-tier diesel fuel injector manufacturer is essential.

The Global Landscape for a Diesel Fuel Injector Manufacturer

The diesel fuel injection industry is a massive, interconnected global web. For any diesel fuel injector manufacturer, success means navigating economic shifts, rapid technological advances, and ever-tightening environmental regulations.

Market Overview and Key Players

The diesel fuel injection market is projected to grow from USD 25.3 billion in 2022 to USD 34.5 billion by 2030, showing a healthy 4.0% compound annual growth rate. This demonstrates that despite the rise of electric vehicles, diesel power remains essential for heavy-duty trucks, construction equipment, and agricultural machinery.

North America commands over 30% of the global market share, driven by its vast highway system, large agricultural sector, and active construction and mining industries. The market is split into OEM suppliers, who create injectors for new vehicles, and the aftermarket segment, which serves the millions of diesel vehicles already on the road. Companies like G2 Diesel Products are key players in the growing aftermarket, providing high-quality replacement injectors for Volvo, Mack, Kenworth, and Paccar applications. Services like Diesel Fuel Injector Rebuilders and efficient Fulfillment Solutions for Diesel Parts are crucial for keeping fleets moving.

Key Challenges for a Diesel Fuel Injector Manufacturer

Leading manufacturers face constant challenges that spur innovation.

Stringent Emissions Standards: EPA and Euro VI regulations demand systems that produce fewer pollutants. This adds complexity that can sometimes lead to issues like Mack Truck Injector Problems.

High-Pressure Engineering: Modern common rail systems operate at pressures over 30,000 PSI. Designing components to reliably contain and control these forces over millions of cycles is a major engineering feat.

Material Science Limitations: Injector materials must withstand extreme pressure, heat, and corrosion. Finding materials that offer the necessary strength and wear resistance while remaining cost-effective is a continuous challenge.

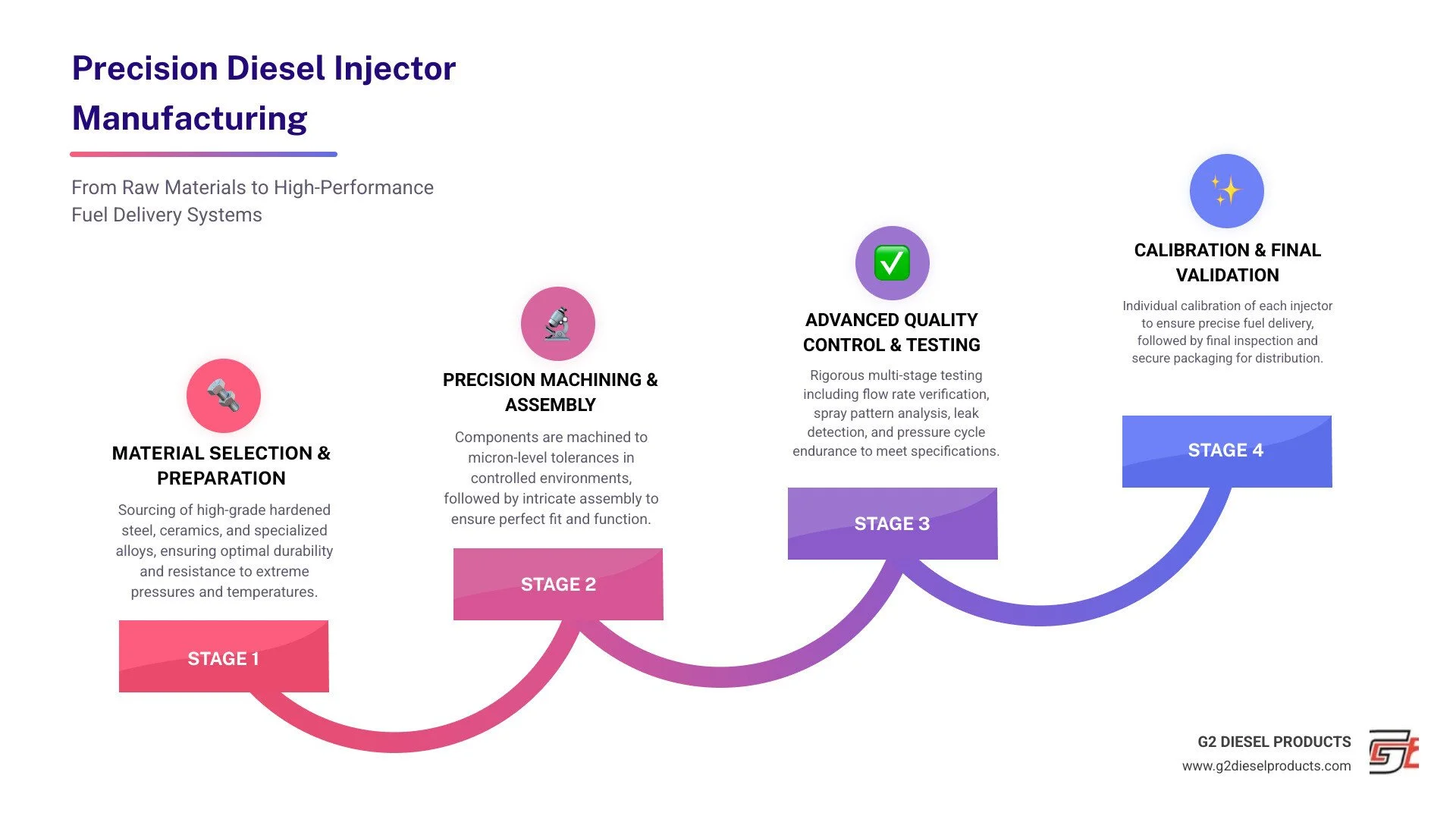

Manufacturing Precision: Tolerances are measured in microns, meaning the smallest imperfection can lead to failure. Achieving this precision in mass production requires significant investment in machinery and expertise.

Cost Competitiveness: Despite the engineering challenges, there is constant pressure to keep prices affordable for fleet owners.

Technological Advancements and the Future of Injection

Innovation in diesel injection is moving fast.

High-Pressure Common Rail (HPCR): Systems are evolving toward even higher pressures for finer atomization and more efficient combustion.

Multiple Injection Strategies: Instead of one large injection, modern systems use a sequence of smaller injections (pre, main, and post-injection) to reduce noise, boost power, and control emissions.

Advanced Nozzle Geometry: Computer simulations and advanced manufacturing allow for complex nozzle designs that optimize spray patterns for better combustion.

Smart Injectors: The future points toward injectors with built-in sensors that monitor their own performance and communicate with the engine's ECU. This enables predictive maintenance and self-correcting systems. G2 Diesel Products is embracing this with advanced solutions like Smart F2P Injectors for applications like Paccar Fuel Systems.

The Role of Emissions Regulations in Driving Innovation

Regulations like EPA standards and Euro VI norms are the primary catalyst for innovation.

Soot Reduction: Finer fuel atomization from higher injection pressures leads to more complete combustion, significantly reducing soot formation.

NOx Reduction: Multiple injection strategies help control combustion temperatures to minimize NOx. Aftertreatment systems like Selective Catalytic Reduction (SCR) also depend on precise injection of Diesel Exhaust Fluid (DEF), sometimes via a "7th injector" as discussed in What Does the 7th Injector Cost for a Mack Truck. This continuous cycle of regulatory pressure and technological breakthroughs results in cleaner, more efficient diesel engines.

Ensuring Peak Performance: Reliability, Durability, and Operating Factors

Diesel fuel injectors are precision instruments working under immense stress. For fleet operators, understanding what makes these components reliable—and what causes them to fail—is the key to maximizing uptime and minimizing costs.

Critical Factors for Reliability and Durability

When choosing a diesel fuel injector manufacturer, you are betting on their engineering and manufacturing quality. True reliability is engineered into every component.

Material Selection: Injector durability is founded on advanced materials. Components are not made of ordinary steel but specialized hardened steel for structural integrity and advanced ceramics for wear surfaces to withstand extreme pressures and temperatures.

Manufacturing Tolerances: Precision measured in microns—about 100 times thinner than a human hair—separates average injectors from great ones. This level of accuracy is essential for proper sealing and spray patterns, preventing leaks and premature failure.

Quality Control Processes: Rigorous quality control is vital. From raw material inspection to final performance testing, each injector undergoes multiple checks. Specialized Diesel Injector Testing Equipment is used to ensure every unit meets strict Electronic Unit Injector Testing Specs. Professional Diesel Injector Testing Services validate that every product is ready for the demanding world of heavy-duty trucking.

How Fuel Quality Impacts Injector Longevity

The fuel you choose has as much impact on injector life as the injector's manufacturing quality.

Cetane Rating: A higher cetane number promotes smoother, more controlled combustion, reducing mechanical stress on injector components.

Lubricity: Modern ultra-low sulfur diesel has reduced natural lubricity, which is critical for lubricating the fine moving parts inside injectors. Without it, premature wear is inevitable.

Contaminants: Microscopic debris can clog tiny nozzle holes or cause abrasive wear, while water can lead to corrosion and microbial growth that clogs the entire fuel system.

Bio-diesel Blends: While beneficial for the environment, some bio-diesel blends can absorb more water and act as solvents, dislodging old deposits that can then clog injectors.

Regular use of a quality Diesel Fuel Injector Cleaner helps prevent buildup, and professional Diesel Fuel Injector Cleaning Service can restore performance.

The Effect of Different Operating Conditions

A quality diesel fuel injector manufacturer designs components to thrive under real-world punishment.

High Pressure: Operation above 30,000 PSI subjects injectors to immense forces. Components like those in Precision Injection: A Guide to Volvo D13 Fuel Injectors and robust Cummins XPI Injectors are engineered to handle these pressures reliably.

Temperature Extremes: Injectors must maintain precise tolerances during cold starts and under the soaring heat of heavy loads.

Engine Load Variations: From idling to climbing a steep grade, injectors must respond instantly to deliver the exact amount of fuel required.

Vibration and Harmonics: Injectors are mounted directly to the engine, experiencing constant vibration. Proper design prevents these forces from compromising performance or reliability.

Troubleshooting and Maintenance: Common Failures and Prevention

When you manage a fleet of hard-working diesel trucks, injector problems are inevitable. The good news is that understanding common failures and how to prevent them can save you thousands in downtime and repairs.

Common Diesel Fuel Injector Failure Modes

If your truck starts running rough, blowing black smoke, or losing fuel economy, you may be dealing with one of these common failures.

Clogged Nozzles: The microscopic holes in the injector tip can get blocked by carbon deposits or fuel contaminants. This disrupts the fuel spray pattern, leading to incomplete combustion, power loss, and smoke. These are classic Fuel Injector Problems in Fuel Injector Problems Diesel applications.

Sticking Internal Parts: The precision needle valve inside the injector can become sluggish or stuck due to contamination or wear. This can cause fuel to dribble into the cylinder, erratic injection timing, and engine misfires.

Leaks: Internal leaks can occur when seals wear out, potentially diluting engine oil or causing pressure loss in the fuel system. External leaks from the injector body are a fire hazard and a clear sign of component failure.

Solenoid Failure: The electromagnetic switch that controls the injector can fail, causing the cylinder to go dead. You'll feel an immediate power loss and a rough-running engine.

Worn Nozzle Needles: After millions of cycles, the needle valve can wear down, affecting its ability to seal properly. This leads to fuel dribbling and poor atomization.

Prevention and Replacement Best Practices

Smart maintenance pays dividends by extending injector life and preventing failures.

Regular Fuel Filter Changes: This is your best defense. Fuel filters stop dirt, water, and rust from reaching sensitive injector components. Change them at recommended intervals.

Use of Quality Fuel Additives: Additives can restore lubricity to modern diesel, disperse water, and clean existing deposits, keeping the entire fuel system healthy.

Proper Engine Maintenance: A healthy engine runs more efficiently. Clean oil, a functional cooling system, and working sensors reduce stress on the fuel system.

Professional Diagnosis: Don't guess when it comes to injector issues. A qualified technician with specialized diagnostic equipment can pinpoint the problem accurately. Knowing How to Replace Diesel Injectors properly and when to use How to Clean Common Rail Diesel Injectors are crucial.

What to Look for in a Diesel Fuel Injector Manufacturer

Choosing the right diesel fuel injector manufacturer directly impacts your operating costs.

ISO Certifications: ISO 9001 certification demonstrates a manufacturer's commitment to internationally recognized quality management standards.

Remanufacturing Standards: A quality remanufacturer completely disassembles, cleans, inspects, replaces all worn parts with new ones, and tests the final product to meet or exceed OEM specifications.

Warranty and Support: A strong warranty shows confidence. Equally important is accessible, knowledgeable technical support that understands your application.

Technical Expertise: The best manufacturers invest heavily in R&D and employ skilled engineers who understand the nuances of different engine platforms.

G2 Diesel Products is built on these principles. We specialize in manufacturing high-quality injectors for Volvo, Mack, Kenworth, and Paccar applications at our Harrisburg, PA facility. We focus on quick lead times and customer-specific packaging to minimize your downtime. For local customers, we are a trusted source for Diesel Parts Harrisburg PA. We also partner with respected distributors, such as Miller Diesel Inc, to ensure our quality parts are widely available.

Conclusion

From microscopic nozzle holes to the global marketplace, it's clear that diesel fuel injectors are the heart of every modern diesel engine. These compact components control the power, efficiency, and environmental impact of the massive engines that haul goods, build our infrastructure, and deliver products daily.

The evolution from simple mechanical injectors to sophisticated, computer-controlled piezo systems was driven by the need for cleaner air and better fuel economy. This makes the role of a quality diesel fuel injector manufacturer more critical than ever. When dealing with extreme pressures and micro-tolerances, there is no room for error.

At G2 Diesel Products, we have built our reputation on this principle. We don't just make injectors; we craft precision instruments specifically for the demands of Volvo, Mack, Kenworth, and Paccar trucks. Our specialization in these four major brands allows us to deliver solutions that perform flawlessly in the real world.

Quality extends beyond the product to the entire customer experience. We have invested in quick lead times and customer-specific packaging because we know that when a truck is down, every hour counts. Our streamlined process ensures you get the right part, right when you need it.

The future of diesel technology will continue to evolve, and we are excited to be at the forefront of this innovation. Your choice of fuel injector manufacturer is an investment in your fleet's reliability and profitability. By choosing quality components from a specialized manufacturer, you are choosing peace of mind.

Ready to experience the difference that precision engineering makes? We invite you to find the right diesel fuel injectors for your truck and find why fleet managers trust G2 Diesel Products to keep their trucks running strong.